Today, drywall is very popular. It is used for leveling walls, creating partitions and decorative structures. GCR is mounted on a crate made of a metal profile, the individual elements of which are fastened with special self-tapping screws. At the same time, their hats sometimes interfere with the tight fit of drywall sheets. To avoid this, a drywall cutter is increasingly being used.

What it is?

This tool began to be used in construction not so long ago. Most ordinary users and home craftsmen have a poor idea of what a drywall profile cutter is, how it works, and on what principle it works.

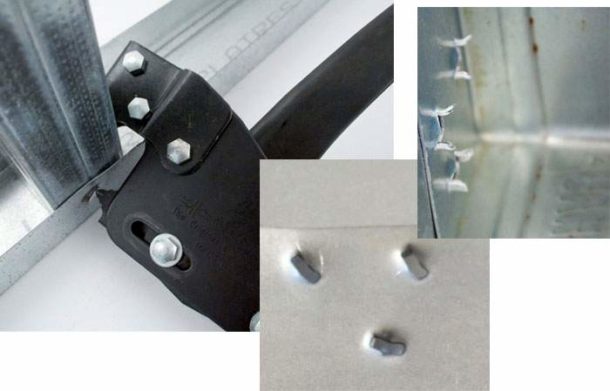

Outwardly, the tool resembles pincers: it has 2 handles, one of which is attached to a bracket at the end. A cutting element (punch) is installed on the second of them. The principle of operation is also very simple: 2 profiles are combined, the junction is placed between the bracket and the punch, the handles are pressed, and a hole appears on the metal (it is also called a groove), which holds the profiles in a given position. Some devices on the back side tightly press the protruding edges, some do not.

Varieties of cutters

There are 3 types of cutters for a metal profile for drywall:

- conventional manual;

- reinforced;

- professional.

All of them are arranged in the same way, but they have some differences. First of all, this is the load for which they are designed, and operating conditions.

Manual cutters are small. They fit comfortably in one hand. Most often, this type of tool is used by home craftsmen. Their margin of safety is quite enough for a small repair in the apartment, and they are much cheaper than their professional counterparts.

Reinforced cutters are most often purchased by small construction teams. These tools are made from stronger alloys. They also differ slightly in design: they usually have a removable punch, it is easy to change it if it gets dull. Thanks to this, the tool will last longer.

Professional tools are usually used for large volumes of work. They are larger and more massive than their counterparts, more powerful, and can pierce thicker profiles. Of course, such a cutter costs much more than its "brothers". It makes no sense to acquire it if it is planned to build one partition.

These features must be taken into account when choosing a tool. The most popular at the moment are reinforced cutters.

When choosing a suitable device, you need to pay attention to a few more parameters:

- The thickness of the punched metal. For example, 0.55 mm is the standard thickness for manual models, a reinforced cutter is able to make a hole in a profile with a thickness of 1.5 mm.

- Hole diameter. It varies from 2 to 5 mm depending on the choice of interchangeable bits that come with the tool.

Benefits of using a cutter

The installation of profiles using a cutter differs markedly from the classical method, which involves the use of self-tapping screws. The advantages that this type of attachment has:

- savings on consumables - self-tapping screws;

- no additional tools (drill, screwdriver) are required for installation;

- profiles are not deformed;

- there is no risk that the self-tapping screw will go too far;

- no need to waste time on markup;

- a hole is punched much faster than a self-tapping screw is screwed in;

- the holes have even neat edges, nothing sticks out of them;

- no dents on the frame;

- does not consume electricity;

- the connection is reliable, but if necessary, it can be quickly and easily disassembled.

Many builders, after working with a cutter, refuse to use self-tapping screws, because the process metal frame assembly much faster and easier.

How to work with the tool

Using a cutter for a metal profile for drywall does not require any special skills or special skills from its owner. The frame elements are connected very simply:

- profiles are set relative to each other and fixed in the desired position;

- the handles of the cutter are maximally bred in different directions;

- the ear is wound so that the junction is between the lip and the cutting element;

- the handles are sharply compressed, as a result, the punch makes a hole in the profile;

- the handles are again spread apart and the tool is moved to the side or removed.

Thus, the profiles are interconnected.

Operating tips

The cutter is a very simple and undemanding tool, however, it also needs proper care and compliance with some rules:

- most cutters are designed for a total profile thickness of not more than 1.5 mm;

- you can not make jerks about the breakdown;

- strikes are also prohibited;

- the cutter must be placed strictly perpendicular to the punched plane of the profiles;

- it is impossible to make a breakdown in the place where the profile is built up or joined;

- hinges need to be lubricated periodically.

A drywall profile cutter is a simple and convenient tool. Even a beginner can assemble the frame with it.