Peculiarities

Screw pumps are volumetric rotary gear units. The devices are highly resistant to mechanical stress and aggressive chemicals, which allows them to be used when working with all types of liquids, including contaminated and industrial effluents. Pumps are able to pump water with sand without the risk of clogging or failure. Unlike surface models, screw devices need to be completely submerged under water.

The scope of use of screw pumps is very wide. The devices have found their application in the food industry. With their help, pumping of viscous substances, such as condensed milk and batter, is carried out. The devices are actively used in gas, oil and artesian wells, in the arrangement of fountains and domestic water supply, to fill storage tanks and pools.

The operation of the units is carried out at a depth of 8 meters, the rotor rotates at a speed of 6 thousand revolutions per minute, and the fluid pressure at the outlet is from 4 to 25 atmospheres, depending on the purpose of the pump and the number of screws.

Screw pumps have a very large output resource, high strength and durability. This allows them to be used not only for household needs, but also as pumping equipment at large mining and processing industries. The performance of the models varies from 1500 to 6000 liters per hour.

Types of screw pumps submersible and surface

Modifications:

- submersible or deep - are placed inside the well on a flexible cable.

- surface borehole - mounted on the surface of the earth and it is advisable to use them to create pumping stations.

Popular models of screw pumps:

- Aquarius - used in wells with a passage diameter of at least 100 mm. It is produced in two modifications - NVP 0.32-32 and NVP 0.32-63. Productivity - about 0.32 x 10 -3 m 3 / s, pressure - up to 63 meters, weight - 12 and 17 kg.

- Belamos - household models of the 3SP and SP series are produced. All of them have a stainless steel body. Pumps of the 3SP series are designed to supply water from wells with an internal diameter of 80 mm. Nominal head up to 40 meters, flow rate up to 1.5 m³/h, cable length not less than 15 m. Pumps of the SP series are designed for individual water supply of dachas and country houses. The hole diameter is at least 4 inches. Capacity 1.7-1.8 m³/h, head 95-150 meters, power cable length 20 m.

- Unipump ECO VINT is available in 3 modifications. One of the best water pumps for a private house - autonomous water supply, watering a garden and a summer cottage. Designed for wells with a diameter of at least 85 mm. Head up to 90 meters, capacity up to 33 l / min, equipped with a cable 20 meters long. Water supply is carried out due to the rotation of the working screw in the rubber cage. The absence of a driven screw simplifies pump maintenance and increases its reliability and durability.

- Sprut ZGD is designed for pumping relatively clean water. The pump body is made of cast iron, the auger and the drive shaft are made of stainless steel. Ceramic graphite mechanical seals, motor power 750 W, flow rate 3.6 m³/h. Together with a hydraulic accumulator, ZGD is used as a reliable pumping station for uninterrupted water supply to consumers.

Advantages of submersible screw pumps:

- simple and convenient design, allowing easy maintenance and repair;

- the possibility of carrying out repairs in the field, without the use of special tools and equipment;

- the use of standardized self-locking couplings, which make it easy to dismantle and mount oil seals and mechanical seals;

- the shell body allows to turn the soaking-up branch pipe on 90 °;

- the use of electric motors that do not create vibrations, which significantly reduces the generation of acoustic waves and reduces the noise from the pump;

- the use of advanced processing technologies that reduce the cost of pump parts without losing consumer properties;

- the ability to pump water with various contaminants (sand, mud, suspensions) without compromising performance, for example, a submersible mud pump for wells;

- high reliability and durability.

Recommendations for correct installation

In order for a screw pump for a well not to cause problems during operation and to effectively cope with the task of pumping out a liquid medium, it is important to install it correctly. Although the installation of pumping equipment of this type is in many ways similar to the rules for installing centrifugal hydraulic machines, there are certain nuances in this procedure that must be taken into account.

Like any other type of submersible pump, screw devices are lowered into a casing pipe installed in a pre-drilled well. To fix the screw pump at a certain depth, a metal cable is used, on which the equipment is suspended in the inside of the casing. The power supply of the pump submerged into the well, as well as the supply of control signals to the elements of its automation, is provided by a special cable connected to the appropriate terminals.

In cases where high-power pumping equipment is used to equip the well, several cables can be used at once to connect it to the power supply network and the control unit. The supply of liquid medium, pumped out by a screw pump, from the depth of the well to the surface is carried out by means of a powerful hose, the inner diameter of which, depending on the model of the equipment used, can be in the range of 25–50 mm.

Screw pump prepared for immersion in the well

The process of connecting and installing a submersible screw pump is carried out according to the algorithm below.

- The pump, which is planned to be lowered into the well, is connected to the power supply and starts for a short period of time. This is necessary to check the functionality of the device.

- If the pump is functioning normally, then an electric cable is connected to it, which will be lowered into the well with it.

- A hose is connected to the pressure port of the screw pump, through which liquid from the source will be supplied to the surface.

- The hose and cable of the pump power supply are pulled together by clamps, and such connections must be made along the entire length of the hose and cable.

- A safety cable is tied to the pump (for this purpose, there is a special mounting hole on the hydraulic machine body).

- If a float-type liquid level sensor is supplied with the pump, it must be connected to the equipment.

- Connected to all communications, the pump is carefully lowered into the casing to the required depth. This should be done as carefully as possible so as not to damage the body of the device when it comes into contact with the pipe walls.

- After the pump is at the required depth, its position should be fixed by tying the upper end of the safety cable to a crossbar mounted on the surface of the earth.

- The upper part of the pressure hose is connected to the pipeline, on which a check valve (if it is not in the design of the hydraulic machine itself), a gate valve, a pressure gauge and a branch elbow must first be installed.

- After all connections are made, and the pump is securely fixed in the well at the required depth, a test run is carried out.

The pipe is removed from the casing string through the well head along with the power cable

During the test run of the installed submersible screw pump, attention should be paid not only to the flow of the liquid medium through the pressure hose, but also to the presence of knocks and vibrations during operation of the equipment. In the event that such phenomena are observed, the installation of the screw pump is incorrect

This must be corrected by reinstalling the equipment according to the above scheme. Unlike submersible centrifugal pumps, screw models do not create vibration during their operation. That is why the presence of vibration (and even more so knocking) during the operation of a screw pump is evidence of its improper installation or malfunction. This requires the extraction of equipment from the well and a thorough diagnosis of its technical condition.

Advantages of screw pumps

- The screw pump for water does an excellent job of pumping solids without damaging the mechanisms of the device.

- The device is incredibly compact, which allows it to be used in various conditions.

- The pump weighs relatively little, so it is possible to carry it without any extra effort.

- Screw pumps for wells can be suspended on a cable, which makes it easier to operate in certain situations.

- The device works effectively in both vertical and horizontal positions.

- The pump is able to work for a long time without interruption.

- The powerful mechanism of screw pumps for wells perfectly copes even with thick silty mixtures.

The unit is easy to maintain and repair. - The pump does not create unnecessary noise even with hard work, and there is no vibration, which significantly extends the life of the device.

Varieties and main technical characteristics

There are two categories of screw pumps. The fundamental parameter of such a division is the working depth at which these hydraulic machines are capable of operating. So, depending on this characteristic, they distinguish:

- standard screw pumps;

- deep category devices.

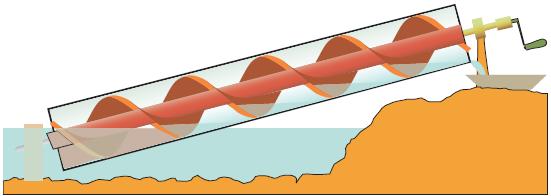

A screw pump belonging to the standard category is used to pump water from wells or wells, the depth of which does not exceed 20–25 meters. Such pumps are often used to service wells with a small flow rate, which were drilled on aquifers of sandy soils (sand wells). Since a screw pump can be used to pump liquid media with different capacities, while maintaining a stable pressure of the generated flow and not paying attention to the content of sand inclusions in the water composition, this equipment is optimally suited for servicing wells of this type.

Screw monoblock pump with the top location of the water intake

The screw well pump of the deep category is equipped with an elongated screw, which determines the impressive technical capabilities of such a hydraulic machine. With high power and reliability, it can successfully serve artesian wells, the water in which is located at a depth of up to one hundred meters. Of course, the price of such models is much higher than the cost of devices of the standard category, but in many cases, when it is required to provide water supply from wells of considerable depth, such equipment is simply indispensable.

Consider the technical characteristics that a borehole screw pump has, related to models of the middle price category:

- performance, showing how much liquid medium the pump is able to pump per unit time - 1500–2000 l / h;

- the pressure of the generated fluid flow is 40–60 meters of water column;

- the temperature that the pumped liquid medium may have is from +5 to +40 ° С;

- particle size of insoluble solids that may be contained in the pumped water - 2–2.5 mm;

- the power of the electric motor that drives the rotor and screw is 1–1.5 kW.

Sprut screw pump range

Most models of medium-priced screw pumps, which are often used to equip household autonomous water supply systems, can be operated from a 220 V electrical network.

Screw pumps for industrial use have more impressive technical characteristics. In particular, such devices, without prejudice to their technical condition, can successfully pump liquid media, the temperature of which significantly exceeds the above values. In addition, industrial screw-type pumps are able to work with liquid media containing insoluble solids in their composition, the particle size of which exceeds 2–2.5 mm.

Downhole screw pump for artesian water intakes

The main part of the body parts of screw-type borehole pumps is made of stainless steel, individual elements are made of durable plastic. To seal the elements of the internal structure of such hydraulic machines, gaskets made of rubber and silicone are used.

Since the moving elements of the internal structure of screw pumps are constantly in contact with the pumped liquid medium, they do not need to be provided with additional cooling.

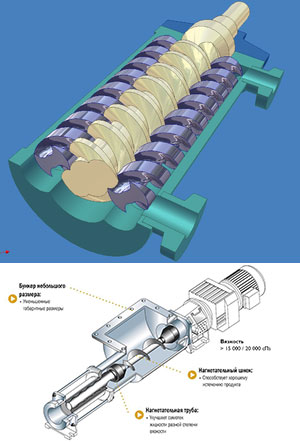

Screw pumps

These devices are similar to rotary ones. In them, a propeller with blades serves as a working element. The unit is similar to the auger of a meat grinder. When it rotates, water is sucked in by the device and supplied under pressure to the outlet pipe.

The advantages and disadvantages of all configurations are the same. They differ only in a few technical characteristics.

Advantages of screw pumps

When deciding which is better - a vortex or centrifugal pump for your water supply system, consider the advantages of the first type of units:

Disadvantages of screw pumps

- Bulky. The difference between a vortex and a centrifugal pump is that the second one is much more compact.

- Inability to dose the supplied volume of water.

- Inconvenience during repair and maintenance - due to the fact that all units with a submersible screw. The device will have to be removed from the well, and if it breaks down in winter, this is problematic.

Calculation of a pump for a well

If the experimental determination of the amount of liquid pumped out by an electric pump does not cause great difficulties, then simple formulas are used to find the required pressure. There are several options for calculating pressure, one of them is as follows:

H(m) = P x 10.2 + Hb + Hp, where

H(m) – determined height of liquid rise in meters;

P - pressure that needs to be created in the consumer's line, indicated in atmospheres or converted to bars (bar);

Нв - height difference between the suction filter of the electric pump and the consumer's line;

Np - pressure loss due to hydraulic resistance of the pipeline.

Rice. 11 Table for calculating pipeline losses

We will consider the choice of a suitable electric pump for a water well using the example of a family of 5 people, whose needs require a supply volume of about 3 m³ / h, with a maximum system pressure of 3 bar. It is assumed that the height difference is 30 m, and the water main is made of a plastic pipe with an internal diameter of 1″ inch (outer diameter 32 mm) for a standard electric pump outlet, its length is 50 meters.

The main difficulty in these calculations is the determination of hydraulic losses in the pipeline. The fact is that they depend not only on the material of manufacture of pipes, but also on the volume of liquid passing through them, therefore, in calculations, this indicator is easier to determine in accordance with the table in Fig. 11.

The columns contain two rows of numbers, we are only interested in the lower figure with the designation of losses on a 100-meter section of the pipeline (data are given in meters).For more accurate calculations, the table shows the losses in the elbows, valves, tees, check valves (the desired parameter is also indicated in meters).

Suppose that we have a system with one check valve, a tee, a stopcock and 3 elbows at an angle of 90 degrees, the total loss length of which, based on the table, is 12 m.

So, we define losses:

Hp \u003d (50 + 12) x 11 \ 100 \u003d 6.82 (m)

And we get the overall result:

H (m) \u003d 3 x 10.2 + 30 + 6.82 \u003d 67.42 (m)

To determine which pump to choose, we will use, for example, a table for Grundfos models (Fig. 12). It can be seen from it that the SQ 3-65 modification is most suitable for this pressure and pumping volume. In the absence of such tables, the electric pump is selected according to pressure characteristics and flow (point 1 in Fig. 13).

Rice. 12 Table for Grundfos pressure characteristics

Selection and maintenance of screw technology

In order to choose the screw technology that is best suited to the needs of your production, it is worth considering some design features. To decide which device to choose, first you should determine the type of device you need, on which the performance indicator in cubic meters per hour or liters per minute will depend.

Then determine the desired pressure level and the height of the liquid column in the nozzle area, the so-called NPSN indicator. In addition, it is necessary to take into account the indicators of the chemical composition, density and viscosity, temperature and acid-base balance of the pumped substances. In addition, consider the amount of abrasives and the possible presence of solid particles in the composition of the pumped material.

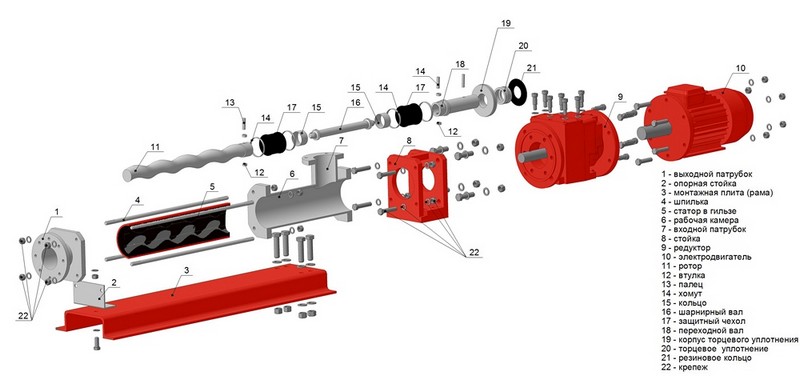

Three screw pump device

Well, do not forget to take into account the voltage and frequency of the power supply, and the type of transmission mechanism from the motor to the pump. A repair kit with the most necessary spare parts, which is included in the list of equipment, will be of considerable help.

A screw pump repair kit usually consists of a replacement screw and a rubber gasket. Therefore, the replacement of the auger in case of wear can be carried out independently without the need to contact the service department.

Areas of use

Screw technology is used in many areas of industrial production and for domestic needs. Among the main types of screw type pressure equipment are:

Detailed screw pump diagram

- screw pump for water (various variations of a centrifugal pump - vacuum electric pumps, pneumatic screw pump, deep submersible pump);

- food screw pump (milk, oil and fat, confectionery and others);

- devices for the pharmaceutical and chemical industries;

- equipment for the oil and gas and petrochemical industries;

- equipment for power plants;

- equipment for the marine and shipbuilding industry.

The increased level of chemical-mechanical resistance to various non-abrasive inclusions and viscous elements that may be present in the liquid is due to the elastomer composition of the stator housing. In addition, it is the composition of the stator housing that determines the maximum allowable temperature range with which screw technology can operate.

For example, in the oil industry, housings are made from NBR grade elastomer, which can withstand temperatures up to 80°C. In screw technology for general industrial use, EPDM and HYPALON materials are used, which are able to operate at temperatures up to 120 ° C. And in the chemical industry, rubber elastomer type FKM is used, which can withstand temperatures up to 150 ° C.

Advantage of screw pumps

The ability to pump water with a large number of inclusions is provided by the special structure of the inside of the device. To understand how a borehole screw pump works, it is enough to consider a conventional kitchen meat grinder, where the main part - a screw or auger - rotates and promotes minced meat or other consistency. In the pump, it is placed in a rubber shell, connected to the engine by means of a cardan shaft. Devices designed for pumping large volumes have rigid shells and are able to withstand significant pressure.When the shaft rotates, the screw moves, which follows the developed trajectory - the turns of the screw and the rubberized inner surface form cavities that constantly rise to the supply hose or pipe. The liquid moves into the chamber, the pressure forces it to continue moving upwards, rarefaction areas continue to form in the inlet pipe, which ensures a uniform supply of water from the well.

If you carefully examine the sample (or, again, a meat grinder), you can see that sand or other inclusions have nowhere to get stuck or linger - they rise along with the liquid flow.

The choice of the optimal equipment is influenced by where it will be installed. For installation in a well, samples are suitable that are attached to the wall of the well shaft. When installing in a well, it is easier - you need a sample with a strong cable. For the home, a model designed for standard voltage is suitable.

Recommendations for choosing a pump for a well

Among the various types of pumping equipment used to pump water from a well or well, submersible devices are the most popular. Such popularity is explained by a number of advantages of submersible pumps, which include:

- no noise during operation;

- the ability to ensure uninterrupted water supply from a serviced well;

- ease of installation;

- the ability to provide water supply from wells of considerable depth;

- compact dimensions;

- no need for additional cooling of the drive motor;

- anti-corrosion properties of the materials from which the body is made.

When choosing such a device, you should pay attention to such parameters as:

- the total need for water intake points in water, which the selected pump must provide;

- characteristics of the well from which water is to be pumped out (diameter and depth);

- geological data of the area where the well was drilled (depth at which groundwater is located, soil type, etc.);

- the presence on the site where it is planned to install pumping equipment, a power source.

The main technical characteristics by which the choice of pumping equipment is carried out are:

- the performance of the device, which characterizes how much liquid it can pump per unit of time;

- head (this parameter, measured in meters of water column, indicates to what height and how far the pump is able to transport liquid through the pipeline system).

This approach when choosing pumping equipment will give you the opportunity to further upgrade your pumping station, if necessary.

Installation of deep-well pumps, as a rule, does not cause any particular difficulties; it can be performed even without experience in implementing such procedures. When operating submersible pumps, as well as pumping equipment of any other type, one should not forget about their regular maintenance, which will significantly extend the period of their trouble-free use.

The principle of operation and the device of centrifugal electric pumps

The main element of a centrifugal pump is an engine hermetically placed in the body of the apparatus, and an impeller in the form of a disk with a one-sided impeller, mounted on its shaft.During operation, the liquid is drawn in through the inlet of the housing, located in the central part of the impeller, and its radially curved blades push it to the periphery. Water is collected in a snail-shaped annular collector and forced out through the outlet pipe under pressure by the next flow of water entering the housing.

Rice. 2 The principle of operation of a centrifugal type deep-well pump

Rice. 2 The principle of operation of a centrifugal type deep-well pump

To increase the pressure in the system, several wheels with separate chambers and outlet pipes, called stages, are often used, from each of them to the next the liquid is transferred with increasing pressure. Centrifugal pumps are highly efficient and can handle turbid water.

Rice. 3 Centrifugal water pump device

Rice. 3 Centrifugal water pump device

The device of a centrifugal type submersible pump of a standard industrial design, made in accordance with GOST, is as follows:

- Frame. In the domestic pump, it is made of a steel pipe with thick walls - this gives the unit high rigidity and strength. For massive devices, the rod method of fastening in the well is used.

- The impellers are designed with dynamic unloading - this led to a decrease in the pressure forces on the axial bearings, and significantly increased their service life.

- Centrifugal wheels are made using a patented technology of durable plastic reinforced with stainless steel - this increases their service life.

- To improve the removal of sand from the mechanism, octagonal bearings are used.

- The inlet of the pump is closed by a perforated built-in stainless steel filter.

- The shaft of the electric motor, on which the impellers are placed, is also made of stainless steel.

- The "squirrel cage" assembly of the electric pump rotor is made of copper alloy - this increases the reliability and performance of the electric motor under heavy loads.

- The significant length of the stator and rotor is designed to increase the reliability of the electric motor, reduce its susceptibility to fluctuations in the supply voltage, and improve cooling conditions.

- Self-aligning angular contact bearing absorbs axial pressure.

- The winding copper wire of the stator with a high-temperature insulating coating (up to 100 C) in the form of insulated bundles is placed in its grooves, the production technology reduces the response of the electric motor to voltage surges and increases its service life.

- The built-in non-return valve prevents the wheel from rotating in the opposite direction, keeps water in the system, making it easier to start the electric motor and preventing water hammer.

Rice. 4 Scheme of the industrial centrifugal pump for water ETsV