floor soundproofing

The design of houses suggests that they should be made with noise protection. Sound insulation of the floor in the apartment and modern materials are used mostly for elite buildings. But for ordinary standard high-rise buildings, additional measures are needed to reduce noise after the tenants have settled in their apartments.

The easiest way is to choose the right finish. It can be carpet, linoleum with a felt base, and even an ordinary carpet laid on a plank floor.

The next option is to use a soundproofing pad with a high level of sound absorption, which is located under the floor covering. It can be polyethylene foam, a roll cork or a special soft, cellular or porous material. Its main parameter is the sound absorption coefficient, by which the protective properties of materials are evaluated.

Structural and impact noise is best handled by a floating concrete floor for sound insulation, when the floor slab is not connected to ceilings and walls, and sound waves are damped in the substrate.

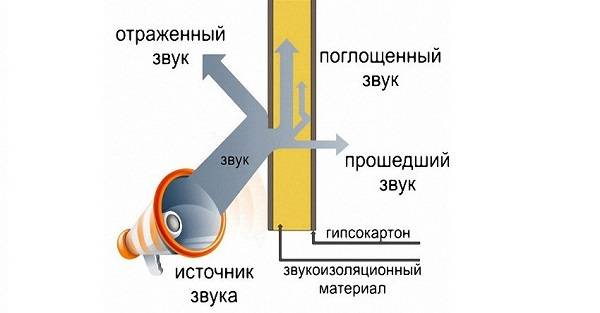

Sound absorption is rated on a scale from 0 to 1. The larger the value of the coefficient, the better the sound insulation of the floor in the apartment when using this material. At zero, the material completely reflects the sound. If the coefficient is equal to one, this means that the sound is completely absorbed.

"floating floor"

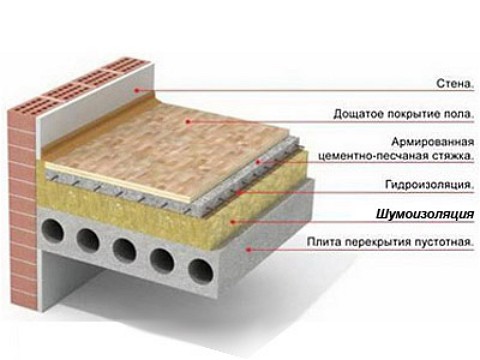

This design is the most effective means of reducing noise. The floor sandwich structure does not come into contact with the supporting structures and as a result does not participate in the transmission of sounds.

"Floating floor" exists in three varieties:

- concrete screed;

- dry screed;

- prefabricated covers.

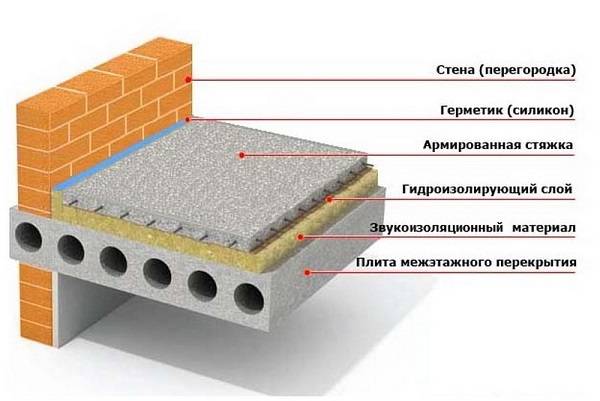

floating concrete floor

The concrete covering consists of noise insulation: expanded polystyrene or mineral wool. From above it can be covered with a waterproofing film. A floating floor is also arranged in a wooden house, but a vapor-permeable membrane is used between the wooden subfloor and the insulating substrate.

An edge tape is laid around the perimeter of the room. On top of the sound insulation is a concrete screed, which is in contact only with it. Then the top coat is applied.

The disadvantage of floating floors is the significant weight and reduced height of the room. However, they are often made, especially when it is necessary to create a floor heating system of a similar design. To do this, you only need to choose a reliable heat and sound insulating material on which the concrete slab will be located.

Dry screed

The method is characterized by simplicity and high speed of execution. A concrete base or a rough wooden floor is covered with a vapor barrier, on which mineral wool or extruded polystyrene boards are laid. Soundproofing material can be poured on top.

A double protective layer with different densities reliably protects the floor from airborne and impact noise. Gypsum fiber boards are laid on the backfill, a second layer of the same type is glued and fastened with self-tapping screws, but with a shift so that there is no coincidence of the seams. The thickness of the floor on a dry screed is 30-40 mm, which allows you to maintain the height of the room.

prefabricated floor

The method consists in laying the topcoat on a thin layer of sound insulation, which is used as a soundproof polymer substrate. Mechanical or adhesive bonding of the coating to the base is not required here. The top layer is rolled polymeric materials, prefabricated parquet, grooved board, MDF board.

Cork flooring can be used as a finish. The unique moisture resistance allows it to be used in the bathroom. A distance of about 10 mm should be left from the wall to compensate for deformations with changes in temperature and humidity.

Types of noise

Before getting rid of noise, you should understand what sound interference exists and how to protect against them. Noise types:

- Shock - with mechanical influences on the structure: work with a hand construction tool, hitting and clattering of heels on the floor, children's jumps, etc. A noise wave occurs when exposed directly to the ceiling. To suppress it, soundproofing panels with a cellular structure are used.

- Structural - vibration impact on building structures from working power tools, furniture movement, etc. It is transmitted when there are no soundproofing pads between the supporting structures of the house. At the same time, it is difficult to determine where the sounds come from, since they spread throughout the building. To cope with structural noise, it is necessary to protect the joints of structures with special gaskets.

- Air - sound transmission from the street, from other apartments or neighboring rooms: colloquial speech, working TVs and household appliances, traffic signals, etc. Sounds are transmitted through the air. Their weakening is helped by a porous or fibrous soundproofing material.

Noise is of the following types:

- external - from the side of the street;

- inside the house - from the landing or from neighboring apartments;

- intra-apartment - from the actions of people from neighboring rooms of the apartment;

- indoor - from a conversation or work of audio, - and television equipment in this room.

Completely suppressing noise is almost impossible

It is important that it does not exceed the level of comfort. If the background remains from sharp sounds, it is no longer annoying

To some extent, noise is necessary for a person for whom complete silence is even harmful.

Floor soundproofing is a real problem.

The most pressing problem that almost every apartment owner faces is the soundproofing of a living space. One of the components of the soundproofing of the apartment can be confidently called the soundproofing of the floor. Perhaps I’ll buy an apartment in a new building near Moscow, and suddenly the neighbors will get “funny ones”. And these neighbors will dance day and night. What to do? Soundproofing the floor? And how to do it - this article will tell you.

The resonance system, which includes floor slabs and soundproofing material, directly depends on the value of the resonant frequency of the floor structure. This implies the conclusion that the smaller the value of the resonant frequency, the higher the soundproofing ability. In practice, this means that it is simply necessary to choose a soundproofing material that provides soundproofing for the floor of the apartment. How to increase this indicator and what can be considered the best sound insulation for the floor?

More recently, using a massive floor screed and a gasket made of traditional materials (glass wool, basalt wool, expanded clay and foamed polymers), the sound insulation of the floor was ∆Ln,w = 23-28 dB. However, modern soundproofing materials have made a splash, reducing the level of impact noise to 40-50 dB.

Modern materials for soundproofing the floor in the apartment are the main characteristics, advantages and disadvantages.

Teksound.

Main characteristics:

- produced on a mineral basis;

- has a thickness of only 3.7 mm;

- can be laid on the floor, ceiling and walls;

- has a high density and weight (7 kg per 1 sq. m.);

- able to absorb airborne noise up to 28 dB.

Material advantages:

- resistant to temperature extremes and decay;

- flexible and elastic;

- has a high sound absorption coefficient;

- easy and simple to install;

- has an unlimited service life;

- is low flammable, self-extinguishing.

Flaws:

requires a mandatory substrate (it cannot be laid on a “bare” concrete slab).

Mineral wool.

This category includes several materials at once: slag, glass and stone (basalt) wool. All of them, although similar to each other, have different indicators of density, thermal conductivity and moisture resistance. It is because of them that in relation to the floors of residential premises it is permissible to use only the last type - stone wool.

Its main characteristics:

- ability to withstand high temperatures - up to 550˚С;

- has a high density;

- does not contain formaldehyde resin;

- does not require when installing the crate.

Advantages:

- environmental friendliness;

- durability;

- shrinkage resistance;

- heat resistance.

Cons: none.

Isoplat.

Main characteristics:

- made from coniferous wood;

- produced in the form of plates;

- able to absorb airborne noise up to 27 dB.

Advantages:

- natural ventilation;

- environmental friendliness;

- ease of installation.

Flaws:

high price.

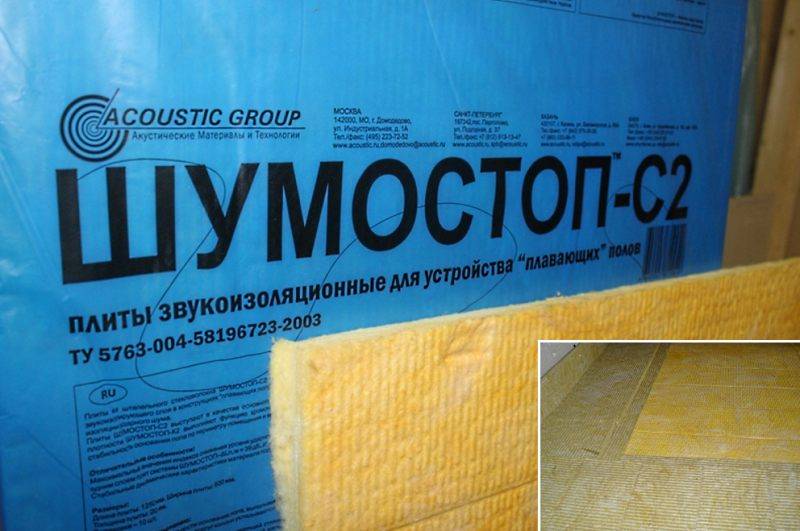

Noise stop.

Main characteristics:

- high level of sound insulation from impact noise - more than 39 dB;

- complete polymerization after 24 hours.

Advantages:

- small thickness - 20 mm;

- long service life;

- ease of installation.

Flaws:

low density for the screed leading to sagging over time.

Cork.

Main characteristics:

- it is produced in the form of tiles, rolls, panels, therefore it can be used both as a soundproof substrate and as a decorative floor covering;

- only 2 cm of this material can reduce the amount of noise coming from the neighbors below by 2 times.

Advantages:

- environmental friendliness;

- small thickness;

- excellent thermal insulation properties;

- the ability of the material to "breathe".

Flaws:

- may break due to inaccurate installation;

- too soft, therefore, in places of high pressure (under furniture where they often go) it tends to settle.

Vibrostek-V300.

Main characteristics:

- produced in rolls based on fiberglass type "C";

- characterized by an impact noise reduction index of 29 dB.

- used as a substrate.

Advantages:

- durability;

- small thickness - 4 mm;

- resistance to long-term loads.

Flaws:

- high price.

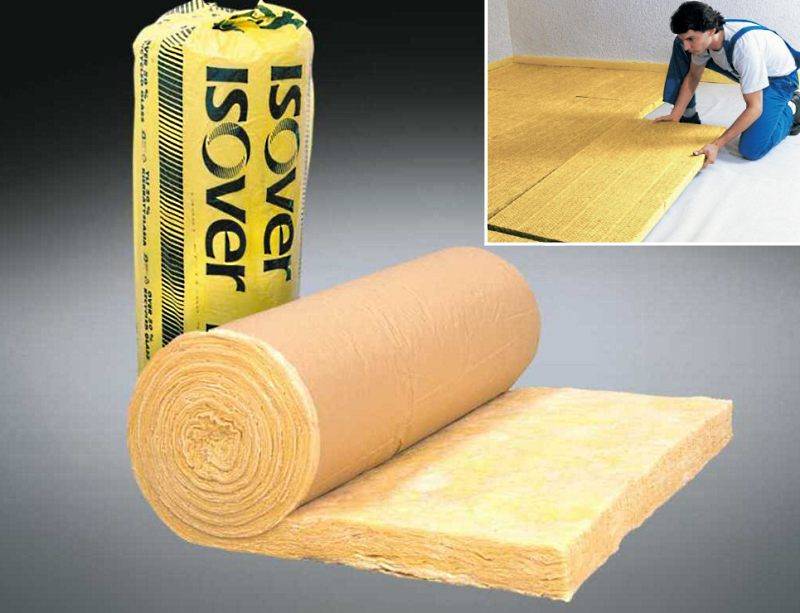

isover.

Main characteristics:

- designed for arranging a wooden floor on logs;

- made from fiberglass;

- has a high level of sound insulation - up to 38 dB.

Advantages:

- low thermal conductivity;

- low price.

Flaws:

absorbs moisture.

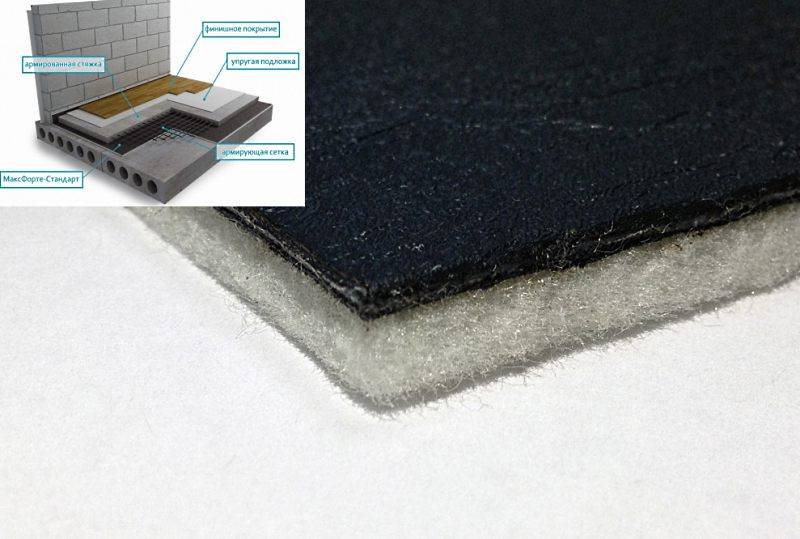

Maxforte.

Main characteristics:

- produced in rolls;

- can be mounted both under a coupler, and under a finishing floor covering (parquet, laminate);

- has an impact sound insulation index of 27 dB and a noise reduction factor of 0.52.

Material advantages:

- allows you to refuse laying a waterproofing layer;

- waterproof (at a pressure of 0.2 MPa) for 2 hours;

- not affected by rodents and insects;

- flexible and elastic;

- ecologically pure;

- resistant to temperature extremes (from -25˚С to + 85˚С);

- has an unlimited service life.

Flaws:

high price.

Soundproof

Main characteristics:

- is a bitumen-polymer lining material;

- elastic;

- has an impact noise reduction index of 23 dB.

Material advantages:

- allows you to refuse laying a waterproofing layer;

- environmentally friendly;

- waterproof (at a pressure of 0.2 MPa) for 2 hours;

- decay resistant;

- has a long service life and a very democratic cost.

Cons: none.

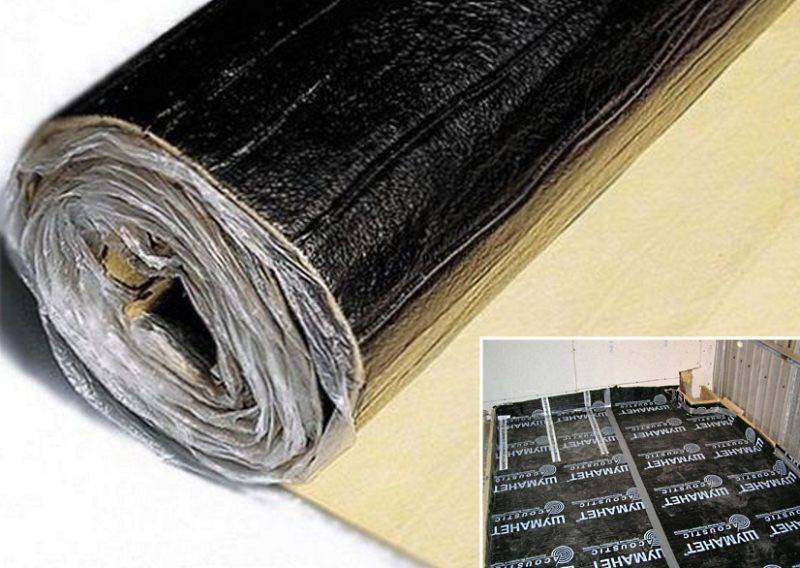

Shumanet.

Main characteristics:

- incorporates multilayer fiberglass;

- characterized by an impact noise reduction index of 23 dB.

Advantages:

- allows you to refuse laying a waterproofing layer;

- waterproof for 2 hours at a pressure of 0.49 MPa;

- high tensile strength along the web - not less than 170 N - with a small thickness;

- excellent acoustic properties;

- long service life;

- not combustible;

- environmentally friendly.

Flaws:

can only be installed at positive temperatures.

Peculiarities

Soundproofing the floor in an apartment can not only protect the home from unnecessary sounds from neighbors, such as the screaming of small children or the endless playing of musical instruments, but also reduce the noise from the use of flooring. Thanks to soundproofing, laminate, parquet or plank floors will not squeak.

Soundproof building materials often also have thermal insulation properties, which favorably affects room temperature. They are usually used in a house with ceilings, respectively, a massive board will not crack in a short period of operation, and the floor will not “float”.

Soundproofing materials

The most common soundproofing quality flooring materials are all types of mineral construction wool. Construction wool is included in the group of porous materials. Good sound insulation has a material whose porosity is not lower than 80%, and the pore diameter does not exceed 1 mm. This group also includes aerated concrete and fibreboard.

With many advantages of mineral wool, its main disadvantage is the large thickness of the plates (from 25 mm). They occupy a significant part of the space in the room. To maintain the height of the room, thin foamed synthetic materials are used, containing a large number of small air bubbles in the structure, which serve as good sound insulators.

Membrane soundproofing materials are common: plywood, thick cardboard, special fabric. The membrane is a reliable barrier, passing through which sound waves lose energy.