Batteries fire

Sometimes the reason why radiators in a private or apartment building sometimes start to shoot lies in themselves. This is due to the fact that the pipes are made of metal. This material expands when heated and shrinks when cooled, resulting in a gunshot-like hum. Close contact with the wall can be prevented with the help of melon, a pipe insulation.

Thermal insulation for pipes

But this is not the only reason that the radiators in the house periodically begin to knock. Also, noise can occur due to poor-quality installation of the system. Use the rules that will help you avoid common installation errors.

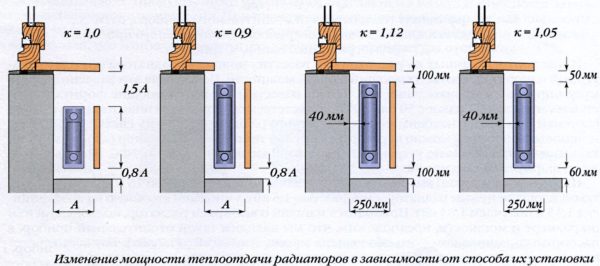

Rules for fixing radiators:

- The distance from the floor should be 14 centimeters;

- The distance from the window sill to the battery must be at least 10 centimeters;

- The distance from the wall should be 5 centimeters;

- Meron must be installed between the radiator and the wall;

- Pipes should be fixed on a flat wall;

- Raise the edge with the air vent by a centimeter.

Fixing radiators to the wall

Expert advice on preventing extraneous noises and sounds

Some types of noise in heating communications can be removed independently or prevented from occurring during the design and installation of heating.

If the batteries in a multi-storey building are connected without a bypass, it is impossible to change pipes for communications of a smaller diameter during repairs. You can’t turn off the battery with taps - you will leave your neighbors without heating, and they won’t say thank you for it. If there is no bypass, thermostatic valves cannot be used.

The recommendation of experienced plumbers is to use radiator taps, not valves. Their design is more reliable, there is less hydraulic resistance, there is no stagnant zone where debris is collected. It is also better not to install valves. The advantage of using ball radiator valves is that the direction of water flow does not matter for them. In the event of an erroneous installation, the direction of the coolant current will not affect them.

The video shows some ways to get rid of noisy heating pipes.

Reasons for overheating of a solid fuel boiler

Even at the stage of selection and purchase, it is important to consider the performance characteristics of the heater. Many models that are on sale today have a built-in overheating protection system.

Whether it works or not is another question. However, it is necessary to adhere to certain knowledge and skills, hoping to create an effective and safe autonomous heating system at home.

The reliable operation of the heating unit depends on the operating conditions. With obvious violations of the technological parameters of heating equipment and the abuse of standard safety rules, there is a high probability of an emergency.

You can prevent possible negative consequences even at the stage. Proper piping of the heater will be the key to your safety and reliable operation of the unit in the future.

Speaking in detail, in each case, the protection system of a solid fuel boiler has its own specifics and features. Each heating system has its pros and cons. For example:

When it comes to solid fuel boilers with natural circulation of the coolant, it is necessary to take care of the safety and performance of the heating equipment even during installation. The pipes in the system are metal. Moreover, the diameter of such pipes must exceed the diameter of the pipes used for laying the circuit with forced circulation of the coolant. Sensors installed on the water circuit will signal a possible overheating of the coolant.The safety valve and expansion tank play the role of a compensator, reducing excess pressure in the system.

A significant disadvantage of the gravitational heating system is the lack of an effective mechanism for adjusting the operating modes of solid fuel boilers.

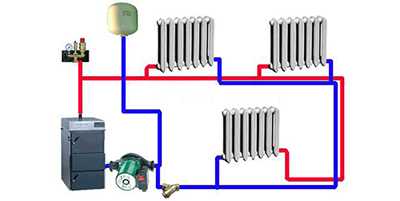

Great technological opportunities for consumers are provided by those working with forced circulation of the coolant in the system. Already only the presence of the second circuit significantly increases the ability to regulate the heating temperature of the boiler water. The only negative in the operation of such a system is a working pump, which can make it difficult to operate the heating system with its work.

This is due to the fact that when the electricity is turned off, the pump ceases to perform its functions. Stopping the circulation process and the inertia of solid fuel heating boilers can lead to overheating of the heating unit. If the boiler equipment is not equipped, the situation with a power outage is fraught with extremely unpleasant consequences.

Effective protection against overheating of a working solid fuel boiler should be based on the mechanism for removing excess heat generated by the heating device.

Whistling, rustling, hissing in radiators

Why is a whistle and hiss heard in the battery, and what to do in this case? It is not necessary to exclude the leakage of the coolant, and the place of leakage can be anywhere. sometimes water seeps through the pipe, and sometimes the radiator itself leaks. It is noteworthy that the pipe can leak in one place, and the sound will be heard in the next room or apartment.

If you have an apartment in an apartment building and you do not find an obvious leak in your apartment, talk to your neighbors. Probably, one of them has already gathered a puddle in an inconspicuous place. After that, it is worth checking the common riser, walled pipes and those points where the riser overcomes the floors (these are the weakest points).

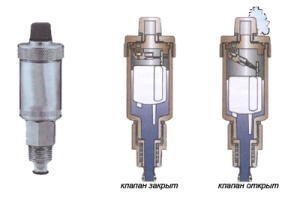

Residents of private houses who also have noise in the radiators, but it is not clear what this is connected with, need to start by checking the pumps and the boiler itself. When hissing does not occur constantly, but periodically, malfunctions in the operation of the air vent (automatic air vent from the system) cannot be ruled out. The device is placed on radiators to automatically bleed the air accumulated inside. This is accompanied by a hiss.

Another reason why water hisses and a kind of rustling is heard is the wrong choice of pipeline diameter. Heating pipes are connected by adapters, in which pressure drops occur, turbulences form. This contributes to vibrations and extraneous sounds of a different nature. What to do if the sound of water is heard precisely for this reason? You will have to dismantle the old pipes and mount a new system in their place.

Boilers with semi-automatic ignition.

Heating equipment equipped with Eurosit 630 or similar automation is classified as semi-automatic, because the main burners are ignited by a wick flame that burns throughout the entire operation of the boiler.

Causes and methods for eliminating boiling water in boilers with semi-automatic ignition.

Malfunction of coolant temperature sensors.

The temperature of the water in the heating circuit is controlled by sensors (thermistors) that are placed in the supply and return lines of the boiler. A serviceable sensor changes its resistance when the temperature of the coolant changes. For example, at 25 0C it will be approximately equal to 10 kOhm, and at 45 0C - 4.913 kOhm. According to the type of design, the sensor can be overhead (takes parameters through the copper wall of the pipe) or submersible (contacts with the coolant without an intermediary). If the probes are not inspected in time, then non-metallic deposits form on the contact surface, which impairs heat transfer and causes damage to them.

To study the condition of the thermistor, a tester is connected to the sensor contacts in the position of an ohmmeter. If it fixes:

- resistance within 1 - 30 kOhm, then the sensor is working;

- 1 or 0, the probe must be replaced.

Temperature sensor replacement procedure:

- Depending on the type of probe, it can be unscrewed or removed from the pipe.

- Before installing a new sensor, for overhead thermistors, thermal paste, for example, MX 4, is applied to the prepared base, from which dirt, oxides, and fat are removed.

If the probe breaks down in automatic boilers, a fault code will be displayed on its dashboard. Also, the coolant may overheat due to a pump malfunction and filter contamination. Methods for identifying and resolving such problems are described above.

Unfortunately, knowing almost nothing about the heating system in your home, we cannot help with specific advice. It's like in medicine: in order to make a diagnosis, the doctor must get the results of the tests and examine the patient. And we are not even aware of the “anatomy”, you did not attach a diagram to the question. You need to know not only the general location of the heating devices, but also the structure of the boiler room, the location of the air vents, etc. But, even knowing these parameters, trying to determine the nature of the problem in absentia is largely guesswork. There can be many local reasons for the system to malfunction, we will present the correct, in our opinion, algorithm for finding and eliminating them:

A manual air blower (Maevsky crane) must be installed on each radiator

The cause of poor circulation can also be the general contamination of the system, primarily the batteries are clogged. The heater can be removed and blown out with compressed air or washed out with a powerful jet of water.

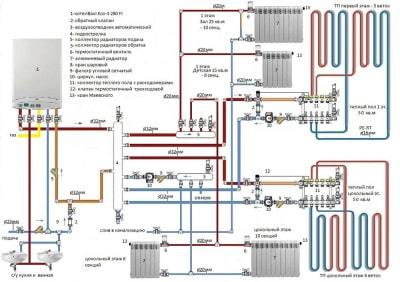

The diagram shows that air vents, automatic on combs (5, 11) and Mayevsky taps (13) are placed on all heating devices without exception. This was done for a reason, but to eliminate situations like yours.

Cats on cold batteries do not sleep.

Why does a gas boiler boil

During normal operation of the equipment, the coolant in the circuit is heated to a predetermined temperature. After that, naturally or forcibly due to the pump, it is carried through the heating system. This heats up the radiators in the room. Then the liquid moves along the return circuit and returns to the boiler.

In case of overheating of the coolant, thermal sensors are triggered. As a result, the operation of the device is blocked. What to do if the boiler boils? To restore the heating, it is necessary to find the cause of the breakdown. Sometimes the self-diagnosis system displays an error code:

But if this did not happen, you can identify the problem by external signs.

What causes overheating:

- Clogged filters;

- accumulation of air;

- Blockage of the heat exchanger with scale;

- Problems with the circulation pump;

- Failure to comply with the regulations for the room where the equipment is installed.

Why does the boiler boil and how to fix this problem

Overheating of equipment is unsafe for both residents and the heating system, so it is important to diagnose the problem at the first sign and make the necessary changes to the functionality. Experts emphasize that it is important to take into account the type of working unit.

Most Common Situations

The most common source of the problem is an air lock in one of the nodes. It is necessary to carefully examine the entire system, focusing on the circulation of hot water. If a warm liquid comes out of a pipeline instead of a hot one, it means that this is where an accumulation of air has formed. It is necessary to bleed excess air from the system using bleed valves. If this problem was not detected during the check, most likely the cause of boiling lies directly in the functionality of the boiler.

Overheating of the boiler, which is the basis of the gravity heating system, can be caused by insufficient intensity of the coolant circulation in the circuit. In this situation, it is necessary to place an expansion tank at a point in the house that will be the highest, in which case an additional load will be placed on the boiler and the required heated resource will be sent to it.

Experts recognize the installation of a circulation pump and equipping the heating system with an admixture circuit as the most practical method of solving the problem. Both types of devices allow you to reduce the load on the functionality of the heater, cooled water will be added to the network. The boiler will receive a return flow, it will provide its natural cooling.

Causes of boiling in different types of boilers

In addition to insufficient circulation and airing, gas devices suffer from clogged filters: the latter need to be periodically cleaned or replaced. If exfoliated scale particles clog the duct, knocking, clicking sounds can be heard, here you need to clean the unit with special chemicals. Overheating can be caused by prolonged stagnation of the system and the subsequent abrupt start (it is necessary to ensure a preliminary run of the ventilation engineering).

Actions relevant when the gas boiler boils:

- checking the completeness of the circulation of the coolant and filters;

- control of serviceability of cranes on radiators and the circulation pump;

- chimney draft control;

- cleaning the heat exchanger.

Solid fuel boilers overheat due to incorrect correlation of their power with the parameters of the serviced premises. Also, the problem of pressure growth in the equipment caused by the shutdown of the circulation pump is often fixed.

Steam boilers are seriously dependent on the presence of liquid in them: due to the low level, the walls overheat, an emergency occurs. Here you should stop the fuel supply, wait for the device to cool down and top up the working medium.

Why does an electric unit boil:

- clogging with scale;

- thermostat malfunction, causing the heating element to function even after the temperature rises;

- membrane failure;

- insufficiency of the coolant;

- breakdown of the circulation pump;

- the regulators on the return flow are not open.

Prevention of overheating will be the introduction of a buffer tank that does not allow the boiler to boil, excess heat energy will be directed into it. An uninterruptible power supply will allow you not to be afraid of turning off the control units and the pump. An additional circuit for a solid fuel boiler will provide timely cooling. Also, experts recommend periodically inspecting and maintaining (cleaning) the ventilation system.

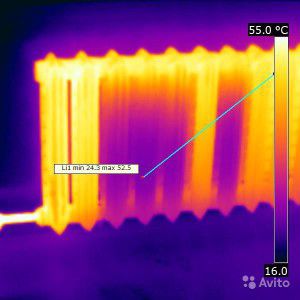

Pipelines cause low heat

Failures in the heating mode are characteristic of a two-pipe heating system. In this case, the supply line does not heat, distributing the coolant to the radiators. Identification of the "problem" zone can be done by measuring the temperature on the surface of pipes or a thermal imager.

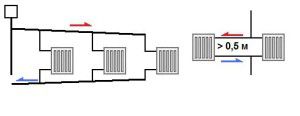

natural circulation

What could be causing such problems? If the heating does not heat well, it is possible that the slope of the main line is not observed. This only applies to systems with natural circulation. According to the standards, the slope of the pipes should be 10 mm per 1 r.m. In addition, the direction is taken into account - from the accelerating riser to the radiators. For the return pipe, the slope must be towards the boiler.

At the first stage, it is necessary to measure this indicator using the building level. If it corresponds to the norm, but the heating radiator does not heat, there is a possibility of air locks. In this case, an integrated approach is recommended, which includes the following steps:

- Tilt angle measurement. If necessary, change it to the required indicator;

- Flushing pipes to remove limescale;

- Filling the system with coolant with open Mayevsky taps on radiators.

This technique will eliminate the low rate of heat transfer of the heating system.

Forced coolant circulation

For a system with forced movement of water in the pipes, the formation of air pockets can be avoided by using an air vent installed at the top of the system. In part, it performs the functions of an open expansion tank, but it does not reduce the pressure in the pipes to a critical level. Its absence is an indirect cause of poor heating of the heating radiator.

The specificity of closed heating systems lies in the optional observance of the level of pipe installation. However, when the critical level of heating of the coolant is exceeded, steam is released, which is the main cause of air locks. Since air has a lower density than water, it will concentrate in the upper region of the pipeline sections. If heating radiators in a closed system do not heat well, the reason may be a decrease in the volume of coolant in the pipes due to air resistance.

What needs to be done in this case? First of all - check the performance of the air vents. If the valve is left idle for a long time, it can become covered with limescale, which makes it impossible to open it with air pressure.

In addition to this factor, it is necessary to take into account the excess of hydraulic resistance in the system. That is why the battery in heating does not heat up if the initial calculation is incorrect. Therefore, before proceeding with the installation of a new system or the modernization of an old one, it is necessary to fulfill the calculated part of the operational and technical parameters:

- Selection of pipes of the appropriate diameter - the larger it is, the less hydrodynamic resistance. However, this increases the volume of water;

- The probability that a two-pipe heating system will not heat is much less than that of a single-pipe one. Therefore, it is preferable to install radiators with parallel connection;

- Heating of the heating circulation pump occurs due to incorrectly selected power. It directly depends on the calculated hydrodynamic parameters.

The video shows the main causes of poor heating of the radiator for a single-pipe heating system:

what is it, a photo of the diagram for this type, why does water boil quickly in the expansion tank

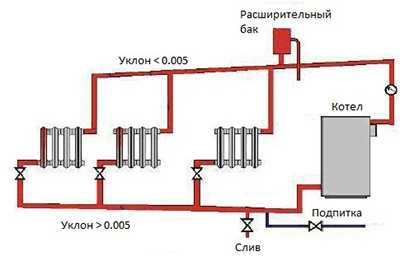

The main difference between open or gravity systems (OS) from closed ones is that in the OS the coolant communicates with the surrounding air in an open expansion tank.

The coolant is in the system at atmospheric pressure, there is no excess pressure.

Vkontakte

Odnoklassniki

Description of the open type heating system: what is it

The heating circuit of the OS consists of a boiler located at the lowest point of the building - a basement or a pit.

A vertical riser for supplying the coolant to the upper point of the building (attic or attic) departs from the boiler, where the expansion tank (RB) is located.

Horizontal pipes with a slight slope depart from the RB along the top of the building to vertical risers, through which the coolant is delivered to the radiators.

From the heating devices at the bottom of the room, the return line also departs with a slight slope towards the boiler.

Principle of operation

Schematically, the OS heating circuit can be represented as a long vertical ring. One side of the ring is with hot water (the supply riser from the boiler to the RB), the other side is with cold water (the riser with a return from the radiators). The density of a hot coolant is less than a cold one - water expands when heated.

Therefore, the weight of water and the pressure of the water column in the cold part of the circuit will be higher than the weight of the water and the pressure of the column in the hot branch.

According to the law of communicating vessels, the fluid will tend to balance pressures - to move from a cold branch to a hot one.

what to do Why does water boil in a heating boiler Why does a solid fuel boiler boil

2017-06-23

Evgeny Fomenko

Causes of boiler overheating

There are many different reasons why this can happen, let's try to consider them using examples of boilers with different ways of working.

Gas

The first reason why a gas boiler overheats and the liquid boils in it is the lack of circulation in the heating circuit. The reason for this lies in the clogging of the filters, or the heating circuit has been aired. It is necessary to inspect all filters, wash them, and, if necessary, replace them with new ones. If the problem lies in airing, it is necessary to remove the air. Very often this situation occurs in old Navien gas devices.

The next reason may be a banal clogging with scale, that is, particles of plaque have exfoliated and clogged the duct. At the same time, clicks may occur during operation, or such sounds as if it is knocking. The solution is quite simple - you need to clean the device with special chemicals, or using acids.

It is also possible that there was a prolonged non-use of the system, and then its start-up without a preliminary run of the ventilation system. Noise sounds are possible at start-up and the device gives an error about insufficient circulation. This can be caused by sticking in the pump due to downtime. It is necessary to disassemble the pump and rinse, then restart the start again.

A poor-quality gas-air mixture can cause an explosion, there are lower and upper limits at which an explosion occurs.

Another reason is non-compliance with the recommendations for the installation site of the equipment. If the room has high air humidity or low temperature, the metal from which the boiler is made will deteriorate. Corrosion may occur if sulphurous fuels are used.

After all, there are such areas that it is not possible to clean completely with the help of blowing, for example, the gaps of pipes and partitions. If the boiler is constantly in working condition, moisture cannot damage it, and when it is turned off, the ash, as well as the lining surface, absorb moisture, which then leads to corrosion, and this in turn can lead to gas leakage and explosion.

Often users have a question why water gurgles, there may be several reasons. The first is that the pump is out of order or wedged, the coolant boils and similar sounds are heard. Second, the battery is clogged.

If your device overheats, follow these steps to fix it:

Flushing the heat exchanger

Check the draft in the chimney, pay attention to whether there is a smell of carbon monoxide during operation.

Boilers with automatic ignition.

The water circulation in the heating circuit is disturbed.

Due to the slow movement of the coolant in the heating system, the water in the heat exchanger overheats and the boiler stops in emergency mode. The speed of movement of the liquid in the system can be affected by a decrease in the efficiency or breakdown of the pump, contamination of the filter installed on the "return" of the heating circuit, improper operation of the three-way valve.

The performance of the circulation pump is reduced due to contamination of the turbine blades or the internal cavity.

Photo 1 - gas boiler circulation pump module with automatic ignition.

For its revision it is necessary:

- Stop smoothly by moving the water temperature regulator knob to the extreme zero position and wait for the process to complete, turn off the power to the boiler.

- Dismantle the front of the housing.

- Determine the location of the pump.

- Close the shut-off valve (No. 2, No. 3, No. 4 photo 2) of the supply, return line, cold water supply.

- Drain water from the boiler through the drain cock and leave it in the open position.

- Loosen pump fasteners until air enters the circuit to drain residual fluid from the system.

- Dismantle the fastener, power plug and remove the module (engine with turbine).

- Clean the blades, the inner cavity and the rubber seal of the mechanism from dirt.

- Assemble the pump.

- Open the cold water supply tap.

- Slightly open the make-up valve to check the tightness of the hydraulic part of the boiler.

- Open the supply and return valve.

- Fill the system with water up to a pressure of 1 bar.

- Turn on the boiler in circulation mode to remove air.

Photo 2 is an example of piping of a heating system.

In boilers with electronic control, if the pump breaks down, the corresponding fault code will be displayed on the dashboard, which is decoded using the boiler passport or electronic catalogs posted on the manufacturer's website.

Checking and cleaning the filter:

- Gently stop the boiler.

- Using the taps (No. 1, No. 2) installed in front of the filter and behind it, shut off the water supply.

- Using the drain cock of the filter, remove water from the isolated area.

- Unscrew the flask and clean the strainer.

- Assemble all filter components.

- Open previously closed valves.

- If the system pressure drops, energize the circuit.

- Switch the boiler to the venting position.

Checking the three-way valve.

In double-circuit wall-mounted gas boilers, switching from heating mode to hot water position is carried out using a three-way valve. It consists of a servo drive (motor with a gearbox), a stem, rubber seals, a valve and a housing with inlets and outlets. A malfunction of this device can lead to a cessation of the circulation of the coolant and, as a result, an overheating of the heat exchanger is formed.

To check the condition of the three-way valve, it is necessary to smoothly stop the boiler and de-energize the system. Check the condition of the engine, and for this, connect the ohmmeter probes to the power terminals. If it shows 80 - 300 ohms, then the engine is working, and if other indications (0 or 1), then it is faulty.

The three-way valve may not switch due to jamming of the actuator gearbox, or due to deformation of the valve itself. If violations of the valve operation are detected, it is changed to a serviceable one, or is subject to revision.

Conclusion

You can determine the cause of the sound in the heating system yourself. To do this, check its airiness, piping, install gaskets, distance from the wall and fasteners, the functioning of the main heating elements. If all these indicators are normal, but there is still a buzz, call a specialist. To find out why the heating battery is noisy, it is necessary to comprehensively consider all possible breakdown options. Only diagnostics of the entire heating system will help determine the cause of the extraneous sound.

https://youtube.com/watch?v=ybF7d5lxQV4

Conclusion

Assessing the technological capabilities of modern solid fuel boilers, one should think not only about its operating power, but also foresee the installation of protection elements for the entire system. Overheating of the boiler is a frequent and well-known phenomenon for the inhabitants of private houses. Using the available means to ensure protection will not only avoid emergency situations, but also extend the operation of the heating units. Everyone is free to choose the means and method of protection. It will be enough for one to install an electric generator, which, together with the UPS, will not allow the circulation of water in the system to stop. Other owners of a private house, on the contrary, will need to install a bypass or equip a spare, emergency circuit for safety reasons.

According to experts, installing a buffer tank or installing a bypass are the most effective ways to protect the heating system from overheating.

Note: in the USA and in European countries, the operation of solid propellant devices without a buffer tank is prohibited.

2017-06-23

Evgeny Fomenko