Sealing tape KNAUF-DICHTUNGSBAND

Elastic self-adhesive finely porous tape Digtungsband with closed cells is made from high-quality physically cross-linked PPE foam (tape analogues: KNAUF, TDStils).

The tape is used for acoustic insulation of metal partitions, claddings and ceilings. Insulation is attached to partition profiles and ceiling or floor guides, as well as to rack profiles of wall cladding.

Noise isolation is achieved due to the dense adjoining of the frame to the supporting building structures at the junction points.

Knauf dichtungsband tape is used during the installation of partitions or wall cladding, is used when installing the frame of partitions, cladding walls with drywall to level the surface and ensure a tight fit, guides and building structures.

Specifications

- Width: 30, 50, 70, 95mm;

- thickness: 3mm;

- packing: box 24 rolls, 12 rolls, 6 rolls.

It provides a soundproofing effect for structures with plasterboard partitions in those places where they are adjacent to the surface of the floor, walls and ceiling, smoothes out the effect of "resonant" walls, compensates for expansion when heated, and also increases the thermal insulation properties of the structure.

Sealing vibration-insulating tape of the Dichtungsband type is used to provide sound insulation in metal frames, partitions, ceilings, and other structures that are constructed during the construction of various houses, buildings and structures.

In buildings where this material is used, noise is not heard, the source of which is behind the wall, in the corridor or outside the window. Thanks to such noise isolation applied in the office, employees will not be distracted by extraneous sounds and will be able to do their work faster.

In residential areas, there are also many benefits from using tape. The material is usually glued to the guide profiles of the ceiling and floor. In some cases, it is attached to the rack profiles of wall cladding.

Dichtungsband vibration isolation tape is widely used as a sealant during the installation of sandwich panels.

Dichtungsband sealing tape protects the joints well, seals the seams and provides vapor barrier. With the help of a sealant, you can easily and quickly create a durable protective layer in fireproof partitions.

Other properties of dichtungsband tape

Dichtungsband sealing tape can serve as a heat-insulating coating for air ducts, pipelines, door and window openings of buildings and structures for various purposes. Thanks to such a sealant, a favorable microclimate is created in the room, the appearance of drafts, which often cause colds, is excluded.

The dichtungsband sealant is recommended for use when installing plastic double-glazed windows, this guarantees reliable protection of the seam from the negative effects of moisture and ultraviolet radiation.

In order to properly organize the installation work, it is necessary to use the dichtungsband tape, this will have a positive effect on the service life of the assembly seam, and in general will contribute to the service life of the entire structure.

Characteristics of dichtungsband tape

| The name of indicators | PPE Tape |

| Thickness, mm | from 2 to 5 mm |

| Width, mm | 30, 50, 70, 95, 120mm |

| Length, m | 15, 20, 30 m |

| Color | White gray |

| Adhesive layer | Yes |

| Density (kg/m3) | 33+3 |

| Compressive strength 25% (MPa) | 0,035 |

| Thermal Conductivity (W/m K) | 0,038 |

| Elongation at break (% not less than) longitudinal/transverse | 130/100 |

| Water absorption (% by volume) | 0,1 |

| Acoustic properties | good sound insulator of shock-dynamic noise |

| Microbiological resistance | high |

| Resistance to aggressive environments | high to oil, petroleum, gasoline, alcohol, alkali, acids |

| Environmental Safety | high, complete hygienic safety, non-toxic, colorless, odorless, does not cause allergies |

Installation conditions

- Clean the surface from dirt, dust and moisture;

- The adhesive side is applied to a pre-prepared segment of the guide profile;

- Lay the tape against the surface and fix with light pressure;

- After that, the profile itself is fixed to the concrete structure with the help of dowels;

- It is necessary to glue the sealant at a temperature not lower than +5 and not higher than +40°C.

Sealing tape for drywall profile

Sealing tape for drywall profile– a special material used to create a metal frame for drywall, as well as during the sealing of plasterboard joints. It has its own varieties and distinctive properties.

Sealing damper tape is a sound insulator and vibration absorber

Advantages

The main advantages of sealing tape for drywall are the following facts:

- good noise, steam, sound insulation;

- vibration cancellation;

- missing water absorption;

- temperature stability;

- elimination of various surface roughness;

- resistance to all kinds of negative manifestations;

- the existence of construction allowances that help the structure not to deform when the geometry of the frame walls changes.

All of these properties are achieved due to the flexible, soft texture of the material. The positive side is ease of use when sealing joints. The price range ranges from 75 to 1500 rubles.

Fixing the sealing tape is not difficult

Types of sealing tape

There is a large amount of sealing agent on the construction market, which is different in its structure and purpose. Almost all types of tape have the only common property - on one side it has a sticky layer designed to fix the material to the base. This layer of adhesive is protected by paper, which must be removed before use.

The tape and its application can be conditionally divided:

- for rough finish - damper;

- for sealing joints between drywall sheets - reinforcing; Knauf Kurt Tape has distinctive dimensions and is applicable on large drywall surfaces

- for separation - sliding joints.

The tape is intended for the joint in the corner of the gypsum craton and the load-bearing wall, which goes through the shrinkage stage

Before you start finishing an apartment or office, you need to figure out where which representatives of drywall sealants are used.

Characteristics of the sealing damper tape

This type is made from polyethylene foam material. On the one hand there is a sticky layer for gluing. It is easily superimposed on the metal elements used in the creation of the frame for drywall, firmly fixed. This tape has the following advantages:

Damper sealing tape for metal profiles under plasterboard

- is a noise absorber;

- when using the tape during installation, the metal profile does not come into contact with the concrete base, which prevents the formation of condensate and oxidation;

- absorption of vibration arising from neighbors from above or from construction (other) work on the street.

If there is a vibration of the structures, the use of the material prevents the appearance of cracks in the drywall.

Watch the video: the use of sealing tape.

The sealant is not always used when working with drywall, but it is advisable to use it.

Application

Observing the correct technology for the use of a damper sealant in repair work, it will create additional protection for the drywall structure from harmful effects.

The sealing material should be glued on the side of the mounted profiles to the rough surface. For convenience, you should have a cutting knife on hand. Since the tape has a layer of glue, it is quite easy to fix it on the profile.

The cost in the construction market ranges from 157 rubles. up to 400 rubles per roll.

Drywall Profile Sealing Tape

Drywall sealing tape is a specialized insulating material that is used during the installation of drywall structures. In its external appearance, the product in question is a tape of a microporous composition on an adhesive basis. Most often, it is used to achieve a tighter pairing of walls and ceilings with cladding and frame profiles of various partitions.

Advantages

The main advantages of this material are:

- providing sound insulation;

- providing sound insulation;

- vibration damping;

- minimal water absorption;

- resistance to temperature changes;

- steam insulation;

- elimination of irregularities on the surface;

- high level of resistance to various negative factors.

The above positive aspects are ensured by the flexibility, softness and thickness of the sealing tape. An important factor is the ease of use that the sealing tape provides when sealing joints.

Self-adhesive sealing tapes PPE and NPE

Application of sealing tape

In advance of using the sealing tape for the profile, it is necessary to carefully familiarize yourself with all the quality characteristics, while following the recommendations for installation. The main rules should include:

- selection of the appropriate width of the tape, which will be equal to the profile of one or another size;

- preparation of the profile surface to be glued, that is, degreasing with technical alcohol or dedusting;

- unwinding the sealing tape, as well as removing the protective film;

- applying a tape to a metal profile with an adhesive side and without much tension;

- tight gluing of a self-adhesive tape by pressing it to the surface of a direct profile;

- attaching the prepared profile to the wall or ceiling surface with the side to which the tape is glued. It is in this way that a soundproof sealing layer is provided between the plasterboard structure and the profile. Among other things, vibration is significantly reduced.

Damper tape for partition walls

Elastic self-adhesive finely porous tape Digtungsband with closed cells is made from high-quality physically cross-linked PPE foam (tape analogues: KNAUF, TDStils).

The tape is used for acoustic insulation of metal partitions, claddings and ceilings. Insulation is attached to partition profiles and ceiling or floor guides, as well as to rack profiles of wall cladding.

Noise isolation is achieved due to the dense adjoining of the frame to the supporting building structures at the junction points.

Knauf dichtungsband tape is used during the installation of partitions or wall cladding, is used when installing the frame of partitions, cladding walls with drywall to level the surface and ensure a tight fit, guides and building structures.

It provides a soundproofing effect for structures with plasterboard partitions in those places where they are adjacent to the surface of the floor, walls and ceiling, smoothes out the effect of "resonant" walls, compensates for expansion when heated, and also increases the thermal insulation properties of the structure.

Sealing vibration-insulating tape of the Dichtungsband type is used to provide sound insulation in metal frames, partitions, ceilings, and other structures that are constructed during the construction of various houses, buildings and structures.

In buildings where this material is used, noise is not heard, the source of which is behind the wall, in the corridor or outside the window. Thanks to such noise isolation applied in the office, employees will not be distracted by extraneous sounds and will be able to do their work faster.

Vibrostek-M damper tape: characteristics, application for vibration isolation, varieties

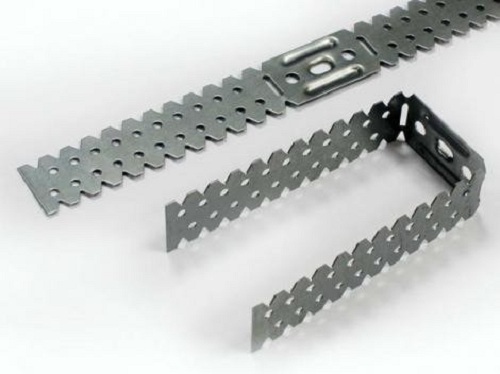

Vibrostek-M is a damper tape made of vibration-insulating fiberglass, packed in a roll. Due to the porous-fibrous structure, the material provides insulation from shock and vibration noise. Vibrostek-M retains its properties under static load and is suitable for laying under the lower end of a carrier beam or drywall profile.

Characteristics of soundproof tape

To protect metal frames from noise, during the construction of ceilings and walls, laying flooring, a damper tape is used. The rolled material is 30 m long, 10 cm wide and 3 mm thick. Surface density: 300 g/m2. The adhesive layer is applied on one or both sides of the tape.

Vibrostek-M soundproof gasket has the following characteristics:

- Compliance with the price of the material efficiency.

- Reliable protection against structural noise, despite the small thickness.

- Long operational resource.

- Resistant to various intense loads.

Vibration isolation tapes are in demand in the construction of residential buildings, office premises. With Vibrostek-M, rooms become more comfortable for staying. Tapes are mounted between special materials. This ensures high-quality acoustics.

Tape sound insulation is not subject to deformation even under the influence of external factors and phenomena. The material has a number of characteristics:

- Zero water absorption.

- Resistant to oxidation, UV radiation, alkalis and weak acids.

- Elasticity and softness.

- Light weight (1 kg).

Vibroacoustic characteristics of the Vibrostek-M tape: dynamic modulus of elasticity 0.18 MPa at a load of 2 kPa; at 5 kPa - 0.35.

Possibilities of using Vibrostek-M

Soundproofing tape is used as a cushioning material when mounting:

When installing sandwich panels, the tape is laid in two layers at the points of contact with the ceiling and side walls, at the points of support on the floor. When installing frame partitions, sound insulation is placed between the fasteners and load-bearing building structures, at the junction of the sheathing sheets of the partition.

Vibrostek-M is used in the arrangement of wooden floors. The material is laid under the logs and floor beams - at the points of their support on the walls. The width of the tape must be greater than 10mm on each side of the beam or joist. Vibrostack is also laid on the ends of the beams, which rest on the walls.

Vibrostek-M soundproof gasket is indispensable for:

- When assembling various soundproofing systems (with and without a frame).

- In cladding and wall structures.

- When arranging suspended ceilings.

The tape is used as a border layer in the manufacture of a floating floor.

Sealing tape

Sealing substrates are made of flexible polyethylene foam. These are cellular strips covered with a self-adhesive layer on one side. They are protected by special paper, which is peeled off before use. Form of release of sealing strips - rolls of various lengths.

The material differs in brand, length and thickness of polyethylene foam. There are 3 varieties:

- Non-crosslinked gas-filled.

- Chemically crosslinked.

- Physically stitched.

Tape width varies from 30 to 90mm. The common thickness is 30mm.

Sealing gaskets provide a tight joint between the metal profile for drywall, as well as load-bearing structures - walls and floors. The tape is used not only for sealing, but also for vibration reduction and sound insulation.

Reference.A plasterboard partition made of sealing gaskets will serve not only as noise protection, but also as a screen that attracts and amplifies vibrations and sounds from neighboring rooms.

The material is glued to guides through which sounds pass from one room to another. The rack profiles fixed to the walls are also pasted over with insulating tape.

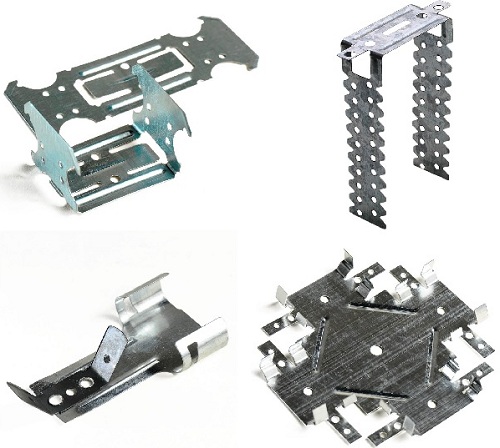

Additional fittings

Additional components include various kinds of suspensions and connectors. Some of them can be replaced (especially if you need a small amount), and without some it is impossible to make even the simplest frame for walls or ceilings.

The main components of the frame are the following elements:

- Direct hangers. This is one of the main parts of the frame, which is used in the same row with guides and rack profiles, drywall and accessories. It is a rectangular plate up to 300 mm long with perforation over the entire surface. These suspensions are used to connect frame racks with load-bearing walls, or when attaching the entire base to the ceiling of a building.

Like other metal elements, direct suspensions are zinc coated. The length can be different: 75, 125 or 300 mm. For use, the plates are bent, giving them the shape of the letter "P". The top, which is attached to the bearing surface with dowel-nails, and the frame racks are fixed to the free ends.

Direct suspensions have a significant margin of safety, each element can withstand a load of up to 40 kg. This ability allows them to be used when assembling the base for suspended ceilings.

- Single-level connectors for CD profile ("crabs"). Such a detail is used to connect the ends of the profile butt-to-butt, or crosswise in a single-level plane. The connector has latches that fix the ends of the CD profile. If the load on the joints does not exceed more than 20 kilograms, then you can do without additional fastening material (bugs), in case of a larger load, rigid fixation with self-tapping screws will be required.

- Two-level connectors for CD profile. Such accessories are designed to connect the frame rails crosswise, in two planes, when one profile lies on the second, and at a right angle (perpendicular). During installation, the connector is bent into the shape of the letter "P" and fixed with "fleas".

- Anchor hangers. Such a component for the base under the gypsum board is used when installing the ceiling frame. The main task, as well as direct suspension, is to connect the base to the supporting floor. It consists of the suspension itself and a long rod. Details are used in the case when the length of the direct suspension is not enough, and the ceiling frame itself will be located at a considerable distance from the bearing surface.

Anchor hangers are produced with different lengths of 250, 500, or 1,000 mm. The margin of safety allows you to withstand loads up to 25 kg.

- CD profile extensions. The purpose of the part is to add the length of the frame rail. It is mounted inside the main profile and fixed using self-tapping screws.

- Corner or T-shaped connectors. These types of parts are used for perpendicular joining of the profile to another rail. Most often, it can be replaced with one single-level connector of the "Crab" type.

All these fittings, as a rule, are produced by companies that produce drywall and profiles, in particular, by Knauf, which has established itself in the market.

Also fasteners can be attributed to drywall fittings: dowel-nails, “fleas” (bugs), press washers.

Types of reinforcing tape

The construction market provides a choice of reinforcing tape. Reinforcing tape options:

- Serpyanka. Consists of fiberglass. It looks like a fine mesh. One side has glue on it. Its price is 65 rubles per roll.

- Paper.It appeared first in the building materials market. And now it is in great demand, because paper tape has many advantages - it does not stretch when wet, it does not tear, it is thin, which makes it easy to level the entire surface. The price of such a tape is 25 rubles per roll. The Knauf tape has special holes through which air escapes.

- Metal inserts in reinforced tape. This is a paper tape, in the center of which there are metal strips. It is very popular in sealing drywall corners.

- Damper. Composition - foamed polyurethane. A layer of glue is applied to the tape, so it does not cause difficulties in installation. Basically goes as a sealant under a plinth.

The tape plays a big role in sealing joints and corners of drywall constructions. With its use, the product will last a long time.

paper tape

This is the classic version. This tape was used even when there was no sickle, but even now paper tape is widely used in construction and repair work. Pros of paper tape:

- She is thin. Therefore, it is used for small defects on the surface;

- It adheres well to putty and at the same time retains its properties;

- Price. This is a cheap building material, distinguished by its quality;

- When using it, specialized education and the purchase of additional materials are not required.

Application of paper tape

Paper tape, like serpyanka, is widely used in the repair of premises. When strengthening the boundaries at the junction of the GKL, eliminating cracks and other repair work.

To apply this tape, you must:

- Knead the required amount of putty mixture.

- Well, with pressing, apply this putty to the border of the GKL.

- The paper tape should be slightly dampened for better adhesion.

- Exactly, along the seam put the tape.

- With a spatula, slightly pressing, draw along the entire length of the tape.

- Excess solution is carefully removed.

- After drying, apply another layer of putty, leveling the entire surface and eventually wipe the entire plane.

The paper tape does not tear and has a good seam fastening property. Watch a video on how to properly glue paper tape at the joints of the GKL.

Advice

When using reinforced tape, you need:

- monitor the humidity in the room;

- room temperature 10 degrees, not lower;

- at the time when work is carried out with the tape, there should be no air movement (drafts);

- before attaching the tape to the GKL joint, you should make sure that the drywall construction is strong, if it is “flimsy”, the reinforcing tape will not help.

To seal large borders and large cracks, it is best to take a high-quality and wide Kurt tape, which, when applied, will capture a large area on the sides, thereby repairing will be better.