Charcoal kilns device and design, general information

Today, when it comes to charcoal burning equipment, we have plenty to choose from. A variety of models and designs allow you to choose exactly what is required for a particular situation, but the result will be achieved in any case, the only question is time and efficiency. (See also: Sitemap)

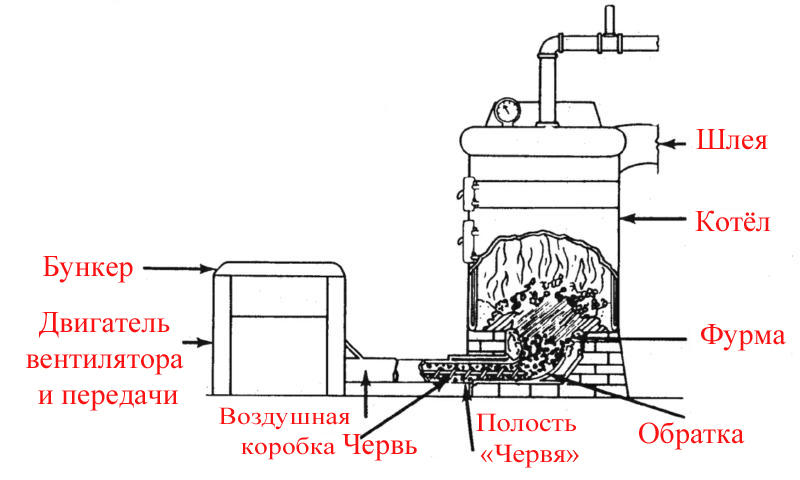

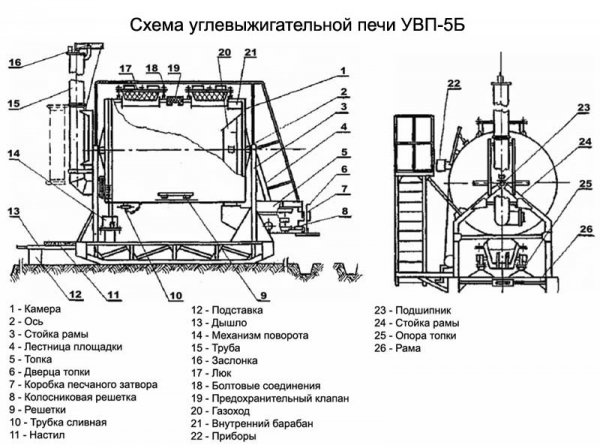

The purpose of charcoal kilns is to pyrolyze wood, in other words, to produce coal. But depending on the purpose of the design of such a furnace, they may vary. For example, mobile ovens are used at logging sites or construction sites, while stationary models lack mobility, but are designed for higher productivity.

But the variety of options is not limited to the creation of mobile models; in such furnace installations it is possible to use different types of fuel. Most often, wood production waste acts as fuel - thus, it is possible to kill several birds with one stone:

recycling of production waste;

heat source;

coal production.

The device of a charcoal kiln, as already noted, can be very different. In the simplest versions, wood is used as fuel. At the same time, no additional fuel is required for the process to proceed, which greatly contributes to savings. (See also: How to choose a relief valve)

But what, besides wood and wood waste, can serve as fuel for such installations? Almost anything, even old tires, is converted into liquid fuel by pyrolysis. Thus, these ovens are a great tool for recycling and recycling, which is why they are widely used today.

Making a device with your own hands

Performing brickwork is a rather difficult job with a lack of experience. Therefore, before starting construction, it is better to seek advice from the master.

When making the furnace yourself, it is important to carefully follow all the steps and not change the selected project scheme

Project selection, drawings

The choice of furnace model is primarily influenced by the desired power of the device. The efficiency of the heater depends on the size of the combustion chamber. Typically, coal combustion has a heat output of about 500 kcal/hour. Therefore, a device with standard dimensions of 110 cmx90 cm is suitable for heating a room up to 35 square meters. m.

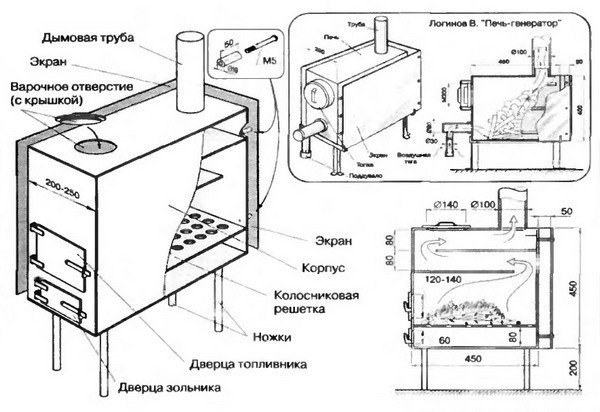

Photo 1. Drawing of a metal furnace on coal. The device is small in size, it will fit even in small rooms.

Photo 2. Drawing of a coal stove made of metal. Arrows also indicate all parts of the device.

Materials and tools

To build a coal stove, you will need fireclay bricks that can withstand heating up to 1400-1650 degrees without cracking. For the preparation of masonry mortar, greasy clay is used mixed with water and sand. To lay out the outer walls you will need a solid red brick.

Doors and hinges, a grate are purchased at a hardware store.

Tools will also be required for work: hammers, trowel, as a rule, mortar shovel, hacksaw, grinder, building level, plumb lines, tape measure.

Stages of work

When choosing a place to build a furnace, factors such as the location of the chimney and the size of the room are taken into account (in a large area it is better to install the equipment in the center).

The walls and ceiling in the selected area are sheathed with refractory material.

It is better to immediately think about the place where the coal will be stored - in order to avoid fire hazards, it cannot be located in the immediate vicinity of the furnace. And also it is necessary to take into account the fact that coal is very dusty and dirty.

A massive brick oven is installed only on a concrete foundation, which is not connected to the main one.Therefore, its location is better to calculate at the stage of building a house.

To fill the foundation of the furnace, the following steps are performed:

- A pit is dug - a pit, not less than 50 cm deep (calculated based on the level of groundwater).

- The bottom is tightly packed and covered with a layer of wet sand.

- Lays a drainage layer of crushed stone 15 cm wide.

- Formwork is installed and concrete is poured.

- The foundation is left for three weeks until completely solidified.

- Waterproofing is laid - a double layer of roofing material.

So that the severity of the furnace does not cause the foundation to skew over time, it is made quite wide.

After the concrete has completely hardened, laying begins. The duration of the work usually lasts no more than one day.

Construction is carried out in a certain sequence:

The first row is laid out, then the walls of the ash pan are erected. Before starting each row, it is recommended to first lay it out without mortar in order to calculate the correct position of the bricks.

Install the ash pan door (galvanized wire is used for fastening).

Mount the grate.

The walls of the combustion chamber are erected. They are often made inclined downwards.

Spread the body (between it and the firebox, be sure to leave a little space).

Install a cast iron door.

Build the vault of the combustion chamber

This is the most difficult part of the work, so when doing it, it is important to do everything exactly according to the scheme. The hole for the chimney is usually not closed with a view, since the draft is controlled using a blower.

They build a chimney - the masonry from the inside is thoroughly cleaned of the solution and wiped dry with a rag

Ideally smooth pipe walls will ensure the absence of ash accumulations and good traction.

When performing masonry, each row is checked using the building level and plumb lines

It is important that the thickness of the masonry joints does not exceed 3-5 mm.

The space in front of the oven is covered with a metal sheet.

Household brick stoves for coal remain worthy competitors to solid fuel boilers in a situation where in winter it is necessary to heat a dwelling of a small and medium area, and the main gas is not supplied. If in some respects coal stoves lose to steel and cast-iron heat generators, then in other parameters they have no equal. Therefore, the demand for the construction of brick kilns remains consistently high.

The choice of materials for the construction of the furnace

When the device of a coal furnace is already realized and understandable, you can proceed to the selection of materials. (See also: Do-it-yourself smoking oven)

Brick - necessary in order to assemble the main body of the furnace and the chimney. When choosing a brick, it is necessary to remember the need to withstand high temperatures in the furnace and chimney, therefore, for greater reliability, two types of brick are needed:

- burnt clay brick not lower than the first grade, which is distinguished from a simpler and baser one by a pronounced red color, it will be used for outdoor work with the furnace body;

fireclay bricks, which are much more needed for a brick coal stove than for a wood-burning one due to the fact that, in addition to the crucible, they need to lay out a significant part of the chimney from the inside.

(See also: DIY rustic oven)

Clay, familiar to this type of construction, will also be required in two versions:

- ordinary oily or bold oil with a low content of sand, which you can independently extract from the banks of rivers and lakes;

fireclay clay is purchased at hardware stores and is intended for work at elevated temperatures.

- For a tighter fit of the brick and its high-quality fixing in the masonry with clay, a special heat-resistant adhesive is needed, which is available in the form of a powder and mixed with clay according to the instructions placed on the package.

To assemble the outer masonry of the furnace, instead of a scarce clay mortar, you can use its cement substitute. But when choosing cement, you should not consider material of industrial classification below 500 as a substitute for clay, this will avoid difficulties in the further operation of the furnace.

- Cast iron products are necessary in order to assemble a coal stove with your own hands without having special skills in the construction of such structures. Cast iron products are used because they have a similar thermal expansion characteristic to clay and clay products. And also products made of cast iron are extremely resistant to temperature changes and therefore, in order for them to burn out, it takes much longer than for steel.

Steel products - you can’t do without them in the modern realities of building furnaces. First of all, the steel sheet will be used to protect the flooring from fire, and it must be fixed before the blower. Secondly, steel yushki will be indispensable when creating combined furnaces designed for several types of fuel. And thirdly, a home-made coal stove will not do without neat steel doors with reliable fastening and bolts.

Properties of a natural fuel stove

As already mentioned, the combustion temperature of coal is quite high. With sufficient air supply to the firebox, it reaches 1000-1100 ° C, so not every material is able to withstand such conditions for a long time.

For comparison: dry wood under identical circumstances can give no more than 700 ° C in the firebox, and then very rarely. In addition, coal fuel is much more caloric than firewood.

That is, when burning 1 kg of anthracite, almost 2 times more thermal energy is generated than from the same amount of wood, as shown in the table:

| Type of fuel | Calorific value | |

| MJ/kg | kW/kg | |

| Wood moisture 25% | 10,1 | 2,8 |

| hard coals | 21,5 | 5,9 |

| brown coals | 15,5 | 4,3 |

Previously, in old houses, heating stoves or slabs were laid out only from solid red brick. With constant burning of high-calorie coals, the masonry began to gradually crumble from exposure to high temperatures, so the owners lined the firebox from the inside with thick steel soles from the railway tracks to protect the walls.

At the moment, the problem of burning coal is solved much easier - with the help of fireclay bricks. The design of the furnace provides for the lining of the fuel chamber with fireclay stone of the ShA, ShB or ShV grades to a thickness of a quarter or half a brick. This material is able to withstand temperatures of 1400 °C without problems and for a short time up to 1650 °C.

There is another point: due to the higher calorie content than wood, a greater amount of heat is released, part of which goes with the combustion products into the chimney.

To avoid this, a more developed network of smoke circulations is provided in the coal furnace, where the flue gases have time to transfer heat to the brick walls, and not immediately fly out into the chimney.

Otherwise, this is an ordinary brick stove with all the advantages and disadvantages.

Barn with a gable roof made of metal

This barn was built alone. The building is also framed: the cheapest way. In this case, the assembly method - "balloon" - the gradual setting of racks. It all starts the same way: first they made columns for the foundation. Only this time brick.

Foundation for a brick shed

As you can see, studs are mounted in the corner posts. Holes are drilled in the strapping beam and it is put on studs. They can be made not only in the corners, but also on intermediate pillars too: it will hold on tighter.

This barn has a small veranda porch, so a cross beam is installed at the required distance. And it will be supported by a wall. Under it, columns are also pre-made.

The lags were also attached to the plates

Logs can also be attached with a notch. Then a notch is cut out in the strapping beam in the form of a log.In depth, it should not exceed 30% of the thickness of the beam, because the log is cut so that it stands flush with the strapping. This method is more labor intensive.

Next, the frame was assembled: corner posts 100 * 100 mm, intermediate - 50 * 100 mm, the upper trim and rafter system were assembled from the same board. The triangles at the top are reinforced with overhead metal plates. Smaller plates were also attached at the junction of the upper strapping bar and racks. They were joined end-to-end without cutting, nailed on top and obliquely. The plates have reduced the likelihood of folding under side loads.

Next, a rafter system was assembled - a board 150 * 50 mm, on it - a crate for a metal tile. It was chosen because the dacha is covered with the same material.

Assembled truss system with crate

The frame was sheathed with OSB sheets - the most convenient size for construction. Subsequently, the walls will be finished with wood siding.

This is an almost finished barn with a gable roof. Remaining wall decoration

Sheathing, by the way, does not have to be plywood or OSB. You can fasten the lining or board immediately and the racks. But then, when assembling the frame, you need to put slopes: without the rigidity of the plate material, the building will be flimsy. If mowing is not set, you can swing by hand.

Such braces will give sufficient rigidity to the walls of the frame shed.

After installing the braces, you can stuff a board, lining, block house, imitation timber, siding - the choice is yours.

The frame shed is sheathed with a board

Similar frame sheds can be made from a profile pipe. For strapping and corner posts, a section of 60 * 60 mm or 60 * 40 mm is sufficient, for intermediate ones even less - 20 * 40 will be fine. Only for fastening the outer skin, it will be necessary to assemble and fasten the crate. Read more about building a shed from pipes and metal profiles here.

For those who care about the appearance of the building, a few ideas on how to make the barn beautiful in video format.

Benefits of a brick heat source

Installing a solid fuel boiler is easier and cheaper than building a brick heating stove in the middle of the house. On the other hand, for the operation of the unit, it is necessary to install a water heating system, and the stove can do without it.

Despite the high cost and complexity of construction, many homeowners still prefer brick ovens. The reasons are weighty:

Features of the placement of the furnace in the house.

- Durability. When coal is burned in the firebox of any heater, a rather high temperature occurs, which eventually destroys steel products. While even an ordinary ceramic brick will last for decades.

- Cast iron heat exchangers of boilers risk cracking from temperature changes, while brickwork calmly tolerates temperature shock.

- Heat capacity. A coal-fired brick oven accumulates a large amount of heat during operation, and the boiler needs a buffer tank for this, which costs a lot of money.

- The accumulated heat of the masonry is given to the room for a long time after the attenuation of the coal in the combustion chamber.

- The stove gives off healthy, pleasant heat, transmitted through infrared radiation and convection.

Since coal stoves still cannot do without firewood required for kindling and heating, an indescribable atmosphere is created in the house, saturated with the natural smells of nature. There are 2 types of such heat sources:

The main elements that contribute to the process of design and improvement of the courtyard of the house

Arrangement of the courtyard of a private house begins directly with the project itself, after which estimates are drawn up, planned costs are calculated. Then building materials, small architectural forms and planting material are purchased.

There are basic elements that should not be forgotten. These include the following components:

1. Buildings and structures. These elements are basic and dominant.On private territory, there is always a house for living, as well as some buildings: a garage, a bathhouse, an outbuilding (storage of working equipment, various accessories), a greenhouse, and so on.

2. Road and path network. It separates all zones according to their functions. When planning, all paths should be laid only over the shortest distance, which will save time when moving and financial resources for building materials.

The courtyard of a country house can also contain complex systems of paths with a variety of paving options.

3. Lighting - the presence of lighting fixtures is provided. It can be used not only for practical purposes, but also to create a beautiful decorative effect.

4. Flower beds - giving the aesthetics of the territory. Probably not a single owner can imagine how to equip a yard without planting flower plants.

There are a huge number of such elements: a flower bed (a regular-shaped flower garden), a mixborder (a complex flower garden consisting of perennial flowers), a border (a flower garden along the paths), a rockery, a rock garden (a complex flower garden that includes natural stones and various mountain plants), and other. This element will perfectly complement any territory.

5. Small architectural forms. Thanks to them, you can distinguish which zone is which. These are various garden furniture, sculptures, fountains, lanterns and lamps.

6. Tree and shrub plants. They can be planted in beautiful groups, hedges and beautiful unique tapeworms. Thanks to the correct fit, the surprise of open views is guaranteed, their smooth transition into each other.

7. Reservoirs are an excellent element that will perfectly give a sense of nature, naturalness and natural beauty. It can be small ponds, fountains, cascades and decorative waterfalls, streams and pools. They look very beautiful with natural stones and aquatic plants.

Thanks to the correct planning of the territory and the presence of the main elements, your yard will be the most compelling and beautiful, constantly attracting everyone's attention.

Everyone living in a private house knows that a room is needed to store solid fuel for the winter. I suggest the option: "corner with a lifting roof." The question immediately arises: why with a lift? From the experience of last year, when I had to throw coal into a square, I realized that this was an unpleasant job.

To make a square, I needed: profile pipe 20x40, 40x40.50x50, 25x25 mm, door sheds, welding machine, electrodes, grinder, cutting discs for metal, level, tape measure, drill with drills, anchor bolts, pgs, cement, sand, concrete mixer.

To do this, I just needed to lengthen the parking lot and I just dumped it and concreted it. On the one hand, instead of formwork, I laid out a brick “wall”, and on the other, I laid an asbestos-cement pipe. On a concrete base, with the help of anchors, I fixed a “device” to hold the pillars, made of a profile pipe 50x50, 200 mm long and a metal plate 3 mm thick with dimensions of 150 x 150 mm.

Principle of operation and design

For the manufacture of coal stoves, brick or metal (cast iron and steel) is used. Metal devices are more compact, but very hot during operation, they require the installation of a protective screen.

Brick has the ability to accumulate and gradually release heat, so these stoves make better use of the high heat transfer of coal fuel.

Good traction is essential for the efficient operation of the equipment. When coal is burned, air enters the combustion chamber from below, and not from above, as when burning wood. Therefore, instead of the bottom, a grate is installed in the furnace chamber. The ash pan located under it, with the door open, performs the functions of a blower.

The temperature in the furnace furnace can exceed 1100 degrees.

In order to ensure the durability of the masonry, heat-resistant fireclay bricks are used. In some cases, the chamber is additionally reinforced with thick sheets of refractory steel or a cast-iron firebox is made.

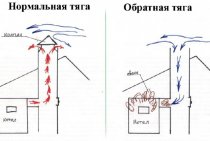

Attention! There is often a temptation to take advantage of the high efficiency of a coal stove by building a heating shield or a multi-channel chimney. But in this case, the result will be a deterioration in traction, which will create a danger of carbon monoxide poisoning.

How to build a stove

First you need to understand what requirements are put forward for a heating furnace for coal:

the heater must warm up evenly and quickly, intensively giving off heat to the indoor air;

the outer walls of the brickwork facing the rooms can warm up to a maximum of 90 ° C;

fuel combustion must be efficient;

the stove should be located in the house in such a way that its walls warm up several rooms;

when erecting the furnace body and chimney, it is important to follow all fire safety rules;

during the construction it is not allowed to use combustible materials;

masonry should be even, without cracking;

the heater should be finished in accordance with the interior of the home.

When the requirements are known and worked out in relation to your home, you should choose an appropriately sized stove design and lay a solid foundation for it.

Foundation laying

A coal stove is a massive and rather heavy structure, and therefore the foundation for it must be made reliable. Its dimensions in the plan are taken 5 cm more in each direction from the dimensions of the future structure.

An important condition: the foundation of a brick heating or cooking device should not be joined to the base of the building itself, but be at least 10 cm away from it. Foundation laying work is carried out in the following sequence:

Foundation works are carried out in the following sequence:

Construction of a coal furnace

Before starting construction, each of the owners will choose their own design option. Someone will prefer to install a long-burning coal stove in the house, while someone will stop at the economical option “baby” or “housekeeper”. But for each of the available options, the sequence of construction work remains unchanged.

If you don’t know where to start the construction of the furnace, and the materials and tools have already been selected, then the first step is to prepare the construction site. To do this, you will have to clean it of foreign objects and debris. Then, if the stove is being built indoors, the flooring must be removed, which is an unreliable combustible material and is not suitable for the base of the stove.

When building a coal furnace for a long time, even if the most economical and lightweight design option is chosen, one should not forget about a reliable foundation. It is he who will not allow the furnace to go into the ground over time or change the geometric dimensions due to the lowering of one of the corners. The foundation must be made reliable and solid, then, if necessary, change the configuration of the furnace or upgrade it, you will not have to deal with it again.

When the place and foundation of the future furnace are ready, you can begin its serial construction. The ordering scheme can be taken from open sources. It is she who will not allow a novice specialist to make a mistake when erecting load-bearing walls and internal lintels.

When the coal stove is folded, it is necessary to make a chimney for it. Here it is necessary to apply all the knowledge accumulated by the ancestors and modern developments, because the chimney will essentially be constantly open and it is necessary to prevent the room from rapidly cooling down and back draft. The basis of the chimney of a coal stove should be a horizontal or vertical chimney, which will reduce the speed of the exhaust gases and allow the furnace body to receive additional heat from them.

During the construction of a coal stove, special attention must be paid to its safe operation, and the space in front of the firebox on a combustible floor covering should be covered as much as possible with metal material.

Recommendations for masonry

For laying the stove, where it is planned to burn coal, you will need 2 types of mortar - clay-sand and refractory. With the help of the first, the body of the furnace is built from solid ceramic bricks, and the second goes to the inner masonry of fireclay stones. The thickness of the seams also differs: for ordinary masonry it is a maximum of 5 mm, for refractory - 3 mm.

For the preparation of both types of mortar, it is recommended to purchase ready-made building mixtures that are commercially available. Only experienced stove-makers can make a good solution from natural clay. You also need to prepare a masonry and measuring tool, and then proceed with the construction of the furnace:

The furnace solution does not harden, but dries up, for which it needs to be given 2-3 days. After that, it remains to lay out the chimney, observing the rules for passing through the floors and roof, and at the end, make a test firebox. It is possible to fill the stove with coal only after full heating, making sure that there are no cracks and crevices.

This site uses Akismet to fight spam. Find out how your comment data is processed.

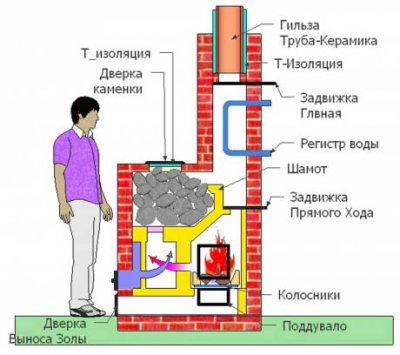

Scheme of a coal stove for a house

The design of a coal-fired brick oven is almost the same as a conventional wood-burning stove.

It consists of, arranged in a certain sequence: a foundation, an ash pan, a combustion chamber, a vault, a chimney.

The main difference between a coal stove is a reinforced firebox and an increased volume of an ash pan (when burning coal, more ash is obtained than when wood is burned).

Also, a larger grate must be installed (ideally, it replaces the bottom of the firebox).

Coal in the combustion chamber of the furnace burns out from below, so the walls of the compartment are made inclined - this design helps the upper layers of coal to fall as they burn out. The dimensions of a standard device are 110x900 cm, the height without a chimney is about a meter.

For a bath

The device for a bath is characterized by the presence of a heater - a container for stones. Together with it, the height of the furnace will be 1.6 m, length 1.1 m, width 90 cm. The heater is made open and is located in the upper part of the furnace. Because of this, the chimney is not located above the combustion chamber, but on the side.

More compact metal stoves are often installed in the bath. The dimensions of a standard metal furnace on a coal are 50x80 cm and a height of 80 cm. It is recommended that the wall thickness be at least 8-10 mm.