The use of vibration damping mastic

Let's consider it:

First, dry, clean, degrease the surface to be treated. Add the component to the base of the mastic and stir with a mixer, using a drill with a nozzle, for five minutes, until a homogeneous mass is obtained.

We provide access to the treated surface. To do this, you need to use a lift, jack, pit. If there is no possibility of access directly, then remove the wheel. Now you can apply mastic two millimeters thick. One jar is enough to process one arch. Also remember that it takes no more than forty minutes to work with mastic.

Freezes the drug within twenty-four hours

But the vibration protection will only be activated after seven days.

When working with mastic, take precautions. Can't work with bare hands

Be sure to wear goggles to protect your eyes. Be careful not to get mastic on clothes or body parts. Since it is difficult to wash off from any surface. Also use a respirator to protect your lungs.

NoiseLIQUIDator two-component liquid

NoiseLIQUIDator liquid is presented in the form of a solution that has a thick, uniform consistency. It is made using epoxy resins. Also, various substances are added to it, which serve as additives, which gives the mastic a better presentation and improves its characteristics. Mastic lives from forty minutes to an hour. Then it dries up and can no longer be used. Hardeners are used to create the drug. The liquid is mixed with them only right before application.

NoiseLIQUIDator liquid is presented in the form of a solution that has a thick, uniform consistency. It is made using epoxy resins. Also, various substances are added to it, which serve as additives, which gives the mastic a better presentation and improves its characteristics. Mastic lives from forty minutes to an hour. Then it dries up and can no longer be used. Hardeners are used to create the drug. The liquid is mixed with them only right before application.

Let's consider them in more detail:

- First, let's talk about strengthening. Its main characteristic can be called the rigidity and strength that it gives to the car body when coated with a layer two millimeters thick. As a result, the strength characteristics are doubled.

- Secondly, thanks to the mastic, the function of vibration absorption is manifested. This becomes possible, since the substance plays the role of vibration damping, which significantly increases the properties of the internal structure of the car. Also, thanks to the NoiseLIQUIDator mastic, it is possible to achieve an increased anti-corrosion performance. The substance perfectly tolerates the effects of oil, gasoline, antifreeze, brake fluid. Mastic also has anti-shock properties.

Now let's look at the properties:

- Water absorption should be no more than five percent.

- Corrosion resistance is excellent, after applying the mastic there are no traces of metal damage at all.

- When exposed to external objects, for example, stones or dirt hitting the mastic, cracks do not form on it, and there is no chipping.

- If the reinforcing mastic needs to be bent, then it retains its strength, its value is not less than seventy Newtons.

- Mechanical losses for vibration-absorbing mastic have a coefficient of at least two tenths.

If you need to process the wheel arch, then the vibration damping liquid will do just fine. As for the hardening preparation, it is used in the processing of the luggage compartment, the bottom of the car, the front guard, and the thresholds. It protects the interior of the car from the penetration of noise interference from the surface of the wheels or from sandblasting.

When it is necessary to process the upper part of the body, then a facing material is used. That is, fiberglass is applied on top of the liquid, or aluminum foil can be used. So the appearance of the car will not be spoiled. In addition, the strength of the coating will be increased.

Both mastics are used to protect the car from corrosion. Therefore, if rust has appeared on the surface of the body or its individual parts, then it's time to use one of the types of mastic. It all depends on where the rust is formed.

CLAIM

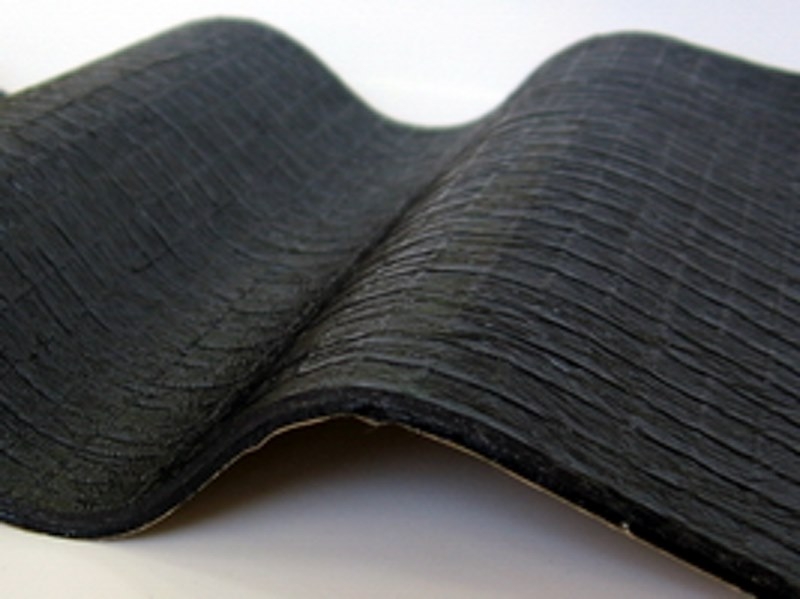

one.Vibration-damping elastomeric material, comprising a copolymer of nitrile rubber and polyvinyl chloride with an acrylic acid nitrile content of 23-30%, a vulcanizing system, a filler, a softener and processing aids, characterized in that it additionally contains nitrile butadiene rubber with an acrylic acid nitrile content of 32-49 %.

2. The vibration-damping elastomeric material according to claim 1, characterized in that the vulcanizing system includes sulfur, a thiazole-type vulcanization accelerator, zinc oxide, stearic acid, or a complex of synthetic fatty acids.

3. Vibration damping elastomeric material according to claim 2, characterized in that stearic acid is used.

4. Vibration damping elastomeric material according to claim 2, characterized in that a complex of synthetic fatty acids is used.

5. Vibration-damping elastomeric material according to claim 2, characterized in that 2-mercaptobenzothiazole is used as a thiazole-type vulcanization accelerator.

6. Vibration-damping elastomeric material according to claim 2, characterized in that di-(2-benzthiazolyl)-disulfide is used as a thiazole-type vulcanization accelerator.

7. Vibration-damping elastomeric material according to claim 1, characterized in that as a softener, a set of softeners based on raw materials of plant origin or a set of bitumen-type softeners is used.

8. Vibration-damping elastomeric material according to claim 6, characterized in that factis and rosin are used as a complex of softeners based on raw materials of plant origin.

9. Vibration-damping elastomeric material according to claim 7, characterized in that rubrax is used as a complex of bitumen-type softeners.

10. Vibration damping elastomeric material according to claim 1, characterized in that a mixture of active and inert fillers is used as a filler.

11. Vibration damping elastomeric material according to claim 10, characterized in that hydrated silicon oxide is used as an active filler.

12. Vibration damping elastomeric material according to claim 10, characterized in that chalk is used as an inert filler.

13. Vibration-damping elastomeric material according to claim 1, characterized in that phenolic or amine-type antioxidants and pigments are used as technological additives.

14. Vibration-damping elastomeric material according to claim 13, characterized in that benzopyridine, polymerized 1,2-dihydro-2,2,4-trimethylquinoline, poly(1,2-dihydro-2,2,4 -trimethylquinoline), 1,2-dihydro-2,2,4-trimethylquinoline homopolymer, trimethyldihydroquinoline polymer, 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 2,2-methylene-bis(4-methyl-6 -tertbutylphenol).

15. Vibration-damping elastomeric material according to claim 13, characterized in that phenyl-α-naphthylamine, n-hydroxyphenyl-α-naphthylamine, N-phenyl-N-isopropyl-n-phenylenediamine are used as amine-type antioxidants.

Characteristics of liquid Adem

Releases a variety of liquids

Let's focus on a few. Let's start with the liquid "Adem"

This is a one-component, high-viscosity preparation that is required to obtain a vibration-damping surface. The drug allows you to reduce the noise or vibration curtain, which occurs precisely because of vibration. This mastic is needed to build ships when it is necessary to carry out work on the processing of individual spare parts. It can also be widely used in other areas. For example, cars, wagons, metal-plastic devices, etc. are being built.

Let's pay attention to the characteristics and advantages of Adem liquid:

- Each brand has its own vibration absorption rating. The coefficient ranges from 0.18 to 0.30. In this case, the noise decreases from two hundred to eight hundred Hertz.

- You can work at a temperature that fluctuates between minus sixty and plus one hundred degrees Celsius.

- There are no problems in smoke emission, toxicity and explosiveness when the temperature rises. Since the drug belongs to the group of slow-burning substances. Smoke is practically not formed, the flame spreads very slowly.

- Thanks to the substance, there is no corrosion, which usually affects the surface of the car body. Mastic forms a waterproof, oil-rejecting and petrol-resistant coating.

- The Adem mastic is applied using spraying or a spatula. Since this mastic is one-component, there is no need to mix with other components.

- When working with mastic, no harmful substance is released, since the level of household chemicals reaches four, and the working area is ten milligrams per cubic meter.

- Mastic "Adem" is guaranteed to last at least twenty-five years. Therefore, your machine will work properly for a quarter of a century.

Let us consider in more detail the characteristics of the mastic "Adem":

- Loss in the field of mechanics has an energy fluctuation coefficient of the same frequency, which has a range of two hundred to eight hundred Hertz, which is located on a metal nail, while the coating must be damped at least twenty-one degrees Celsius.

- The density must be no more than a certain size, measured in kilograms per cubic meter:

- For mastic from one thousand three hundred and fifty to one thousand four hundred and fifty,

- To cover from one thousand one hundred to one and a half thousand.

- The adhesion to the surface has a strength under a load of five hundred kilograms and a spreading speed of ten millimeters per minute should be at least half a percent.

- The mobility of the mastic, that is, its density ranges from eighty to one hundred and forty millimeters.

Mastic properties

- You will receive anti-corrosion body protection.

- No need to remove the wheels, easy and simple to apply.

- The effect is visible in applying to the metal arches of the body, as well as to other elements of the fender liner, including plastic ones.

- High degree of adhesion to any dry surface.

Now consider what mastic gives for a car enthusiast:

- Reduces the level of noise in the cabin, which may appear from the noise of the wheels, from the ingress of gravel into the body, from water, from dirt, from the work of the suspension, from sandblasting, from running noise.

- Extends the life of the body, as well as the fender liner of the car.

- Increases the dynamics of the car, as the rigidity of the body increases.

It's time to dwell on the properties of mastic:

- Its very name suggests that it is vibration-absorbing.

- It has anti-corrosion and anti-gravel properties.

- Increases the rigidity of the car and the dynamic nature of the body.

- It is possible to obtain high resistance against shock loads. Here we are talking about the strength and durability of mechanical elements.

- Possesses water resistance.

It is important to take into account the note, which is that mastic is used not only for processing cars from the outside, but also in places where it is difficult to approach, for example, in complexly curved elements

Table 1. Characteristics of vibration damping materials.

| Material | Density, kg/m3 | Dynamic modulus EP, n/m2 | Loss factor η | Noise reduction efficiency frequency range, Hz |

|---|---|---|---|---|

| Mastics: | ||||

| -VD-17-58 | 1860 | 6 • 108 | 0,44 | up to 1000 |

| -VD-17-59 | 1760 | 8,2 • 108 | 0,3 | |

| -VD-17-63 | 1700 | 3,9 • 109 | 0,23 | |

| Antivibrit-2 | 1500 | 3 • 109 | 0,44 | |

| Antivibrit-5M | 1600 | 2,4 • 109 | 0,25 | |

| Viponite | 1200 | 1,2 • 108 | 0,5 | |

| Agate | 1400 | 109 | 0,33 | |

| Rubber grades: | ||||

| — 615 | 530 | 1,8 • 106 | 0,27 | >1000 |

| — 922 | 70 | 3 • 106 | 0,35 | |

| — 1002 | 750 | 107 | 0,6 |