Advantages of wooden floors

Installation of wooden elements of the building does not require the involvement of special construction equipment and hired labor. This compares favorably with the laying of heavy concrete slabs. Moreover, such an interfloor overlap in a wooden house in the presence of a second floor or attic is the only right decision.

An important parameter of the quality of the wooden elements of the building is the absence of cold bridges. If sheet materials (foam plastic, mineral wool boards) are used for insulation, the sheets are cut strictly to the size of the openings between the beams. If the installation of a wooden floor between floors involves the use of loose or fibrous materials, it is necessary to ensure that all cracks are filled.

It is extremely important to ensure high-quality vapor permeability. Therefore, when laying polyethylene on the insulation, and not a special hydrovapor-permeable membrane, gaps are left

The installation of a wooden floor is completed with a finishing floor and finishing work.

More articles on this topic:

The correct design of the walls of the frame house

How to make wood wall decoration with your own hands

Wooden interfloor ceiling of the first floor

The wooden floor between the first and second floors must meet certain established requirements:

The floor structure must be very strong and withstand the expected loads from above, it is recommended to calculate the magnitude of the loads with a margin.

Wooden floor beams must be rigid for arranging the floor on the second floor and the ceiling on the first.

The ceiling must have the same service life as the entire wooden house as a whole.

Reliable overlap during the construction phase will ensure safety and prevent repairs.

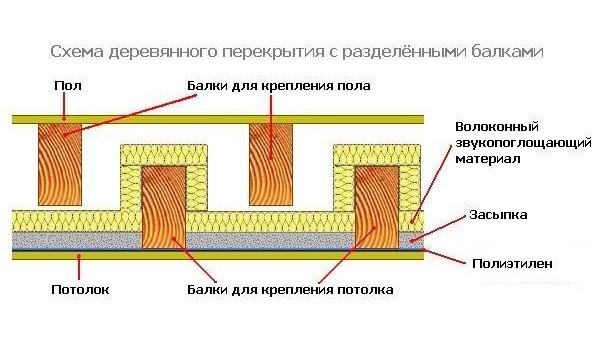

It is very important to equip the floor with additional heat and sound insulation. Scheme of a wooden floor with divided beams

Scheme of a wooden floor with divided beams.

Wooden beams as a floor perform all the basic functions, and they differ from reinforced concrete slabs in their simpler installation. Human strength is enough, there is no need to use heavy machinery. Using beams, you can significantly reduce the overall load on the foundation. The advantages of wooden floors include low price. And with proper processing and installation, such a design will last for more than a dozen years.

The disadvantages of wood include such a detrimental process as decay. In addition, the disadvantages of wood products are high flammability in case of fire.

In order to minimize the likelihood of such processes, it is very important to prepare the beams immediately before installation work. For overlapping it is best to use coniferous wood

In order to avoid deflection of the beam, it is not recommended to make a span of more than 5 m. If the span is larger, it is necessary to make additional supports in the form of columns or crossbars.

Roll decking recommendations

In order to make the ceiling of the first floor, it is necessary to roll forward. This stage of work can be carried out using a wide variety of materials.

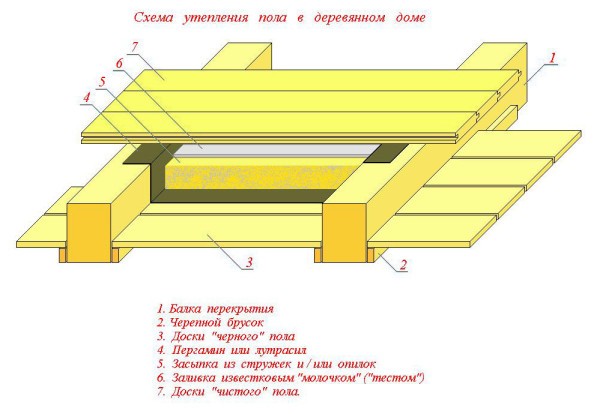

Scheme of the flooring.

In the most common version, cranial bars are nailed along the side of the beam. Such bars should have a section of 40 * 40 or 50 * 50 mm. They should not protrude below the main beam. It is on them that even boards will subsequently be attached, the thickness of which should be within 10-25 mm. In order to knock out the ceiling, you can use sheets of plywood. Using sheet material, you can get a perfectly flat ceiling. The minimum thickness of plywood in this case should not be less than 8 mm

It is very important to control that the edges of the sheets lie exactly in the middle of the beam

Instead of using cranial bars, special grooves can be made in the beams. In order to use this method, the beam section must be thought out in advance.

As a flooring option, the lower part of the floor elements can remain open; for this, the cranial elements are not nailed flush, but slightly higher. Thus, the flooring is carried out between the beams.

After the roll is done, you can start laying the floor of the second floor. If instead of the second floor there is an attic, then the execution of the subfloor is sufficient. If there is a room on the second floor, then the floor must be made of high-quality material. Wooden boards will be laid directly on the logs.

Advantages and disadvantages of wooden floors between floors

An interfloor wooden floor made of beams is installed on the condition that the span width is not more than 8 m. There are also load-bearing structures between the floors, and these are beams for which a beam with a section of 150x100 mm or 150x150 mm is used. To determine the distance between the beams, you can do the calculation yourself. As a rule, this parameter varies 0.6-1 m.

Among the advantages of wooden floors between floors, it is worth noting the long service life and reliability

Among the advantages of wooden floors between floors, it is worth noting the long service life and reliability

In any case, a hydro-vapor barrier film is required, which excludes the penetration and formation of excess moisture.

The surface of the floor, both the attic and the basement, must be treated with special antiseptics for wood. Wooden floors are the lightest and therefore they are installed in residential buildings, especially used for the attic.

- Environmentally friendly;

- It has good thermal insulation;

- Looks very aesthetic.

There are disadvantages to the wood canvas and they consist in the tendency to the formation of microorganisms, fungi and mold, rotting and destruction, deformation of the canvases, if they are initially of poor quality.

In what cases is it recommended to lay cold floors on the second floor

To convincingly answer this question, we must recall a few elementary rules of heat engineering.

-

The heated air rises and accumulates under the ceiling. This is the warmest zone in the room, the air temperature here is about 5–8°C higher than at the level of 1.5 m from the floor and 9–11°C higher than on the floor. The most effective, from the point of view of heat engineering, is considered to be space heating due to floor heating; to ensure the most comfortable temperature at a height of 1.5 m, a minimum amount of thermal energy is required. This is an axiom, there is no need to prove its correctness.

-

Warm air from the ceiling of a room on the first floor automatically heats the floor of the second floor. Heat is not lost anywhere, but heats up additional rooms. Of course, if they are residential, and not cold attic spaces. The question is, why build insulated structures and worsen the comfort of living for your own money, lose additional finances for heating the second floor, and remove heat from the first floor with the help of ventilation?

Most professional builders strongly do not recommend making insulated floors on the second floor if its premises are used as residential. You need to know that in addition to unnecessary losses of money and thermal energy, another problem may appear. If the technology is violated, the heat-insulating material increases its humidity, all wooden elements are operated in very difficult conditions. Heat plus moisture is an excellent environment for the development of fungi and rot on load-bearing wooden elements, and no state-of-the-art impregnations can protect them for a long time. Over time, we have to deal with very unpleasant premature repairs. We hope that this information will help you make the best decisions in each specific case.

Scheme of wooden floor insulation

Technology of installation of wooden floors

To perform the work, you will need the following tools:

- axe;

- a circular saw;

- hacksaw;

- hammer;

- screwdriver;

- screws and nails;

- plane;

- waterproofing and heat-insulating materials;

- building level at least 80 cm long.

- When walls are erected, special openings or recesses for beams are formed in their upper part. Before starting work, these nests are cleaned of dust and debris and waterproofing material is laid in them. The most commonly used ruberoid. If the walls are made of brick, the nests can be treated with bitumen or mastics based on it.

- The ends of the beams are coated with bitumen.

- Lay supports in pre-prepared openings.

If the structure is built of wood, the beams are cut into the upper crown. There is such a way of attaching the supporting elements to the wall, like a dovetail. It is used in houses built of logs or timber. This connection method is simple and reliable. To fix the beams, metal brackets are needed.

Wooden floors in the house are mounted according to the following rules:

- the beam laid in the nest must be at least 4 cm from the walls of the recess;

- beams should be located at a distance of 40-50 cm from the chimney;

- each 3-4 beam is attached to the wall with anchors;

- the space between the beam and the walls of the nest is filled with tow or glass wool.

The scheme of installation of interfloor ceilings provides for the installation of heat and sound insulation. Therefore, the gaps remaining after laying the beams are filled with mounting foam.

Flooring technology

Depending on the location of the observer, the wooden floors between floors can be either the floor or the ceiling of the room. There are special requirements for floor installation. Before proceeding with the installation of the flooring, each beam is hemmed on both sides with cranial bars with a section of 40x40 cm or 50x50 cm.

They will serve as a support for the subfloor. You can do the same with the flooring device that forms the ceiling. But the installation technology of this structural element does not have special requirements for performing such work.

The device for overlapping on wooden beams begins with fastening to the bottom of the supports of unplaned boards with a thickness of 15 mm or more. They will subsequently serve as a rough ceiling. A waterproofing material is laid on top of the flooring obtained during the filing process: roofing felt, a special membrane or dense polyethylene. It has a heater on it.

Mount the sheathing of the upper part of the ceiling on wooden beams. Boards are fixed with nails or screws. Knowing the sequence of work, it is easy to do it yourself. The overlap of the house should be a sealed, durable, high-quality insulated structure. This element of the building experiences the greatest weight loads, therefore only high-quality materials are chosen for its construction.