Pn 20 pipe what does it mean

According to GOST 32415-2013, which regulates the technical conditions for pipes made of thermoplastics, Pn is an indicator that determines the main mechanical characteristics of the product. Pn corresponds to the pressure at which the pipe can withstand a service life of at least 50 years at a temperature of the transported medium of +20 °C. The digital value of Pn corresponds to 0.1 MPa or 1 bar (atmosphere) and is calculated by the formula:

Pn = 20 MRS / (C ∙ (SDR – 1)), where

- MRS – indicator of minimum long-term strength, MPa;

- C - margin of safety in the form of a coefficient greater than 1, takes into account the operating conditions and the physico-chemical properties of the pipe material;

- SDR is a standardized ratio of outer shell diameter to wall thickness.

It is well known that the service life of any thermoplastics has an inverse relationship with the temperature of the transported medium, that is, the same pipe in hot water supply will last less than in cold water. Also, the nominal pressure Pn drops with an increase in the temperature of the transported liquid, which flows in the pipes.

If we consider popular PP pipes, the best choice for DHW systems is a Pn20 pipe with a fiberglass layer and a nominal temperature of up to +80 ° C, which will have a much higher margin of safety than analogues with Pn10 or Pn16.

Rice. 8 PP pipe Pn 20 and Pn 25 - dimension tables

There are pipes marked PPs.

This is the designation of fire-resistant polypropylene pipes with special flame retardant additives.

They have low flammability according to the German Standards Institute DIN 4102 B1.

It can be used, for example, in the production of chimneys for condensing boilers, in electrical insulation or in any area where resistance to high temperatures is required.

In our case, these are pipes for fire extinguishing systems and sprinkler systems.

But in this place I had to make a small remark.

I know several companies that make polypropylene pipes for water-filled automatic sprinkler fire extinguishing systems.

But you can't just sell such systems, they must be certified. Certificates are issued only by the Ministry of Emergency Situations of Russia and certificates have an expiration date.

I thought that it would be correct to list not all manufacturers, but only those who received such a certificate. I also wanted to show their products to make life easier for young designers or those who are building a fire extinguishing system in their garage or bathhouse.

Started calling companies to get samples. (By the way, you can’t buy such pipes in plumbing stores.)

But I was surprised by how and what they answered me. In short: they told me that I was not a good person, that I should not engage in nonsense, that they would not sell pipes to me, they asked me if I had produced something in my life, before criticizing someone, they said that I was why - then I must set fire to the pipes with a lighter, that I must ask permission. (Will they let me say that such pipes exist!)

In the end, I got tired of explaining, and just waved my hand. Do not want as you want. I am writing to you, dear Russian manufacturers of polypropylene pipes for sprinkler systems. This place could have your company names and samples of your products, for free, just to let interested viewers know about you. Not! Thank your colleagues, they defended the right to remain anonymous. Selya vie. Think - write. But it will be for money.

Therefore, I will name only one system of a German company - aquatherm.

Red pipes marked PP-R FS are called (red pipe), formerly firestop.

The pipe is based on their own polypropylene PP-R fusiolen, which includes more than 30 different additives and innovations.And if you buy sprinklers (sprinklers), then know that they all react to different temperatures, from 57 degrees to 343 degrees Celsius.

And one more thing, on the website of the PP-course there is a list of companies that produce PP pipes for fire extinguishing systems

When buying, pay attention to the current certificate

If you are a manufacturer and your pipe is not on the list, then write to us and we will add to the list.

Briefly about the manufacturers who have received certification from the Ministry of Emergency Situations for applicability in sprinkler fire extinguishing systems:

Similar pipes are produced by the German company Aquatherm Firestop (Red pipe) with the red PP-R FS marking. Pipes for fire extinguishing systems are manufactured by Blue Ocean Red. Production in China.

Aegis Proff makes AntiFire pipes, nothing is written about the production, so most likely the production is located in China. Red pipes.

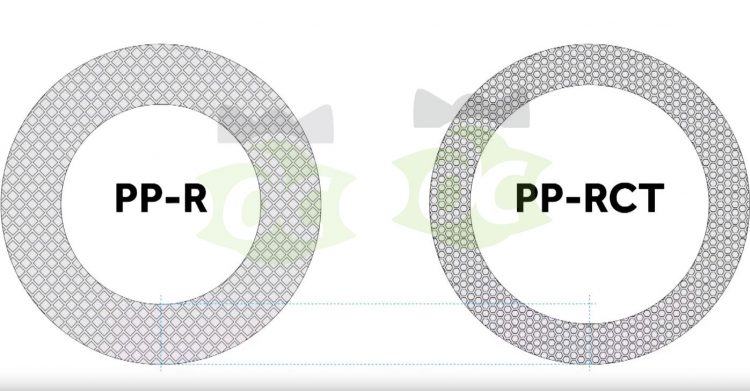

The abbreviation PP-RCT is another material.

Which some refer to the 4th type of polypropylene, although this is an improved third type of Random Soplimer.

This is a heat-stabilized polypropylene, which has higher strength characteristics, due to the fact that the number of faces of the PP-RCT crystal is greater than that of PP-R, which means that the molecular bond is stronger, due to the greater amount of contact between the crystals,

as a result, with the same characteristics in terms of pressure and temperature, the pipe can be made with a thinner wall and increase the throughput without increasing the outer diameter.

Such pipes also have a much smaller linear elongation with temperature changes. More resistant to ultraviolet radiation. And pipes made from this material can withstand temperatures of more than 100 degrees, against 90 from PP-R.

This does not mean that all pipes can withstand temperatures of 100°C. Each manufacturer keeps the composition of polypropylene a secret, so before installing a pipe in your system, familiarize yourself with the characteristics and operating class of this pipe.

But this is a topic for a separate post and of course I will check it.

Marking of plastic pipes

Almost every polymer pipe has a marking on the surface shell that reflects its dimensional, basic physical and chemical parameters. When applying it, they are often guided by the international standard ISO / TC SC4 No. 651, which regulates the following alphanumeric designations of thermoplastic pipes and their sequence:

- Symbols indicating the documentation on the basis of which the product was certified according to EN ISO 9001 or otherwise, according to which the product was released.

- Trademark (trademark, brand) of the manufacturer of the product.

- Information about whether the manufacturer has a certificate for the manufacture of products that meet the standards of their country or world requirements.

- The number of the domestic (GOST) or European standard, according to which the goods are produced. For example, the symbolism of DIN EN ISO 12162 corresponds to the standard for thermoplastics used in the laying of pressure pipelines. The act regulates the classification, designations and strength properties of pipes and fittings. Rice. 5 Examples of deciphering the marking of multilayer and CPVC pipes

- The letter designation of the pipe material (detailed above), as well as its classification according to the generally accepted standard for minimum long-term strength MRS according to DIN EN ISO 12162. GOST R 50838-95 with a minimum strength of MRS 8 MPa.

- Pipe shell diameter and wall thickness. For polymer pipes, standardized sizes of 10, 12, 16, 20, 25, 32, 40 mm are established, many foreign manufacturers mark their products in inches, the actual indicators of which (3/8 ″ - 9.53 mm; 1/2 ″ - 12.7 mm; 3/4 "- 19.05 mm; 1" - 25.4 mm).In practice, they are rounded up to the integer values \u200b\u200bgiven above, for example 3/8 ″ - 10 mm; 1/2″ - 12 mm and so on.

- Standardized dimensional ratio for pipes made of any materials (including metals) SDR, obtained by dividing the outer diameter by the wall thickness. It is clear that the lower the SDR value, the greater the strength and the smaller cross section of the passage channel has a pipe made of the same material. Rice. 6 Examples of marking PP pipes

- Nominal (working) pressure Pn, expressed in kgf / cm2, which corresponds to bars or atmospheres, standard Pn indicators for pipe thermoplastics are 10, 16, 20, 25 bar. Usually, the Pn 25 pipe, which is used in pipelines for transporting hot water or coolant in heating circuits, has the maximum pressure indicator among polymers.

- Workspace. By default, it is assumed that thermoplastic pipes are designed for operation in plumbing communications, sometimes for gas pipes that differ from those transporting liquids, the letter symbol GAS is added.

- Production date, batch. The standard European symbol includes the year of manufacture (2 digits) and a 15-digit digital strip indicating: month, ten days (Latin letters), shift, installation, production line, batch. Sometimes a letter symbol of the origin of raw materials is affixed to the marking. For the export version, indicate the city or country of origin.

The standard step of the applied marking mark is 0.5 - 1 meter, sometimes the length of the roll or segment is indicated on the pipes.

The presence of all the listed items in the pipe marking and the observance of their order is not mandatory, for an ordinary consumer or specialist, the information received about the material of manufacture, dimensions and working pressure of the product is sufficient. To find out the temperature range of the pipe, they are guided by the data obtained.

Rice. 7 Applications of pipes with different Pn and structure

Color marking of pipelines according to GOST 14202 transporting hazardous substances

It is not uncommon for enterprises to transport substances hazardous to life and health of people, the environment through pipelines. For these substances, an additional designation is provided - warning color rings.

Also, hazardous substances differ in properties: flammable, flammable, explosive and poisonous, toxic and radioactive. Correspondence of the color of the warning rings and the hazardous properties are presented in Table 2.

| Table 2 - Colors of warning rings | ||

| Signal color samples | Name of signal colors | Property of the transported substance |

| Red | Flammable, flammable and explosive | |

| Yellow | Danger or harmfulness (poison, toxicity, ability to cause asphyxiation, thermal or chemical burns, radioactivity, high pressure or deep vacuum, etc.) | |

| Green | Security or Neutrality |

The degree of danger of transported substances for humans also differs. GOST 14202 divides substances according to the degree of danger into 3 groups, each group corresponds to a certain number of hazard rings (table 3).

| Table 3 | ||||

| Group | Number of warning rings | Substance being transported | Pressure in kgf/cm² | Temperature in °C |

| 1 | One | superheated steam | up to 22 | 250 to 350 |

| Hot water, saturated steam | 16 to 80 | St. 120 | ||

| Superheated and saturated steam, hot water | 1 to 16 | 120 to 250 | ||

| Combustible (including liquefied and active gases, flammable and combustible liquids) | up to 25 | From minus 70 to 250 | ||

| Non-flammable liquids and vapors, inert gases | Up to 64 | From minus 70 to 350 | ||

| 2 | Two | superheated steam | Up to 39 | 350 to 450 |

| Hot water, saturated steam | 80 to 184 | St. 120 | ||

| Products with toxic properties (except for highly toxic substances and fuming acids) | Up to 16 | From minus 70 to 350 | ||

| Combustible (including liquefied and active gases, flammable and combustible liquids) | 25 to 64 | 250 to 350 and minus 70 to 0 | ||

| Non-flammable liquids and vapors, inert gases | 64 to 100 | From 340 to 450 and from minus 70 to 0 | ||

| 3 | Three | superheated steam | Regardless of the pressure | 450 to 660 |

| Hot water, saturated steam | St. 184 | St. 120 | ||

| Potent toxic substances (SDN) and fuming acids | Regardless of the pressure | From minus 70 to 700 | ||

| Other products with toxic properties | St. 16 | From minus 70 to 700 | ||

| Combustible (including liquefied and active gases, flammable and combustible liquids) | Regardless of the pressure | 350 to 750 | ||

| Non-flammable liquids and vapors, inert gases | Regardless of the pressure | 450 to 700 |

GOST 14202 provides for the use of all possible options for the color marking of the pipeline.

For example, if the pipeline transports a dangerous toxic substance from the “GAS” group, then the color of the pipeline must be yellow, and yellow warning rings must be applied to it (depending on temperature and pressure).

However, yellow rings will not be visible on a yellow background. For this, GOST 14202 recommends applying borders along the edges of the rings.

For yellow rings on a yellow and orange background - black borders, for green rings on a green background - white borders.

Thus, the main requirements of GOST 14202 for the color marking of pipelines are as follows:

- - color marking of pipelines depending on various groups of transported substances;

- - color marking of pipelines depending on the degree of danger of the transported substances.

To specify the type of substance, its parameters, direction of movement through the pipeline, markings are applied in the form of arrows of the appropriate shape and danger signs, the requirements for which are also contained in GOST 14202.

As a result, the correct color marking of pipelines in accordance with GOST 14202 covers the needs of any enterprise in the identification of pipelines transporting both substances of different groups and substances with different degrees of danger.

Pipe selection

The modern market offers various brands of pipes. The choice of the necessary product depends on its further purpose. This requires technical knowledge, without which there is a risk of choosing a pipe of the wrong marking.

Range

The construction market offers a wide selection of polypropylene pipes and accessories for them. For example, according to the wall thickness of the pipe are divided into three categories. The thickest polypropylene pipes withstand maximum pressure without any negative consequences. They also differ in thermal characteristics and color.

Color can be matched to the interior of the room

The difference in colors does not offer any advantage, but black pipes are more resistant to UV radiation than others. The color does not affect the operating conditions, since the same technology and the same materials are used in the manufacturing process.

Pipe selection criteria

When choosing a pipe for a heating or plumbing system, you should pay attention to the following parameters:

- linear expansion;

- diameter;

- Maximum temperature;

- limit pressure.

With low pressure, polypropylene pipes are not subject to rapid wear and can last longer. The same applies to temperature: the lower it is, the longer the service life.

It is worth remembering that during operation, an elongation of polypropylene pipes inevitably occurs due to temperature fluctuations, especially if products without reinforcement are used. The coefficient of linear expansion is equal to 0.03 mm / m ° C for reinforced pipes, and even more for unreinforced pipes - 0.15 mm / m ° C. The installation of special compensators will help to solve this problem.

Thus, polypropylene pipes are the best replacement for similar metal products.They are not only easy to connect using various mounting methods, but also inexpensive compared to other pipes.

Main characteristics

The diameter of pipes made of polypropylene is varied. Mostly produce products with a diameter of 15 to 65 mm. The amount of water that the pipe is able to pass in a certain time depends on the diameter. During installation, the outer diameter is usually not taken into account when calculating the patency, but the strength of the product itself and the force of water pressure are taken into account.

Despite the rather long service life of polypropylene pipes - more than fifty years - over time, the risk of air getting inside the products increases. If the pipes are part of a heating system, air penetration can adversely affect the condition of the heating boiler.

Material Advantages

Polypropylene has the following advantages:

- Polypropylene is not susceptible to corrosion, so the service life of the material on average exceeds that of metal products.

- Inside pipes made of polypropylene, salts and lime are not deposited, as is the case on metal surfaces.

- The cost of steel pipes is much higher than the cost of propylene. After installation, the system does not require special costs associated with its operation.

- Pipes do not require painting, and repair of damage is carried out without special expensive devices.

Easy to install and repair

Since the material has a low thermal conductivity, the temperature difference between the liquid or compressed air at the inlet and outlet is minimal. Another advantage is the low weight of polypropylene pipes, which gives advantages in transportation over similar metal products.

PN marking

There are several brands of pipes used during installation. Each of them may differ in a number of characteristics and properties. Some modifications work at high temperatures, while others can deteriorate quickly in similar conditions. When purchasing pipes, you need to decide on their purpose, and then choose a specific type. There are four main brands of the PN series:

- PN 10. In PN 10 pipes, the liquid pressure cannot exceed 10 atmospheres. They are usually used for the transportation of any heat carriers, the temperature of which does not exceed 45°C. Due to low operational capabilities, the cost of such polypropylene pipes is minimal.

Differences in the structure of pipes of different markings

- PN 16. Products of the PN 16 brand allow a greater linear expansion of polypropylene pipes. Due to their higher performance, they can be operated at a pressure of 16 atmospheres. In this case, the operating temperature reaches 60°C. The cost of the material is slightly higher than the previous brand.

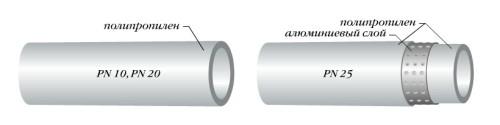

- PN 20. Polypropylene pipes marked pn20 are laid as central heating systems for various structures. The pressure in such pipes does not exceed 20 atmospheres, however, the maximum temperature of the coolant reaches 95°C.

- PN 25. To the question of what pressure polypropylene pipes withstand at maximum coolant supply, one can give an unambiguous answer - 25 atmospheres. These products marked PN 25 have increased strength, and as a result of high-quality fastening, they are not susceptible to deformation under the influence of high temperature. Polypropylene reinforced pipes are most often used when installing a heating system. The water temperature reaches 95°C.

Aluminum reinforced polypropylene

Other marking options

Other subtypes of polypropylene pipes are also produced:

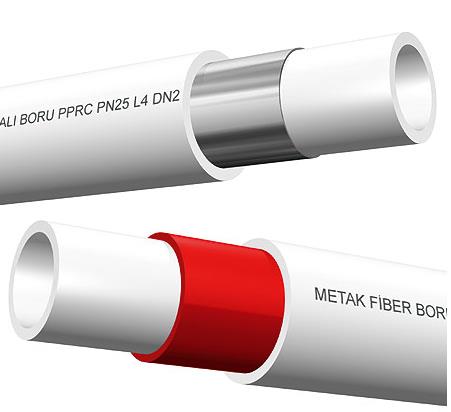

- Pipe SPK ALUMINUM PN 25 is designed for heating systems and pipelines. Inside there is a foil, which is located between the outer and inner layer of polypropylene. The throughput of the polypropylene pipe does not deteriorate as a result.This system greatly simplifies and speeds up the installation process.

- PPR pipes are laid for industrial water supply. Products are reinforced with fiberglass, which, as in the previous case, is located between the layers of polypropylene. Before installation work, pipes do not need to be pre-cleaned. The maximum pressure is 25 atmospheres. The maximum temperature level of the medium inside the product is 95°C.

Installation of pipelines made of polypropylene

Welding of polypropylene pipes

The most common method of joining polypropylene pipes is diffusion welding. In the process of joining by diffusion welding, the materials interpenetrate the molten edges of the products.

Apparatus for welding

In the welding process, it is necessary to use products made of the same material. The durability of the structure is provided by the special physical properties of the seam formed as a result of welding.

- Before work, the product is cut to the desired size strictly at a right angle.

- The welding machine must be set to the soldering mode with a temperature of 260 ° C.

- Before proceeding with the welding process, you need to clean the surface of the pipe, and then degrease it with a solvent.

- If the material is reinforced with aluminum, before welding, the end of the pipe is cleaned of this metal using a special device.

- After welding is completed, both connected ends must be fixed. In this position, the pipe should be from 4 to 8 minutes.

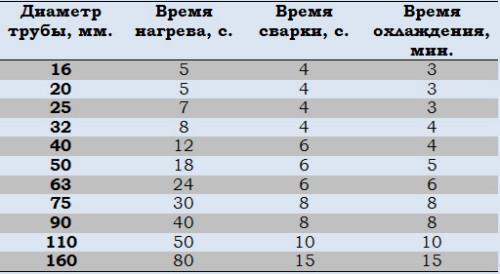

In the process of welding, the duration of heating of the material depends not only on the diameter of the pipe, but also on the thickness. The welding time, the width of the formed weld, as well as other parameters depend on the characteristics of the pipe (its diameters, composition). Therefore, before starting work, a table of polypropylene pipes is needed.

Pipe Welding Table

Installation work

Pipeline installation consists of the following steps:

- To begin with, a detailed diagram is drawn up, on which taps, filters, as well as corners and tees are marked. When planning, you need to consider what temperature polypropylene pipes can withstand.

- Then you should assemble the individual elements of the water or heat pipeline into a complete system.

- Welding is preferably carried out while holding the elements to be connected in a horizontal position. If the departments of the system are not particularly large, welding can be carried out by one person. For more complex mounting, vertical soldering should be performed. The coefficient of linear expansion of polypropylene pipes will depend on the result.

Installation recommendations:

- After welding or brazing the PP pipes, it is necessary to check whether “sealings” have formed that cause a decrease in the clearance. If they are found, they must be eliminated immediately. This phenomenon is most often found in pipes for heating small diameters.

- If polypropylene pipes are not placed in the wall, then the fasteners that will hold them are advised to be placed every 40-50 cm.

- Pipes with rubber seals at the ends must be manually inserted one into the other.

Scope of application

Polypropylene pipes are used as a distribution mechanism in various types of buildings and are part of the process and drinking water pipeline. They are also laid to transport chemicals and pressurized air.

Polypropylene pipes - the technical characteristics of these products are absolutely safe for the environment - are installed for watering vegetable gardens and orchards.

Installation of pipes is carried out without difficulty due to the special properties of polypropylene. The material is easy to weld, and the joints remain strong and reliable. Polypropylene products are often used as a drainage system or for space heating, as well as in the "warm floor" system.

Polypropylene pipes are suitable for installing a "warm floor" system

Reinforced polypropylene pipes are used in heating systems - the temperature of the coolant in such a system can reach 75 ° C and must be determined very accurately in the project. Aluminum and fiberglass additives are used as a reinforcing layer. If it is higher than 75°, cross-linked polyethylene is recommended. Products made of polypropylene have a sufficiently high coefficient of expansion, and therefore cannot be used at very high temperatures.