Sealing seams and joints

If in new buildings the problem is the poor quality of filling joints, then in old houses cracks are added to this, which are the result of deformations and displacement of elements. These defects allow sounds to freely penetrate structures. A soundproofing device without the elimination of through gaps will not provide confidence in the final result, since the protective layer will be insufficient.

If work is carried out on a bare floor base, then you should carefully evaluate the joints between the panels and the interface lines between the wall panels and the ceiling. If cracks, chips are found, the cement or other sealing filling is removed to the base material, and the resulting void is filled with mounting foam or non-hardening building sealant.

Treatment of joints and cracks in floor panels.

When improving the properties of the existing coating when performing repairs without completely dismantling the base, it is recommended to open it along the perimeter to the base, fill the joint with sealant and cover it with a cement-sand screed to the level

Sometimes they do not pay attention to the passages of pipelines through the floor panels located in the bathrooms and kitchen. By eliminating through gaps around them, they reduce the penetration of sounds and uncontrolled air exchange, which is a source of odors and affects the microclimate of the premises

Features of processing walls and ceilings

From the point of view of the ratio of price and quality, the best option for soundproofing walls in monolithic houses is drywall. It is mounted on a metal frame. Apply 2-3 layers of GKL, soundproofing material (most often, mineral wool) is laid between the profile

The frame structure is given special attention. It is fixed around the perimeter to the protective structures (you can use wall mounts)

Further work is carried out in the following order:

- The outer surface of the metal profile, when fixed to the wall, is covered with a sealant.

- The frame is mounted to the floor and ceiling with anchors and dowels. To improve sound insulation in monolithic houses, it is advisable to use soundproof suspensions.

- The cavities formed by the frame are tightly sealed with mineral or specialized acoustic wool. (The last option is preferred.)

- Lay communications inside the sound-absorbing layer, sealing the exit points.

Wall cladding is carried out by means of a combination of soundproofing materials. The structure of two layers of drywall sheets, covered with GVL, is characterized by excellent performance. GKL joints should not be combined in different layers. The joints of the lower level must be covered with the upper ones, covered with a non-hardening sealant or putty.

There is an alternative solution for soundproofing walls in a monolithic house: sandwich panels, ZIPS panels. Products are mounted directly to the wall.

To protect against sounds, a vibration-independent metal frame on suspensions is assembled from the premises from above. The empty space between it is filled with mineral (or acoustic) wool, sheathed with soundproof panels with quartz sand. At the final stage, the ceiling is finished with plasterboard sheets.

Silence is the key to peace

It is difficult to talk about a quiet life if extraneous sounds are heard from everywhere - both day and night. The neighbors' television, barking dogs and other noises and sounds interfere with a good rest in the early morning. Constantly chattering neighbors cause irritation, often scandals arise for this reason. Poor soundproofing can easily ruin your mood.

Even if you ask your neighbors to be quieter, it is unlikely to give anything, so you cannot do without good sound insulation in a city apartment. How to improve the sound insulation of the apartment?

It is not necessary to entrust this task to professionals, as their services are not cheap. It is much more economical to purchase the necessary materials, learn the basic principles and soundproof your home on your own.

Soundproofing is a rather troublesome business, but the efforts made are worth it in order not to experience discomfort due to third-party noise in the future.

On a note! Based on the personal experience of numerous residents of panel houses who made soundproofing of apartments, mineral wool is the best sound insulator.

Other materials can be combined with each other and supplemented with mineral wool, but no other sound insulator has such a high level of sound absorption, and besides, it is cheap and practical. The choice can be stopped on one of the varieties of wool, for example, basalt, or fiberglass.

Cotton-type soundproofing materials are sold in various versions: in the form of plates (very convenient to use), in rolls, in the form of mats. The main thing is that it should not be a half-rigid variety: although such a material has a smaller thickness, it has a lower degree of noise absorption.

It is precisely the parameter of thinness that is lacking in insulators based on cotton wool. Thin sound insulators make it possible to economically use space, but in terms of creating comfortable living conditions, they also heat-insulate surfaces

Taking into account the fact that drywall will also be used to mask the batten and insulator, the living space will decrease by about 10 cm from all surfaces for which you will perform soundproofing

All surfaces need insulation, although many believe that it is enough to take such measures only for walls - this is a delusion. The floor, ceiling and other surfaces of the room also cannot be ignored. In addition, it is pointless to count on complete sound insulation, since when building panel-type houses, they do not adhere to the rules for protecting the structures of the structure from extraneous sounds.

Important! Structural noise waves transmitted by vibrations through the constituent structures of buildings cannot be completely eliminated by anything - they can only be reduced. If someone starts repairs on other floors, the echoes of the work will inevitably be heard in your apartment

If someone starts repairs on other floors, the echoes of the work will inevitably be heard in your apartment.

Applicable materials

The range of materials is varied. Noise isolation of the floor in the apartment is carried out using the following of them:

- Polymers and plastics with derivatives (sound insulators and reflectors);

- Materials with mineral components (mineral wool, cement mortars, expanded clay);

- glass wool;

- Chipboards and other modern building materials.

Noise-absorbing substances are divided into groups according to the degree of rigidity:

- Solid. Contains vermiculite and perlite. Created with the participation of granulated mineral wool.

- Semi-rigid (cellular mineral wool was used).

- Soft (based on fiberglass, felt or mineral wool).

It is hard materials that reflect the sound in the house: brick, drywall, concrete, stone, etc.

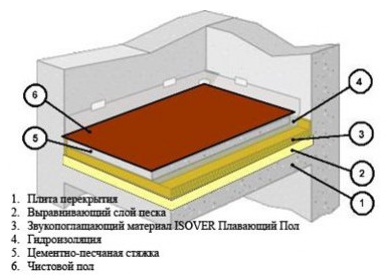

floating floors

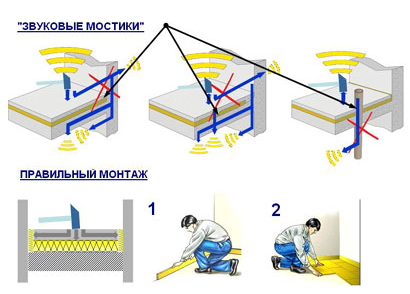

Most extraneous sounds are transmitted in the form of vibrations from the walls to the base. If, say, it is possible to somehow separate the walls from the floor, then it will be possible to significantly increase the soundproofing characteristics of the room. This is what was taken as the basis for the development of technology for laying a floating floor.

The rough floor is filled with a screed that does not reach the walls. Between the walls and the screed, a material is laid that levels out all vibrations. Installation work is easy. They can be done by hand. True, this method of soundproofing is quite expensive.

Consider how to properly equip a floating floor. Installation work begins with the preparatory stage. It is necessary to level the rough base.If there are defects, then they need to be eliminated. In this case, cracks, gaps or chips are puttied, and it is advisable to cut the bumps. You can, of course, level the base, focusing on the highest point of the floor.

But in this case, it will be necessary to lay a sufficiently thick layer of screed. As a result, the height of the room will be significantly reduced. Yes, and the difference between the height of the floor in different rooms will be significant. Therefore, you will have to puzzle over how to arrange the transition from one room to another.

Cracks, chips or gaps can be sealed with a cement-sand mortar, sealant or self-leveling mixtures. The easiest way to work will be with sealant. It is sold as a ready-to-use formulation. A cement-sand mortar or self-leveling mixture will still have to be prepared.

Next, you need to lay the insulating material. It is better to opt for those materials that are resistant to moisture. Otherwise, you will also have to deal with waterproofing the floor. It is advisable to lay a reinforcing mesh on the heat-insulating material, which will make the structure more durable.

Then, you need to lay the screed. It shouldn't stick to the walls. Therefore, you first need to lay a material along the walls that levels vibrations. If it is unstable to moisture, then it must be waterproofed.

Next, you need to lay the screed. If the room in which soundproofing is performed is large, then beacons should be used when arranging the screed. If the work is done by hand, then it is advisable to use self-leveling mixtures when arranging the screed. They are plastic, which facilitates installation work.

The last stage of work involves the installation of a decorative floor covering, which, like the screed, should not come into contact with the walls. Gaps between decorative flooring and walls created during installation should be sealed with a vibration dampening sealant.

After the sealant has dried, you need to install the baseboard. At the same time, this decorative element should be fixed only to one of the bases: either to the floor or to the wall. Sound proofing is ready.

Such sound insulation has a number of advantages, which include a long operating period, protection against the penetration of extraneous noise, the absence of mechanical fasteners, and even distribution of the load over the surface.

In addition, after the arrangement of the floating floor, the characteristics of thermal insulation increase, which is important in a panel house. All installation work can be done by hand

During operation, there is no need for repair or maintenance of the floor.

As for the disadvantages, such sound insulation is expensive and requires strict adherence to the installation technology.

Soundproofing the ceiling and floor in the apartment

Soundproofing the ceiling is very important, since most often the inconvenience is associated precisely with the noise that the neighbors from above produce. The soundproofing of the ceiling is carried out according to the same principle as the soundproofing of the walls.

First, a frame is assembled from the profiles, and one should not forget about rubber gaskets at the points of its attachment.

After that, all its internal space is filled with some kind of sound-absorbing substance: glass mat, foam rubber or special sound-proof slabs of basalt or mineral wool. Such plates, with their small thickness, have an excellent absorbing effect. After installing them, the ceiling height in your apartment will decrease quite a bit.

If there is no intermediate layer between the floor covering and the ceiling, the noise from the apartment below will constantly penetrate into your apartment. At the same time, your neighbors will be able to hear everything that is happening in your house, down to the sound of moving chairs and even footsteps. The issue of soundproofing the floor is solved with the help of a special sound-absorbing material that has a small thickness.

This material consists of special paper, fiberglass, foamed polymer or other synthetic material. During the repair process, depending on the type of sound-absorbing layer material, such material can be placed either directly under the screed or under the laminate. This type of sound insulation perfectly dampens vibrations, and also absorbs shock. When laying the soundproofing layer, a waterproofing film is placed on top of it.

Soundproof underlays

This group of building products allows you to increase the insulating properties of the coating in a panel house without completely dismantling existing structures. Due to the small thickness, the materials do not cause the floor level to rise from the top of the allowable. Depending on the type of finish layer, acceptable height, acoustic characteristics of the substrate, a product with suitable parameters is selected.

Roll and slab substrates based on natural cork are popular. In addition to environmental friendliness, durability, immunity to moisture, they successfully combine low thermal conductivity with the ability to absorb acoustic vibrations. A tangible result is achieved by using modern multilayer products, for example, a felt coating reinforced with a polymer base.

Underlay made of natural cork.

Cheap and relatively effective materials include soft fiberboard substrates, despite the name, the material is not subject to deformation, retaining its original thickness under load, which allows it to be used under type-setting and panel parquet and laminated coatings. The choice of soundproofing substrates in the distribution network is significant, manufacturers are constantly expanding the range of products, but when buying them, one must not forget that, despite advertising promises, the possibilities of thin materials are limited, although often sufficient.

Building types

Frame-monolithic buildings (monolithic houses) have gained recognition due to the simplicity and high speed of their construction. Apartments in them are inexpensive due to the cost-effective construction technology. Reduces the price and the fact that most of them are usually sold "under repair". This means that a new occupant of a monolithic house receives the frame of his dwelling, consisting of walls, columns, ceiling and floor (at best, with a flooded screed), and has the right to dispose of the layout and decoration of the future apartment at his own discretion.

Indeed, it is very convenient, but the sound insulation of an apartment in a monolithic house (new building), or rather, its quality, depends solely on the owner’s costs for its implementation. It is at this stage that you need to think about and make significant investments in soundproofing your home, because then it will be more difficult and expensive.

Building structures made of bricks or blocks quickly absorb a significant part of sound vibrations, preventing their propagation. Owners of wooden houses using particle-cement boards do not need to worry about this at all. The construction materials of such structures are in themselves good sound insulators.

Worse, if not catastrophically bad, is the case with panel and monolithic buildings. Panels for construction are made by pouring concrete into a metal core. Therefore, such structures are homogeneous, and, therefore, are a good conductor of sound vibrations. Soundproofing an apartment in a monolithic house is the most in demand.

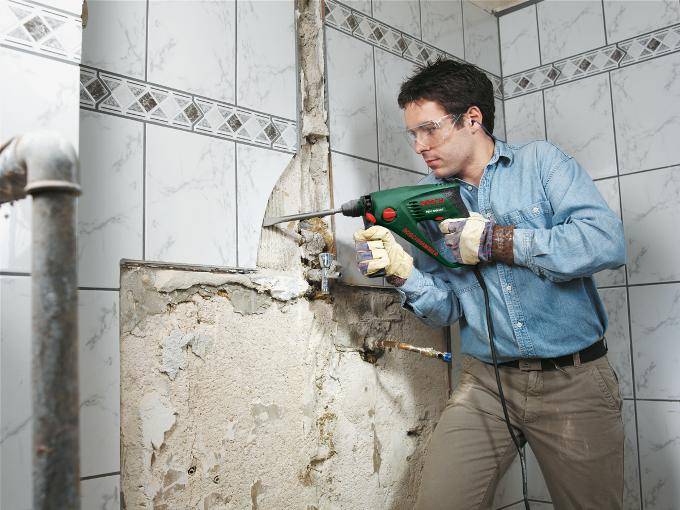

Monolithic technology implies the manufacture of a metal frame of the entire building with its subsequent pouring with concrete. In this case, a situation is obtained when all the supporting structures are rigidly interconnected, more precisely, they constitute a monolithic structure.Due to this, there are simply no obstacles to the propagation of shock vibrations, and the sound from the operation of the perforator on the first floor of the building can be heard well on its last level due to the ease of its propagation along the monolithic column. This implies the special requirements that the sound insulation of an apartment in a monolithic house imposes.

Slabs or monolithic surfaces (walls, floors and ceilings) form devices similar to membranes. Through such structures, airborne and structural noise propagates almost unhindered.

It is for these reasons that the sound insulation of an apartment in a panel house, and even more so in a frame-monolithic one, requires special measures to be taken at the repair stage.

Types of noise

Let's start with the fact that the noises are different from each other. Currently, experts divide them into four groups:

- Drums. For example, neighbors hammer a nail into the wall separating your and their apartment.

- Air. These include a conversation, a crying child, the cry of an animal or bird, waves from music.

- Structural. This type includes wave vibrations inside the building, which are transmitted through its supporting structures. For example, the movement of the elevator, the creaking of the front door, the waves inside the ventilation system from the rotation of the fan propeller.

- Reflecting. A complex view, which is a subspecies of all the previous ones. In fact, these are sound waves that penetrate the interior of the apartment and are reflected from objects located inside the rooms.

As you understand, we will be interested in percussion and air sounds that come from the neighbors' apartments. How can you get rid of them, and if not completely, then at least partially. Option one is to install a soundproofing system on the wall. But you need to understand that soundproofing should in this case perform two functions at once.

- This is actually insulation, that is, a reflective ability that does not allow noise to penetrate into your apartment from the neighbors.

- And the ability to absorb sounds. This feature will save your neighbors from noise coming from your apartment.

Soundproofing the ceiling

Let's start isolation from extraneous noise from the ceiling. The primary task is to install the frame base for attaching drywall.

Important point! It is necessary to fix the corners not docking with the ceiling surface, but through a noise-absorbing tape to prevent the transmission of vibrations coming from the upper floor.

If the budget allows this, put a thin film under the frame to increase the level of sound insulation. There are several varieties of such membranes on the market, for example, Texound vinyl film. Such a protective film should not only provide sound insulation, but also absorb vibrations.

After completing the design of the frame, fill the cavities between the profiles with mineral wool as tightly as possible. Soundproofing work should be carried out with safety glasses, otherwise the pile from cotton wool will clog your eyes.

After filling the cavities, the ceiling is sheathed with plasterboard.

Lighting is designed after the completion of soundproofing work. The following technique will help to make the decrease in the height of the room less noticeable: instead of a chandelier, the light source should be placed in the plinth on the ceiling. Naturally, the plinth must have a massive lower element attached to the wall and be hollow inside.

Window.

Few people know that not only the noise of the street or a traffic intersection can penetrate through the windows into the apartment, but also the sound from the home theater located at your neighbors. If you replace the old frames with modern metal-plastic structures, then the problem is solved very quickly. But, sometimes minor edits of the "junk" can give a more effective result. It should also be noted that very often one can hear complaints about the fact that after dismantling a wooden window for a metal-plastic one, some types of extraneous noise become more audible. The reason for this is the so-called "camouflage effect", which was created due to street noise.

Tip: In order to soundproof the old structure, first of all, glass should be replaced, which used to be 4 mm thick with thicker, modern ones - 5-6 mm. Immediately after dismantling, coat the frame structure with transparent silicone sealant.The installed window must be strictly in size. Firmly install the glass into the silicone seam, then press it with glazing beads and remove the protruding excess.

It is very important to attach a special rubber seal around the entire perimeter of the sash, which has a section in the shape of the English letter “D”. Today in the construction market you can find a great variety of different seals for such purposes.

If, after the performed operations, the sash closes with effort, then it is better to turn to the carpenter for recommendations, who will determine in which places it is necessary to remove the layer of wood.

Before installing metal-plastic windows, you need to understand that thicker double-glazed windows (3 glasses) do not provide higher sound insulation compared to standard single-chamber options with a similar total glass thickness.

| Note. We advise you not to use drywall when leveling slopes, due to the fact that resonant phenomena in the air can reduce the sound insulation index of the window structure. Correctly use cement mortar for these purposes. |

Floor soundproofing technology

Stage 1

The first step is to prepare the base of the floor. This includes cutting bulges, sealing cracks. It is also necessary to pre-prime the surface. The best option for sealing floor defects is a vibration-isolating sealant.

Stage 2

Insulation should be closed. This is necessary so that moisture does not penetrate the non-insulating material either during the execution of the screed or during operation. As protection, a reinforcing mesh or plastic film is usually used.

Stage 3

Now you can pour the floor screed. To do this, beacon rails are exposed, a reinforcing layer is laid for coupling adjacent layers. After that, you can fill the floor with a cement screed. It is recommended to take a ready-made mixture than to prepare a cement-sand mortar on your own, since the factory screed has higher adhesion and elasticity.

Stage 4

When the floor screed is completely dry, the floor covering is mounted. At the same time, it must be remembered that tiles or laminate should not fit close to the walls. A gap remains between the finish flooring and the wall, which is sealed with sealant, and then closed with a plinth.

For a brief overview of the properties and use of materials for soundproofing the floor in an apartment, see the video below:

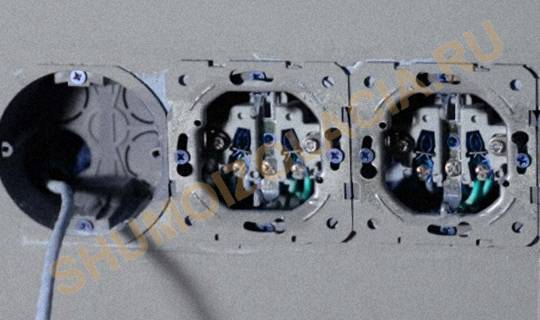

Mounting electrical junction boxes.

These boxes, in which the electrical wiring is connected, are usually installed at the top of the wall. Often you may not be aware of them, as they are hidden behind the wallpaper. It is very easy to find by light tapping. Exactly as in the previous example, the holes for installing junction boxes are through and covered from above with a thin layer of plastic.

Tip: Soundproofing electrical distribution boxes can be done in the same way as electrical outlets. We strongly recommend that you contact an electrician, since fire safety depends on the correct twisting of the wiring!

Question about doors.

It’s sad, but the additional soundproofing of the front door will not become an obstacle to the noise emitted by the elevator and the operation of its winch (this sound spreads almost throughout the entire structure of the house), but at the same time it will help get rid of the noise of nearby neighbors, the sound of walking heels on the stairs and others similar unpleasant sounds.

Tip: Soundproofing professionals advise making an entrance group in the form of a vestibule of two doors. The door in contact with the entrance must be resistant to burglary and unauthorized opening, and the inner door can be simply decorative.To ensure maximum sound insulation, it is necessary to achieve the complete absence of any gaps in the closed position of the door leaf. To do this, there must be a threshold on the door frame and a rubber seal around the entire perimeter. Profile rubber seals do an excellent job of this task. These gaskets in the form of the English letter “D” showed themselves best. Note that the presence of a threshold at the door increases the noise insulation index up to 15 dB.

Often, when installing an entrance door, builders fill the voids formed with building mounting foam, which is not recommended, since it does not have properties that absorb noise. If this is noticed, then remove all the foam and fill the resulting space with a cement mixture. After the mortar has dried, treat the junction of the box to the walls with silicone sealant so that deformation cracks do not form in the future.

How soundproofing works

Noise isolation works in two main directions:

- Soundproofing. Sounds coming from neighboring apartments are reflected and do not reach your hearing, so you will hear absolutely nothing from what the neighbors are doing.

- Sound absorption. The sound waves that come from the noise in your apartment are absorbed, so the neighbors won't hear you either.

Varieties of noise

Noises come in several forms. Let's consider them in more detail.

- Air. Such noise includes all sounds transmitted through the air. This is a scream, loud speech, laughter, etc. Such sounds penetrate the house through doors, windows and cracks.

Shock. The most annoying noise of most high-rise buildings. It includes the sound of a perforator, drill and other construction tools. This noise penetrates through the walls and ceilings in the house. The closer you are to the source of the noise, the louder you hear it.

Structural. This noise comes from vibration. It, like shock, penetrates through walls and its source is also working construction equipment. Sometimes these two noises are combined into one.

The very first obstacle to noise in a high-rise building will be walls and ceilings. And the key to calm nerves of the residents of the house are high-quality sound-absorbing walls.

An important point in good soundproofing of walls is the quality of the material from which they are built. Unfortunately, in our country, the quality of wall material is far from always at a high level, so they cannot provide reliable protection for the apartment from extraneous noise. This is especially felt with shock and structural types of noise that occur in the house and have a wide range of impact. It happens that the inhabitants of the first floor hear the noise of repairs coming from the ninth floor of the neighboring entrance. It is also easy to hear the noise of a car from a garage near the house through the walls and windows into the apartment.

Permissible noise standards

Sound loudness is measured in decibels (db). There are accepted permissible noise levels in an apartment that are optimal for the perception of the human body and do not cause harm - this is 40-45 dB, which corresponds to the noise level from a quiet conversation between two people. But even this norm is valid from 7:00 to 23:00. At night, when relative silence is required, the noise norm is 25-30 dB, which can be compared in volume with a human whisper, which is 20 dB.

For very noisy enterprises, the permissible noise level is 85 dB, but on the condition that workers can work no more than 8 hours a day. Scientists have proven that during such a time the level of boundary noise does not harm human health. At higher noise levels, special protective equipment must be used. The critical level of noise that begins to irritate the ear is 110 dB, and its increase to 130 dB can even cause discomfort on the skin.

In a high-rise apartment, decibels coming from neighbors often cause unpleasant emotions, a loss of a sense of peace. This is what pushes apartment owners to surround themselves with soundproofing, protecting walls, ceilings and floors from noise.

Before soundproofing an apartment with your own hands, you need to determine the noise level, which will help you choose the best soundproofing option for your apartment.

Soundproofing the floor

The first step is the dismantling of the skirting boards encircling the floor. Dismantle them carefully so as not to damage, as they will then be installed in their original place. If the flooring is an old budget material, such as linoleum, soundproofing can be done on top of it.

The new coating is disassembled, and after the soundproofing work is completed, it spreads again.

Noise insulation of the floor begins with the flooring of the layer, consisting of fiberglass. Be sure to wear gloves and take care of eye protection. This material consists of tiny fibers that irritate the skin.

Wooden bars are laid on the fiberglass layer - at a distance identical to the width of the insulating plates, leaving a margin between the tips and the walls.

Wooden bars do not need to be fixed - rigid fasteners will make it possible for noise to be transmitted through wood, since its sound absorption level is low.

The next step is laying mineral wool in strips between wooden elements and sealing with gypsum fiber boards, which are laid in a double layer.

Important! Lay the joints of the plates with the walls with sound-absorbing tape. It remains to lay the top coat of your choice on the draft soundproof floor

It remains to lay the top coat of your choice on the draft soundproof floor.

Video on how to soundproof the walls of an apartment using soundproof ZIPS panels

As an insulating material against noise, various sealants are also used at the joints of surfaces (wall - ceiling; wall - floor; heating and water supply risers).

The first method requires a complete renovation of the premises using materials that increase the thickness of the walls, which leads to a decrease in the size of the area, so it is not advisable to carry out these works in small rooms.

Partial insulation may be suitable here, for example, soundproofing the ceiling, which is mentioned at the beginning of the article. Windows and front doors play an important role in protecting the premises from noise. These are plastic double-glazed windows with soundproofing properties and sealed, tight-fitting entrance doors. Sound insulation of doors can be improved by sealing openings and a snug fit to the door frame.

Joints between floors and walls.

Over time, deep depressions, cracks and crevices appear at the junctions of walls and floors. This is typical because in the process of building the facility, low-quality materials and the negligence of builders were used. It is these flaws that serve as an excellent conductor of extraneous noise.

Tip: Dismantle the skirting boards throughout the apartment. If possible, then using a powerful screwdriver (chisel) and a hammer along the walls, make a strobe of 25-50 mm to the depth of the screed. Fill this seam with new mortar. Be sure after it hardens, you need to walk on top with a silicone non-hardening sealant. This will prevent its destruction in the future.

If parquet is laid as the upper floor covering in the living room, and the above work cannot be done, then simply fill the edge between the wall and the parquet with the same sealant. Put the plinth on top in its original place.

Soundproof base

This design is sometimes referred to as a "floating floor", emphasizing the separation of the finish floor and interfloor panel.The functions of sound insulation in it are performed by rigid slabs of ecowool, mineral wool or extruded polystyrene, as the most suitable for this purpose. They are laid on a leveled base along a waterproofing membrane, the perimeter is three to five centimeters filled with soft stone wool.

A protective leveling screed with a thickness of one and a half to five centimeters is applied over the insulating boards, along which a clean floor is mounted. Such a coating effectively dampens the energy of sound waves, although polystyrene is often distrusted, considering it more of a heat insulator.

Soundproofing with bulk material, dry screed.

Good performance is provided by bulk materials, among which expanded clay of small and medium fractions is in the lead. It is used to create a base for a screed, as a sound and heat insulating backfill between the lags and for laying floors on a dry screed. An alternative to expanded clay is perlite or vermiculite, traditionally used for insulation and insulation of floors.