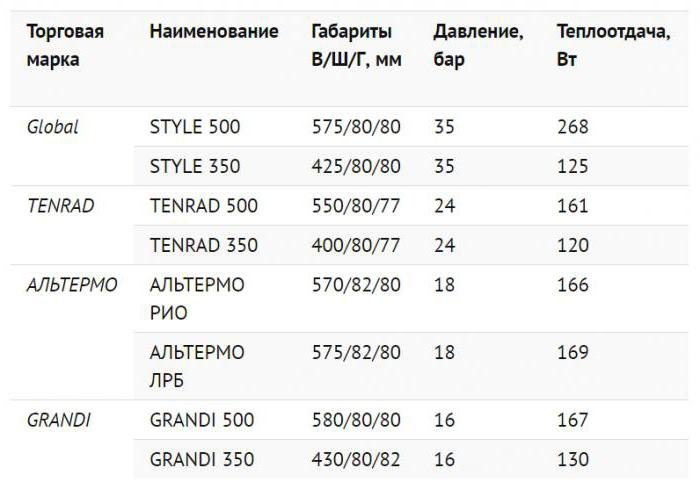

Parameters of bimetallic radiators

The technical parameters of bimetallic radiators are due to the specifics of their design - in a lightweight aluminum casing there is a rod made of anti-corrosion steel in contact with the coolant. Such a symbiosis of materials gives them anti-corrosion resistance, high heat transfer and low weight, which facilitates the installation process.

Of the minuses, one can note the high cost and low throughput.

Based on the foregoing, semi-bimetallic radiators can be used for private houses with individual heating, but only bimetallic ones can withstand the aggressive water environment of central heating.

Structurally, these types of heating devices are divided into monolithic and sectional. The first two are twice as long as the second type in terms of service life and three times in terms of working pressure. And as a result, the cost.

Steel radiators

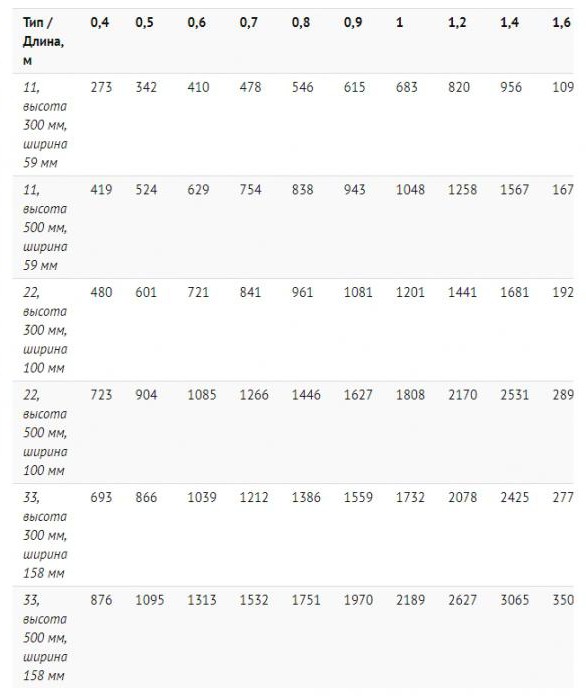

Heating appliances made of steel are presented on the market in a wide range. Structurally, they are divided into panel and tubular.

In the first case, the panel is mounted on the wall or on the floor. Each part consists of two welded plates with a coolant circulating between them. All elements are connected by spot welding. This design significantly improves heat dissipation. To increase this indicator, several panels are connected together, but in this case the battery becomes very heavy - a three-panel radiator is equivalent in weight to cast iron.

In the second case, the design consists of lower and upper collectors connected to each other by vertical tubes. One such element can contain a maximum of six tubes. To increase the surface of the radiator, several sections can be connected together.

Both types are durable, with good heat dissipation heaters.

For design purposes, tubular steel radiators can be produced in the form of partitions, stair railings, mirror frames.

The heat transfer table of steel heating radiators is located later in the article.

Real heat dissipation of the radiator section

As already mentioned, the power (heat transfer) of radiators must be indicated in their technical passport. But why, after a few weeks after the installation of the heating system (or even earlier), it suddenly turns out that the boiler seems to be heating as it should, and the batteries are installed in accordance with all the rules, but it is cold in the house? There can be several reasons for the decrease in the actual heat transfer of radiators.

Pig-iron radiator Viadrus (Czech Republic)

Here are the indicators of the heating surface and the declared heat transfer for the most common models of cast iron radiators. We will need these figures in the future for examples of calculating the real power of the radiator section.

| Radiator type | Heating surface, m2 | Heat output, W m2 (90/20°C) |

| M-140-AO | 0,299 | 175 |

| M-140-AO-300 | 0,17 | 108 |

| M-140 | 0,254 | 155 |

| M-90 | 0,2 | 130 |

| RD-90s | 0,203 | 137 |

As already mentioned, when using such radiators for medium-, low-temperature heating systems (for example, 55/45 or 70/55), the heat transfer of a cast-iron heating radiator will be less than stated in the passport. Therefore, in order not to be mistaken with the number of sections, its actual power must be recalculated according to the formula:

Q = K x F x ∆ t

where:

K is the heat transfer coefficient;

F is the heating surface area;

∆ t - temperature difference ° С (0.5 x ( t input +tout. ) - text.);

wherein

tin - the temperature of the water entering the radiator,

texit - water temperature at the outlet of the radiator;

text.- average air temperature in the room.

When the temperature of the incoming coolant is 90 gr., Outgoing 70 gr., And the temperature in the room is 20 gr.

∆ t \u003d 0.5 x (90 + 70) - 20 \u003d 60

The K coefficient for the most common cast iron radiators can be found here:

| Thermal head | 50-60 | 60-70 | 70-80 | 80-100 |

| Heat transfer coefficient (K) | ||||

| High cast iron radiators | 7.0 | 7.5 | 8.0 | 8.5 |

| Medium cast iron radiators | 6.2 | 6.4 | 6.6 | 6.8 |

Even the real heat transfer of one section of an average cast-iron radiator with an area of 0.299 sq. m (M-140-AO) at an inlet water temperature of 90 g, and an outgoing water temperature of 70 g will differ from the declared one. This is due to heat losses in the supply pipes, and for other reasons (for example, reduced pressure), which cannot be foreseen under laboratory conditions.

So, the heat transfer of a section with an area of 0.299 sq. m. at a temperature of 90/70 will be:

7 x 0.299 x 60 = 125.58 W

Considering that heat transfer is always indicated with some margin, we multiply this figure by 1.3 (this coefficient is used for most cast iron radiators) and we get: 125.58 x 1.3 = 163, 254 W - compared to the declared 175 W.

There will be even more difference in numbers if the water entering the radiator does not heat up above 70 degrees. (and the outgoing coolant, respectively, cools down to 60-50 degrees), so before buying new radiators, it is advisable to find out the real thermal parameters of your heating system.

How to save on heating?

The first rule of reasonable savings is to remember what you should never save on! Radiators should always be taken with a margin, because you can reduce the temperature in the room by reducing the temperature of the water in the system or by using stopcocks. But if the actual heat transfer is lower than declared by the manufacturer, the rooms will be cool at best. By the way, Conner cast-iron radiators, which are quite good in terms of most parameters, in real operation have a heat transfer of 20-25 percent lower than indicated in the passport

Radiator 1K60P-500 (Minsk)

As already mentioned, heat transfer may differ from the declared one due to the fact that the water temperature in the heating system is much lower than the “standard”, that is, the one at which the factory tests were carried out, since the declared radiation power is achievable only under laboratory conditions. Imagine that the section of the MS-140 radiator (power 160 W is indicated) at a water temperature of 60/50 degrees. (and more “the boiler does not pull”!) Will produce power of no more than 50 watts. And if you believed the technical data sheet and decided to install 5 heating sections, then instead of 800 W (160 x 5) you will get only 250.

However, it is quite possible to foresee this situation and even take advantage of it! Based on the calculations given above, the lower ∆ t (that is, the temperature of the heat carrier water), the larger the radiant surface of the radiator should be. So at ∆ t 60 for radiation of 1 kW, a radiator with a height of 0.5 m x 0.520 m is sufficient, and at ∆ t 30 - 0.5 m x 1.32 m.

"Traditional" cast iron radiator MS-140M2

Characteristics of heating radiators

Battery efficiency depends on the following factors:

- coolant supply temperature;

- thermal conductivity of the material;

- battery surface area;

The higher these indicators, the greater the thermal power of the devices.

It is customary to consider W / m * K as a unit of measurement for the heat transfer of a radiator, along with this, the format cal / hour is often indicated in the passport. Conversion coefficient from one unit of measure to another: 1 W / m * K = 859.8 cal / hour.

Depending on the materials of manufacture, cast iron, steel, aluminum and bimetallic radiators are distinguished. Each material has indicators for the following parameters:

- heat transfer of one section;

- working pressure;

- crimping pressure;

- capacity of one section;

- weight of one section.

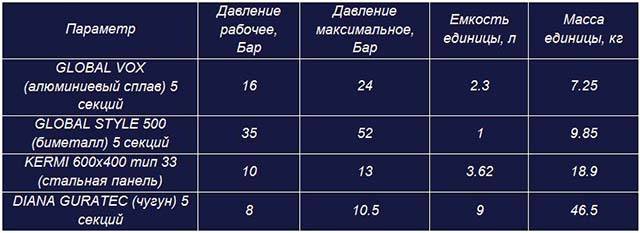

Thermal power comparison

If you carefully studied the previous section, you should understand that heat transfer is greatly influenced by air and coolant temperatures, and these characteristics do not depend much on the radiator itself. But there is a third factor - the heat exchange surface area, and here the design and shape of the product plays a big role.Therefore, it is difficult to ideally compare a steel panel heater with a cast iron one, their surfaces are too different.

The fourth factor affecting heat transfer is the material from which the heater is made. Compare for yourself: 5 sections of the aluminum radiator GLOBAL VOX with a height of 600 mm will give 635 W at DT = 50 °C. Cast iron retro battery DIANA (GURATEC) of the same height and the same number of sections can only deliver 530 W under the same conditions (Δt = 50 °C). These data are published on the official websites of manufacturers.

You can try to compare aluminum with a steel panel radiator, taking the nearest standard size that is suitable in size. The mentioned 5 GLOBAL aluminum sections 600 mm high have a total length of about 400 mm, which corresponds to the KERMI 600x400 steel panel. It turns out that even a three-row steel device (type 30) will give out only 572 W at Δt = 50 °C. But keep in mind that the depth of the GLOBAL VOX radiator is only 95 mm, and the KERMI panels are almost 160 mm. That is, the high heat transfer of aluminum makes itself felt, which is reflected in the dimensions.

In the conditions of an individual heating system of a private house, batteries of the same power, but from different metals, will work differently. Therefore, the comparison is quite predictable:

- Bimetallic and aluminum products quickly warm up and cool down. Giving more heat over a period of time, they return colder water to the system.

- Steel panel radiators occupy a middle position, as they transfer heat not so intensively. But they are cheaper and easier to install.

- The most inert and expensive are cast iron heaters, they are characterized by a long warm-up and cool-down, which causes a slight delay in the automatic regulation of the coolant flow by thermostatic heads.

All of the above leads to a simple conclusion.

It doesn’t matter what material the radiator is made of, the main thing is that it is correctly selected in terms of power and suits the user in all respects. In general, for comparison, it does not hurt to get acquainted with all the nuances of the operation of a particular device, as well as where which one can be installed

How to choose a cast iron radiator

What performance characteristics of the radiator should be considered when choosing radiators? First of all it is:

- operating pressure;

- operating temperature in the heating system for which heat transfer is calculated;

- heat transfer;

- heat-radiating surface area;

The first of these indicators determines the pressure of the coolant (water) that the radiator can withstand. The higher the number of storeys of the building, the stronger it should be. The second indicates at what temperature the coolant is supplied to the radiator and at what temperature it leaves it for subsequent heating. So the indicator 90/70 means that the water entering the first section of the battery has a temperature of 90 degrees. and coming out of its last section - 70 deg. Heat dissipation is an indicator that indicates how much heat a radiator section gives off during the time the water in it cools from the inlet temperature (for example, 90 degrees) to the outlet temperature (for example, 70 degrees).

The form of the acquired radiator deserves special attention. It's no secret that a biased attitude towards cast-iron radiators is caused by the fact that when they are mentioned, many people recall the "cast-iron accordion" familiar from childhood under the window. Indeed, the usual "finned batteries" have a small and inefficient surface of the heating area (heat transfer) - so for the section of the familiar MS 140 radiator, this figure is 0.23 sq.m.

Part of the heat of the incoming coolant is lost “on the way” from the heating boiler to the water heating battery, because massive supply pipes are used for such systems. In addition, for heating water to a design temperature of 90 degrees. only high power steam boilers are suitable.Therefore, in private homes, the heating system sometimes operates in a lower temperature mode.

However, modern cast-iron radiators, both in appearance and, accordingly, in parameters, can differ significantly from their “accordion” predecessors. Retaining all the advantages of traditional cast iron batteries, it is devoid of many of their shortcomings. So, the Minsk-made radiator 1K60P-500 is assembled from flat plates, each of which has a small heating area (0.116 m2) and low power (70 W).

However, a radiator assembled from them, in fact, is a heating panel, which (unlike finned batteries) gives a wide directional heat flow. Other manufacturers also provide a wide selection of such radiators.

The advantage of modern cast iron radiators is that many models allow you to assemble batteries of the required power from separate sections.

Radiators sold in assembly (for example, Conner, STI Breeze and some others) are formed from the number of sections designed for rooms of different sizes based on the engineering calculation of the required heat output per square meter of the room.

For example, you can purchase one radiator of 4-6-8-12 sections or two radiators of 4 (6, 8, sections).

Cast iron radiators, their advantages and disadvantages, varieties

Although they have been in use for over a century, the popularity of cast iron radiators continues to rise. They are made by casting, have thick walls and an extremely simple but reliable design. Especially often they are placed in country houses and cottages, since they are ideal for solid fuel heating systems. Repairing them is much easier than analogues from other metals. In addition, modern cast-iron radiators are produced according to quite fashionable design developments. Decorative patterns or other images are placed on them. Radiators designed in retro style are especially fashionable today. They can have a different volume and shape, and outwardly they already bear little resemblance to their counterparts produced during the Soviet era. The main advantages that cast iron radiators have are the following.

Extremely high resistance to corrosion. During use, the surface of cast iron is covered with an oxide film that prevents corrosion. In addition, this surface is so hard that it is practically not damaged by solid fragments that periodically enter the heating system along with hot water.

It looks like a radiator made of cast iron.

The ability to keep warm for a long time. An hour after the coolant supply is cut off, the cast-iron radiator retains 30% of the heat, while the steel one retains only 15%.

Huge service life. If during the casting of cast iron there were no defects in the form of air chambers and microcracks, then cast iron radiators can serve for several decades. Instances are known that have been successfully functioning for 100 years or more.

Features of the chemical composition of cast iron exclude the possibility of electrochemical corrosion. There will be no conflicts with the plastic supply pipeline.

Simplicity of design and simple manufacturing process dictate the low cost and affordable consumer prices of cast iron radiators.

The main disadvantage of all cast iron products, including heating radiators, is their heavy weight. That is why wall mounting of their batteries can only be done on a main wall, which has a large margin of safety. In addition, their installation requires a lot of labor and takes a long time. Another significant disadvantage is the long heating time, which is the flip side of the ability to store heat for a long time.

Types of cast iron radiators

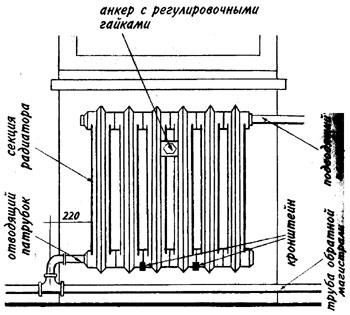

Diagram of the radiator device.

These heating radiators may have different specifications, but structurally they are divided into three categories: tubular, sectional and panel. The former have a large internal volume and are a non-separable structure of two large-diameter pipes combined into two circuits. As a rule, they are used in rooms with a large internal volume. Usually these are public or industrial buildings. The latter make up the bulk of cast iron heating batteries. They are assembled from separate sections, depending on how much heating power is needed in a particular room. They are most often used for heating living rooms or offices. How much such a battery weighs depends on the number of sections and the inner diameter. Its main advantage is that, as necessary, you can reduce or increase the number of sections of a ready-made functioning circuit.

Panel radiators are flat rectangular plates in which channels for supplying coolant are laid. They can be installed either in series or in parallel. However, they have almost the same technical characteristics as sectional ones. Having the same volume of heat transfer, such radiators are much more bulky and difficult to install. At the same time, repair presents big problems. That is why they are almost never used anymore, gradually being replaced by more modern models.

How to increase heat dissipation

There are several simple ways to increase the heat transfer of a heating battery:

- Install heat reflective material behind the heatsink. You can attach a thin metallized or foil insulation to the wall behind it. It should fit snugly against the wall and be at least 1 cm away from the radiator housing, which will ensure good air circulation.

- Clean the case from dust, which inevitably accumulates on it even in the “cleanest” apartment.

- Excess layers of paint greatly reduce the heat transfer of the heating device. Therefore, if you are going to repaint it, remove the old paint before work. (Here it is written how to do it correctly).

- Do not cover heating radiators with solid floor-length curtains. They block the normal air circulation, and the space near the window is heated mainly.

- Check if air has accumulated in the radiator. This will be understandable if its upper and lower parts differ significantly in temperature. To remove air, a Mayevsky crane is used, which must be installed on each heating device.

- If temperature regulators are installed on the battery, check their position and serviceability.

In addition to simple methods that are feasible during the heating period, in the summer you can try to solve the problem radically:

- Rinse the battery and heat supply pipelines. The coolant inevitably contains a certain amount of contaminants. Central heating is especially “sinful” with this. These contaminants settle in the pipes and internal channels of the radiators and gradually reduce their diameter, making it difficult for the coolant to pass and transfer its heat to the body. This procedure is recommended to be carried out before each heating season. (This article describes various ways to flush the heating system).

- Change the connection of the radiator or its location, if they were not done effectively enough, and this allows the room and the design of the heating network.

- Increase the number of sections in the heating battery. All types of radiators, except for panel and tubular ones, make it easy to carry out this operation by increasing the size of heating devices.

- In an apartment building, the reason for the decrease in heat transfer may not be the shortcomings of your heating devices, but the neighbors. For example, they can build up their batteries so much that the coolant in them will cool down much more than the architects and builders foresaw, and come to your apartment cold.In this case, you will have to contact the managing organization to check the condition of the riser and, then, to the mayor's office to take action against the negligent neighbor.

Comparison by other characteristics

One feature of battery operation - inertia - has already been mentioned above. But in order for the comparison of heating radiators to be correct, it must be done not only in terms of heat transfer, but also in other important parameters:

- working and maximum pressure;

- the amount of water contained;

- mass.

The operating pressure limitation determines whether the heater can be installed in multi-storey buildings where the height of the water column can reach hundreds of meters. By the way, this restriction does not apply to private houses, where the pressure in the network is not high by definition. Comparing the capacity of radiators can give an idea of the total amount of water in the system that will need to be heated. Well, the mass of the product is important in determining the place and method of its attachment.

As an example, a comparison table of the characteristics of various heating radiators of the same size is shown below:

Heating radiator, comparison of several types

for each of them there are certain conditions

- Sectional cast iron radiator.

- Aluminum heating device.

- Bimetallic sectional heating devices.

We will compare different types of heating devices according to the parameters that affect their choice and installation:

-

The value of the heat output of the heating device.

- At what operating pressure? the device is operating efficiently.

- Required pressure for pressure testing of battery sections.

- The volume of heat carrier occupied by one section.

- What is the weight of the heater.

It should be noted that in the process of comparison it is not necessary to take into account the maximum temperature of the heat carrier, a high indicator of this value allows the use of these radiators in residential premises.

In urban heating networks, there are always different parameters of the working pressure of the heat carrier, this indicator must be taken into account when choosing a radiator, as well as test pressure parameters. In country houses, in villages with cottages, the coolant is almost always lower than 3 bar. but in the city, central heating is supplied with a pressure of up to 15 bar. Increased pressure is necessary as there are many buildings with many floors.

The dependence of heat transfer on the material

The best material for the manufacture of radiators are metals, because they have the best thermal conductivity. The higher this indicator, the better the material transfers heat from the hot coolant to the surrounding air.

The table below contains the heat transfer coefficients of metals used in the manufacture of heating appliances:

As can be seen from the table, copper is the most beneficial from this point of view - it transfers heat better than others. However, with such advantages, it is very "inconvenient" in terms of manufacturing and operation:

- easily damaged;

- rapidly oxidizes;

- chemically active.

Aluminum

Aluminum is used more often than copper, although its thermal conductivity is half that. It heats up quickly, is light, and almost any shape can be made from it. But it has the same disadvantages as copper. In addition, when aluminum comes into contact with other metals, corrosion quickly begins.

Cast iron

For a long time, cast iron heating batteries have been deservedly popular. This metal is durable, inexpensive and resistant to corrosion. Its disadvantages include only a large weight and fragility. But the large weight of the batteries in some cases is good for them. In networks with solid fuel boilers, a large thermal inertia due to the weight of the radiators helps to smooth out their inherent fluctuations in the temperature of the coolant and maintain the temperature in the room after the fuel has burned out.

Steel

The thermal conductivity of steel is even lower.In addition, it is subject to intense corrosion, which significantly reduces the life of such radiators. But the relatively low price and ease of manufacture of panel radiators attracts many manufacturers. Radiators of this type are two interconnected steel plates with stamped channels for the movement of the coolant.

Bimetal devices

Each of the considered materials has its advantages and disadvantages - there is no ideal metal for making a radiator. But by combining two different metals, good results can be achieved. Recently gained popularity bimetallic radiators are made from steel and aluminum. The aluminum outer part of the device perfectly transfers heat from the durable steel inner part. As a result, their heat transfer is much higher than that of cast iron or steel. The table shows the heat transfer value of heating radiators of the same standard size:

Dependence of heat transfer on the shape

For the quality of heat transfer, in addition to the material from which the radiator is made, its shape is of great importance.

For example, the simplest panel radiator measuring 0.5 m by 0.5 m has a thermal power of about 380 watts. So, if it is provided with additional fins and the area is increased, the heat transfer will increase one and a half times: up to 570 watts. Without increasing the temperature of the coolant, its speed, without changing the size of the channels - only by increasing the surface area in contact with the surrounding air.

Therefore, all manufacturers strive to increase the heat transfer of their products precisely according to this principle - they are looking for a form that will more efficiently transfer the energy of the coolant without additional costs.

Lightweight heating radiators and their features

Aluminum light radiators.

Aluminum radiators have the lightest weight, allowing them to be placed on walls even with a small margin of safety, such as plasterboard internal partitions. However, they are susceptible to corrosion of internal surfaces due to aggressive impurities in hot water. In addition, electrochemical corrosion can occur if the water supply system is made of plastic pipes. Therefore, the service life of such a heating radiator is quite small. A steel radiator is much more reliable in this regard, but it is heavier and stores heat for a very short time. In addition, it is quite expensive.

Bimetallic heating radiators are designed in theory to combine the advantages of both. In them, only the steel surface is in contact with hot water, while the surface parts are all made of aluminum alloy. Therefore, it is almost impossible to visually distinguish bimetallic radiators from pure aluminum ones. This can only be done by picking them up, since the first ones have a slightly larger weight. At the same time, bimetallic radiators can have a completely steel frame or only water channels reinforced with steel pipes.

In the second case, loosely fixed steel inserts, due to the difference in thermal expansion of iron and aluminum, can move and block the lower collector of the entire heating battery. Even if this does not happen, bimetallic systems periodically emit a crack due to this difference, which not everyone likes. And yes, they are quite expensive. Meanwhile, despite the different materials of execution, heating radiators have technical characteristics that are significant for the consumer, if not identical, then often quite close. Mounts can also be used both wall and floor.

The figure shows bimetallic radiators.

The power of the cast-iron radiator calculation, the factors on which the heat transfer and accounting of the coolant depend

The main elements of a standard heating system are radiators that provide uniform heating of the premises, so their installation must be carried out in accordance with all requirements.Today, consumers have access to a diverse selection of models, the differences of which are both in form and in materials of manufacture. Over time, cast-iron radiators have not become obsolete, but still continue to occupy a stable position in the apartments and houses of users.

This material, as before, remains one of the most reliable and durable. Given the fact that modern cast-iron models have changed their appearance, becoming more modern and elegant, they continue to be bought. For this reason, it is worth considering how their heat transfer should be calculated so that a constant comfortable temperature is maintained in the premises.

In the photo - a standard cast-iron radiator

Indicators affecting the calculation of the number of sections

Choosing a radiator for a particular room, you need to take into account the technical features. For example, the calculation will be different for a corner and non-corner room, for rooms with different ceiling heights and different window sizes, etc. The most important parameters that are taken into account when determining the required radiator power are:

- the area of your premises;

- floor;

- ceiling height (above or below three meters);

- location (corner or non-corner room, room in a private house);

- whether the heating battery will be the main heating device;

- there is a fireplace in the room, air conditioning.

Other important features must be taken into account. How many windows are in the room? What size are they, and what kind of windows are they (wooden; double-glazed windows for 1, 2 or 3 glasses)? Was additional wall insulation done and what kind (internal, external)? In a private house, the presence of an attic and how insulated it is, and so on, matters.

Pig-iron radiators Conner (China)

According to SNIP, 41 W of thermal energy is needed per 1 cubic meter of space. You can take into account not the volume, but the area of \u200b\u200bthe room. For 10 sq.m of a standard room with one door and one window, one door and an external wall, the following heat output of the radiator will be required:

- 1 kW for a room with one window and an outer wall;

- 1.2 kW if it has one window and two outer walls (corner room);

- 1.3 kW for corner rooms with two windows.

In reality, one kilowatt of thermal energy heats:

- In the premises of brick houses with a wall thickness of one and a half to two bricks, or from timber and log houses (the area of \u200b\u200bwindows and doors is up to 15%; insulation of walls, roofs and attics) - 20-25 square meters. m

- In corner rooms with walls made of timber or brick of at least one brick (the area of windows and doors is up to 25%; insulation) - 14-18 square meters. m

- In the premises of panel houses with internal cladding and a heat-insulated roof (as well as in the rooms of an insulated dacha) - 8-12 square meters. m

- In a "residential trailer" (wooden or panel house with minimal insulation) - 5-7 square meters. m.

Conclusion

High heat transfer on a bimetallic heater can be obtained not only at high pressure. For both types of radiators, even for cast iron and steel structures, heat transfer can be increased by at least 20% if you use not water as a coolant in home boilers, but special types of antifreeze or antifreeze. The pressure will not change, and it will remain 3-4 atm., And the temperature at the outlet of the boiler will increase to almost 95-97 ° C, which will give an increase in heat transfer by 15-20%. In addition, antifreeze will ensure the good safety of aluminum, cast iron, steel pipes and heat exchangers.