Sound absorption

The main purpose of the above characteristic is to prevent sound from bouncing off the wall. According to their structure, soundproofing boards consist of fibers or cells. The noise absorption coefficient varies from 0 to 1. If it is zero, the sound is reflected into the room, and if it is one, the sound is completely absorbed by the material. Materials corresponding to a number of 0.5 and above have a noise absorption characteristic. For a comfortable state, a person should be in a room with a noise of 25 dB, since at a lower coefficient he will feel oppressive silence, and at a higher one he will complain about noise and headaches. A person calmly endures noise up to 60 dB, but a higher volume can adversely affect health. In order to protect yourself from noise, you can use soundproof heaters, depending on what your goal is.

Such material has its own degree of rigidity:

-

solid material - created with mineral granular water. The composition of this kind of raw material includes vermiculite, perlite and pumice. The absorption coefficient is optimal 0.5 dB at a mass of 300 kg/m3;

-

semi-rigid material - mineral wool slabs, having a structure in the form of cells. Sound absorption coefficient from 0.5 to 0.7 dB with a mass of 130 kg/m3;

-

soft material - created on the basis of cotton wool or felt. Sound absorption coefficient from 0.5 to 0.95 at a weight of 70 kg/m3.

In the construction of private houses, soundproofing devices of the last specified parameter are usually used. You should also choose soundproofing with the necessary properties for the nature of the noise emitted.

Types of noise emitted:

-

air, emitted from televisions, receivers, animals;

-

percussion, emitted when walking, repairing, drilling;

-

structural, appearing in the presence of connected load-bearing structures of the building.

To cope with impact noise, soundproofing soft materials with a cell structure are usually used. Sound-proof fibrous materials are used against air, and special cushioning materials protecting the joints of structures are used against structural.

|

|

|

| Acoustic perforated gypsum boards Knauf | Acoustic panels in various finishes |

The nature of sound absorption

The fibrous structure of sound insulation is widely used in modern construction. Such plates perfectly protect from airborne noise, providing comfortable conditions. Few people think about how noise absorption of sounds occurs, while everything is quite simple and easily explained.

It should be understood that when air with sound enters the insulating structure, the average sound absorption coefficient, then it rubs against the fibers of the product. Each villus distributes sound through friction and vibration, absorbing it. Depending on the noise level, both the coefficient and the design index of the slab are selected. With proper calculation and installation, it is possible to provide the necessary level of protection with minimal material losses.

Physical foundations of building acoustics

The concepts of “architectural acoustics” and “room acoustics” are firmly rooted in the terminology of modern architectural and design projects. In practice, this implies the solution of two interrelated tasks: protecting the room from external sounds and ensuring the high-quality propagation of useful sounds inside it. Both tasks involve reducing the energy of sound waves, but the first - when they pass through the fence (sound insulation), and the second - when reflected from the fence (sound absorption). In this case, there are two concepts - "sound" and "noise".

Sound is a mechanical vibration of an elastic medium (gaseous, liquid or solid) in the range of audible frequencies and is characterized by frequency, intensity and sound pressure. The speed of propagation of sound waves depends on the elastic properties, temperature and density of the medium in which they propagate. For example, the speed of propagation of sound waves in air at a temperature of 20 ° C is 343 m/s, in steel - 5000 m/s, in concrete - 4000 m/s.

Noise is a random chaotic mixture (set) of sounds of different frequencies. According to the nature of distribution, it can be air, structural and impact. Airborne - this is noise emitted directly into the air, and the source of noise is not associated with building envelopes. Structural noise is created from mechanical impact (for example, when vibration of communications in buildings) and spreads to other rooms by means of a sound wave in solid conjugated structures, i.e. it is the sound inside the building structure. Impact noise is created from the direct contact of an object against an object (hitting a wall, knocking on pipes, etc.) and also spreads over long distances.

Noise level is measured in decibels (dB). Sanitary standards, depending on the sound frequency, establish the permissible noise level in industrial premises of 80 ... 85 dB, administrative - 38 ... 71 dB and hospitals - 13 ... 51 dB. The minimum requirements for sound insulation of partitions between apartments are 54 dB, for interior partitions - 43 dB. Prolonged exposure to noise of 90 dB or more adversely affects people's health (nervous disorders, hearing loss and other more serious consequences).

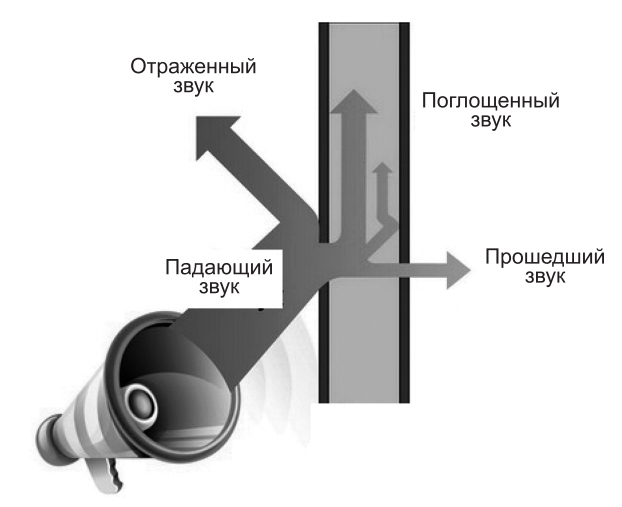

Rice. 1. Scheme of the impact of sound waves on the material of the fence

When a sound wave falls on the enclosing surface, part of the sound energy is reflected, part is absorbed by the material, and part passes through the enclosing structure (Fig. 1). Materials and products that can reduce the energy of sound waves and reduce the volume level of internal or external sound are called acoustic. Giving them soundproofing properties is based on three main physical phenomena: the reflection of air sound waves from the surface of the fence, the absorption of sound waves by the fence material and the damping of impact or airborne noise due to deformation of the structural elements and materials from which it is made. At the same time, their physical essence lies in the fact that the energy of a sound wave incident on them is reflected to a much greater extent than it passes through them.

Soundproof material and its technological properties

In the cinema, it is necessary to create an unprecedented acoustic ideal sound insulation with the help of additional materials. This is necessary so that all vibration, all hum and all sounds must remain in one isolated room. Carpet, in turn, perfectly copes with the task entrusted to him. It not only easily reduces sound transmission, but also does not violate acoustic performance at all. This material is very easy to install as it is very malleable and very easy to cut and stretch. Without problems, it can also be fixed on the ceilings, which forms a perfectly smooth surface.

The only condition for the installation of the Carpet is the temperature of the room. All soundproofing should take place in a room whose temperature should not fall below 16 degrees. Otherwise, the carpet completely stops stretching, which does not allow the webs to be joined on uneven areas.

In such cases, the use makes it possible to minimize noise and provide comfortable acoustic conditions for the rooms that are adjacent to the cinema hall.

Do not forget that the soundproofing of the hall makes it possible to enjoy the film, completely immersing in its atmosphere, without being distracted by a rather loud noise from the corridor or the neighboring cinema hall.

In the modern world, for the full implementation of the sound insulation process, materials are used that sufficiently have sound-reflecting or sound-absorbing properties.

Priority areas for soundproofing a cinema or bowling hall.

The most important task is to isolate the sounds of a cinema or bowling alley from nearby rooms. Therefore, soundproofing is necessary not only for walls, but also for ceilings and floors. This will prevent further sound propagation.

For a cinema, soundproofing of all rooms in which a movie is being watched is mandatory.

An important task is to provide acoustic comfort directly in the hall where a movie is being watched or a bowling game is being played. This requires sound insulation as well as technical equipment: air conditioners, fans, refrigerators, etc.

Do not forget that soundproofing should not interfere with the comfortable viewing of movies.

The speech of the actors should be easily receptive and audible. In a movie theater, the sound needs to radiate evenly and rationally through the auditorium in order to reach all the rows at the same time. In the bowling alley, such subtleties are not provided.

Therefore, the owners of such premises should carefully and thoughtfully choose soundproofing materials to prevent conflict situations with visitors.

When purchasing such acoustic materials, you should also pay attention to the thickness of these coatings. For those who have a large enough area, do not worry

In this case, the thickness of the coating will not be particularly noticeable. But for owners of small rooms and premises, this issue is a priority. To do this, it is necessary to choose those coatings whose thickness should not exceed 1.2 centimeters.

They should not forget that before buying noise-absorbing materials, it is necessary to determine the type of noise character.

When noise is received from neighbors, it is necessary to soundproof the room from the side of the walls. Such equipment, which has noise-absorbing effects, is suitable for those who watch TV loudly or play musical instruments. In this case, all sound is converted into heat.

For the best option, we recommend purchasing complex materials. But it must be remembered that this may lead to some loss in area. This is due to the installation of equipment and the installation of thick layers of sound insulation.

You can call us at tel. +7 (495) 227 41 93 and we will also tell you in detail about the terms of delivery, installation and operation features.

Rockfon (Denmark) and Parafon (Sweden) Acoustic false ceiling. Rules and choiceEcophon Ecophon (Sweden) Soundproofing between adjacent rooms Vertical soundproofing

Sound-absorbing materials and products

Sound-absorbing materials include materials that, as a rule, have through porosity and are characterized by a relatively high sound absorption coefficient (α > 0.4). They are intended for use as an absorbing layer in the structures of lining the internal surfaces of rooms and noise protection structures in order to reduce the intensity of the reflection of sound waves, as well as in the structures of light multilayer fences in order to improve the insulation of airborne noise. Their task is to absorb sound, prevent it from reflecting back into the room from the barrier and thereby regulate the acoustic characteristics of the room.

The ability of materials to absorb sounds is mainly due to their porous structure and the presence of a large number of communicating open pores on the side of sound incidence. The maximum pore diameter should not exceed 2 mm, and the total porosity should not be less than 75%. This is due to the fact that when a sound wave passes through the thickness of the material, it sets the air contained in its pores into oscillatory motion. Small pores at the same time create more resistance to air flow than large ones.The movement of air in them is inhibited, and as a result of friction, part of the mechanical energy is converted into heat. The higher the open porosity of the insulating surface, the higher the sound absorption. Conventionally, porous sound-absorbing materials, resonant sound absorbers and individual sound absorbers are distinguished.

Sound-absorbing materials can have a fibrous, granular or cellular structure and have different degrees of rigidity (soft, semi-rigid, rigid or hard). Solid materials with a fibrous structure are made in the form of mineral wool slabs (mainly stone or glass) on a starch or synthetic binder. Their density should be up to 200 kg / m3, the diameter of the fibers should be at least 1 micron and not more than 20 microns, and the content of non-fibrous compounds (prills) should not exceed 5% by weight.

The surface of mineral wool boards, as a rule, is painted or may have another coating that is decorative and permeable to sound waves, and has a different texture (corrugated, grooved, cracked). The sound absorption coefficient is in the range of 0.6 ... 0.7, the density is 300 ... 400 kg / m3. Sound-absorbing boards can also be made from white and colored cements and porous aggregates (perlite, vermiculite, pumice, wood wool), cellular concrete, cast gypsum, etc.

As semi-rigid, mineral wool boards with a synthetic binder content of 10 ... 15%, wood-fiber boards, from porous plastics of a cellular structure (polystyrene foam, polyurethane foam, etc.) are used. The sound absorption coefficient of such products is in the range of 0.5 ... 0.75, density - 80 ... 130 kg / m3.

Soft sound-absorbing materials (rolls, mats) are also made from mineral wool without a synthetic binder and in combination with perforated sheet screens (aluminum, polyvinyl chloride). The sound absorption coefficient is in the range of 0.7 ... 0.95, the density is up to 70 kg / m3. Soft and semi-rigid sound-absorbing fibrous materials and products should be manufactured and used only with protective (blown or non-blown) shells that prevent fibers and dust from spilling out. At the same time, protective shells should not affect the sound-absorbing properties of the protected material.

Currently, the most effective sound-absorbing materials are super-thin mineral (glass and stone) fibers. However, their use is allowed in the presence of special coatings that provide a high degree of protection against unwanted emission of fiber particles. At the same time, in order to perform its acoustic functions, such a coating must be porous; leaky. In some cases, a variety of fabrics, carpets, skins and rugs, which also have some acoustic effect, can be used as finishing coatings for sound-absorbing structures.

The sound-absorbing properties of materials are also affected by their elasticity. In products with a flexible deformable frame, there are additional losses of sound energy due to the active resistance of the material to forced vibrations under the action of incident sound waves. The main qualitative characteristics of all sound-absorbing materials and products are dynamic stiffness and dynamic modulus of elasticity, specific resistance to air flow and air blowing, normal and reverberation sound absorption coefficients and indexes of improvement in impact noise insulation and sound absorption.

Characteristics of acoustic products

Soundproofing materials from different manufacturers (summary table No. 2).

Table number 2

|

Manufacturer/ product |

Density, kg/m3 | Temperature resistance, °С | Moisture resistance, % | Environmental friendliness |

| Illbruck/ Pyramide | 9,5-11 | up to 150 | — | safe |

| Ecophon/ Gedina | 125-200 | up to 800 | 95 | safe |

| Ecophon/Focus | 125-200 | up to 800 | 95 | safe |

| Rockfon/ Koral | 70-90 | up to 1100 | 95-100 | safe |

| Rockfon/ Sonar | 200-280 | up to 1100 | 95-100 | safe |

| Parafon/ Exclusive | 140-280 | up to 1100 | 95 | safe |

| Parafon/ Classic | 100-140 | up to 1100 | 95 | safe |

Continuation of table number 2

|

Manufacturer/ product |

Thermal conductivity, W/mK | Light reflection, % | Possibility of cleaning |

| Illbruck/ Pyramide | 0,054 | — | dry/wet |

| Ecophon/ Gedina | 0,040 | 84 | dry/wet |

| Ecophon/Focus | 0,040 | 84 | dry/wet |

| Rockfon/ Koral | 0,034 | 84 | dry/wet |

| Rockfon/ Sonar | 0,034 | 84 | dry/wet |

| Parafon/ Exclusive | 0,040 | 85 | dry/wet |

| Parafon/ Classic | 0,040 | 83 | dry/wet |

Soundproofing materials in this table #2 reflect the difference in performance. For example, foam acoustic based material melamine resin Illbruck (Germany), has a low density, as well as a rather low resistance to temperature extremes. This indicates the need to take into account that the scope of such materials is very limited. Soundproofing materials and their density produced by Ecophon, Parafon and Rockfon are about the same level. The similarity of this parameter is provided by a similar insulating structure of this material. Soundproof boards of these brands have a density that is much higher than that of foamed materials, and in relation to the density of gypsum panels (900-1200 kg/m3) it is lower. At the same time, products for sound insulation made of basalt fiber are distinguished by the properties of fire safety, moisture resistance, environmental friendliness, thermal insulation and durability. This is quite a big advantage, allowing them to be used in the installation of suspended ceilings and as acoustic soundproofing wall panels for all types of premises: from apartments and offices to cinemas and recording studios.

Soundproofing products in the premises of cinemas perform the main task - this is the preservation of the sound regime throughout the entire area. Materials should not allow this sound to spread outside of it.

The implementation of such sound insulation is carried out immediately by a set of actions. For example, for such work, several types of materials are used at once, which are engaged in sound absorption. Such materials sheathe not only walls and ceilings, but also the floor.

Such coatings are called carpet. It is necessary when decorating rooms, because it has a very beautiful and even surface with a short pile. This makes carpet very similar to carpet or carpet.

Also for owners of cinemas, soundproof products are provided in a huge selection of colors. And there are not only standard colors, but also various shades that will suit almost any interior and hall design. Owners can choose not only the quality that suits them, but also choose the color, the ratio of which to the upholstery of the furniture will be ideal.

Our company can offer its clients:

- Acoustic materials and technologies

- Carpet for the cinema

- Rockfon panels

- Carpet for cinema