Finishing chimneys how to properly sheathe

When performing finishing work, it is necessary to adhere to fire regulations. The gases leaving the chimney structures have very high temperatures. It is mandatory for all types of chimneys to ensure sufficient draft force.

One of the main requirements for finishing chimneys is the use of exclusively non-combustible materials. Therefore, such a solution, how to sheathe a pipe on a roof with a metal profile, is considered the best. When the chimney is installed next to the ventilation ducts, it must be led out above the common cap.

Today, stainless steel chimneys with internal thermal insulation are widely used. They are allowed to be brought to the roof without brickwork, using a metal apron.

Ways to finish the channels facing the roof are varied and largely depend on the preferences of the homeowners. It is possible to sheathe the pipe with profiled sheets, clinker bricks, cement fiber boards, lime-cement plaster, artificial or natural stone, ready-made double-circuit construction. The latter option is convenient and has an attractive appearance.

Functionality and safety norms and regulations

Since the heating system is a source of increased fire danger, its arrangement is strictly regulated by the norms and rules for the construction of SNiP 41-01 of 2003. This document combines the requirements for the construction work of ventilation, smoke ducts and air conditioning systems.

According to the official instructions:

- For insulation and lining of the chimney pipe, it is correct to use non-combustible materials. If you choose materials that, in principle, are capable of burning, then the temperature from ignition should be 20 degrees higher than the maximum heating of the pipe. The heating temperature depends on the type of fuel used in the system.

- Iron cladding is permitted provided that the steel is either stainless steel or with an anti-corrosion coating.

- The brickwork of the chimney must be thicker than 12 cm. The concrete pipe is not thinner than 6 cm. The installation of an iron or asbestos-cement pipe is not allowed in all heating systems (for example, in solid fuel stoves, the temperature of gases significantly exceeds their capabilities), their operating conditions are indicated in certificates and documents for finished products.

- The distance from the chimney wall to combustible materials and structures must be at least 25 cm, with insulation - 13 cm.

- The top of the pipe is equipped with a deflector or a protective umbrella. If the roof is covered with combustible material, then a spark arrester must be installed.

Clinker tiles are considered the best material for pipe lining. She has a great appearance (many natural shades), she is durable and non-flammable. The ideal option is a pipe completely made of clinker bricks. The refractory brick plus tile cladding option is more common.

Good appearance, performance properties shows classic plaster. This type of chimney pipe finishing can be called budget. Laid on a metal mesh, it comes out thick enough to provide thermal insulation to the pipe and serve as fire protection for the roof. The difficulty is that not everyone is able to independently perform high-quality plaster while on a roof slope.

Metal or cement siding will give your chimney a presentable look. Properly mounted on a frame with insulation, it also performs a high-quality protective function for the pipe.

Framed corrugated board is a popular, inexpensive and easy-to-install material for finishing a chimney. This option is convenient for self-assembly, easy to match in color, durable and reliable in operation.

Final assembly of the flue system

What needs to be done during the installation of the chimney so that the equipment works efficiently and is safe for others?

The sealing of the chimney on the roof requires the following conditions:

- Between the channel and the roof, especially if a flammable material was used for it, there must be a gap, its dimensions are regulated by regulatory documents

- The chimney itself in this area must be treated with insulating materials (asbestos) that can prevent fire

The passage of the chimney can be made on a ridge or a roof slope, while each of the methods has its own characteristics.

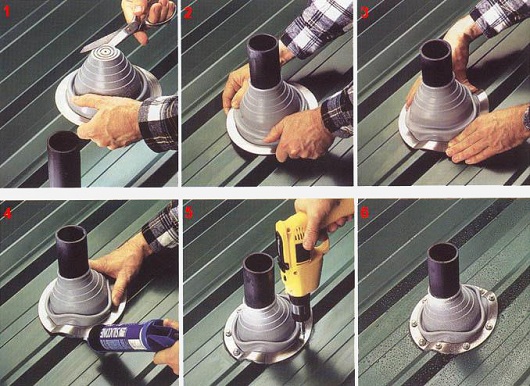

After the pipe passes through the roof, it is sealed. The building materials market offers a wide range of units that can be used in various conditions.

Of the traditional options, this is a salary of metal strips corresponding to the dimensions of the pipe.

For a roof made of tiles or a corrugated plate, the elements are fastened with a lying seam, and on pitched structures with a slope of more than 30 °. Behind the chimney, a special beam is installed. It serves as protection against rain water.

An elastic apron is installed along the perimeter of the pipe in two layers, leading the lower one under the roofing, and mounting the upper one from above and closing it with metal profiles.

Insulation from steel sheets is placed on the roofing insulated with roofing material. Its individual elements are attached along the perimeter of the channel, starting from the bottom. The grooves are filled with silicone or polymer sealant.

Finishing the top of the chimney

The metal chimney is insulated in the following way: a second pipe (larger diameter) is put on it, and the space between them is filled with basalt wool. A metal chimney outside for beauty can be finished with any material that is used for brick. Fastening of the finish is carried out on a frame made of a metal profile, if it is a sheet material.

All private houses have an individual heating system. Even if it is a boiler, and not a wood-burning stove, it still requires the removal of gas and smoke from the system resulting from the combustion of fuel.

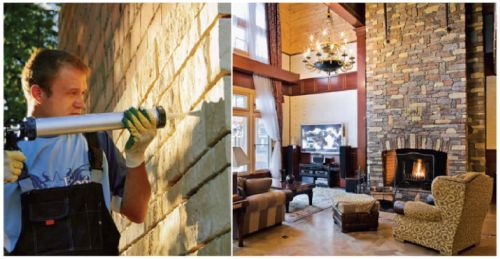

When the heating boiler is located in the basement of the house, the instructions for its operation allow the removal of the chimney along the outer wall. And then it can be considered as an element of the facade, and its decor can be made in accordance with the exterior finish of the house.

If the building has a stove or fireplace, the chimney passes through the space of the room in which they are located and the attic. In this case, the interior decoration of the mansard roof is made taking into account the existing chimney.

Chimney on a metal roof

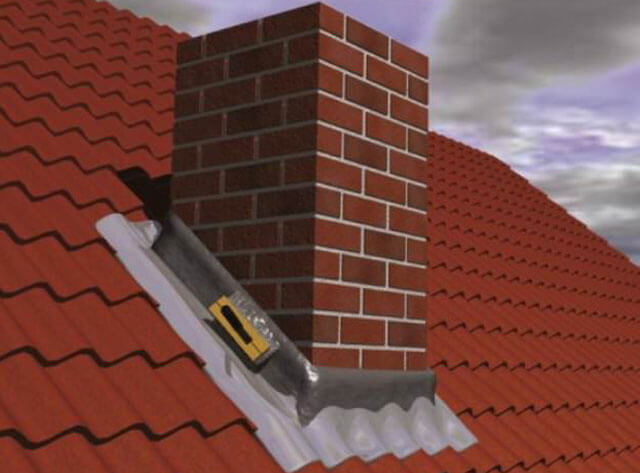

Bypassing the chimney with metal tiles is a complex process. It does not bend like an ondulin and is difficult to lay hermetically.

Sealing includes the following steps:

- Roof waterproofing is installed on the side walls of the pipe

- Behind the pipe, at a distance of 80 cm, a chute is built into the waterproofing material to remove moisture

- A box is installed in the roof and a chimney is removed

- A groove for the wall profile is being chiselled

- Install profile. The process is described above.

- Set language

- The roof is covered with metal tiles. Around the pipe, it should go on the profile and on the tiles flowing around the pipe

- Install apron. For metal tiles, they are made smooth. It should be fixed to the protrusions of the coating with self-tapping screws

Chimney lining and special caps

One of the finishing methods is cladding. To do this, use natural or artificial stone, but this option is not practical. This is explained by the fact that the cladding often breaks off from low-quality bricks, while together with the top layer of ceramics, which spoils the roof. If the brick is of high quality and beautiful, it makes no sense to close it.

When the sheathing is heavy, it should be fixed not only with the help of an adhesive composition, but also with hardware. For this purpose, metal brackets or dowels are used - nails directly through stone tiles.

To protect the ventilation ducts from atmospheric troubles, protective caps are installed on the pipe heads. They reduce the traction force, so their size should not be too large. In this case, the distance from the top of the pipe to the lowest point of the cap must be made at least 15 centimeters. The shape of this product and the material of its manufacture can be very different.

Finishing the pipe with slate stages of work

Facing the chimney on the roof is necessary not only for better preservation of the chimney structure, but also as a decorative finish, so it is customary to make it from materials that are most suitable for roofing. One of the most durable, durable, and also very aesthetic is the stanets.

- Purple

- Green

- Graphite

It can be in the form of tiles or panels. Slate can be fastened with copper nails with a wide head with a diameter of 2.5 mm and a length of 40 mm.

When performing work, it should be borne in mind that deformation of materials is possible during temperature changes. Therefore, the nails are not nailed to the end; a small gap must be left between the cap and the tile.

The installation of tiles is carried out on the crate, the bars are fixed at the corners of the chimney, and if it is more than 60 cm wide, one more additional bar will be required.

- The extreme guides are set according to their level, the rope is pulled (from above, below and in the middle - at a height of more than 2 m), and then intermediate bars are set

- If necessary, the smoke channel is insulated

- Plywood sheets are laid on the guides

- Tiles are being laid (its installation is carried out in such a way that one overlaps the other within 1.2, and the angle is not less than 22 °

There are several ways to lay slate - from the standard rectangular to resembling fish scales. They are selected taking into account the pattern of the roofing.

The first is performed on a pre-primed surface. To do this, the dry mixture is diluted in a bucket with water in the proportions indicated on the package. Please note that it is usually sold in white, and color is added to obtain a color coating.

The diluted composition is applied in a thin layer and left to dry, and then cleaned with a steel brush. Then a second layer is applied - if necessary, but experts still recommend limiting themselves to one. The final touch is surface treatment with a grinder and grouting with an iron spatula.

Venetian plaster, unlike marble, is considered expensive, but it looks amazing.Moreover, if you do everything yourself, you can save a certain amount of money.

It is also sold in bags, has a white color and is diluted with water with the addition of color for application. Apply with a spatula or trowel. But to obtain a high-quality coating of Venetian plaster, the use of forced drying technology with a building dryer is required. The cracks that appear are treated with paint or varnish and, after drying, polished with a grinder.

Wild stone as a facing material

Another option for finishing the chimney can be the use of natural materials. In this role, a wild stone has proven itself well. It is laid on cement using a plaster mesh fixed to the surface for adhesion rigidity. The seams are sealed with cement with the addition of color to it.

The importance of chimney trim

In this article, we looked at the assembly, insulation, and cladding of a combustion exhaust system. Each of these stages is mandatory for the efficient operation of heating equipment, but can be performed using various materials. Which one is the best is up to you. After all, it depends both on the design features of the chimney and on the architectural style of the entire building.

All private houses have an individual heating system. Even if it is a boiler, and not a wood-burning stove, it still requires the removal of gas and smoke from the system resulting from the combustion of fuel.

When the heating boiler is located in the basement of the house, the instructions for its operation allow the removal of the chimney along the outer wall. And then it can be considered as an element of the facade, and its decor can be made in accordance with the exterior finish of the house.

If the building has a stove or fireplace, the chimney passes through the space of the room in which they are located and the attic. In this case, the interior decoration of the mansard roof is made taking into account the existing chimney.

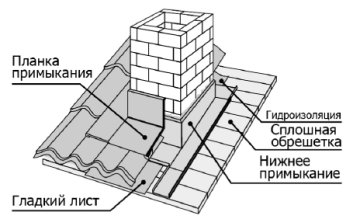

Roof chimney waterproofing for rectangular pipe

So, the materials are prepared, it's time to do the insulation. The process consists of several stages:

To strobe means to make a shallow groove (strobe) in the pipe wall in the place where the upper edge of the wall profile will end. It will be hammered into this groove for tightness. To do this, attach the profile to the pipe and mark a line along the upper edge. Then gently grind a groove in the brick with a grinder. Embedding depth - 2-3 cm, depending on the depth of the bent edge of the profile. When everything is ready, carefully remove the debris and moisten the wall with water, thoroughly smearing the resulting groove. You can pour water from a bottle by making holes in the lid.

Starts at the front of the pipe. We attach the part to the pipe and measure. On the upper part, where the profile enters the furrow, we make an allowance of 5 cm on each side so that it can be bent over the wall. From below, where the part will lie on the roof, we leave an extra 10-15 cm on each side. We carefully drive the upper edge into the groove on the pipe, and attach the lower part to the crate with self-tapping screws. Thus, we lay all 4 sides. The edges of the profile overlap on all sides.

We coat the top edge of the profile with sealant. You can install an abutment bar - a metal plate that closes the seam between the profile and the pipe.

The tie is installed in front of the chimney. We start its edge under the edge of the profile and fasten it. It should reach the edge of the roof. Sometimes a waterproofing material is laid between the apron and the pipe, then it is not necessary to ditch. The canvas is screwed on top with a metal plate.

The apron is laid on top of the roofing. It is not necessary to make a strobe for it, it is attached to the pipe with self-tapping screws. The lower part covers the entire structure adjacent to the roof.

Chimney center lining

The middle part of the chimney pipe, passing through the attic, is lined only for thermal insulation. If an attic is being built, the pipe passes through it and heats the room. In this case, the chimney lining should harmoniously combine with the interior of the attic. For work, you can use heat-resistant plaster, but first the pipe must be insulated. To do this, use basalt wool, which is attached to a pre-installed metal frame.

Wool slabs are laid so that they are held by the frame itself. Additionally, self-tapping umbrellas are used. For plastering work, a reinforcing mesh is pulled over the insulation boards. Such thermal insulation excludes the formation of condensate inside the chimney, and its subsequent destruction.

Roof chimney box

First of all, you need to take care of the through hole. In order to seal and protect the roof materials from contact with a hot pipe, a box is made. This is a construction made of ceramics, asbestos or metal, which prevents the pipe from touching the roof. Sometimes they make their own truss system for the chimney as a box. In this case, the box will be wooden. Design scheme in the figure:

To install a box made of non-combustible material, it is necessary to prepare a hole for the pipe outlet. The box itself is bought or made independently. The size of the box depends on the diameter of the pipe - the minimum distance between the walls of the box and the pipe should be 15 cm. Then we follow the algorithm:

- A box is inserted into the hole so that its upper edge is aligned with the level of the roof

- A pipe is inserted or laid out through the box from above

- From the inside, the box is glued with a waterproofing film along the walls so that the entire hole is closed, and the edges can be glued to the pipe

- The edges of the insulation are hermetically glued to the pipe. Use flame retardant sealant and reinforced tape

- Insulating material is laid inside - expanded clay, stone wool, etc. This will create thermal insulation. Do not stuff too tightly, air circulation must be maintained

Next comes the chimney trim.

Recommendations for choosing a location for installing a chimney

Any construction work, especially those that involve the removal of smoke and combustion products from the premises, is carried out after agreement with the fire departments and architects. Where to install the chimney, the customer decides in the end, but it is still worth following some rules.

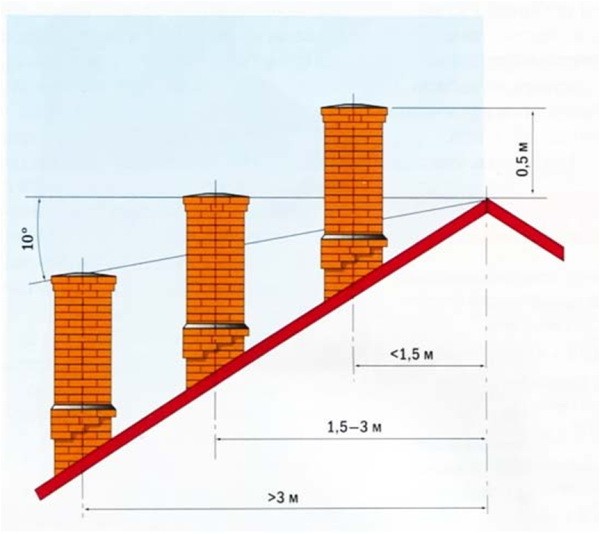

- The best option is to install next to the ridge. In this place, snow accumulates the least, so the junction of the roof to the chimney will be less exposed to precipitation and the likelihood of leaks is reduced significantly. In addition, the higher the pipe will be located to the roof ridge, the lower it must be installed.

- Do not install in valleys, places where precipitation accumulates. Even if it is very good to seal the chimney with waterproofing materials, sealants, there is still no guarantee that the roof will not leak sooner or later.

- In order not to blow smoke from the chimney into the attic window, the chimney should be installed as far as possible from such windows.

- It is not recommended to make the junction of the pipe to the roof rigid, otherwise, if the roofing system is destroyed, the chimney will also collapse.

Postulates of chimneys in a private house.

Fire safety requirements lay the foundation for any chimney in a private house. According to SNiP 41-01-2003, channels are designed vertically, bends up to 30 ° are allowed (relation from vertical to meter). The chimney is created of equal section along the entire length, with a smooth inner surface. The height of the pipe is from 5m.

Chimney in a private house

Chimney in a private house

Gases are easily removed through round pipes, more difficult in square, rectangular shapes. The cross section of the chimney is selected according to the power of the heating boiler and is prescribed in the instructions. It corresponds to the dimensions of the outlet pipe. If the channel section is made smaller, then the waste is poorly removed, the fuel burns poorly, and gases enter the room. If more - the heat "flies into the pipe", due to which the automation goes astray. Plus, more condensate is formed (smoke is cooled). The minimum section of the chimney for the furnace is 140 * 140mm and grows with an increase in its power. For fireplaces, a ratio of 1/15 of the furnace parameters is displayed.

Interfloor cutting for the chimney channel has its own standards, where an increase in fire safety will not be superfluous.

Chimney in a private house

Chimney in a private house

How to make pipe trim on the roof sheathing options

The part of the pipes that rises above the surface of the roofs is constantly exposed to external loads, so they need to be protected. To prevent a decrease in the functionality of the roofing pie, the roof should be sealed with high quality. Also important is the appearance of the pipes, which must correspond to the architectural appearance of the household.

On each roof of a private house, you can see several types of pipes - smoke and ventilation. Finishing the pipe on the roof involves the implementation of mandatory sealing at the points of contact of the roofing with vertical surfaces, protection of channels from precipitation and thermal insulation of the chimney. In addition, the aesthetic design of the exit points to the roof matters.

Roof chimney waterproofing

When making a passage through the roof, it is important to comply with SNiP standards. Between the elements of the roof and the chimney, a gap should be left, the size of which is regulated by the documents

At the place of passage through the roof, a box is usually mounted (wooden or galvanized metal), in which all the free space around the pipe is laid with non-combustible material - stone or glass wool.

Sealing the chimney on the roof can be done using improvised means or using unified elements. Around the chimney, a so-called collar should be made, or a salary - a finish made of metal strips, about 40 cm wide, in accordance with the dimensions of the pipe. The bending angle of the steel strips must correspond to the angle of passage of the chimney through the roof. To calculate the length of the section, you need to take into account:

- slope angle;

- chimney dimensions;

- chimney type.

If the salaries are made of galvanized sheet, then they are interconnected with an overlay and soldered. The steel sheet elements are joined by a double standing seam. The lap seam connection is used to seal the passageway assembly on roofs made of corrugated boards and tiles. If the angle of the roof slope is more than 30 degrees, a special beam should be installed behind the chimney - a “bumper” that will protect the pipe from rainwater flows and excessive snow pressure in winter.

The protective elastic apron for the chimney can be made:

- from a flexible metal tape (lead or aluminum);

- made of galvanized metal with a polymer coating.

The apron is installed around the pipe in two layers around the entire perimeter. The bottom layer of the apron is placed under the roofing, and the top layer is mounted on top of the roofing material. To close the top layer of the apron, a waterproofing film and metal profiles are used.

The top folded edge of each apron must fit into a groove cut along the perimeter of the chimney. After mounting the edge into the groove, the joint is filled with polymer sealant or silicone for the roof.

Ready solutions

The sealing of the chimney on the roof is a rather difficult task, the quality of the solution of which depends on the reliability of the thermal and waterproofing of the roof.You can complete the passage assembly yourself, using various materials and special strips, or mount a finished structure, which includes a wide protective apron.

Ready-made roof cutting on the construction market is presented in many versions - the models differ in material and manufacturing method, as well as the angle of inclination of the element that protects the place where the pipe passes through the roofing pie from water. The angle of inclination can be from 15 to 55 degrees, therefore, the cutting of the chimney on the roof is designed for the most popular slope slope options.

For the installation of such a design, a hole of the appropriate size is made in the roofing pie. A seal made of rubber is attached to the structure from the outside with the help of silicone. The distance between the pipe and the collection passage is filled with non-combustible insulation. The roof penetration covers the passage assembly, after which the penetration can be attached to the roof with self-tapping screws. It is recommended to use a sealant to seal the connection.

When choosing the option of how to close the chimney on the roof, you can use other ready-made solutions, for example, Master flash roof penetrations.

https://youtube.com/watch?v=rL-_Irakk4s

Options and features of exterior finishes

Finishing the chimney on the roof performs a decorative role. To avoid maximum smoke removal and prevent the formation of condensate, the outer part of the pipe must be insulated, and insulation materials need mandatory external protection. The finish of the chimney pipe should be in harmony with the design of the roof, and it will make the smoke exhaust structure a full-fledged decorative element.

There are a lot of finishing options, we can name the most relevant of them:

Plaster. This is a simple solution that allows you to protect the pipe from the cold and make it look nice. At the request of the owner of the house, mineral chips are added to the plaster solution, which makes it possible to give the finished cladding a beautiful relief structure.

Decorative brick. This is another common solution that is widely used in the decoration of brick buildings. This finish of the fireplace chimney allows you to keep the temperature in the pipe, it lasts a very long time and does not collapse even from very strong heat.

Artificial or natural stone. The stone chimney looks very solid and stylish, it draws attention to the roof and performs its functions perfectly. This is an almost eternal facing material that will make the smoke exhaust system more reliable.

Finishing the chimney with corrugated board. It looks interesting option in which the smoke channel is designed in the same way as the roof itself. Finishing the chimney with a metal profile is a fairly strong and durable option; such a lining is installed on a metal frame and reliably closes the insulation material.

These are just some of the options for external cladding that will help make the chimney beautiful and very noticeable. An ordinary pipe can be turned into a real decoration of the house.

Finishing the chimney with a metal profile from the outside

Finishing the chimney on the roof with corrugated board is one of the simplest options, even a novice home master can handle this job. A galvanized sheet provided with an anti-corrosion coating will become a strong and durable solution: it does not burn, does not collapse under the influence of high temperature or strong vibrations, and the installation of such a cladding does not take much time. However, this is a cold material, so the chimney will have to be insulated.

Finishing the chimney with a metal profile is carried out after the construction of the metal frame. Metal sheets are overlapped on it to ensure the most durable connection. To ensure that the sheets are evenly positioned, a building level is used when attaching them.

The metal profile is attached with self-tapping screws; this work is more convenient to carry out with a screwdriver.Between the metal sheet and the chimney there is a layer of non-combustible insulation.

Finishing the chimney inside the building

A fireplace or stove is usually mounted in a living room or study, so it becomes necessary to draw smoke paths through the second floor and the attic or attic room. Finishing the chimney inside the house can be very diverse in appearance, but in any case, it is installed on a common basis. The interior of the chimney is carried out as follows:

- For lining the chimney, a metal profile frame is constructed around it, which is sheathed with special plasterboard sheets. They must be fire resistant, this will ensure the fire safety of the house. Such sheets are designated by the special abbreviation GKLO.

- The frame is insulated: a layer of mineral wool or other non-combustible insulation materials is laid around the chimney.

- Smooth drywall sheets are finished with any chosen materials: it can be ordinary wallpaper, ceramic tiles, plaster and much more. This finish of the fireplace chimney allows you to harmoniously integrate it into the space of the room, and the choice of material depends on the style of interior design.

The interior trim of the chimneys can have a wide variety of colors, so you can choose it for every taste. However, in any case, it is recommended to choose non-flammable materials so as not to increase the risk of fire.

This is especially important in a wooden house: walls located near the chimney, and especially all bend sections, must be treated with flame retardants.

External and internal finishing of the chimney will turn it into a full-fledged decorative element: the choice of materials depends on the design features of the building and on the financial capabilities of the owner. Self-installation of the cladding will save a lot, but it must be carried out with strict observance of all technological requirements.

You need to enable JavaScript or update the player!

Finishing the chimney choice of materials

Among the negative factors affecting the chimney are :

- atmospheric influences (wind, precipitation, ultraviolet radiation);

- ambient temperature difference;

- high temperature workloads.

Due to the difference between the temperature of the working pipe and the air temperature in the chimney, condensate forms, which provokes the destruction of the pipe during the combustion of heating oil. To avoid the formation of condensate and protect the pipe from external influences, it is required to provide reliable insulation of the chimney due to the cladding.

Various materials are used for sheathing the protruding part of the pipe. When choosing, consider :

- resistance to external factors, wear resistance;

- appearance and color scheme (corresponding to the roofing or wall decoration of the building).

It is recommended that the chimney lining be completed prior to laying the roofing material to avoid damage or soiling of the roof covering.

Finishing the chimney on the roof is most often done using :

- clinker bricks or tiles;

- plasters;

- cement fiber boards;

- roofing material (corrugated board, slate).

Characteristics of finishing materials

Finishing the chimney on the roof with plaster is characterized :

- affordable cost;

- simple installation;

- versatility (suitable for any roofing);

- the ability to implement any color solutions (plaster can be painted with silicone paint).

Plastering of pipes is carried out using the same technology as the finishing of facade walls. Traditional cement or lime-cement mortar can be used, but a more durable option is to use mineral, silicone, silicate or acrylic plaster. Painting the dried surface increases the wear resistance and durability of the finish.

Small format fiber cement boards are durable, resistant to ultraviolet, moisture, temperature fluctuations, and are light in weight. It is an environmentally friendly, non-flammable material. For lining the chimney, you can use smooth or structured plates, the material is on sale in a wide range of colors.

If slate is used for roofing, the chimney lining on the roof is usually made from the same material. Slate slabs can be in the form of an arc, scale, rectangle or octagon. The color of this natural material depends on the deposit. It is usually graphite, green or magenta in color.

A fairly simple and budget option for finishing the pipe is the use of corrugated board. It is used if the roof covering is made of the same material. A chimney finished in the color of the roof looks aesthetically pleasing.

Prefabricated chimney elements for the roof passage have an aesthetic appearance and are quite easy to install. They are equipped with a steel chimney channel and can have a ready-made external cladding of any material, or be prepared for self-finishing so that the chimney externally harmonizes with the roof. The modular steel structure is not additionally finished, it is enough to mount it at the point of passage through the roofing pie.