Drywall constructions are widely used in the repair and redevelopment of apartments. These are walls, suspended ceilings, niches and partitions, boxes and decorative fireplaces. For high-quality assembly, reliable fasteners are required, so it is important to choose the right screws for fixing the profile under drywall.

What self-tapping screws are needed for the profile and drywall: all types

Fasteners used when working with gypsum boards are divided into 3 groups:

- for fastening the guide profile to walls, floors and ceilings;

- for connecting frame elements;

- for screwing drywall sheets to the profile.

Let's take a look at each type in the order in which they are used.

For fastening the profile to the wall, floor, ceiling

To fix the guide profiles - the basis of the frame for drywall - you can use:

- Dowel-nails. Usually fasteners with a diameter of 6 mm and a length of 40 mm are used.

- Self-tapping screws with a press washer (MCP) with dowels matched to them. The length of the self-tapping screw for a brick wall is 41 mm (for concrete, you can take a little shorter), the dowel is 6 × 40 or 6 × 37 mm. It is with such a dowel that a self-tapping screw with a diameter of 4.2 mm will twist tightly and hold tightly.

- Anchor bolts. They are used in special cases: when attaching a reinforced profile and with increased loads.

- Wood screws. Used for mounting rails on a wooden wall.

ibuilder.decorexpro.com/en/ recommends: when choosing between dowel nails and self-tapping screws with a press washer, it is better to prefer the latter. In the first type of fastener, the screw is driven into the dowel, while the self-tapping screws are screwed in and provide a more reliable, “eternal” fastening.

There is another option for fixing the profile on the walls and ceiling - using a gas mounting gun. It is used to drive dowels into the base and allows you to get the job done quickly and easily. However, both the tool itself and the components are expensive, so only professionals working with large volumes can afford it.

To connect frame parts

Screws of this category are used to connect metal frame elements - racks and rails. There are 2 types of such fasteners:

- With cylindrical head. Among the masters, they are often called bedbugs, fleas or seeds. Such names are primarily due to the size of the hardware.

- With a press washer. Such self-tapping screws have a thin, but wide hat, similar to a washer.

- Self-tapping bug

- For a profile with a press washer

For screwing plasterboard to the frame

To fasten sheets of drywall to the frame, self-tapping screws with a cone head are used: during installation, they are completely recessed deep into the material. This ensures that the fixing points are not visible after finishing the holes, which means that there are no problems when finishing.

Self-tapping screws are used depending on the material of the frame:

- For metal with fine threads to fasten the plasterboard to the profile.

- On wood, if the crate is made of timber.

To choose the right self-tapping screws, consider their types in more detail.

Fasteners for a frame with a cylindrical head ("bugs")

The stores offer a wide selection of such products with different characteristics:

- Length from 9 to 11 mm. Professionals recommend using shorter ones: there are practically no differences in the quality of fastening, and the savings are good.

- Black oxidized and bright galvanized. Beginners believe that the second is more durable. In fact, the characteristics of both types are the same, so take those that are available.

- Sharp or with a drill at the end. Masters recommend using sharp ones: they are better kept in the profile due to a small, neat hole. In addition, their price is lower.The advantages of using self-tapping screws with sharp ends are visible in the photo.

- With serifs on the back of the hat and without. If possible, it is better to take screws with serifs: they prevent the connection from unwinding during vibrations.

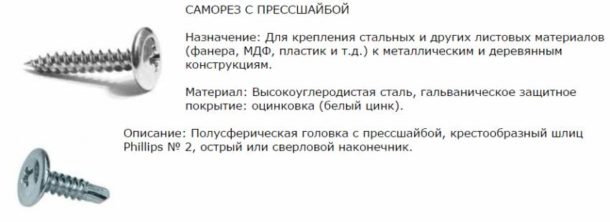

Self-tapping screws with a press washer (for the frame)

These elements are also used to fasten metal profiles. They have several significant advantages over the type with a cylindrical head:

- A wide hat provides a stronger grip of the frame elements among themselves.

- They protrude less above the profile plane, which facilitates the subsequent installation of drywall sheets on it.

The main drawback is the cost: such hardware will cost more than bedbugs.

On sale there are self-tapping screws with a press washer up to 80 mm long, but 13–15 mm is enough to assemble a frame for drywall.

They have a zinc coating, are available with a drill at the end (MTsSP) or sharp (MTsP). Professionals recommend MCP for a regular profile and MCSP for a thick one.

Self-tapping screws for fastening drywall to a metal profile

Finding out and choosing such hardware is simple:

- A fine thread pitch will ensure a reliable connection with the metal of the frame.

- The length varies from 16 to 152 mm. For high-quality fastening, the length of the self-tapping screw must exceed the thickness of the material to be screwed twice. Therefore, when installing drywall in one layer, screws 3.5 × 25 mm are used, in two layers - 3.5 × 35 mm.

- The conical cap is recessed into the drywall. It is most convenient to use a screwdriver with special nozzle-limiter: it will not allow the screw to be driven too deep and damage the material.

Masters who are professionally involved in working with drywall use self-tapping tool. It costs a lot, so it makes no sense to buy it for the repair of one apartment.

Fasteners for fixing plasterboard on a wooden frame

When using lathing from beams, wood screws with a wider thread are taken. This is the cheapest type of hardware of all listed. For fixing drywall to the bars, the following screws are used:

- 3.5 × 32 - for wall cladding;

- 3.5 × 25 - for ceiling work.

The length of the self-tapping screw also depends on the parameters of the wood: for loose wood, longer screws are taken.

Important! For fastening to a metal profile, wood screws are not suitable. When installing a metal frame, they are used to attach drywall to wooden bars that reinforce areas near a doorway or a place for hanging a TV or other equipment.

Pro Tips

We found out that different types of screws will be needed for different stages of work. The standard budget set of fasteners for mounting a drywall construction will include:

- dowel-nails 6 × 40 mm for attaching guides;

- self-tapping bugs with a sharp end without a drill for a profile;

- self-tapping screws for gypsum boards for metal.

ibuilder.decorexpro.com/en/ recommends another set that is used by experienced crafters. It will cost a little more, but it will make the structure more reliable and facilitate the fastening of the plasterboard.

- Self-tapping screws with a press washer (MCP) 41 mm long + dowels 6 × 40 or 6 × 37 mm for guides.

- MCP screws 13–15 mm long for fastening profiles to each other.

- Self-tapping screws for mounting drywall 25 or 35 mm.

Tip: wherever possible, it is better to use cutter. Self-tapping screws are screwed only in hard-to-reach places. This connection method will ensure a tight fit of the drywall to the frame (there will be no bulges from the screw heads) and, with large amounts of work, will help save on fasteners.

Calculation of the required number of hardware

There are several ways to calculate the required number of hardware:

- Draw a detailed diagram of the frame, and then count the number of self-tapping screws for its assembly and for fixing the plasterboard.

- Use the tables according to the Knauf method: they give the consumption of all components per 1 m2 of drywall coating.

- Use an online calculator.

Table of approximate consumption of hardware for wall cladding in one layer:

| Name | Quantity per 1 sq. m |

| Dowel-nails | 1,6 |

| Self-tapping screws for connecting profiles | 2,7 |

| Self-tapping screws for fastening GKL | 17 |

For a partition with drywall fastening in 1 layer:

| Name | Quantity per 1 sq. m |

| Self-tapping screws for plasterboard | 34 |

| Dowel-nails | 1,6 |

For false ceiling:

| Name | Quantity per 1 sq. m |

| Screw LN 3.5 x 9 mm | 1,4 |

| Self-tapping screws for plasterboard | 23 |

| Dowel for mounting profiles PN 28/27 | 0,7 |

| Anchor dowel | 0,7 |

Self-tapping calculator for a drywall profile

Advice from ibuilder.decorexpro.com/en/: buy hardware with a margin of at least 10%. During installation, screws can (and will) break and get lost.

When buying, even if the screws are sold in sealed boxes, it would be useful to open one of them and check the quality. The thread should be even, and the hardware coating should be solid. Often there are overheated self-tapping screws: when tightened with a screwdriver, their hats simply fly off. As a result, the body of the hardware has to be pulled out of the profile or beam using pliers. It takes time, is inconvenient and not always possible. Therefore, it is recommended to purchase screws in reliable and trusted stores. This will save time, money, and nerve cells.