Sound insulation instructions

Soundproofing a wooden floor begins with an antiseptic treatment of all wood. Then:

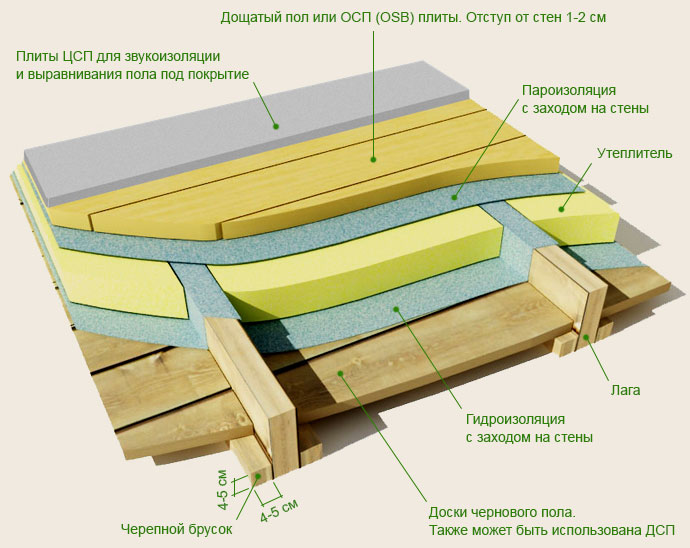

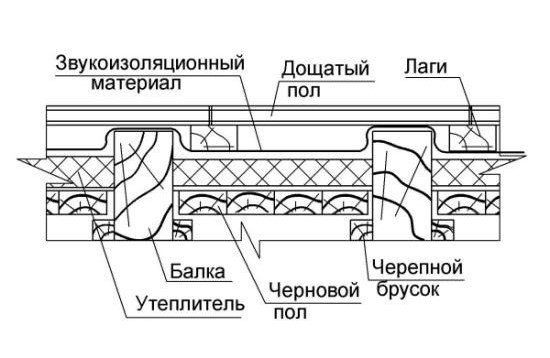

- A rail is fixed on the bottom of the beam. A board with a thickness of 2.5 cm or more is sewn into the resulting gap.

- Add a vapor barrier. 10 cm from its edge are bent on the wall.

- The space above the beams is filled with felt, and between them - with fibrous mats.

To complete the base on the lower floor, the ceiling covering is hemmed. You can use drywall, boards or lining. The upper part of the ceiling is also prepared for flooring.

To install the flooring lay boards 40x150 mm. From above, they either make a heat-insulating layer for plywood, or a substrate for parquet and laminate.

To absorb high-frequency sounds, materials with a fibrous structure are used. To dampen low frequencies - flooring. The combination of both types increases the effectiveness of sound insulation.

Soundproofing with sand

Sand has excellent soundproofing properties. Air vibrations first compress the sand and then are absorbed by it.

In addition, the sand layer fills the voids in the floor slab. Thus, sand isolates both high and low frequency waves.

This method has a drawback - interfloor floors become heavy. Therefore, under the sand, you must first select a beam support made of strong materials.

When soundproofing with sand:

- As in the procedure described above, a rail is fixed on the underside of the beam and the gap is sewn up with massive plywood. Then the vapor barrier is added.

- To tie a wooden partition, when laying the transverse boards, a slot is made under the beams. As a result, relatively small cells are formed, where sand is subsequently poured.

- When backfilling, it is recommended to leave 5 cm from the top edge. This is necessary in order to ventilate the ceiling.

- Having finished pouring sand, felt is stuffed onto the logs, after which plywood is laid.

This completes the preparation of the base for the finishing floor.

Subfloor or floating floor

The draft floor is plywood laid on transverse logs with a distance of 30 mm from the wall. Felt is placed on the plywood that covers the boards, without making gaps, after which the floor is laid. This design significantly increases the level of sound insulation.

The floating floor also helps improve sound insulation. Its difference from the subfloor is that the plywood is not fixed, but simply laid on top of the felt. To fasten plywood sheets to each other, a rail is installed down. At the same time, a free space is formed between the floor and the beams, which eliminates the possibility of friction of the wood and increases sound insulation.

How is the soundproofing of the ceiling in a house with wooden floors

Soundproofing the ceiling in a house with wooden floors is an important stage in the construction of the building. Problems with isolation of noise and sound are always relevant. Especially if some overlaps are unreliable and thin. And this happens in houses made of wood, or where wooden partitions and ceilings are installed.

To avoid unnecessary complications and problems, it is worth eliminating them immediately. When renovating or building a house, everyone is wondering about noise isolation.

And this is the main point, because in a house with wooden coverings such an element is relevant.To solve this problem, you should first figure out what is needed to install the soundproofing of the ceiling in a house with wooden coverings, interfloor ceilings and what errors are allowed during installation.

And in order to eliminate such questions, you should know some facts.

Required Tools

Sound insulation of the floor, interfloor ceilings and ceiling should take into account the properties of the purchased materials

This is important to comply with regulations that prevent fires or other accidents. Also, materials purchased in specialized stores must have all the necessary certificates and documents confirming the quality:

- Fire hazard. The category is indicated on the packaging of any building material.

- Noise isolation factor.

- Availability of a certificate of sanitary and hygienic standards.

- The thickness of the coating itself.

To start installing soundproofing floors in a wooden house, you should purchase all the materials and tools necessary for this:

- Nails or screws.

- Materials with the help of which the soundproofing of interfloor ceilings and floors located in a wooden house is carried out. Their selection will depend on what exactly is planned to be protected from noise.

- Hammer or screwdriver to secure.

- Plywood or boards.

In the installation work, it is important to choose the right building materials and approach this work responsibly.

Soundproofing the ceiling

Ensuring sound insulation between floors and on the ceiling should begin with surface treatment from paint residues and other substances. Then we build a frame of beams. When finished, it should resemble cells. Materials that provide sound insulation are attached to glue or screws. These include felt, slabs or glass wool. The gaps between the ceiling and the wall should be filled with a mass of acrylic. It will provide additional insulation. After all the steps, you can use the ceiling tiles or make a false ceiling to finally block the access of extraneous sounds. When textiles and furniture are brought into the room, the noise becomes less. They also have the property of not missing sounds.

It is important to choose a fabric that transmits the least sound.

Soundproofing the ceiling in a wooden house plays an important role, especially if the room has several floors.

Warm and not expensive floor

The problem of floors that would not burn your feet in winter with their icy cold has existed for as long as the houses themselves have existed. Also, there are solutions to this problem for a long time and in various ways. And as a rule, these solutions are both technologically advanced and expensive. Therefore, we are faced with the question: is it possible to get a warm floor that does not freeze in winter frosts for little money? Having started building our own house, we solved this problem with the help of old technologies and new materials.

Draft floor

The basis of the floor in our house, as in any other, was the floor beams. We have beams measuring 150 by 50 mm, the distance between the beams is 80 cm.

A rough floor was laid on the beams from a board 150mm by 25mm with an interval of 400mm. From above, between the transfers to the crate, a foil thermal insulation 8 mm thick was lined with the foil side inside the house.

The edges of the thermal insulation were tightly sewn to the beams with a stapler

Now the thermal insulation lies on the crate and is not hemmed with a monolithic carpet, but sewn to the sidewalls of the transfers, in order to ventilate the beams from the underground, which is extremely important for the durability of wooden structures

Finished floor

After that, we set about laying the finishing floor. The flooring is supposed to be made of linoleum and laminated floorboards. For these works, usually for the purpose of leveling the floors. whatever they are, use plywood with a thickness of 10 - 12 mm.

To ensure airflow and ventilation in the inter-gender space, it is necessary to drill ventilation holes in the finished floor at the corners of all rooms.

The floor construction described by us has been repeatedly tested and proved to be very good. And we know that insulated linoleum or parquet board, lined with a footboard, will only add warmth under our feet.

Many may be confused by the apparent lightness and low bearing capacity of such a floor. I assure you, it only seems to be. At first, slightly playing floors, gradually taking on the full load, settle and behave no worse than monolithic reinforced concrete.

Materials for soundproofing wooden floors

If at the stage of the construction of the ceiling you took care of its sound insulation from impact noise, then you can proceed to the isolation of acoustic sound. For this purpose, you will need soft, fibrous, porous materials. Their structure is not monolithic. There is air between its fibers. It is thanks to the internal voids that fibrous and porous materials absorb acoustic sounds and noises.

Soundproofing materials

Such materials include mineral wool mats, basalt slabs, fibreboards. These materials have excellent acoustic sound absorption properties.

Materials with a lower density simply cannot "confuse" and absorb sounds in their thickness. The wooden floor must be at least 250 mm. Of these, at least 150 mm must be allocated for a layer of fibrous mats.

Mineral wool

Another type of soundproofing material is roll decking. For example, from felt or cork. They also absorb noise very well. The flooring can also include a heavy soundproof membrane based on minerals. Despite the rather thin layer from 2 to 4 mm, all rolled floorings have proven themselves well on wooden floors.

Soundproof membrane

Do I need to soundproof windows and doors?

Windows and doors are the most vulnerable places that transmit sound well into houses made of SIP panels. It is necessary to install window and door blocks in the openings of the assembled house kit in accordance with GOST. The problem of street noise penetration is solved by soundproofing door and window openings, as well as by installing multilayer entrance doors and double-glazed windows.

Metal doors with a leaf thickness of 70-90 mm are sold by Guardian, Torex, Termo and other manufacturers. Cork sheet, isolon and extruded polystyrene foam, laid in 3-7 layers between steel sheets, reliably protect the house not only from noise penetration, but also from icing.

When choosing noise-insulating double-glazed windows, you need to pay attention to the type of glass. It is recommended to install windows made of film or laminated triplex with intermediate layers of PVB (Polyvinyl Butyral) or EVA (Ethyl Vinyl Acetate)

Choosing a material

Soundproofing materials are divided into basic and additional. The first - with a fibrous structure that dampens noise. Preference can be given to:

- Basalt or mineral wool, which is able to dampen high-frequency sounds and partly with medium ones. Low damping with a sufficient thickness of the noise insulator.

- Ecowool.

- Felt and other noise insulators with a similar structure.

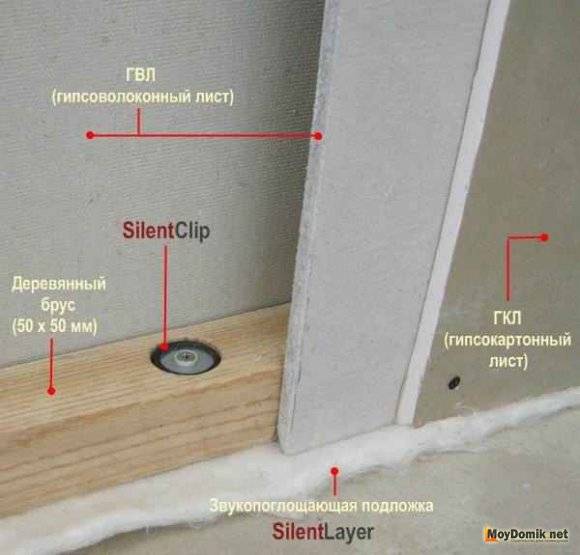

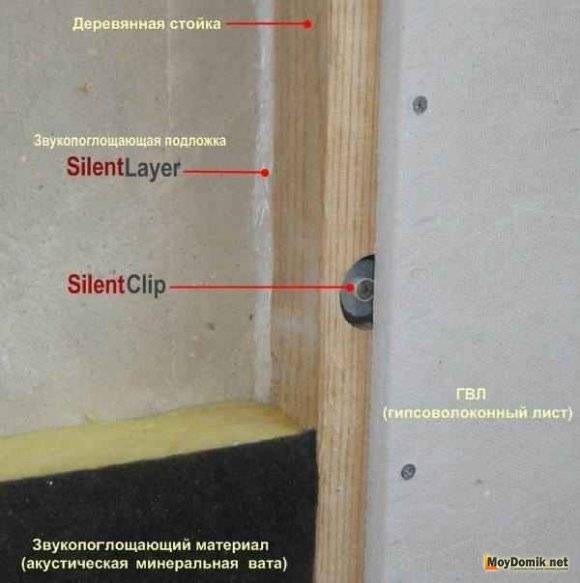

As a soundproofing material, OSB or chipboard boards are used when installing a subfloor on the 2nd floor. To achieve the maximum effect, the plates are only connected to each other, and not screwed to the logs. The plinth should only be screwed to the wall. The lack of a rigid mount will reduce the chance of intrusion of noise resulting from impacts.

In addition to materials with a fibrous structure, bulk materials are used. A sufficient amount of sand can provide the necessary level of sound insulation. However, in this case, the load on the supporting structures increases, which must be taken into account when choosing a suitable material.

Technological features

The sequence of work depends on the characteristics of the soundproofing material used. The difference lies in the order of laying the soundproofing.

We lay the plates

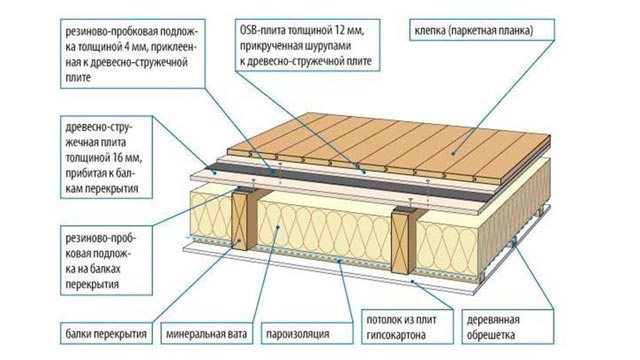

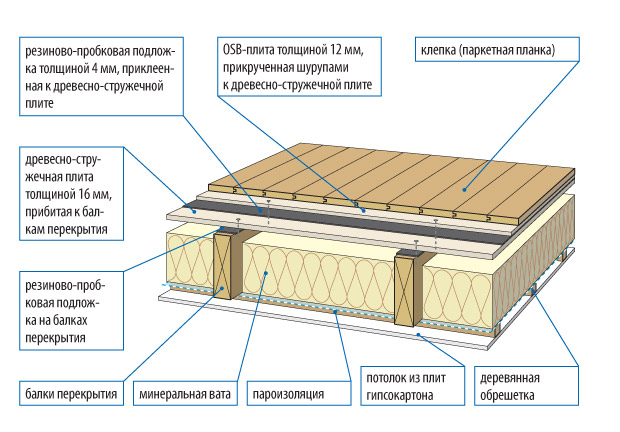

To make it quiet in a house with wooden floors, installation work is performed in the following sequence:

- Dismantling the old floor, if any.

- A vapor-permeable material is laid on the boards used in the installation of the ceiling of the lower floor.

- The selected soundproofing material is laid between the beams. Its thickness is sufficient to provide a sufficient level of sound insulation. Laying - without a gap. In the presence of gaps, the quality of work is low.

- A layer of waterproofing material is laid.

- A rubber-cork substrate is being laid, designed to dampen shocks. To prevent displacement of the substrate during operation, glued to the base

- Laying chipboard sheets. To achieve the effect, a "floating" floor is mounted. They are used as a base for decorative coating.

- The underlayment is laid. Its characteristics depend on the type and parameters of the floor covering. A natural cork underlay has proven itself well, allowing to improve the quality of the insulation.

- The space between the panels and the walls is filled with felt or other material with similar characteristics.

If the thickness of the lags does not allow you to lay a sound insulator of sufficient thickness, you should choose a suitable slab. Then, to the already fixed lags, nail another one at an angle of 90 degrees. In the resulting space, lay the missing amount of soundproofing material.

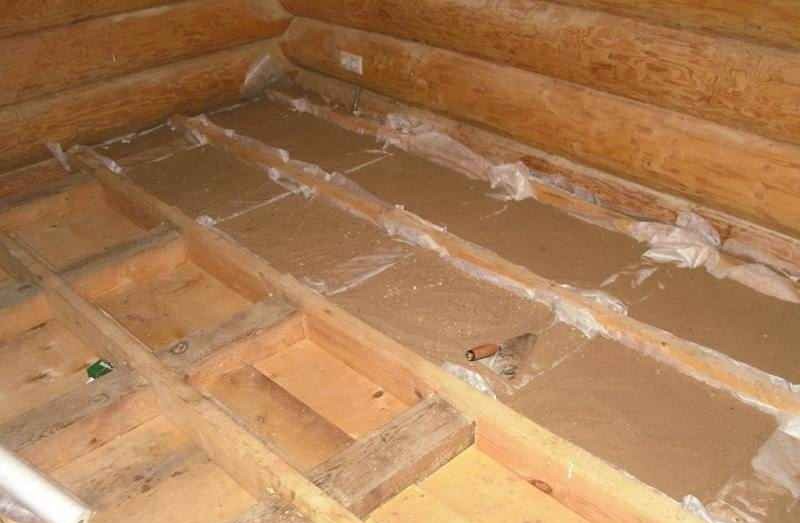

We use sand

Before the start of work check the strength characteristics of the floors. Beams must be powerful and durable. To begin with, slats are sewn on the ceiling of the 1st floor. The space is filled with a board or thick plywood, and then sheathed with a vapor barrier. After that, sand is poured. For ventilation, a gap of 3–5 cm is provided between the top layer of sand and the subfloor. After that, the felt is stuffed onto the logs and thick plywood is spread. It can then be used as a subfloor for a decorative finish.

Thus, if the sound insulation of the floor and ceilings in a wooden house located between the first and second floors is done correctly, there will be no problems during operation of the structure. Properly selected materials and compliance with technological requirements will achieve high results.

Noise insulation of interfloor floors made of wood requires compliance with a number of rules. Unlike concrete and similar materials in monolithic partitions, wood has an increased heat and sound conductivity.

Soundproofing rules with soft materials

Before starting work on soundproofing a wooden floor, you need to carefully treat the wood with an antiseptic. Moreover, all wooden elements that are involved in the process are subject to processing. We attach a 30x40 or 40x50 mm rail to the bottom of the vertical side of the beam. The space between them is sewn up with a board no thinner than 25 mm. Moreover, we fasten it not to the beams, but to the rail.

Wrapping the beams, we lay and fasten the vapor barrier. We bring its edges to the wall with a bend of at least 100 mm. We stuff felt strips over the beams. Then we carefully fill the entire space between the beams with fibrous mats. We lay them tightly together, but do not press from above. You can not stuff strips of felt on the upper ends of the beams. Then the felt flooring must be spread over the beams and insulation with a deflection between the beams.

Now you can hem the ceiling from drywall or other finishing material from below. For example, lining or boards. The base for the ceiling in the lower room has already been prepared. On top of the ceiling, you also have everything ready for flooring. We sew a board 40x150 mm with a step of 150 mm. On top of it, you can spread a layer of thermal insulation.But only if on top of it you will lay a floorboard or plywood 20 or 25 mm under the carpet. If you plan to cover the finished floor with laminate or parquet, then thermal insulation is not needed. Parquet will have its own leveling substrate. Then it is enough just to fill thick plywood over the board, as the basis for the finishing floor.

Fibrous materials are better at absorbing high frequencies, while decking is better at absorbing low-frequency noise. To achieve perfect sound absorption, you need to combine the phased laying of one and the other.

Soundproofing with sand

The principle of this technology lies in the properties of the material. With light shaking, it is able to compress. The sound wave shakes the sand and, passing into mechanical motion, is extinguished. This is, first of all. Secondly, sand creates a mass in the floor, which does not let noise through. Thirdly, soundproofing with sand absorbs all frequencies much more efficiently - both high and low.

The only negative property of this method is the overall weighting of the floor structure. In order for the ceiling to be reliably operated, the beams must be strong and powerful.

It is necessary to sew slats on the beams at the bottom, as in the previous version. Then sew up the space with a board or thick plywood and sheathe it with a vapor barrier. Now the sand bins are ready.

Advice!

For better binding of the floor, you can lay transverse logs by making cutouts for the beams in them. Logs lying across form boxes together with beams. They are much smaller than in the first case. And it will be easier to cover them with sand.

Thus, you did not make a draft floor, but a base for backfilling. But these boards or plywood can not only pull off the floor frame. You can walk on them and backfill. Sand still has the ability to accumulate heat. Such material in the ceilings will be both noise protection and good thermal insulation.

It is not necessary to fill up the sand completely, but leave from 30 to 50 mm of free space for ventilation. Then you need to fill the felt on the frame logs and you can lay thick plywood. It will be the basis for the finished floor.

Soundproofing the ceiling with sand

Subfloor or floating floor?

You can also improve sound insulation with a rough or floating floor. But only improve, not replace. The draft floor is the same plywood over the transverse boards along the beams or logs. On top of the plywood covering the boards, felt is laid in a continuous flooring, and then the main floor.

The floating floor is an additional sound insulation, it is also a layer of plywood. Only in this case, the plywood is not fastened with anything, but simply lies on felt strips or solid textile flooring. Sheets of plywood are connected only to each other through the bottom lining rail. This method eliminates the contact of the floor and beams. In a similar way, they lay coatings in attics and attics

There is another way to improve sound protection - to increase the thickness of the overlap.

On a ceiling insulated and insulated from noise, sew a rail along the outline of the beams. Insert a fiber board into the gaps. Hem with a vapor barrier and again lay drywall, which will be for the front finish. With this technology, the Rw index will be at least 54, and the Lnw indicator will not be higher than 66.

Comfort in a wooden house is not only the enjoyment of natural materials. Noise-, evuko- and thermal insulation of wooden floors will create a cozy and calm atmosphere in your home.

Soundproofing wooden floors

>

Sound insulation of wooden floors between floors norms and requirements

Despite the general approach to the choice of soundproofing material, soundproofing of wooden floors for various purposes is carried out in compliance with different requirements.

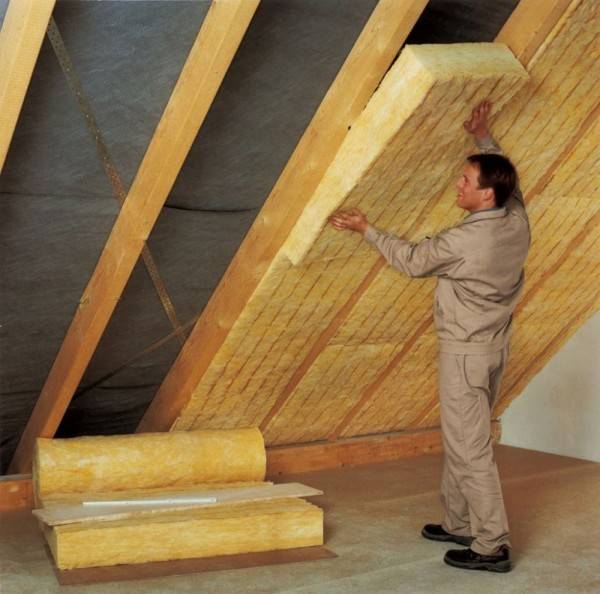

The sound insulation of a non-residential attic floor on wooden beams is considered to be effective if the airborne sound insulation index Rw is at least 45 dB.Such protection is able to provide a layer of mineral wool with a density of at least 50 kg / m3 laid in a layer of 100 mm. If the height of the beams is less than this value, then logs can be filled on them. And place the next layer of material between the lags. In order not to create cold bridges, the logs must be placed perpendicular to the beams. Then the joints will be covered with the next layer of cotton wool.

Sound insulation of interfloor ceilings will be sufficient if mineral or basalt wool mats are used, laid with a layer of at least 200 mm. At a density of 50 kg / m.cub. If the density of the material is higher, the layer decreases proportionally.

Soundproofing wooden floors with sand

The method is controversial. A laborious process, a lot of weight, and most importantly, the sound is partially damped, because. the main resonance is transmitted along the lags. The principle of the device is shown in the photo.

Of course, it all depends on the device method, as the masters advise, you need to fill the sand between the logs and the subfloor, and not just between the floor beams, and mount the floating floor system on top.

Scheme of soundproofing ceilings for drywall

The technology of soundproofing floors for a wooden house, in contrast to brick and concrete buildings, has a number of features that are directly related to the structure of the floors, their properties and sound-conducting characteristics. The methods described above will help isolate or significantly reduce the penetration of sound waves between floors in frame cottages, as well as in houses made of logs or timber.

Noise insulation between floors

Of course, to ensure sound insulation between floors, it is worth insulating on both sides, or rather the ceiling and floor, and doing it at the same time to increase the noise impassability. Soundproofing material must be inserted into the main structure of the interfloor ceilings.

The beams that carry the stability of the building are insulated with glass wool, foam rubber or other sound-reflecting material. Boards or plywood are laid on top, and they are fastened with screws to the beams through the insulation.

These structures will last longer if the soundproofing of the ceiling, floor, walls and coatings located between floors is done in accordance with all the rules. Yes, and in wooden houses, the slightest rustle or creak will be heard by the whole house due to the fact that the tree has the ability to perfectly conduct sound. Glass and lacquered wood surfaces also have a similar characteristic.

Summing up all of the above, we can conclude that such an event as isolation of floors from noise and extraneous sounds in a wooden house is simply necessary to ensure not only good sleep, but also comfortable living throughout the day. It is difficult to live where every rustle is heard.

And by isolating the premises from penetrating sounds, you can ensure full-fledged work and sleep. These are important elements of good mood and life.

Conclusion

When performing sound insulation of interfloor ceilings, it is necessary to select fire-resistant materials with a loose, porous and fibrous structure. Sand allows you to extinguish high-frequency acoustic sounds and low-frequency impact noise.

Sound insulation is affected by the friction of wood. Therefore, it is necessary to make gaps between the walls, the floor and the ceiling, and in the places of contact of the wooden beam with the wall, lay a lining of roofing material.

The most effective sound insulation can be achieved if fibrous materials are combined with flooring in stages and both parts of the interfloor wooden floor are insulated.

Heat loss through the ceiling and roof, according to accepted standards in construction, can be 15%. On the way of its ascent, it passes through the gaps and cracks in the ceiling.Along with the heat, sounds and noises walk up and down the cracks. If at the level of the boundary between the floors it is correct to carry out the entire cycle of insulating measures, then it is possible to build a reliable barrier to heat and sound at the same time.

It is possible to achieve low audibility in vertically adjacent rooms, even if the floor is made of wood. For this purpose it is necessary to understand the nature of noise. And modern materials and building technologies will help you get the best result.

Wooden ceiling on beams

Supporting structures made of wood are often used as spacers. For perfect sound isolation, this is not very good. After all, the tree itself is a conductor of sound. Especially if the beams are based on walls that take on and conduct noise. It is possible to significantly reduce the permeability of noise along the beams between floors. To do this, it is necessary to isolate the beams from contact with the wall using roofing material.

If it is a brick wall, then the ends of the beams must be wrapped with roofing material. In places where the beams rest on a brick wall, put roofing material, and on top of it - a thin wooden gasket.

The same principle applies to walls made of any stone, concrete or composite material.

A similar method of laying beams is applicable for house, attic and balcony walls made of wood. The only difference is that in the case of a wooden wall, a simple winding of the beams with roofing felt at the points of contact with the surface is sufficient. Roofing material or hydroisol cut off the unhindered penetration of noise and sounds along the wall through the beam. If the thickness of the ceiling, excluding ceiling and floor finishes, is equal to the height of the beam, then this measure will significantly change the final indices Rw and Lmw for the better.

Overlay on joists

The second option for arranging wooden interfloor ceilings is to lay logs along the beams. Then the floor will be laid on these logs. Draft or main. In this case, it is much easier to cut off the sounds transmitted along the walls. To do this, you just need to prepare logs of such a size that they do not reach the wall by 15 - 25 mm and lay them across the beams. Then the wall will not closely adjoin the floor.

Air openings between the wall and beams, and subsequently the floor, will be filled with soundproofing material. Its soft structure will dampen the sound vibrations of the walls and will not let them through to the floor. The baseboard will need to be attached to the wall, not to the floor. It also won't be a sound conductor.

A tape strip of felt impregnated with an antiseptic is enough for the sound from the walls to linger on the beams.

The upper side of the noiseless beams must be insulated with a felt pad, regardless of whether the floor lies on the beams or on the logs.

Work on the insulation of the floor from the "shock" sound should begin with wooden beams.

Part of the sound waves is able to penetrate between floors along the walls

It is very important to isolate the wooden beams from the wall. Then part of the noise can be cut off already at this stage

Mutual soundproofing of the upper and lower rooms using this technology will be much more effective.

Wooden floor of the house