Preparation of pipes, valves, fittings

The first step is to study the instructions for the soldering iron. It contains all the recommendations, as well as restrictions on the use of the machine. The instructions also contain a table by which you can determine the heating time of the pipeline elements.

Next, the preparation of the workplace is carried out, as already mentioned above. It is necessary to fix the welding machine with a clamp, connect it to the network. Set the operating mode to 260 oC. The temperature is set on a special regulator.

Now you need to strip the Teflon inserts and put them on the machine. It remains to wait for the heating of welding. During the entire work, you can not turn off the soldering iron. The set temperature regime will not allow overheating of the Teflon inserts. But under no circumstances should the temperature be lowered. The resulting connection will be unreliable, wear out over time and leak.

Now you can proceed to the preparation of pipes. First you need to make segments of suitable sizes. All sections should be carefully processed. The reinforcing layer is removed. With the help of scissors-cutter, the edge of the pipe is cut off, now you need to chamfer with a cone-shaped cutter. The surfaces to be soldered should be degreased, cleaned of dirt, dust and unevenness should be eliminated.

Installation of a valve for polypropylene pipes is carried out at a certain angle so that the handle is in the correct plane. To do this, you need to apply markings for welding on the pipe and coupling. Otherwise, the locking mechanism will be inconvenient to use, and sometimes completely impossible.

Soldering tools for polypropylene pipes and taps

When the problem is solved with the choice of ball valves, you can proceed to the preparation of tools for soldering polypropylene pipes and locking mechanisms. Soldering equipment can be purchased or rented.

In general, this device is useful on the farm, it is often used when repairing breakdowns or installing a plumbing system. It includes a heating element in the form of a xiphoid plate, in which there are holes for various nozzles, and a thermostat. With the help of the latter, you can set a specific soldering temperature. For polypropylene, it is 260 degrees Celsius.

Most often, the power of such devices is 2500 W, and they are connected to a household outlet with a voltage of 220 V. The soldering machine is capable of operating in a temperature range from 50 to 320 degrees Celsius.

The device is equipped with Teflon nozzles of different diameters, suitable for all polypropylene pipes used in plumbing systems. If the pipe is a non-standard size, then the nozzle can be purchased separately.

When a one-time soldering of pipes and taps is planned, the easiest way is to rent a soldering machine. This will save you money while completing the task. But this is not all that is required.

List of required tools:

- A welding machine for polypropylene pipes (it is also sometimes called a soldering iron, because the connection of PP products is carried out by soldering).

- Devices for cutting and stripping pipes. The end cut is performed with a conical knife, precision scissors and a cutter with a roller are also needed. However, it will also be possible to cut a polypropylene pipe with a hacksaw. But then the edges of the cut will turn out to be uneven. For a complete installation of the water supply, you will need a special tool. Sometimes it is included in the set of the welding machine.

- If you plan to solder reinforced pipes, then you will additionally need a hand knife. It will be used to remove the reinforcing layer. Otherwise, welding will be unreliable, such a connection will quickly fail.

- Markup tools.Usually, a construction pencil or marker is used to apply it. With their help, it will be possible to highlight the connection line of the pipe with the tap, along which the soldering will go.

As it has already become clear, all the necessary tools for soldering pipes with stopcocks are not very expensive, which makes the installation of a polypropylene water supply system quite cheap. This material is often used in domestic engineering systems of city apartments and country houses.

Water valve replacement

To replace the valve in the water supply system of an apartment or other residential premises, it is necessary to shut off the water supply.

If a faucet is being replaced, which is part of the wiring in the apartment, for example, a toilet faucet or a washing machine, then you can turn off the faucet located on the riser.

How to turn off the water supply of the apartment

If it is necessary to replace the tap located on the riser, then it is necessary to shut off the water supply in the basement of the house. This will require the assistance of an employee of the management company or housing office.

Preparing for a replacement

At the first stage, you need to prepare:

new valve;

two adjustable wrenches or wrenches

When selecting wrenches, it is important to choose their dimension correctly (in accordance with the dimensions of the fixing nuts);

sealing material. For water, FUM tape or Tangit Unilok thread is most often used.

Thread sealing tape

Replacement procedure

Replacing a valve on a riser or water supply distribution is carried out according to the following scheme:

- after shutting off the water supply, it is necessary to open all the taps in order to drain the remaining liquid from the pipes;

- the old valve is dismantled:

- if the valve is installed on a threaded connection, then with the help of keys it is necessary to loosen the fixing nuts;

- if a valve with a flange connection is installed, then to remove the device, it is necessary to loosen the bolts fixing the mounting flanges;

- if the valve is soldered into pipes, then when replacing, additional equipment will be required for cutting pipes, since it will not be possible to dismantle the valve in any other way;

Plastic Pipe Cutting Tool

- pipes at the valve installation site are cleaned of various types of contaminants;

- a new locking device is installed:

- if the threaded method is used during installation, then the thread must be sealed before installing the tap;

How to wrap sealant tape on threads

- if a flanged valve is mounted, then additional sealing is not required;

- the welded tap is installed using a special apparatus for soldering pipes;

Valve installation by welding

- the tightness of the connections obtained is checked.

How to replace a tap installed on a thread, see the video.

Selection of ball valves

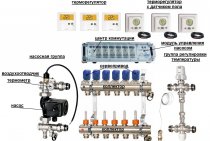

Shut-off valves must be selected for domestic plumbing systems based on the laying diagram

Particular attention should be paid to the location of shut-off ball valves for polypropylene pipes. These components are used to block the flow of water entering a certain section of the system or the entire water supply system.

When choosing a location for the installation of stopcocks, it is necessary to take into account the fact of possible leaks or structural failures. Then, if a breakdown occurs, it will be possible to shut off the water supply to the desired part of the water supply, and then repair or replace the faulty section.

The more complex the design of the water supply system and the longer its length, the more ball valves will be needed. When choosing them, several important factors must be taken into account.

How to repair a valve

Main malfunctions of the valve:

- when closed, the valve passes water, “flows”;

- water seeps down the stem;

- the presence of leakage through the threaded connections of the valve with pipes.

The causes of these malfunctions, as a rule, are the wear of the rubber gasket of the valve, the sink and the gully on the edge of the seat, the “eaten” thread at the stem, which is why it does not press the valve against the seat, the stuffing box is rumpled or dry, the seal is weak, the threaded connections of the valve with pipes are poorly sealed.

To replace a failed gasket, it is necessary, first of all, to turn off the water in the pipeline where the faulty valve is located.After making sure that water does not flow through the pipe when the valve is fully open (or only slightly oozes, which is acceptable), unscrew the valve head using a regular or adjustable wrench. After removing the head, change the damaged gasket or put a new valve.

Often the cause of water leaking through a closed valve is a sink or gully in the seat lip. Finding such a shell is easy if you take a thin screwdriver and run it with a sting along the edge of the saddle. To reliably close a valve with a defective seat, it is necessary to press the gasket against the seat more than usual, which is why it quickly fails - it is cut through by a sharp edge or crumbled by the sharp edges of the shell. Shallow sinks and sharpened edges can be eliminated with a face mill or with the help of emery nozzles of a suitable shape and size, rotating them manually or with a drill. If there is no nozzle and cutter, use a sandpaper: for this, a circle of sandpaper on a fabric basis is glued onto a rubber gasket, which is mounted on a three- or four-sided needle file inserted into the chuck of a manual (not electric!) Drill; after a few turns of the gasket with sandpaper, the seat will be cleaned. Instead of a needle file, you can use a regular bolt by gluing a circle of skin on its head. To eliminate deep gullies, it is often necessary to completely grind the saddle. In this case, it is better to install a new valve (or just change the body).

In the absence of a new valve, a brass bushing of the appropriate size can be pressed into the hole of the old seat, the protruding edge of which will now serve as a new seat. Such restoration of the valve can significantly extend its service life, but is complicated by the need to grind the brass bushing on a lathe.

Do-it-yourself connection of polypropylene pipes with your own hands

Modern technologies allow using polypropylene pipes to create reliable and durable communications. They do not corrode. Therefore, they are widely used. But in this case, the important point is the connection of polypropylene pipes with your own hands. This can be done by soldering or using the method without welding. Therefore, it is not necessary to involve a specialist. Let's look at each in more detail.

We connect with welding

Tool

To get the best result and not provoke problems during operation, you should study the technology and the existing rules well. Only then can you start the soldering process.

And for this process, you will need a welding machine, which experts often call an “iron”. This device is a simple device powered by the mains. In the kit, it often has nozzles of different diameters with instructions.

Soldering technology

Despite their "polypropylene", such pipes are perfectly used for hot water supply or heating. They will last a very long time.

The connection of such products occurs when high temperature is applied to their ends. But there is one subtlety here. The pipes are heated from the outside, and the connection elements from the inside. This is the only way to get strong knots.

Step by step process:

First, the soldering iron is turned on, it must be heated to 270 degrees. Products are cut into the desired pieces and cleaned. You can make convenient notes to understand how deep to immerse them in the apparatus for heating. We evenly insert the pipes and connection elements onto the nozzles of the device

This is also important for quality soldering. After melting the element and the pipe, they are removed from the device and connected to each other

The evenness of the soldering is also important here. It is necessary to press down slightly, but not to scroll around the axis. Pressure also affects the quality of soldering. After joining the elements, they must be held for several minutes in a stationary state.

When performing manipulations, you should pay attention to another important nuance. The inner surface of the seams should not lose patency

Indeed, when melted, a small tubercle appears, which is dangerous if the products are of small diameter.

A strong influx of material caused by excessive heating should also be avoided. To check the patency of the pipe, it can be blown through and let water through it.

It should be recommended that if you do not have soldering experience, you can first practice before proceeding with the basic manipulations. And therefore it is recommended to purchase materials with a margin, because in addition to training, for sure, marriage can occur during the main work. And it is highly undesirable to run or go back to the store in the process of soldering. For more information on DIY soldering, you can also watch a video on the topic.

As for the device itself, it is not necessary to buy it. The device can be rented from someone.

We connect without welding

There is another way that allows you not to use welding - "cold". In this case, compression fittings are used. Therefore, you do not have to buy or rent welding equipment. All you need is a crimp wrench. This tool is often sold with fittings.

However, this method without welding has one significant drawback. The execution time of the procedures is significantly longer in comparison with welding. And this must be taken into account when choosing a pipe connection method.

Conclusion

In a word, there is nothing terrible or very difficult in connecting polypropylene pipes with your own hands. As in most technologies, a clear and correct implementation of established technological standards is required. To do this, you can additionally familiarize yourself with the video materials. Then the process will be carried out not only quickly, but also qualitatively. And this is already a guarantee of durability and reliability of the resulting water supply or heating system.

In this case, it is not necessary to use welding. After all, you can do it in an alternative way. However, the disadvantage of this solution is the increase in time of all work. Therefore, it is necessary to choose a method, taking into account this moment. Then everything will go smoothly, and the system being built will gain the required strength and reliability.

Types of plastic ball valves

Stop valves made of polymers are manufactured in various modifications and may differ in the material of manufacture, purpose, body shape and design of the connecting pipes.

Faucets are made from:

- polyvinyl chloride (PVC),

- low pressure polyethylene (HDPE),

- polypropylene (PPR)

Ball valves made of PVC and PPR are more resistant to difficult operating conditions than products made of polyethylene. PVC and polypropylene fittings are suitable for operation at temperatures up to 95 and 90 degrees, respectively, and pressures up to 20 bar, and HDPE - only up to 45 degrees and 15 bar.

plastic taps

To block or restrict the flow in a plastic pipeline, plastic valves (cranes) are used, which, due to their structure, are commonly called ball valves.

The fact is that the locking mechanism of the plastic tap itself has the shape of a ball with a through hole, which rotates inside a hollow sphere by 90 ºC.

In taps of small diameter (up to 150 mm), the locking mechanism is actuated by means of a lever; in devices with a large diameter, an electric-pneumatic or hydraulic actuator is used.

The use of plastic taps in the installation of plumbing systems

The body of valves that can be put on a PVC or HDPE pipe is made of the same type of plastic as other elements of the pipeline and is mounted in the same way.

Pros and cons of plastic taps

Plastic ball valves are significantly different from their counterparts made of other materials, and have many advantages over them.However, they also have their drawbacks.

Of the advantages it is:

- durability. The service life of such cranes is 25 years or more. This parameter depends, first of all, on operating conditions;

- reliability due to the simplicity of the design;

- availability, which is ensured by the low cost of the material;

- light weight of the product. This parameter greatly simplifies the process of transportation and installation, makes it possible to carry out installation work with your own hands without assistants and additional equipment;

- high level of tightness;

- PVC and HDPE plastic products are not subject to corrosion, fungi, sedimentation;

Plastic faucets are simple in design, not subject to corrosion and are light in weight.

- resistance to chemically active substances, for example, to acid and alkaline compounds, which are used to clean water pipes and sewers;

- plastic ball valves are always made in full bore versions (the diameter of the hole in the ball corresponds to the inner diameter of the pipe), so there is no place for debris to accumulate in them;

- during operation, the product does not require preventive maintenance and maintenance;

- environmental friendliness. PVC and HDPE pipes and taps can be used for drinking, both cold and hot water;

- plastic valves are recommended to be used only to completely shut off or open the flow of fluid. When used to adjust the pressure, the service life of the product is significantly reduced;

- plastic fittings are designed for lower pressure and temperature than metal fittings. Moreover, PVC is more resistant to these parameters than HDPE.