The popularity of drywall is largely due to the ease of use of a lightweight and durable metal profile, which is the basis for attaching sheets. A drywall profile allows you to quickly build a frame of any configuration using a minimum set of tools. If you plan to use drywall during the repair process, you should be aware that the metal products for the frame differ in size, purpose and scope. In order to understand which profile is better to choose in a particular case, you need to get at least a minimal idea about its varieties.

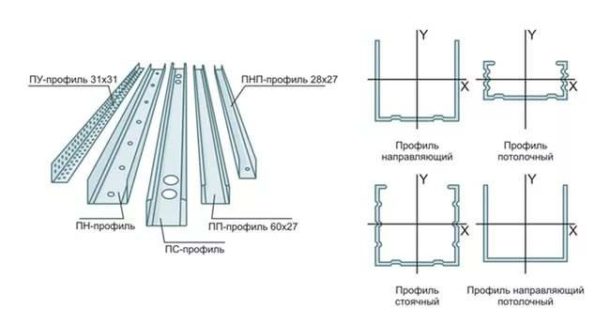

Profiles for drywall can be divided into 2 main types - partition and ceiling. In turn, each type consists of guides (starting) and bearing (main, rack) profiles. Guides are installed along the contour of the future structure, after which a supporting metal profile is inserted into them. It forms a crate on which the plasterboards are attached. With certain methods of connecting different parts, various structures are obtained: wall cladding, partitions, boxes, niches, suspended ceilings.

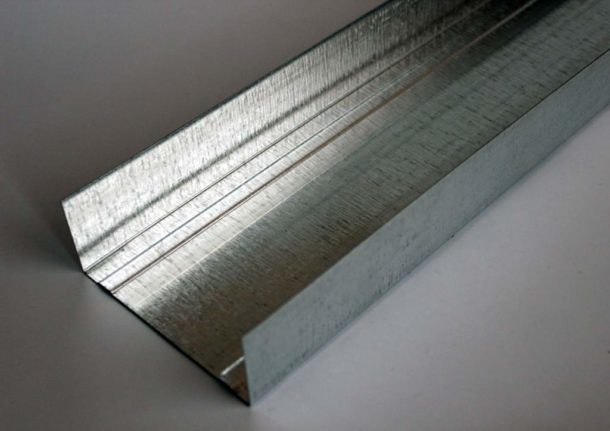

The metal profile is made from a steel strip with a zinc coating 0.4–0.8 mm thick on roll forming machines, where the products are given the desired shape. Thin metal (0.4 mm) can only be used for wall cladding. Thicker metal securely holds the false ceiling and is used to create partitions.

Any metal profile has a back and shelves, only the guide shelves are straight, and the carrier ones are bent at the ends.

Load-bearing ceiling profiles

The false ceiling frame is loaded only due to the weight of the structure. The ceiling profile for drywall, designated PP (CD), forms the basis of the frame and ensures its rigidity.

CD metal profiles are also used for wall cladding and the creation of various structures - shelves, boxes, niches, false walls, therefore they are often called rack profiles or racks, and sometimes planar.

Rack profiles for drywall have stiffeners in which it is convenient to center the screws. The edges of the shelves are folded inward for greater rigidity and for fastening hangers.

Standard size minimizes waste. The length of the rack is 2.6 m, 3 m, 4 m. Most often, products with a section of 60 × 27 mm are used.

Guide profile for ceiling

U-shaped metal profiles PNP (UD) serve to guide and hold rack elements.

The Knauf marking is indicated in brackets in Latin.

The metal profile is used both for wall cladding and for arranging the ceiling, placing it around the perimeter of the room. The guides are located along the perimeter of the frame, ensuring that the surface of the sheets is in the same plane. Their length is 3 m, the cross section is 28 × 27 mm.

Sometimes it is recommended to use the so-called economy profile with smaller shelves and thickness and narrower (guides UD 17 × 25, carrying CD 47 × 17). Its cost is much lower, but such products can only be used for ceilings with thin (0.8–0.95 cm) plasterboard ceilings and for wall cladding of a small area.

Metal profiles for partitions

The starting partition profile PN (UW) is intended for the installation of plasterboard structures. It is mounted on the floor and ceiling as a basis for a future partition. The depth is 40 mm, and the width is from 50 to 100 mm. This diversity is due to the need to select the thickness of the wall.

The wall profile for partitions made of drywall PS (CW) is made with a cross-sectional shape in the form of the letter "C".It is also suitable for wall cladding. Dimensions depend on the thickness and height of the structure. The length of the metal profile is selected according to the height of the room so that there are no joints.

Special profile variations

In addition to the listed varieties, there are special products used in special cases.

Reinforced metal profile UA

A reinforced drywall profile is used to increase the strength of the structure in the following cases:

- the creation of a suspended ceiling with increased weight;

- fastening boxes of doors and windows;

- when it is necessary to strengthen high structures;

- wall decoration with the placement of a large number of communications.

The thickness of the metal is 2 mm, and the height of the shelf is 40 mm.

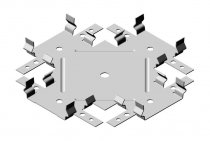

U-shaped metal profile with flanges

The profile is used to save space between the sheet and the base. Fastening is made through the sides to the ceilings and walls. The height of the product is only 15 mm. Such a metal profile must stand on a flat base.

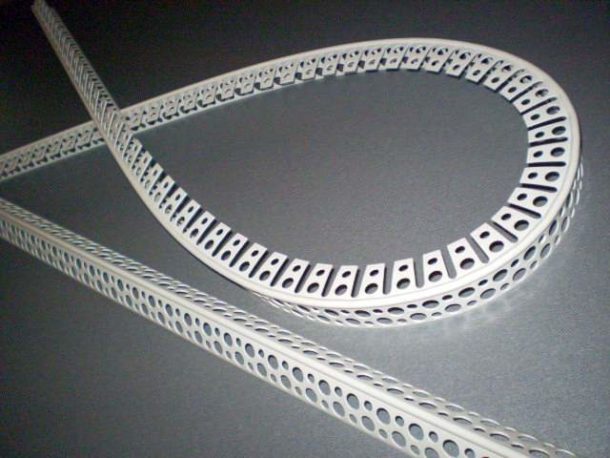

Arch profile PA (CD)

It is used for the construction of structures of complex shape, where there are bends. The products have the same parameters as the ceiling metal profile, but they have curly cuts and perforations. The arched profile can be made independently, for this, the shelves of the ceiling product are cut into sectors and bent, giving it a curvilinear shape.

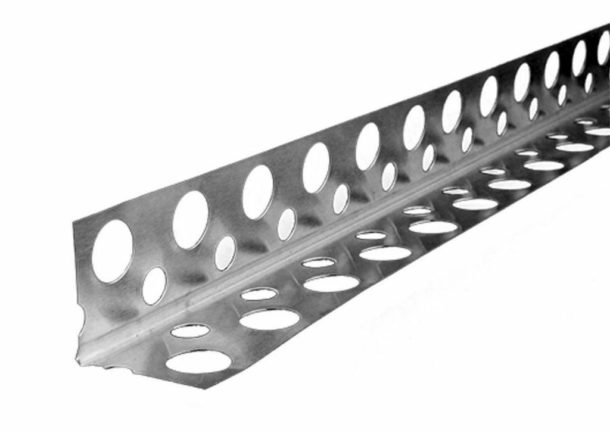

Corner profile PU

A perforated corner of small thickness (0.22–0.25 mm) serves to increase the strength of the outer corners of plasterboard structures. Apply galvanized and aluminum profile. The corner profile is mounted on putty and closed with it.

Vinyl profiles

A flexible vinyl drywall profile designed for finishing corners, connecting structures to window and door blocks, or when the wall has a complex shape. There are several types of vinyl profiles available.

- Arched. It is used to create curved structures with a minimum bending radius of 50 cm.

- J profile. It is put on the edges of drywall. Vinyl holds paint well.

- Cable. A wire is inserted into it to protect against putty.

- Grooved - for separating long drywall structures.

- Perforated corner. It is used mainly for finishing internal corners, giving them clarity and completeness.

Installation of a guide metal profile

There is no difficulty in installing a metal profile, but it must be fixed according to the rules. The methods can be seen in numerous photos and videos.

The evenness and reliability of the rest of the structure depends on the correct fixation of the guide profile for drywall. The sequence of mounting guides for wall cladding is as follows:

- According to the marking on the floor, PN is established. From one part of it, an indent of 0.3 m is made and a hole is drilled. Two more holes are made in the middle and on the other side, after which the profile is fastened with dowel-nails.

- Subsequent guides are installed similarly around the perimeter of the ceiling and walls.

- The entire structure is fastened with dowels in increments of 30 cm. Before final installation, the evenness and accuracy of the installation is checked.

Installation of rack profiles

The wall mounting sequence is as follows:

- Racks are installed in increments of sheet sizes. On the wall, the distance is measured along the width of the sheet and a mark is made. Here the center line of the vertical rack will pass, which will become the junction of the GKL. Such marks are made to the end of the wall, then the central points of the resulting segments are marked. Racks falling on the center of the sheet will also be attached here. With the help of a plumb line, vertical lines are drawn.

- On the lines obtained, marks are made every 60 cm and holes are drilled in these places, after which dowels are inserted into them and suspensions are attached.

- The supporting metal profile is installed in the guides. All profiles are set along a horizontally stretched fishing line, and the loan is fixed with the help of hangers, the ends of which are bent and fastened with self-tapping screws. Racks are attached to the rails with self-tapping screws "bugs" or cutter.

- To increase the strength of the structure, horizontal jumpers from the same type of metal profile are attached to the racks. How many to install depends on the required strength of the frame. They should also fall at the joints of the sheets.

The sheets, together with their halves, are arranged in a checkerboard pattern. Horizontal seams of adjacent sheets should not match.

Conclusion

To create a reliable frame for drywall, you need to understand the parameters of structural elements. The plasterboard construction is more reliable if each profile is used for its intended purpose and not replaced with what is available.

The quality of products depends on the manufacturer. The Knauf drywall profile has gained popularity. Domestic drywall profiles have proven themselves well, the price of which is lower than imported ones.