What is a collet and fitting

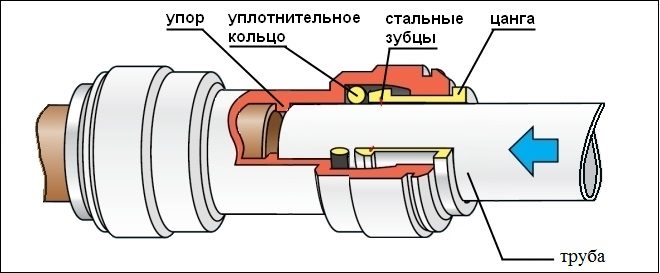

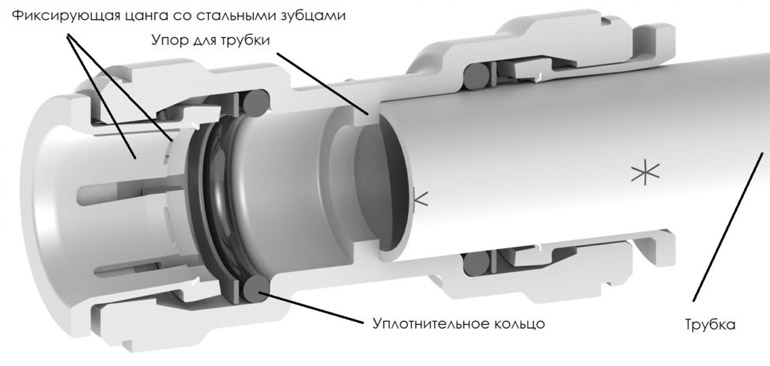

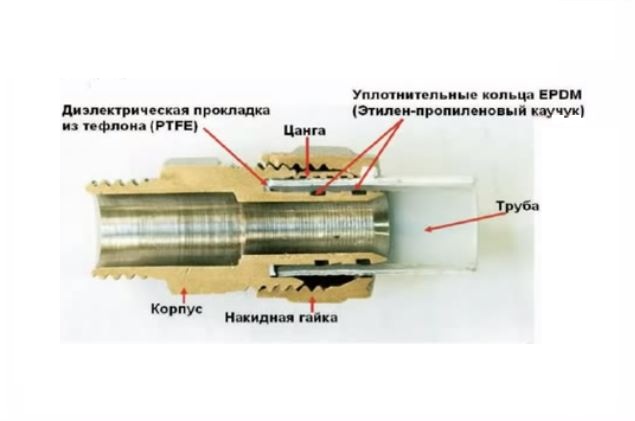

To understand how collet fittings work, you must first understand what a collet and a fitting are. The collet, the design of which is optimally suited to be used for connecting cylindrical parts, is a metal sleeve, on the side of which special cuts are made that form several springy petals. Due to the presence of such petals, the collet exerts pressure on the inner walls of the pipe, thereby pressing its outer surface against the walls of the fitting cartridge. Collet type fittings operating on the principle described above are often referred to as clamp fittings.

Scheme of connecting pipes with a collet fitting

As for the fitting, this term refers to a connecting element used to create pipeline systems for various purposes. Fittings of an appropriate design are used to solve various problems, which, in particular, include:

- connection of pipes of the same and different diameters;

- creation of corner joints in pipeline systems;

- connection of pipes with various plumbing devices and equipment (faucets, filters, meters, pumps, etc.).

Main types of push-in fittings

High reliability, which distinguishes the collet clamp for pipes, is ensured not only by the collet itself, which exerts pressure on their inner walls, but also by the external fixing nut

The pipeline created using such connections is highly reliable, durable and, most importantly, tight

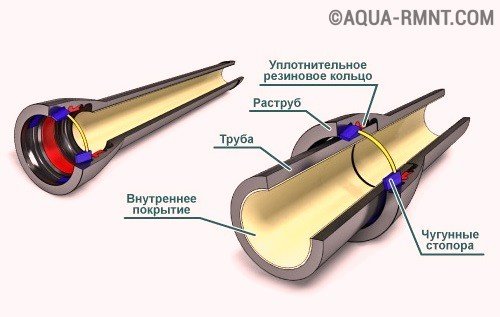

The nuances of the socket connection of parts

The socket method of connecting parts is very simple. The edge of one pipe has a larger diameter, it is he who forms the socket into which the end of the other element is inserted. To make the connection tight, a special rubber O-ring is inserted into the socket, or another seal is used. Installation of a pipeline with connections of this type is not particularly difficult and resembles the assembly of a designer. There are varieties of socket connections.

Option #1 - no o-ring

The method is very often used to connect sewer cast iron pipes. Details are measured. The inserted element is laid on wooden bars and sawn off along the intended line. The end of the outer part of the part must be free of cracks or notches and strictly perpendicular to the axis of the pipe. The prepared pipe is inserted into the socket. The gap inside it must be sealed. Oiled hemp or tarred flax is used as a sealant. The first layer is wound into the pipe with a ring, so that the ends of the strands do not get inside the part. The seal is caulked with a hammer and screwdriver.

The remaining layers of material are laid in the same way until approximately two-thirds of the depth of the socket is filled. The last layer is laid sealant without impregnation, which may prevent adhesion to the solution. The remaining distance to the end of the pipe is filled with cement mortar or asbestos-cement mixture, bituminous mastic and similar compounds.

To seal the socket joint of pipes without a sealant, tarred flax or oiled hemp is used.

Option #2 - with o-ring

It is considered one of the main ways to connect plastic pipes. In this case, the tightness is ensured by a rubber ring, which is clamped between the flat end of the pipe and the socket walls. The seal, which can be either with special plastic inserts or without them, allows you to partially compensate for the possible misalignment of the axes of the connected parts.However, uneven deformation of the sealing band on the ring can cause leaks in the articulation area. Therefore, the curvature of the axis should be no more than the thickness of the pipe wall per each linear meter of the pipeline.

When installing a socket connection with a sealing ring, it is necessary to monitor the alignment of the centers. Otherwise, the skew of the pipe will provoke deformation of the seal and, as a result, insufficient sealing of the joint.

Some manufacturers produce models of tees and elbows not at a straight line, but at an angle of 87 °. Thus, the pipe, which is laid under a slope, enters the socket without distorting the rings. During installation, to prevent damage to the seal, a chamfer is made on the smooth end of the pipe and lubricated with soap, glycerin or silicone. Oils are not allowed. The socket connection with an O-ring is made as follows:

We check the presence of an o-ring in the socket and a chamfer on the smooth end of the pipe

We clean the parts from possible contamination, apply lubricant.

We place the smooth edge of the structure all the way into the socket and put a mark.

Carefully remove the part from the socket, pushing it out by no more than 11 mm, while focusing on the mark set earlier. The resulting gap will compensate for temperature changes in the length of the pipe

On average, one socket compensates for the lengthening of a two-meter pipeline fragment.

If it is required to connect pipes of different materials in this way, special adapter pipes are used.

Option # 3 - socket method using welding

Contact socket welding is designed for plastic parts and is carried out using special equipment. In the connection process, a mechanical or manual welding machine is used, equipped with special devices for heating the elements. This is a mandrel designed to melt the inner surface of the part, and a sleeve that heats up the outer part of the pipe.

Polypropylene pipes are connected by socket welding. For this procedure, a special welding machine is used, which heats the parts to the desired temperature.

The connection process is quite simple. A set of sleeve-mandrel is selected, corresponding to the diameter of the pipes to be connected. Devices are installed on the platform of the device and warmed up. Parts are put on the equipment and heated to the desired temperature. After it is reached, the elements are quickly and accurately removed and connected with a precise movement until they stop. The connection is left motionless until the plastic cools and completely hardens.

Installation

Installation of collet connections is the simplest possible. Classic threaded fittings compete in ease of installation, but there it is necessary to seal the connection independently (with fum tape or linen tow). Moreover, you will need to do this every time anew if you need to disassemble the assembly. In the case of a push-in fitting, this is not necessary.

For work you will need:

- scissors for plastic pipes or a hacksaw for metal;

- calibrator with beveler;

- wrench or wrench.

We will analyze the installation of a collet connection using the example of a metal-plastic pipe. The scheme of work is as follows:

- cut the pipe

- align the circumference by putting the pipe on the calibrator and turning it;

- remove the inner chamfer (it is necessary so that the uneven cut does not damage the sealing rings on the fitting);

- disassemble the fitting by removing the nut and collet ring;

- put the nut and ring on the pipe in the described order;

- pull the pipe onto the fitting until it stops;

- move the collet into place;

- tighten the nut.

Varieties of compression fitting

Push-in fittings for plastic pipelines have an internal fitting, with which the plastic walls of the pipe are pressed against the gasket by twisting the fastener.

Advantages and disadvantages of using

The maximum working pressure depends on the working temperature and ranges from 5 to 10 bar. Polyamide couplings are characterized by high resistance to external mechanical influences such as abrasions, abrasions or impacts, which extends the service life and thus ensures long-term operation.

Although acidic compounds cannot be used, they are resistant to compounds such as. Gasoline - alkaline - car and fuel oil. We offer the following types of twisted connections. Straight-line mounting with external and internal threads and through. Corner headrest with external and internal thread.

Couplings for copper pipes do not have an inner sleeve that the pipe is pushed onto. In addition to this small difference, the design of the clamping device is completely the same: the same method of compression with compression nuts and a sealing ring. They are used for fixing hard pipes, but can also be used for soft materials. In the latter case, a support sleeve is placed inside the plastic pipe so that when the nuts are tightened, the pipe lumen is not deformed.

Like any fitting, collet connections are made from various materials. The most common brass and plastic connections. For copper pipes, copper collet fittings are most often used. Soft copper under pressure tends to rub against the pressure surfaces.

Withstand working pressure of 25 bar and temperature of 115°C. But they are subject to corrosion, it is not recommended to use them in pipelines with aggressive media.

Made from durable polyethylene or polypropylene. Polyethylene parts can be used for type 3 polypropylene (PPRC), cross-linked polyethylene (PEX) and HDPE pipes.

Polypropylene are usually made from impact-resistant technopolymer. The collet clamp is made of stainless steel. The push ring of the collet and the guide sleeves are made of plastic. This fitting can be used to connect pipes made of polyethylene, polyurethane, polyamide, nylon and other synthetic materials. This category includes push-in fittings for plastic pipes.

To strengthen the product, some manufacturers add an outer metal ring over the female plastic thread.

Separately, it is worth considering ways to connect pneumatic pipes. Pneumatic systems are called compressed air systems. Parts with increased pressure resistance are required to ensure leak-tight connections.

Fittings for such systems are divided into several types. They can be both collet and not.

- Pneumatic type MV are mounted in air filtration systems. They are made of high-tech plastic based on acetate polymer. Fittings made of this material withstand pressure up to 12 bar, operating temperature from -10°С to +70°С. They are distinguished by an increased degree of rigidity and resistance to corrosion.

- Pneumatic fittings can be made from other materials such as Teflon, polyethylene, polyamide, polyurethane. Copper, stainless alloys and steel are also used. But brass connections are of limited use in conditions that exclude the impact of aggressive environments.

- Polyurethane and polyamide tubes are used as pneumatic fittings, but they do not belong to the category of compression connections.

The main advantages of pneumatic push-in fittings are the ability to quickly install and dismantle the system. All pneumatic fittings produced today have increased resistance to temperature and high pressure. This type of connection remains reliable for a long time, while maintaining its qualities. Pneumatic fittings are quite specific and are designed to be installed in specific preparation, transport and handling systems.The disadvantages of pneumatic push-in fittings include the fact that they cannot be used to control the main flow of gas or air circulating in the system. For these purposes, another type of pneumatic fitting is used.

What is a push-in fitting

To understand this issue, you need to understand the definition of two terms: collet and fitting.

On the market an abundance of fittings from different materials is presented:

plastic, copper, steel, etc.

They can be used both for simple connection of two pipes of the same diameter, and as adapters between pipes of different diameters, different materials (for example, transition from to metal-plastic ones), serve as tees, crosses, corners, plugs, etc.

Thanks to the collet fixation of the fitting, this connection does not require special knowledge,

tools or large physical costs. But at the same time, the connections produced by this method are tight and durable.

- collet fittings can be used in the installation of pipelines transporting hot and cold water, gases, oils, chemical media;

- the temperature of the transported medium must not exceed 175ºC

; - allowable pressure does not exceed 1.6 MPa;

- the inner diameter of clamp connectors for plastic, metal-plastic or copper pipes on the construction market varies from 8 to 100 mm;

- push-in fitting can be straight, angle, tee, cross, etc.

Types of push-in fittings

- straight push-in fitting or coupling. This type is used to connect pipe segments of the same diameter from the same material;

- a transition fitting is required if necessary to connect pipes of different diameters or to transition between pipes of different materials (for example, connecting metal-plastic and metal pipes);

- a corner or outlet connector is used to arrange corners and turns from 45 to 120 degrees;

- cross - an element that allows in two directions;

- a tee is used if a one-way branch from the flow is necessary;

- the fitting serves as an adapter from the pipe to the hose;

- needed to shut off the flow at the end of the pipeline.

Advantages and disadvantages

Push-in fitting - the most popular connector.

This is due to a number of its undeniable advantages:

- affordable cost;

- wide model range;

- the presence in the assortment of any specialized stores;

- ease of installation work that every consumer can handle;

- the possibility of installation by improvised means without the purchase of any special equipment;

- tightness and high reliability of joints of metal-plastic, plastic or copper pipes;

- durability;

- the possibility of reusing connecting elements. Thanks to this, push-in fittings are convenient to use even in temporary structures;

However, there are also some disadvantages:

from time to time, the collet clamp weakens, so there is a need to periodically tighten the clamping nut;

a consequence of the first drawback is a categorical ban on immuring collet connectors into walls

They should always be available for preventive maintenance and repair;

installation of collet fittings, although it does not require special knowledge and skills, however, requires intelligence and caution. They must be tightened sensitively so that the collet or nut does not crack (this is especially true for plastic connectors).

Fitting classification

Connecting fittings of this type are classified according to such criteria.

Production material

Depending on the material from which they are produced, the parts are:

- metal - from ferrous (cast iron and steel) and non-ferrous metals (brass and copper fittings for HDPE pipes);

- plastic.

Installation rules

According to the installation features of fittings, they are divided into the following types:

- Threaded. Fastening is carried out using a thread.

- Welded. The elements are connected by gas welding.

- Press fittings. They provide a secure fit, but require a special crimping tool.

- Collet adapters. Pipes in this case are fixed with o-rings.

Let's take a closer look at the last one.

Mounting technology

When installing pipes with push-in fittings, it is required to fix the collet into the inside of the structure. The outer nut is screwed on with an adjustable wrench. Thus, an optimal level of tightness of the structure is achieved. The same actions are performed with the second part of the structure.

It should be remembered that these elements exert considerable pressure on the structure. For this reason, if plastic pipes are being installed, the clamping level should be controlled. If excessive force is applied, the structure can be severely deformed. For this reason, it is necessary to try to regulate your efforts, avoiding the occurrence of cracks on the product. If you want to learn more about the features of these crimping devices and the specifics of their installation, you can always see photos on this topic.

Advantages

Push-in fittings appeared on the market relatively recently, but they quickly gained the attention of a consumer audience. And this is not surprising, because they are distinguished by a number of important advantages:

- democratic value;

- Ability to find items in each store of the corresponding profile;

- Easy to install;

- Tightness, quality and reliability of connections;

- Durability;

- The possibility of reuse, which allows the use of elements in structures that are planned, after a certain period of time, to be dismantled.

However, push-in fittings also have disadvantages. In particular, this is a gradual weakening of the clamp. For this reason, such connections require regular tightening.

When installing pipes, it is important not to forget about ensuring unhindered access to the connections. It is also important to remember that structures with such connections cannot be laid in walls.

This reduces the breadth of their use, but not significantly.

If you are interested in collet fittings for pipes, on our website you can see their photos, images with ready-made connections. Whether to purchase these connectors or think about other options depends on your specific situation, the specifics of the installation of the system, and your personal preferences. If you are going to install structures yourself, you will be able to appreciate the ease of working with this type of element.

pipe fitting

To ensure uninterrupted water supply to apartment buildings, plastic pipes are often used. They gained popularity due to their long service life, special reliability and safety in operation. In addition, the installation of plastic pipes is quite simple and fast, due to their flexible design.

However, such pipes provide for connecting fastening with each other, as well as with other equipment for the plumbing system. As a result of this, the question will definitely arise: how to choose the most ideal option, so that in addition it serves for a long time and is easy to install? The answer is simple - such an important element will be collet fittings, time-tested and simple connecting devices.

For copper pipes, the use of push-in fittings is quite rare, which is required when a certain material flexibility is needed.

water outlet double