A bit of theory

Any noise experts refer to three types:

- air

- drums

- structural

The most common noise is airborne noise - any street sounds - passing vehicles, buzzing equipment and sounds made by animals and people.

impact noise occurs when shocks appear, for example, when hammering nails or moving furniture.

TO structural noise - refers to the sounds of nature penetrating into people's dwellings or any other noise propagating through the structures of the house with insufficient sound absorption measures applied during the construction of this house.

The main tasks that soundproofing material must solve are sound insulation and sound absorption. It must either absorb or reflect sound, or better, do both at the same time.

Soundproof materials usually include dense materials, such as concrete, brick, drywall, capable of reflecting sound.

Sound-absorbing materials are materials that can absorb noise and prevent it from being reflected from an obstacle. Sound-absorbing materials have a fibrous, granular or cellular structure.

The sound absorption characteristic is evaluated by the sound absorption coefficient. The sound absorption coefficient varies from 0 to 1. At a zero value of the sound absorption coefficient, the sound is completely reflected, at full sound absorption the coefficient is equal to one. Sound-absorbing materials include those that have a sound absorption coefficient of at least 0.4.

Scientists believe that people feel very comfortable with a noise of about 25 dB. With a smaller value, there is a feeling of unnatural, “ringing” silence, while the person feels some discomfort.

Usually, a person reacts normally to noise up to 60 dB, with prolonged exposure to noise of 90 dB, a serious nervous breakdown occurs, and a noise level of more than 100 dB threatens hearing loss.

Now there is a good choice of materials that can reduce the impact of noise on a person in various life situations.

Porous or fibrous, having a high sound absorption coefficient, cope with airborne noise. To combat impact noise, elastic materials with a closed cell structure are used. Structural noise is reduced with the help of a cushioning material to protect the joints of load-bearing elements.

Scope of application

Best of all, penolon copes with impact noise. Polyethylene foam soundproofing is installed on various objects. These are private houses and apartments in high-rise buildings, office space and social and cultural facilities.

When sticking sheets of cellular polyethylene on the walls in the room, of course, living conditions improve. In cool summers and in the off-season, when the central heating is not working, the material contributes to the preservation of heat in apartments and offices. Penolon is also advised because it is able to speed up repair work. If there are minor irregularities on the walls, the foam acts as a leveling material. The walls can not be puttied, a soft base will hide the flaws.

Penolon is used as a substrate for wallpaper and various floor coverings, including it is laid under laminate and parquet. Foamed polyethylene under the trademark "Acoustic" solves the problem that has prevented the creation of a sound barrier between floors for years. If earlier it was necessary to make a lot of efforts to ensure silence, up to the creation of expensive engineering structures, now the issue is solved very simply. Neighbors below will not hear a sound if there is a foam padding in the apartment above them.

The material is sold in rolls. Anyone can lift and carry it by hand, it is very light. As a rule, the width of the roll is one and a half meters.The thickness is different: the thicker the layer, the smaller the footage of the roll. For example, with a material thickness of 5 mm, the length will be 100 m. If a thicker layer is required, for example, 10 mm, then the length will be halved and will be only 50 m.

Varieties of the insulator

There are many models of this sound insulator on the modern market, each of which is included in one of the following classification groups:

- Smooth roll materials, most often used in floor insulation (substrate for laminate or parquet);

- Reflective insulators with one-sided foiling, used both in insulation and in sound insulation;

- Harnesses, the scope of which are various seams, joints and other gaps;

- Tubular heaters used for insulation of communications or pipelines.

Among the product range, you can find another variety - an insulator covered with foil and reinforced with fiberglass. Due to its high characteristics, the material can be used even at a temperature of +180 degrees Celsius. This is especially true when protecting wooden structures: for example, it is possible to soundproof a wooden ceiling with polyethylene foam. After all, everyone knows that hot air usually rises, so not every insulator can protect the ceiling.

The crying of children, the regular quarrels of neighbors with subsequent reconciliations, the endless repairs at the neighbors two floors above, and many other sounds - all this can unbalance even the most calm person. The fact is that when you move into a new apartment, you have lost sight of such an important point as soundproofing.

Characteristics of the insulator

We talked about the advantages of building materials, one of which is the possibility of application in various areas of the construction industry. But the review of the insulator will be incomplete without specifying the technical characteristics. So, let's begin:

- Foamed polyethylene has an excellent density - from about thirty to eighty kilograms per cubic meter (depending on the model).

- The thickness of the rolls is very different - from one millimeter to fifty, which makes it easy to choose the right product.

- The range of operating temperatures is also quite wide - the operation of the material is possible both at a low temperature of minus sixty, and at a critically high temperature of plus eighty.

- The thermal conductivity coefficient is optimal - W / mºС - 0.04.

- Daily water absorption by volume is less than two percent (and in some models even eight tenths).

- Vapor permeability index - mg / mchPa - up to 0.002.

The most common materials for heat and sound insulation

Foamed polyethylene

The versatility of foamed polyethylene allows it to be used for insulating window openings, gaps between wall ceilings, when installing doors, etc. For the convenience of construction work, foamed polyethylene is produced in the form of rolls, in the form of tubes and cords. In addition to thermal insulation, it perfectly copes with the task of hydro and sound insulation.

The main characteristics of polyethylene material: environmental friendliness, durability, versatility, elasticity, resilience, resistance to mechanical and chemical stress, low thermal conductivity and water absorption.

Noise may vary.

- mechanical (from steps, moving furniture, falling objects, etc.);

- caused by air vibrations (loud music, barking dogs or screams).

Of course, it will not work to completely reduce all noise to “no”, but it is quite possible to make noise discomfort minimal. This will require good soundproofing in the apartment.

No less important is the well-made thermal insulation of the room. It has been proven that heat loss in an ordinary high-rise building can reach up to 40%. This is due to the fact that the materials traditionally used for construction are not able to retain heat. Thermal insulation in the house is designed to maintain a comfortable microclimate for a person. Firstly, it reduces heat loss from the inside, and secondly, it limits the flow of heat in summer, which is necessary for the normal functioning of cooling electrical appliances.

It is noteworthy that the same materials can often be used for heat and sound insulation, which are conditionally divided into:

Such modern materials can be used for roofing, walls, floors or have a highly specialized purpose.

Basic materials

Various materials can be used to reduce noise:

- fiberglass

- foamed polyethylene

- fibrous materials

- spray applied polymers

- stone wool mats

- based on foamed rubber

The most effective materials with high sound absorption coefficients are mineral wool and fiberglass products.

Fiberglass-based materials have increased elasticity, vibration resistance and strength. Good sound absorption is due to the voids between the fibers, which are filled with air. Typically, the length of fiberglass is 5 cm. Also, these materials are fireproof, non-hygroscopic, light in weight, high vapor permeability, chemically passive and do not cause corrosion of metals. Glass wool is used in the manufacture of acoustic partitions in the form of plates and rolls to create a soft layer in multilayer sound-absorbing structures.

Materials based on mineral wool are a fibrous material obtained from silicate melts of rocks, metallurgical slags and their mixtures. The average length of the stone fiber is 1.5 cm.

They, like fiberglass, are fireproof, chemically passive and do not cause corrosion of metals in contact with them. Good sound absorption is ensured by the fact that the fibers are arranged randomly in horizontal, vertical directions, at different angles to each other. Unlike glass wool, mineral wool is somewhat heavier.

Currently on the market there are materials for sound absorption of brands such as

K-Flex, Rockwool, Energoflex, Izover, URSA, Knauf and others.

Pros and cons

Despite the fact that foam has appeared on the construction market relatively recently, professional master finishers often use it for major and cosmetic repairs of residential premises. Feedback from customers who have already tested the new material is only positive. Penolon justified itself as an excellent thermal insulation. This is confirmed by people who lived through the winter period, first without a wallpaper substrate, and then with it.

The sound insulation of the material was to the taste of those who have cheerful neighbors and families with small children living behind the wall. It is noted that a layer of cellular material significantly reduces the penetration of sounds. Measurements showed an efficiency of 30%.

The advantages of the material are not limited to the listed characteristics. The positive qualities include:

- low moisture absorption (no more than 1%);

- long service life (according to the manufacturer, it is at least 80 years);

- lack of decay and the impossibility of the appearance of fungal formations;

- resistance to high and low temperatures;

- hygiene and environmental friendliness;

- the ability to restore shape after unloading;

- light weight, which facilitates the work;

- resistance to oils, gasoline and other chemicals;

- elasticity;

- strength;

- quite democratic cost, that is, availability for a wide range of consumers.

Floor soundproofing based on cross-linked polyethylene foam. What is the fundamental difference

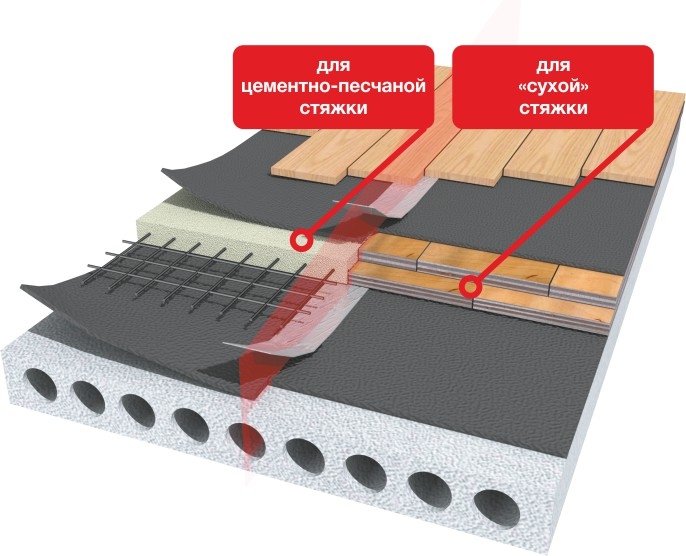

The problem of insufficient sound insulation in modern apartments is particularly acute today. Often there are situations when you can hear neighbors talking or moving furniture in the room. The noise that occurs during mechanical action on the floor structure, for example, when various objects fall on the floor or knocks, is called impact noise. To reduce such noise, professional builders turn to a simple but effective floating floor design, and also use a special sound-absorbing substrate under floor coverings. The design of the "floating floor" is a screed of concrete or gypsum over a layer of soundproofing material. The best sound insulation in this design is provided by the absence of a connection between the ceiling and the walls; in this solution, it provides the best sound insulation in buildings with reinforced concrete floors.

The market for soundproofing materials for the “screed” device is represented by various types of materials, such as cross-linked and non-cross-linked polyethylene foam, fiberglass (fiberglass), polystyrene foam. The most famous brands of soundproofing based on fiberglass: Shumanet, Shumostop. But one of the most popular materials used in the construction of a "floating floor" are materials based on non-crosslinked (NPE) and cross-linked polyethylene foam (PPE).

Builders understand that today non-crosslinked polyethylene foam is not the most suitable material for soundproofing under a screed. Under the weight of a cement-sand screed, such material becomes thinner to a film and becomes unsuitable for sound insulation. The test results prove that the soundproofing characteristics of samples of non-crosslinked polyethylene foam during the first year of being under load deteriorate due to a decrease in the thickness of such materials by 40%. This is because non-crosslinked polyethylene foams do not have good ability to withstand compressive loads, have weak molecular bonds and are subject to aging.

Therefore, today, experts in the construction industry are increasingly using more technologically advanced cross-linked polyethylene foam. The choice of such sound insulation for floors of a residential building is justified. During the production process, the material acquires a denser structure that is resistant to loads (for example, the action of a cement-sand screed), therefore, in the design of a “floating floor”, it does not sag over time. According to the test results of the manufacturer of cross-linked polyethylene foam Refom, the material shows thickness stability under load and only an improvement in the impact sound index.

It is important not to forget about the economy, cross-linked polyethylene foam is more economical than analogues made of fiberglass and fiberglass (approximately 1.5-2 times). Among the trademarks of cross-linked polyethylene foam presented on the construction market of St. Petersburg, it is worth noting Refom, Penolon, Polyfom and others.