What is a centralizer

Every welder knows that reliable fastening of the elements to be welded is the key to a good result. If pipes prepared for welding are not centered and securely fastened, they may vibrate and oscillate during operation. This will cause the seam to come out voluminous, weak and unreliable. At the slightest load, it can leak, or even burst.

Such negligence is unacceptable even when installing household pipelines of small diameter with little pressure and no external load. As for industrial, especially underground, highways, such irresponsibility can be very expensive in the future.

Their task is to securely fix the joint of the pipeline to ensure a high-quality weld.

Connecting and aligning metal parts with a centralizer

The centralizers consist of the body of the device (tensioning mechanism), a stand or a hook and individual typesetting elements, changing the number of which allows you to connect lines of different, including small, diameters.

This equipment is fixed around the junction of two pipes prepared for welding and tightly attracted using a tensioning mechanism.

In other cases, an external one is used. This is due to the fact that the internal guide device is more expensive and much more difficult to install.

We also note that the centralizer for welding PPU pipes of large diameter is a rather bulky and heavy device. Therefore, its use requires the use of additional equipment.

Pros and cons

Like any device, pipe centralizers have their advantages and disadvantages.

We refer to the advantages:

- wide functionality. It is not required to purchase guides separately for each diameter;

- the ability to work with both metal and PPU pipes;

- high-quality and reliable fixation of the connected elements;

- the presence of two modifications - internal and external, which allows you to fix the segments in any conditions and workspaces;

- ensuring high-quality welds, which are the key to the reliability of the pipeline.

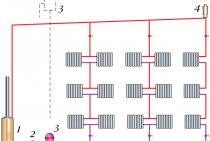

Centralizer for butt welding of polyurethane foam pipes

The disadvantages of this equipment are associated primarily with its bulkiness.

- quite high price. However, we note that if you are constantly welding pipelines, centralizers will pay for themselves in a short time;

- design complexity. Working with this equipment requires certain knowledge and skills;

- bulky and heavy weight (when it comes to welding steel pipes and large-diameter polyurethane foam);

- when connecting segments of large diameter, the use of special equipment is required.

Although pipe centralizers have a number of disadvantages, there is nothing more reliable for welding pipelines, especially for industrial purposes. This device will pay for itself with interest thanks to the installation of reliable pipelines that will last for years.

Types of centralizers

There are two ways to divide pipe centralizers into subspecies. They are subdivided based on the area of fixation and the method of fixing.

According to the fixation area, the guide mechanism for PPU or metal pipes can be internal and external.

- Internal devices are installed inside the connected segments to fix the PPU pipes or from any other materials in the correct position. This equipment is used, as a rule, on large diameter pipelines. It has a rather complex design and provides for the presence of hydraulic pumps, an engine and locking mechanisms.

- The outer centralizer wraps around the welded joint from the outside. It is a rather massive clip of a universal design. It is simpler and more convenient to use.

Centralizer internal

If the internal mechanisms can only work due to hydraulic pumps, then the external ones can be divided into several more categories according to the method of fastening at the joints of PPU pipes or any other products of large and small diameters.

- chain. Around the joint, with the help of special tension chains, a chain is fixed, which fixes the segments for welding;

- link. This device consists of a set of links that can be moved and adjusted based on the diameter of the pipe;

- eccentric. Such centralizers consist of two metal arcs, which are pulled together by a jumper.

In addition to the main, most commonly used guides, there are several less popular devices:

- outer centralizer spring casing. It is used, as a rule, in vertical drilling, to connect pipes of a PPU well. Such equipment has the form of a metal pipe cut around the perimeter with a bulge at the cut points. It is this bulge that gives the equipment its springy effect;

- mobile household devices for connecting PPU pipes of small diameter.

Unit installation

Installation of external centralizers is somewhat different from internal ones. It is performed more simply and quickly.

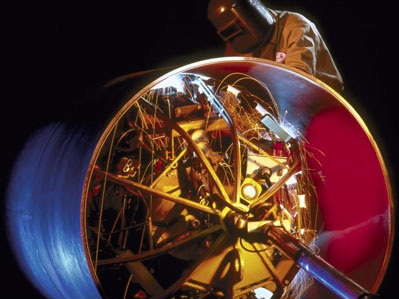

The process of welding metal pipes using an internal centralizer

How to mount the indoor unit:

- We clean the joints to be joined.

- We fix the unit in one of the elements.

- We fix the spring centralizer near the edge of one of the segments.

- We install the second element close to the first.

- We start the engine. Hydraulic pumps compress the segments, leveling them out due to the inner diameter.

- We check the correctness of the connection.

- We weld the joint.

Outdoor unit installation procedure:

- We prepare the joints.

- We install the unit.

- Align the segments according to the level.

- We tighten the bolts of the centralizer.

- We check the correctness of the connection.

- We clamp the tension to the stop.

- Let's start welding.

How to choose a centralizer?

The choice of a centralizer for pipe welding is perhaps one of the main tasks in the arrangement of a water supply system, sewerage or heat pipeline.

Centralizer for welding polypropylene pipes

It is this equipment that will make it possible to hermetically connect pipes and maintain the correct slope angle, which is the key to the reliability and durability of any pipeline. The nuances are:

- Decide what section of pipes you will have to deal with. For work with elements of small diameter (up to 500 mm), an open unit is quite suitable. To connect products from 500 mm, it is better to use a closed device. It is more difficult to manage, but provides a more secure fit.

- To choose between chain, link and eccentric models - decide on the amount of work and the thickness of your wallet. Chain models are the cheapest, most functional, but least reliable. The link devices are average in all parameters. The most expensive, but most reliable - eccentric centralizers. However, for household pipelines, throwing out $150-200 for auxiliary equipment is at least not rational.

Internal

Internal centralizers make it possible to mechanize the assembly process of the pipeline, while the joint is entirely available for welding, the seam is applied continuously, without the installation of tacks. The use of centralizers greatly facilitates the work of the welder, as it allows you to apply the entire seam at once and without stopping.

Depending on the size of the pipes, centralizers can have a different design:

- internal hydraulic centralizers - used for centering both individual pipes and sections, and the device is moved from joint to joint using a special rod;

- manual with expansion wedges - automatically centers pipes, including those with different diameters;

- scissor - depending on the model and design, they can center pipes not only of the same, but of different diameters.

Internal more evenly distribute the difference in perimeters relative to each other throughout the joint. They are able to correct minor dents, deviations from cylindricity and bring the ends to the correct circle.

If a large main pipeline is being built, then self-propelled hydraulic centralizers are used. They are able to travel long distances by remote control.

Internal (spacer) centralizers provide the most accurate coincidence of the edges of the pipes, since the inner surface of the pipe is considered to be the base. Sufficiently powerful mechanisms can perform edge alignment and are used as expanders. They increase the degree of mechanization and assembly productivity of almost all sections of the pipeline.