Features of condensing boilers

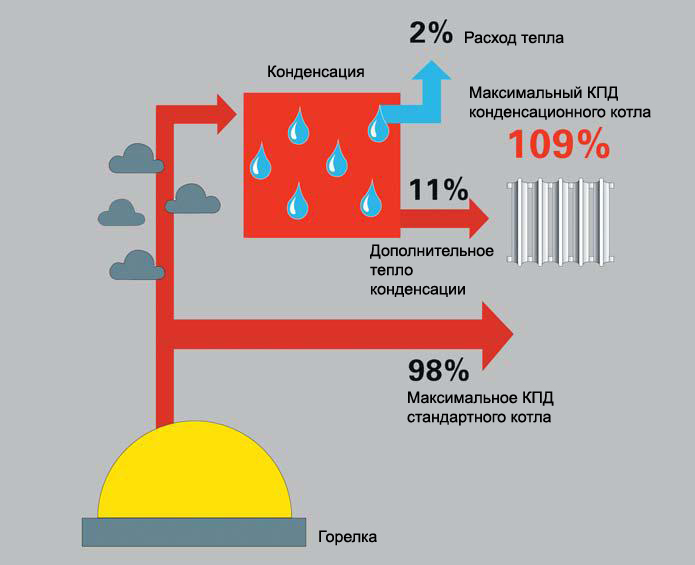

Based on the laws of physics, it is necessary to understand that even slight heat losses are inevitable in any case and the efficiency will not reach 100%. Compared to gas boilers, condensing boilers are more economical. This figure for condensing boilers is higher by about 15-20%.

Condensing boiler efficiency

Condensing boilers are equipped with more modern burners, which minimizes the likelihood of incomplete combustion of the fuel. Together with the exhaust gases, much less harmful substances are released and the temperature of the exhaust gases also decreases, which rarely exceeds 40 degrees. For such boilers, plastic chimneys can also be used, which saves on this component of the heating system. It also reduces the cost of installing chimneys.

As for the execution, the condensing gas wall-mounted boilers are almost in everything similar to traditional gas boilers.

Most often, condensing boilers are wall-mounted, but there are also powerful floor-standing devices. Such boilers are rarely used for residential premises. Basically, they can be found in office premises or in production.

Wall mounted condensing boiler

The main difference from conventional boilers is that in condensing boilers the heat exchanger is made of materials with good resistance to various acids. Usually such materials are stainless steel or silumin. Due to the high acidity, condensate is formed, and it causes a corrosion process if such alloys are used that are used for the manufacture of non-condensing boilers.

Characteristics of the low temperature heating system

The temperature regime of heating systems can be described by three characteristics:

- . Heat carrier temperature at the inlet to the boiler.

- . outlet temperature.

- . The temperature in the heated room.

The boiler data must be indicated in the product data sheet in this sequence. Heating systems of the traditional type (including central heating) were calculated in such a way that the water at the outlet of the heater should have a temperature of about 80 degrees with a temperature of 60 degrees at the inlet. However, today such indicators are somewhat outdated. The temperature can be lowered either by the heating network or by the user himself. European boilers, which today have almost completely replaced Soviet heating counterparts, operate according to slightly different schemes.

According to the European standard, the normal operation of heating systems assumes a temperature of 60-75 degrees Celsius. But here we also talk about the concept of the so-called "soft heat", which implies the parameters of a system with a temperature of up to 55 degrees. And it is this regime that may become normative in the near future, given all the tightening requirements for savings. Thus, it becomes more and more relevant.

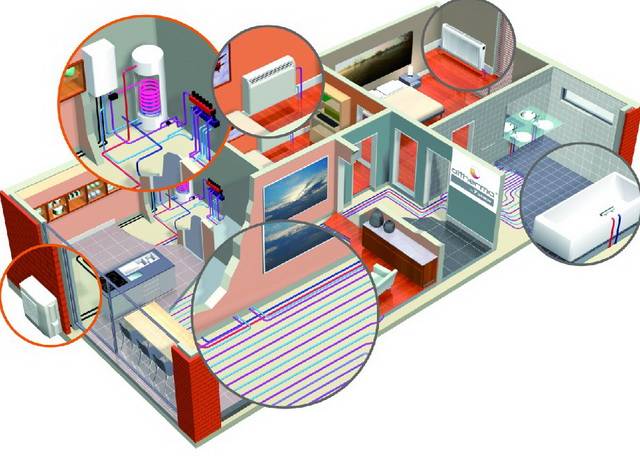

Everyone has probably heard about "warm floors". It is this system that is one of the most striking examples of low-temperature heating. In addition, most owners of a private house today reduce the temperature of the boilers to "one" in order to bring the temperature of the heat carriers to 50-60 degrees.

Advantages and disadvantages of low temperature heating systems

Low-temperature systems have a number of significant advantages:

- significant cost savings by reducing energy consumption;

- reduction of harmful emissions into the atmosphere;

- improvement in comfort levels. Due to the low heating of the radiators in the room, the air does not dry out and there are no strong convective currents that raise dust;

- safety. You can’t get burned on a radiator with a temperature of +50 ... +60 ° C, which cannot be said about a battery heated to +80 ° C;

- reducing the load on the boiler, which increases the operational life of the equipment;

- the possibility of using heat pumps, condensing boilers and other types of alternative equipment with a low temperature regime.

The disadvantages of heating systems of this type are relative. So, a certain minus can be called increased requirements for the radiators used

. However, the use of Ogint Delta Plus batteries completely solves all the problems of choosing heaters.

It should also be noted that in severe frosts, low-temperature systems cannot always cope with the heating of buildings. At the same time, the system without any problems can be transferred to work in a higher temperature regime, if necessary.

In general, low temperature heating systems are more efficient, economical and safer than traditional systems. Therefore, today we can confidently say that the future belongs to low-temperature heating.

A. Nikishov

The development of technical thought has allowed modern man to have a large selection of heating systems, depending on the requirements and material capabilities, which even the previous generation did not have. The gradual development of household thermal power engineering has led to the fact that low-temperature heating systems for housing have become increasingly popular among the population, which will be discussed in this article.

Practice has shown that when comparing two heat sources - with high and low temperatures - the most comfortable conditions for a person are created by a low-temperature heating device, which provides a small temperature difference in the room and does not cause negative sensations. The upper limit of the so-called low temperatures, according to the definition of power engineers, is in the region of 40˚С. Low-temperature heating systems using a coolant operate with temperatures of 40-60˚С - at the inlet to the heat-producing device and at its outlet. And air, electric and radiant heating systems also use lower temperatures, comparable to the temperature of the human body. So the very concept of low temperatures is rather arbitrary, and, nevertheless, the use of a coolant or other heat sources with a temperature of up to 45˚ has many advantages that affect the choice of such a system for home heating, and, due to its features, organically fits into applications with renewable sources of energy.

All heating systems are subject to certain requirements, which are designed to make their use more efficient, comfortable and safe. Construction, climatic, hygienic and technological requirements are detailed in DBN V.2.5-67:2013 in paragraphs 4, 5, 6, 7, 9, 10 and 11. These requirements make it possible to minimize negative and at the same time increase positive impacts on the human body, provided by heating systems.

It should be noted that one of the most important conditions for the efficiency of any heating systems is careful consideration of heat losses, and for low-temperature systems this is perhaps the most important. Otherwise, such systems will be inefficient and unnecessarily energy-, and, therefore, materially costly.

What are the advantages of low temperature heating

At installation of underfloor heating system

, you get the following benefits:

- 1. The main advantage is the level of comfort. It's no secret that too hot batteries dry the air, forming excessive convection in the house, which raises a lot of dust in the house, having a negative effect on the human body.

- 2. Profitability. By refusing intensive heating in favor of selective heating, which is characterized by separate temperature control, you can save up to 20% of heat transfer fluids.

- 3. Technological efficiency. Using the warm pipe mode, you can discover two heating options at once - condensing boilers, characterized by an efficiency of up to 95%, and solar collectors, which allow you to get "free" energy.

By eliminating the main sources of heat loss and wanting to reduce costs when the system pays off in 5-10 years, homeowners can start converting heating systems to a more economical mode of operation.

geo-comfort.ru

Electric heating

This system is represented on the market of heating systems by many manufacturers. It is based on the principle of heating a special resistive cable (Fig. 3) by electric current. The heat removed from the cable is transferred to the environment, creating a soft heating of the room. The system package may include heating cables or prefabricated mats, thermostats and an installation kit for quick and easy installation.

Structural elements of systems

All heating systems, as mentioned above, are designed to maintain an optimal and comfortable ratio of three parameters - the temperature of the coolant after the heat-producing device, the temperature of the heater and the air temperature in the room. This ratio can be ensured by the correct selection of important elements of the system.

Heat producing devices

All devices for the production of heat can be divided into three groups.

The first group is heat generators based on the use of traditional fuel and electricity. For the most part, these are various hot water boilers operating on solid, liquid, gaseous fuels and electric energy. Even for indirect heating of "cold" steam in steam systems of low-temperature heating, all the same water-heating devices are used.

In this group of devices, a household condensing boiler can be noted, which is a device that has appeared as a result of innovative developments in the rational use of water vapor generated during fuel combustion. Research aimed at a more complete use of energy and at the same time minimizing the negative impact on the environment, made it possible to create a new type of heating equipment - a condensing boiler - which allows additional heat to be obtained from flue gases through condensation.

For example, the Italian manufacturer Baxi produces a line of condensing boilers, both floor-standing and wall-mounted. The range of Luna Platinum wall-mounted boilers (fig. 4) consists of single-circuit and double-circuit condensing boilers, with power from 12 to 32 kW. The key element is the AISI 316L stainless steel heat exchanger. Various components of the boiler are controlled by an electronic board, there is a removable control panel with a liquid crystal display and a built-in temperature control function. The burner power modulation system allows the boiler output to be adapted to the energy consumed by the building in the range of 1:10.

The second group is installations that use the heat of non-system coolants. In such cases, heat accumulators are used.

The third group includes devices that use an external coolant for indirect heating.They successfully use surface, cascade or bubbling ball heat exchangers. It is this type that is used for heating "cold" steam in low-temperature steam heating systems.

The main components of the condensing boiler

The heat exchanger for condensing boilers can be made in the form of pipes with a complex cross section. This is necessary in order to increase the volume of the heat exchanger as much as possible, thereby increasing the efficiency of the condensing boiler. In boilers of this type, a fan is mounted in front of the burner, which extracts gas from the gas pipeline and mixes it with air. Further, such a working mixture is sent to the burner.

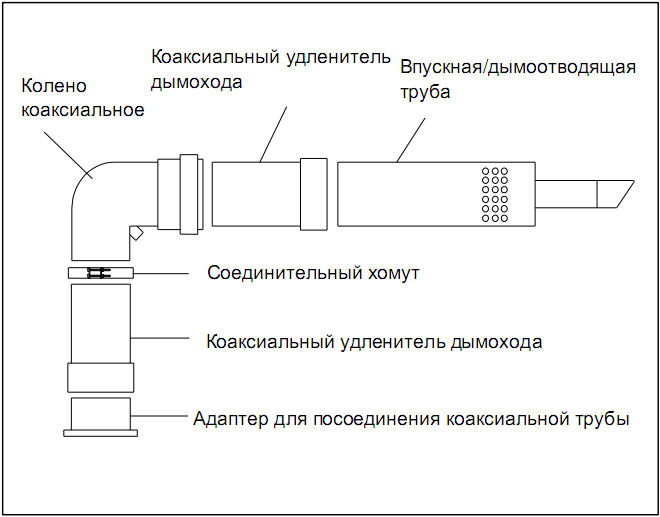

Flue gases leave the system through coaxial chimneys.

For the manufacture of such chimneys, manufacturers mainly use plastic, which has good heat resistance. The pump integrated in gas condensing heating boilers is electronically controlled and optimizes the output of the boiler, thereby saving electricity.

coaxial chimney

The efficiency of the boiler largely depends on the parameters of the heating system as a whole. If the water temperature is low, then the condensation of water vapor will occur more fully. Thus, a significant part of the latent heat will be returned to the heating system. This will also affect the fact that the efficiency of the condensing boiler will be slightly higher.

Not every heating system is suitable for a condensing boiler. The heating system must be designed for a not too high coolant temperature.

That is, it should be a relatively low-temperature heating system. In the return circuit, the coolant must have a temperature no higher than 60 degrees. Outside conditions don't matter. If there is a slight frost on the street, then the temperature of the coolant in the return circuit will not be lower than 45-50 degrees. Thus, the boiler will operate in condensing mode.

Floor standing condensing boiler

Low-temperature heating boilers can be either with one or with two circuits. They can be used to organize a heating system or for hot water supply. Such boilers may vary in power parameters. Their power range is quite large and ranges from 20 to 100 kW. Such power, which is provided by low-temperature heating at home, is enough for any living conditions.

For an industrial area, you will need to purchase a more powerful floor-standing boiler.

You can also purchase various kits for connecting condensing boilers. The list of such components includes: condensate neutralizers, expansion tanks, various safety devices, kits for the exhaust gas system, piping kits and much more.

In many European countries, the use of boilers other than condensing ones is prohibited. This is due to the fact that they have a higher efficiency and they emit much less harmful particles into the atmosphere. In such countries, the state takes care of its people, because it prohibits the use of equipment that does not have good economy and a low level of environmental safety.

Heating appliances

Heating appliances are divided into 4 groups:

- devices with surfaces equal in area, both on the heat carrier side and on the air side. This type of device is known to everyone - these are traditional sectional radiators;

- convection-type devices, in which the surface area in contact with air is much larger than the surface on the coolant side. In these devices, heat radiation is of secondary importance;

- plate air heaters with stimulating air flow;

- panel-type devices - floor, ceiling or wall.In this line of heating panels, for example, one can note the Czech panel steel radiators Korado called Radik, produced in two versions - with a side connection (Klasik), and with a lower one with a built-in thermostatic valve (VK). Panel steel radiators are also offered by Kermi (Germany).

Heating devices of low-temperature systems include various types of sectional and panel heaters, heating convectors, heaters and heating panels.

Heat accumulators

These devices are required in bivalent low temperature heating systems that use energy from renewable sources or waste heat. Heat accumulators can be liquid-filled or solid-filled, using the heat capacity of the filler to store heat.

Devices in which heat is released at the time of phase transformations are becoming more and more widespread. In them, heat accumulates in the process of melting a substance or when its crystalline structure undergoes certain changes.

Also, thermochemical heat accumulators work effectively, the principle of which is based on the accumulation of heat as a result of chemical reactions that occur with the release of heat.

Heat accumulators can be connected to the heating system both according to a dependent circuit, and according to an independent one, when heat is accumulated in them from an off-system coolant.

Thermal accumulators can also be ground, rock, and even underground lakes can be used as heat storage.

Ground thermal accumulators are obtained by placing registers made of pipes in increments of one and a half to two meters. Rock heat accumulators are equipped by drilling vertical or inclined wells in rocks to a depth of 10 to 50 m, where the coolant is pumped. The use of underground lakes as heat accumulators is possible if pipes with a coolant pumped into them are placed in the lower layers of water. Heat is taken from pipes located in the upper layers of underground lakes.

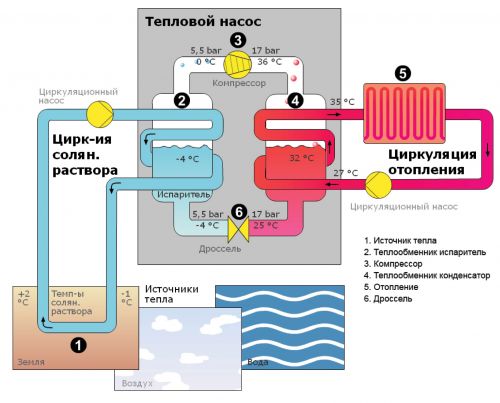

Heat pumps

When using a heat source in low-temperature heating systems, the temperature of which is lower than the air temperature in the room, as well as to reduce the material consumption of heating devices, heat pumps can be included in the system (Fig. 6). The most common devices in this group are compression heat pumps, which give a temperature of 60 to 80 ° C during condensation.

The efficient operation of the heat pump in a low-temperature heating system is ensured by the inclusion of a heat accumulator in the evaporator circuit, which helps to stabilize the evaporation temperature of the "cold" steam. The adjustment of this system is carried out by changing the heat transfer of the pump itself.

Advantages and disadvantages

Low-temperature heating systems win their supporters by creating more comfortable conditions in the room than traditional ones with high heating of heating devices. There is no excessive "drying" of the air, there is no - again excessive - dustiness of the room due to the inevitable movement of air with very hot heaters.

The use of heat accumulators in the system makes it possible to accumulate heat and instantly use it if necessary.

The low temperature spread between the heat producing device and the room air makes it easy to regulate the system using programmable thermostats.

As for the shortcomings, it is, in fact, one - the cost of the finished system is somewhat, if not several times higher than the traditional high-temperature one.

Read articles and news in the Telegram channel

AW-therm. Subscribe to

YouTube channel.

Viewed: 14 617

Selection of the exact number of sections of bimetallic batteries

They are of several types, each of them has its own power. The minimum heat release reaches - 120 W, the maximum - 190 W. When calculating the number of sections, it is necessary to take into account the required heat consumption depending on the location of the house, as well as taking into account heat losses:

- Drafts that occur due to poor-quality window openings and window profiles, cracks in the walls.

- Waste of heat along the path of the coolant from one battery to another.

- Corner location of the room.

- The number of windows in the room: the more there are, the greater the heat loss.

- Regular airing of rooms in winter also affects the number of sections.

For example, if you need to heat a room of 10 m2 located in a house located in the middle climatic zone, then you need to purchase a battery with 10 sections, the power of each of them should be equal to 120 W or its equivalent for 6 sections with a heat output of 190 W.

Steam heating

This type of heating is characterized by the use of "saturated" steam as a heating medium, which leads to the need to ensure adequate collection of condensate. And if there is one heater in the heating system, which does not create problems, then with an increase in their number, it becomes more and more difficult to remove condensate. The solution to this problem was found in the use of "cold" steam as a coolant. Its role in modern low-temperature steam heating systems is played, in particular, by freon-114, a non-flammable, non-toxic, odorless and chemically stable inorganic compound.

The "cold" steam system works by using the heat released during the condensation of saturated vapors, which heats the heating devices. The condensate pipelines operate in a "wet" mode, which is due to the condensate back-up. In this case, steam traps are not needed - the condensate returns to the evaporator by gravity. A make-up pump is also not required. Both steam pipelines and condensate pipelines are mounted both horizontally and vertically. Moreover, it is absolutely not necessary to comply with the slope. In the case of vertical installation, the supply steam line can be placed both above and below.

The adjustment of a system operating on “cold” steam is carried out by influencing the steam pressure and its temperature, for which the system is calculated on a pressure corresponding to the maximum possible steam temperature.

Sectional radiators and convector panels are commonly used as heating devices in a low-temperature steam heating system. To regulate heat transfer, each heating device is equipped with a membrane valve.

What are the advantages of low temperature heating

At installation of underfloor heating system

, you get the following benefits:

- 1. The main advantage is the level of comfort. It's no secret that too hot batteries dry the air, forming excessive convection in the house, which raises a lot of dust in the house, having a negative effect on the human body.

- 2. Profitability. By refusing intensive heating in favor of selective heating, which is characterized by separate temperature control, you can save up to 20% of heat transfer fluids.

- 3. Technological efficiency. Using the warm pipe mode, you can discover two heating options at once - condensing boilers, characterized by an efficiency of up to 95%, and solar collectors, which allow you to get "free" energy.

By eliminating the main sources of heat loss and wanting to reduce costs when the system pays off in 5-10 years, homeowners can start converting heating systems to a more economical mode of operation.

The most important task of technology development is to increase energy efficiency. To solve this problem in heating systems, the most effective way is to reduce the temperature of the coolant. That is why low-temperature heating is today a key trend in the development of modern heating technology.

A low-temperature heating system during operation consumes a much smaller amount of coolant than a traditional system. This results in significant savings. An additional advantage is the reduction of harmful emissions into the atmosphere. In addition, working with a "soft" temperature regime allows you to use alternative types of equipment - heat pumps or condensing boilers.

The main problem in the development of low-temperature heating for a long time remained that at low heating temperatures it was very difficult to create comfortable conditions in heated rooms. However, with the development of building technologies that allow the construction of energy efficient buildings, this problem has been solved. The use of modern building and heat-insulating materials makes it possible to significantly reduce the heat losses of buildings.

Thanks to this, the low-temperature heating system can efficiently and efficiently heat the house. The achieved effect of saving the coolant significantly exceeds the additional costs that have to be incurred for the thermal insulation of buildings.