Despite the variety of floor coverings and options for their installation in the apartment, linoleum is still one of the most practical materials in terms of price and quality. In addition, the coating fell in love due to the simple laying technology, which even a beginner can easily cope with. But it is not always possible to choose a roll of material according to the size of the room that would allow seamless installation. We will find out how and how it is possible to glue linoleum end-to-end at home with high quality and strength.

Methods for gluing linoleum joints

The choice of seam processing method will depend on various factors: the purpose of the room, the availability of special skills and tools, and financial capabilities. Consider the main options for joining parts of the coating, as well as their pros and cons.

Bonding with double-sided tape

A very simple method that is suitable for joining linoleum on a floor area with little traffic.

Benefits of double sided tape:

- This is the cheapest way to glue 2 pieces of linoleum together.

- Even a person far from repair technologies will cope with the task.

The disadvantages of the method are much more:

- The seam will be visible even if you align the 2 halves of the cover as closely as possible.

- The fragility of the result. The glued area will not withstand intense loads, the adhesive tape will begin to peel off, and the edges of the coating will bend.

- This option is not suitable for attaching felt-based linoleum, since the tape simply will not stick to the back of the material.

It is rational to use this method for minor repairs as a temporary option.

Welding joints of linoleum

Welding is a chemical method of joining coating fragments together. Can be cold and hot.

Both methods have a great advantage over the others:

- the result will last for many years, subject to careful operation of the coating;

- seams are almost invisible.

Cold welding

When joining linoleum in this way, polymer adhesive mixtures are used. Their composition is almost the same as the PVC coating itself. The action of cold welding is based on a chemical reaction that occurs when the adhesive comes into contact with the edges of the floor covering, during which the edges melt and stick when solidified.

As a rule, it is in this way that linoleum is glued together in an apartment with their own hands: it is quite simple and accessible to everyone.

Advantages of cold welding coating:

- Strength and durability of the result.

- The seams are not conspicuous.

- You can glue linoleum on felt, fabric and any other basis.

- Suitable for the case when the coating is laid on a wooden floor.

The disadvantages of the method are insignificant if you decide to make high-quality repairs at home. These include the toxicity of the adhesive used. You can protect yourself with gloves, a respirator and well-organized ventilation.

Hot welding

This method is used not for domestic linoleum, but for commercial, which is laid in rooms with high loads and high traffic. Some owners put it in apartments, for example, in the hallway and in the kitchen.

For welding, a PVC cord (rod) is used, as well as special building hair dryer. You will need to have skills in working with these tools and materials.

It is difficult to weld linoleum in this way on your own, at home, the procedure is described here. The services of specialists are also quite expensive, which is the main disadvantage of hot welding.

- Using a building hair dryer with a nozzle

- Removing Excess Welding Cord

And here is the main plus of the method: the resulting seam at the joints is a single unit with the surface.

The use of adhesives

On the shelves of hardware stores you can find two categories of specialized adhesives for linoleum: dispersion and reaction. Each group is divided into separate types suitable for a particular type of coating or special operating conditions.

Dispersion adhesive

This water-based composition contains additives that provide the elasticity and strength necessary for gluing linoleum. It is used for work at home, it is completely environmentally friendly.

Types of dispersion adhesive:

- Acrylic. More viscous composition. It is used for gluing joints of linoleum on a natural (fibrous, jute) or synthetic basis. Withstands high loads in high traffic areas.

- Bustilat. A universal composition that is suitable for linoleum on a foam and pile basis.

- Humilax. Designed specifically for gluing any coating on a substrate made of natural materials (felt, fabric).

- Bituminous mastic. Another type of adhesive composition, which is used to work with fabric-based linoleum.

Dispersion adhesive has several important disadvantages that you should be aware of in advance: this is instability to freezing and high humidity.

reaction glue

It is this type that is used in the cold method of welding linoleum joints. The properties of the reaction composition allow it to interact with almost any materials, but there is a risk of chemical burns if safety precautions are not followed.

There are two types of reactive glue:

- Ordinary universal composition.

- Moisture resistant adhesive for cold welding.

How to properly weld linoleum using the cold method will be described below. The details of the process are described in more detail in this article.

Cold welding technology for linoleum

Since this method does not require special equipment and professional knowledge and is applicable to any type of coating, we will dwell on it in more detail.

For work you will need:

- Glue "Cold welding".

- Construction knife or special edge cutter.

- Sturdy metal ruler.

- Adhesive tape masking and double-sided.

- Soft cloth to remove dust from surfaces.

- Roller made of rubber material for rolling seams.

It is important to consider that the type of composition must be suitable for the type of coating.

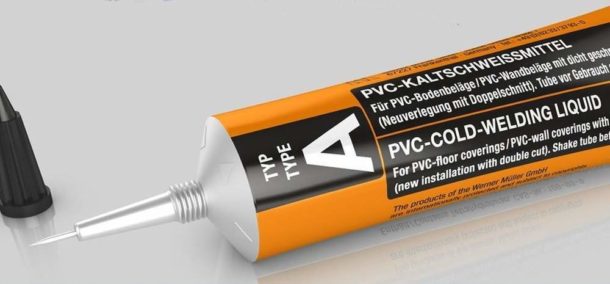

- Type "A" is intended for freshly laid linoleum on a natural or PVC basis.

- "C" - for wide or uneven gaps, as well as for repairing seams that have diverged over time.

- "T" - for coating on a base of felt.

Read more about choosing the right composition here.

Procedure:

- We prepare the floor and the material itself for work. Surfaces should be free of dust, greasy stains, and small debris. Linoleum edges can be processed at least a day after laying the coating on the subfloor.

- We adjust the seams, which should be perfectly equal. This is done in the following way: the edges of the fragments are overlapped, then, using a guide or a strong ruler and a knife, they are cut off in one motion. Excess pieces are removed, and gluing is done along the resulting seam.

If small fragments of the coating are connected so that they do not slip, one of the edges is fixed on the subfloor with double-sided tape.

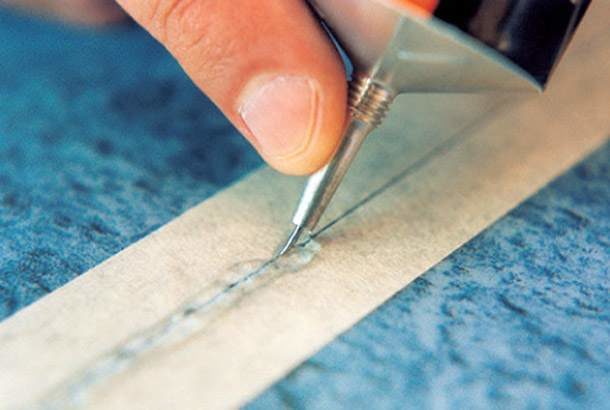

- In order not to damage the surface of the linoleum with glue, the joint is sealed with paper tape.

- Before gluing the seam, the paper tape must be walked with a rubber roller to roll the edges. Then the strip is carefully cut along the seam.

- A nozzle is put on a tube of glue: in the case of type “A” it will be a thin needle, for “C” - a tip with a flattened nozzle, for “T” - with a T-shaped nozzle. Glue is gently squeezed out of the tube in the direction of the seam.

Note! Most often, such compounds shrink when dried, so they need to be introduced with a small margin.

- You can remove the masking tape from the linoleum only after the cold welding has completely solidified. The best solution is to follow the manufacturer's instructions on the package.

The method is used to connect joints up to 4 millimeters wide. Seams larger than this parameter cannot be filled with one welding strip. In such cases, it is necessary to cut off a fragment of the coating that is suitable in size and put it into the gap, connecting the joints with cold welding.

You can learn more about gluing linoleum by watching the video.