Insulation of coil and rod windings of large machines.

The inorganic components of the insulation - mica, mica, mica, fiberglass, at the operating temperatures of the generator practically do not undergo any chemical changes, i.e. do not age.

In thermosetting insulation (TRI), consisting of mica, fiberglass and epoxy resin, the binder, the thermosetting resin, ages, its depolymerization leads to an increase in brittleness - a deterioration in the mechanical properties of the insulation as a whole. In mica compounded insulation (MCI), consisting of mica sheets, paper backing and bituminous varnish, organic components — paper backing and bitumen — also age, while the backing becomes brittle, and its chemical and mechanical destruction gradually occurs. The bitumen-oil varnish, which is part of the mica tape, and the bituminous compound, with which it is impregnated during compounding (impregnation and pressure testing), become brittle from viscous during aging, partially volatilize, and crumble under mechanical stress. As a result, the bond is weakened both between the mica tape layers and between the mica sheets in the layer, the insulation easily delaminates. With prolonged heating of mica insulation, in parallel with chemical processes, there is also a process of so-called "swelling", which is based on mechanical phenomena. With an increase in temperature, the mechanical properties of the varnish and compound deteriorate sharply (they soften), as a result of which mica sheets bent at the corners of the rod section have the ability to straighten somewhat, thereby increasing the radius of curvature of the insulation at the corners of the rod. In this case, the inner layers, which are under pressure from the outer layers, are straightened to a lesser extent, and the outer layers, which are restrained only by the viscosity of the binder and the cover tape, are straightened to a greater extent. Rice. 5

As a result of the described process, the section of the insulated rod takes a barrel-shaped shape, between the layers of insulation, differently curved, air gaps appear or increase, a gap appears or increases between the inner layer of insulation and the surface of the conductors of the rod. On fig. 5 shows a schematic representation of the cross section of mica insulation before swelling (a) and after swelling (b). Swelling is especially pronounced in places where nothing prevents it - in the frontal parts (including the exit from the groove); in the groove part, it is limited by the dimensions of the groove. Thus, the aged state of MKI is characterized by the following features:

- the insulation is thickened in the frontal parts, at the exit from the groove and in the ventilation ducts of the stator (insulation buckling into the duct);

- the insulation removed from the rod is split into layers of mica tape winding;

- the insulation removed from the rod disintegrates into separate sheets of mica (with a very strong degree of aging), the paper substrate is practically absent, the binder crumbles;

- the content of the binder decreases and the content of air inclusions increases.

Other conditions of thermal aging of insulation are possible, for example, a relatively short-term effect of temperatures that significantly exceed the permissible operating temperatures. Such conditions arise, as a rule, during local overheating in the machine: local overheating of active steel, short circuit of a number of elementary conductors in the slot part of the winding, conductor break with random contact at the break point, rod overheating due to clogging of an unacceptable number of hollow conductors in the generator with water-cooled windings, etc.

Regarding the thermal aging of insulation, the following conclusions can be drawn.

- For the insulation of low-voltage machines, thermal aging is decisive.For an experimental assessment of durability, cyclic thermal aging is carried out with periodic exposure to mechanical loads and moisture.

- Thermal aging plays a significant role in the insulation of large machines and air-cooled hydrogenerators, especially for MCI. In this case, aging can be decisive for the life of the insulation, especially if the actual temperature is close to the maximum allowable.

For windings of hydrogenerators with MKI, the service life is about 20 years, and in some cases it was necessary to replace the winding after 8 ... 12 years of operation. With the transition to THW, the estimated life of the winding has been increased to 40 years.

- For generators with hydrogen-cooled windings, the process of thermal aging of the insulation slows down sharply, although the manifestation of thermomechanical phenomena is possible in machines with a maneuvering mode of operation.

- Water-cooled generators have no noticeable thermal aging.

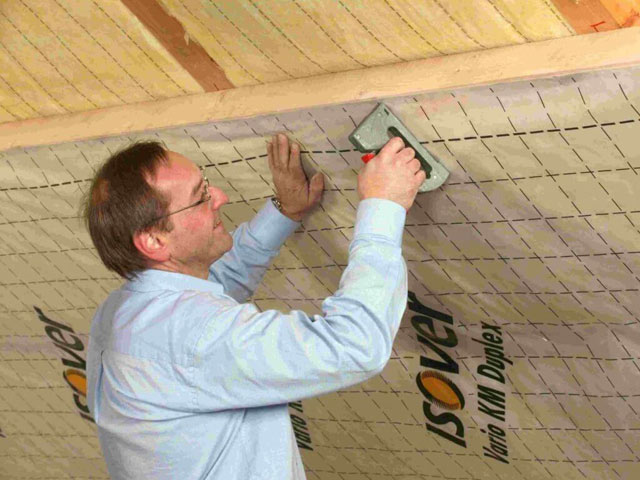

Vapor barrier material features

Have you felt all the “charms” of the increase in electricity prices? Want to keep precious warmth inside your home? Do you want to heat the street? In this case, dear friends, warm yourself. And in order for the thermal insulation to serve faithfully for many years, be sure to stock up on vapor barrier material.

Vapor barrier is a material designed to reliably protect the insulation and the building object as a whole from the penetration of steam. This steam (condensate) can be absorbed into the insulation, for example, into mineral wool. and significantly degrade its thermal insulation properties. Is it possible to do with only waterproofing raw materials?

It is forbidden. Why? Because, unlike waterproofing, vapor barrier prevents the penetration of not liquid, but steam. What is fraught with the absence of vapor barrier material? Loss of all the characteristics of the insulation (even the most expensive), and a decrease in the durability of the entire building object.

Thus, the vapor barrier is not a whim, but a necessity.

Principle of operation

The principle of operation of the vapor barrier material is simple. When using a barrier, moist air from the room does not go outside. This leaves the thermal insulation material dry. And moisture that accidentally gets into the insulation is removed due to the vapor-permeable film, which is mounted on the outside of the insulation. And that's waterproofing.

Energoflex

Energyflex insulation for heating pipes is the most demanded material in our time. It is used for thermal insulation of pipelines with a small diameter. Energoflex for pipes is produced in rolled material, as well as in the form of hollow tubes 1-2 m long, having the shape of a cylinder of different diameters with a longitudinal technological notch.

There are a few things to keep in mind when using this product. Before performing insulation, the surface of the pipes should be checked, which should be cleaned and degreased. The water supply during work is stopped and after they are carried out it is turned off for another day. It is impossible to carry out installation at sub-zero temperatures. First, the reinforcement and protrusions are insulated, and then the flat sections of the pipes. When carrying out work with rolled material, it is necessary to ensure that the upper layer of insulation overlaps the lower joint. The covering during laying should not be stretched.

This type of insulation has hygienic certificates and meets all European and Russian standards. Energoflex for pipes has low thermal conductivity, good sound insulation, resistance to chemical compositions, frost and heat resistance, strength, durability, flexibility, ease of installation.

Advantages and disadvantages

To date, there are a huge number of varieties of vapor barrier raw materials. Of course, some have more advantages, others less. However, there are advantages inherent in absolutely every species.

So, for example, all modern barriers are known:

- security;

- environmental friendliness;

- functionality;

- practicality;

- resistance to the harmful effects of climatic factors;

- resistance to the destructive influence of chemical factors;

- resistance to the harmful effects of mechanical factors;

- invulnerability to the negative influence of biological factors;

- simple installation.

The disadvantage is the fear of fire, that is, the material burns.

Thus, dear friends, vapor barrier can solve a number of problems associated with the construction of an object, regardless of its properties and purpose.

Thermal insulation materials based on mineral

The term "mineral wool» put into use by GOST 4640-93 (DSTU B V.2.7-94-2000).

This is a heat-insulating material consisting of the thinnest (5–12 microns) fibers obtained by spraying melts of silicate materials. Depending on the type of raw material, there are:

mineral (stone) wool - made from mineral rocks: clays, limestones, basalts, granites, tuffs; slag wool - made from waste from metallurgical production - slag; glass wool is made from glass.

Mineral wool is made up of entangled amorphous fibres. In its mass, one can notice a certain number of beadlets - non-fibrous inclusions of a spherical or irregular shape, a fraction of a millimeter in size.

The highest quality mineral wool heat-insulating products are obtained from molten rocks. It is this mineral wool that should be used for thermal insulation of critical structures and where special reliability of structures is needed for many years.

Mineral wool obtained from blast-furnace slag is somewhat worse. It is not so durable in conditions of high loads, humidity and sudden changes in temperature.

But glass wool, containing few non-fibrous inclusions, is elastic and tolerates vibrations well.

Mineral wool is produced either in the form of a mat without filler, or in the form of plates in which the fibers are linked together by a binder to give the plates mechanical strength.

As a rule, phenol alcohol and water-repellent oils are used as a binder, however, the specific composition of the binder is usually not disclosed.

Mats are used if it is necessary to arrange thermal insulation over a large area without gaps.

In facade structures, the insulation is subject to mechanical stress, so they use relatively strong rigid and semi-rigid mineral wool boards.

Mineral wool is not combustible, which, combined with a high heat and sound insulating ability, distinguishes it from other heat-insulating materials.

In addition, it is resistant to temperature deformations, it can be used for thermal insulation of surfaces with temperatures from -200 to +600, and, in some cases, up to 1000 ° C.

Its mineral nature is inherent in chemical and biological resistance, at the same time it is relatively easy to dispose of after the end of the life cycle of thermal insulation, which is an undeniable advantage that is important for solving environmental problems.

Mineral wool has a high resistance to mechanical stress, however, it is easy to process - cut with a knife or saw with a hacksaw, which facilitates installation.

A major drawback of mineral wool is that it is hydrophilic, absorbs water well, therefore, if it is used in facade thermal insulation, it must be impregnated with special hydrophobizing compounds.

But mineral wool is largely vapor-permeable, its thickness is calculated in such a way that the “dew point” is in the outer layer, i.e., so that moisture condenses in the heat insulator, and not in the load-bearing wall.

Insulation materials for heating pipes and their application

In many houses (from buildings that have been standing for more than a dozen years to newly built cottages), people overpay considerable amounts for heating just because the heating system wastes a significant part of the energy (in particular, those networks that run down the street).

Very often this happens due to errors made during the installation of pipelines of heating networks - while losses can reach 40-60%, which, of course, is a lot.

Moreover, this situation not only increases your costs, but also reduces the service life of heating network equipment, which would have worked longer with lower loads.

For this reason, the thermal insulation of pipelines of heating networks is a rather relevant solution that should not be neglected. Consider how the heating pipelines are insulated, what material is used and how exactly this procedure is performed.

Regulatory requirements for the installation of thermal insulation

Before insulating the chimney pipe, you must make sure that it is installed correctly.

- The combustion products outlet pipe must be 5 m high. This indicator provides optimal draft in the heating system.

- A distance of at least 250 mm is required between the roof slab and the outer element of the boiler room.

- If the building is covered with combustible materials, in particular, slate, roofing material, ondulin, then the insulated smoke exhaust structure must be equipped with a spark arrester.

After making sure that the system is installed correctly, you can proceed to subsequent work on winding with thermal insulation.

What is PPM insulation for?

Until recently, in order to reduce heat losses, mineral wool materials were used, which, when laid underground, required the installation of impassable reinforced concrete channels, which not only significantly complicated the installation of the pipeline, but also required large financial costs.

A more modern solution to the problem is the use of pipes with preliminary thermal insulation made of polyurethane foam (PPU) in the factory. However, this insulation required an additional polyethylene sheath, which was needed to protect against mechanical damage and negative environmental influences.

Such heating mains are already in operation in many large cities of the country. And the previously popular and widespread PPU thermal insulation is becoming a thing of the past.

Manufacturer

There are many companies specializing in the production of certain types of vapor barrier material, but the best are such manufacturers:

- Izospan (Russian manufacturer);

- Yutafol (Czech company);

- TechnoNIKOL (Russian company);

- "Tyvek" (American manufacturer);

- "Nanoizol" (Russian organization);

- Eurokron (Russian company);

- Izolon (Ukrainian manufacturer);

- Rockwool (Danish company);

- Megaflex (Russian organization);

- "Ondutis" (Russian manufacturer).

Armed with goods from the above manufacturers, be sure that not a single drop of moisture obtained as a result of the formation of steam in the room will certainly not get into the heat-insulating raw materials.

Thus, comfort, beauty and coziness in a home depend on many factors. And one of them is a high-quality and properly installed vapor barrier.

Anecdote off topic: Husband - wife: - You cheated? - Yes, with whom could I? - Admit it, you changed? - Well, it was once with a neighbor ... - I ask: did you change the password for entering the Network?

Home or bath - durability, comfort and attractiveness, and you - good health, dear readers! See you again. If it was informative - do not forget to share the article with your friends ...

Quote of wisdom: If you make new friends, do not forget about old ones (Erasmus of Rotterdam).

Definition of the word TSB isolation

Isolation - Isolation (from the French.isolation - separation, separation) (biological), restriction or violation of free crossing of individuals and mixing (Panmixia) of different forms of organisms. one of the elementary factors of evolution. C. Darwin, using the example of island faunas and floras, showed the role of I. in the emergence, expansion, and deepening of differences between similar forms of living organisms. If any, more often peripheral, part of the original population is isolated by some kind of geographical barriers, then over time this part of the population can turn into an independent species. Such a geographical (alopatric. See Allopatry) method of speciation, according to many biologists, is the only or, in any case, the main way of speciation. the nature of reproductive I. In microevolutionary terms (see Microevolution), i.e., at the intraspecific level, there are 2 main groups of I.: territorial-mechanical, which includes all cases of barriers between different parts of the population or different populations (for example, water barriers for land and land for aquatic organisms, mountains for valleys and valleys for mountain species, etc.), and biological, which is divided into 3 subgroups: a) ecological I. - individuals of two or more biotypes rarely or not at all occur during reproductive period: b) morphological and physiological I. - copulation is difficult or impossible due to morphological or ethological (behavioral) m) reasons. c) genetic I. proper, due to the inferiority (decrease in viability, fertility, or complete sterility) of hybrids obtained as a result of appropriate crossings. All types of I. can exert different pressure on populations, since any form of I. can be quantified to varying degrees . Territorial-mechanical I. (in large areas - geographical) leads to allopatric shaping and, with a sufficiently long action, usually causes the appearance of some form of biological I. Cases of the primary occurrence of biological I. can lead to sympatric shaping (see Sympatria). Lit. : Darwin Ch., The origin of species by means of natural selection, Soch., vol. 3, M. - L., 1939: Geptner V. G., General zoogeography, M., 1936. Erlich P. and Holm R., The process of evolution , per. from English, M., 1966. Shmalgauzen I. I., Factors of evolution, 2nd ed., M., 1968. Timofeev-Resovsky N. V., Vorontsov N. N., Yablokov A. V., A brief outline of the theory evolution, M., 1969. Shmalgauzen II, Problems of Darwinism, 2nd ed., L., 1969.V. G. Geptner, N. V. Timofeev-Resovsky.

event, dissociationdisease prevention of spread (hospitalization) cholera, rash, typhoid fever, hepatitis, separate provision also special room

| Disease name | Terms of isolation of patients |

| Typhoid fever, paratyphoid | For those treated with antibiotics - up to 23 days after |

| establishing a normal temperature. Employees | |

| food industry, water supply, public | |

| food, children's institutions, hospitals are allowed to | |

| work 30 days after discharge from the medical | |

| institutions with a triple negative result | |

| bacteriological examination of urine, feces and | |

| single - duodenal contents | |

| Dysentery bacterial | Until clinical recovery and three times (with |

| at intervals of 1-2 days) negative | |

| bacteriological examination of feces. Workers | |

| water supply, food industry, public | |

| nutrition, hospitals and childcare facilities are discharged after | |

| three times negative | |

| bacteriological examination of feces and | |

| sigmoidoscopy | |

| Viral hepatitis | Until clinical recovery, but not less than 21 days from |

| the appearance of jaundice or 30 days from the onset of the disease | |

| Polio | 40 days |

| Typhus | 12 days after temperature drop |

| Tularemia | Until recovery |

| Diphtheria | Before recovery, after double negative |

| the result of a bacteriological examination of the discharge | |

| pharynx and nose (with a 3-day interval) | |

| Measles | Up to 5 days from the onset of the rash |

| Whooping cough | Up to 40 days from the onset of the disease or 30 days after |

| onset of convulsive cough | |

| Scarlet fever | Up to 21 days from the onset of the disease (in the absence of |

| complications - up to 15 days) | |

| Chicken pox | Up to 7 days from the onset of the rash |

| Parotitis | Up to 9 days from the onset of the disease |

| (piggy) |

prevention, diseases, infection, timeliness of group, only individual Severity of contagiousness

Types of materials for insulation

The main widespread materials for pipe insulation are:

- foamed polyethylene;

- mineral wool;

- polyurethane foam;

- expanded polystyrene;

- paint insulation.

Let's consider these options in more detail.

Polyethylene

Foamed polyethylene is a soft material. The insulation is easy to use, it is enough just to cut it, creating the necessary pieces.

It is fastened with construction tape, the joints are hidden with a thicker strip of polyethylene.

It looks like foamed polyethylene

Mineral wool

Mineral wool is an excellent material that has a low degree of thermal conductivity and is also non-flammable. Has wide application in warming of pipelines. The main disadvantage of mineral wool is its high cost.

The advantage of mineral wool is its durability

polyurethane foam

Heating pipes can be insulated with polyurethane foam. Such a heater is installed by spraying the composition.

A man sprays in a special suit

The atomized mass turns into a hard and durable material that can protect pipelines from heat loss.

This type of insulation should not be in the zone of exposure to sunlight. If polyurethane foam is used outdoors, then it is necessary to protect it with roofing felt or aluminum foil winding.

Styrofoam

Expanded polystyrene is represented by two shells that repeat the shape of the pipe. Fastening is carried out using special grooves on the design of the insulation.

It is recommended to additionally fasten the joints with glue or other materials during installation.

In the photo - polystyrene foam

Special paint

Insulation can be made with a special heat-insulating paint.

A layer of such insulation can replace other materials. The paint is resistant to high temperatures, its use does not require ventilation of the premises, it is an environmentally friendly material.

Paint is a great solution than to isolate heating pipes in an apartment. It does not take up much space, does not require specific conditions.

Read - what paint to choose for heating pipes?

And how to isolate the heating pipes in the floor?

The "Warm floor" system is often used in private homes. It does not make sense to make complete insulation of such pipes, since the residents must receive heat from the floor.

Here there is insulation of the bottom under the pipes so that the heat does not go into the soil. It is necessary to use the main available heaters. In the case of conventional heating pipes laid in the floor, you can use the standard method of insulation.

When working with any material for insulation, it is important to lay the insulation closer to the pipe, leaving no gaps. If you need to make cuts, then they are best done evenly.

Fasten the materials with construction tape if the insulation allows the joints to be processed with special glue.

Have a nice day!

Why vapor barrier is needed in construction A detailed study of a sensitive issue

I warmly welcome you, inquisitive readers!

Spring is in the yard! The sun is shining brightly, caressing the earth with gentle rays, the birds are chirping loudly, rejoicing at the long-awaited arrival of Spring-Laughter. Flowers are fragrant, pampering people with a heady aroma.Eh! I want to talk about something high, but I have to discuss the vapor barrier material.

So, vapor barrier is a raw material that should not be underestimated, and, of course, should not be neglected. And it is absolutely not recommended to save on it. Why? I'll tell you now. You are ready? Wonderful. In this case, let's not waste precious time.

The meaning of the word Isolation according to the dictionary of medical terms

isolation (French isolation) - 1) in epidemiology - an anti-epidemic measure, which consists in dissociating epidemically dangerous persons from others (infectious patients, persons who are expected to have an infectious disease, and in case of quarantine infections - carriers of their pathogens, as well as persons who were in communication with patients). 2) in psychiatry - the removal of the patient from the family and society with placement in a hospital to prevent possible dangerous actions against others or oneself. 3) in genetics, a set of circumstances (geographical, social, physiological, etc.) that prevent panmixia, i.e., create unequal probabilities of marriage for different couples and population composition.