Sealing gaps on a tiled roof

This is the easiest way to close the gaps between the pipe and the roof with a slate or tile coating, which you can do yourself. For sealing, you will need a moisture-resistant cement-based mortar, a container for mixing the mortar, metal corners, a decorative collar and water.

Work sequence:

- The seam between the outer wall of the chimney and the roofing is lined with metal corners. If the pipe has a rounded shape, then a self-adhesive rubber seal is used for this purpose.

- A galvanized decorative collar is put on through the top of the pipe and fixed with self-tapping screws.

- A waterproof solution is poured through the gap between the chimney and the collar and left for a day to solidify.

- After the solution has completely hardened, an inclined surface is prepared from the sheet steel for the liquid stack. To do this, a hole is cut out in the sheet corresponding to the diameter of the decorative collar, put on through the pipe and fixed with screws at its base.

To seal the roof with a mortar, it is necessary to use a high-quality waterproof mixture, otherwise, at the first serious rain, cracks form through which moisture enters the under-roof space.

Square chimney waterproofing

From the point of view of technology, for the proper organization of work with your own hands, it is not the nature of the roofing material that is important - from metal tiles, from ondulin, but the section of the chimney - rectangular or round.

The waterproofing of the chimney is carried out together with the laying of a waterproofing membrane on the roof.

- The film web in this area is cut so that the material overlaps on the chimney. The film is glued to the walls of the chimney with polymer-bitumen mastic.

- A layer of bituminous mastic is again applied over the tightly pressed edges of the membrane. Such waterproofing is already quite reliable, but does not differ in high strength.

- A crate under the apron is fixed on top of the membrane - the second element is waterproofing on the roof. The distance between the wall and the rail is 5–10 cm. It is recommended that the bars be treated with flame retardants.

- An apron is mounted around the chimney, starting from the bottom element. The apron is located 10–15 cm above the roof and covers an area of 20–30 cm along the perimeter of the chimney. Fastening - dowel-nails with a step of 15-20 cm.

- The joints between the elements and the chimney are treated with a heat-resistant sealant.

- Then the roofing material is laid on top of the bottom apron. Roof elements made of metal or ondulin are laid end-to-end, making sure that the gaps are as small as possible.

If we are talking about a roof made of corrugated board, then here a hole is formed in the sheet under the chimney 1.5–2 cm smaller than the parameters of the chimney. In the corners of the hole, cuts are made, the edges of the sheet are carefully bent. At the stage of laying the roofing, this fragment is put on the chimney and the bent edges are aligned, trying to reduce the joints to a minimum. For waterproofing, a special device is used, like a bituminous waterproofing tape, or roofing material and a water-repellent sealant.

- On top of the roof of corrugated board, metal tiles and other materials, a metal upper apron is mounted, similar to the lower one. You can use adhesive materials, like Wakaflex, Master Flash, Onduflash and more.

In the photo you can see the laying of the apron around the stove chimney on the roof.

Round chimney waterproofing

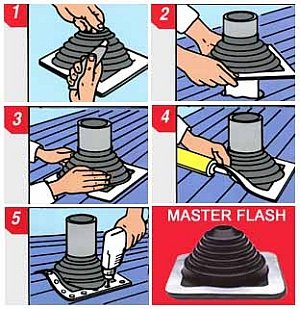

This need arose due to the widespread use of sandwich pipes, which are very practical and more affordable.It is even easier to do it yourself, since here waterproofing is provided by a special device - pipe driving.

The penetration looks like a box made of steel or aluminum with a cap made of polymeric material.

- A wooden crate is arranged around the chimney, just as they did in the previous case. Lay roofing material.

- A hole with the desired diameter is cut in the flexible polymer part of the penetration. The device is put on the pipe, crimped on the roofing material.

- Joints are treated with a special heat-resistant sealant. The penetration is fixed with screws to the crate in increments of 7–10 cm.

The video examines the waterproofing of pipes of circular and rectangular cross-section.

What sealants for chimneys are better to use types. specifications

The chimney is one of the most important communications in residential buildings, the effectiveness of which largely determines the possibility of living in the house. However, in order for the functioning of smoke structures to be efficient and safe, it is not enough just to install them - it is also necessary to ensure the tightness of the structure.

During the operation of the chimney, a very high temperature (1300 ° C) that occurs inside it contributes to the formation of various cracks and fistulas in the structure. This significantly reduces draft and allows toxic combustion products to enter the room. Therefore, the need to ensure the tightness of chimneys becomes vital.

The need for repair and sealing sooner or later arises even for expensive and high-quality tubular products, for example, galvanized or made of stainless steel. In order for sealing to be effective and long-term, a high-quality and reliable sealant for chimneys should be used for this purpose.

Important Points

The waterproofing of chimneys, if it is broken, can be restored in several ways: the choice of the most suitable one depends on several factors:

- The pipe installed on the slate roof must be freed from the cement apron, and then the slate sheets adjacent to the pipe must be dismantled. After checking the condition of the pipe for mechanical damage, an apron should be made of sheet metal. Joints are treated with oven clay with the addition of Portland cement or refractory mastic. Now you can lay slate sheets on the apron, and then coat them with cement mortar.

- Fused insulation can be used to isolate leaky spots, but damaged slate sheets should also be replaced.

- If the pipe is built of brick and the first two of the above points are completed, it is enough to coat it with a clay-cement mortar.

- For a roof made of metal, an apron is needed from the same material: it can be made using special scissors. Outlets of round pipes can be sealed with special corrugated rubber elements.

- With a large distance between the pipe and the ridge, special bitumen tapes with metal inserts are used.

If you do not close the joint

When removing the chimney, a hole is made in the roof. The gap between the coating and the walls of the chimney is sealed with special aprons, collars and seals. You can buy them at any hardware store. These protective elements are easy to do with your own hands.

If you do not seal the seams on the roof in time, the following consequences are possible:

- Increased wear of the roofing material. Water penetrating into the gap enters the inner surface of the roof, which causes deformation of the coating.

- Decrease in the service life of the building frame. Water that is poured into the gap between the pipe and the roofing contributes to the gradual decay of the wood. This is fraught with deformation and destruction of the rafters.

- The heater loses its effectiveness. The heat-insulating materials that the roof is equipped with can quickly lose their properties when wet. If hard insulation is not very susceptible to moisture, then soft insulation quickly begins to rot.

- Increased humidity in the attic. Increased dampness causes the appearance of stale, heavy air. This can negatively affect the interior decoration of the attic.

The way to eliminate the gap between the pipe and the roof depends on its size and type of coating. Also take into account the shape of the chimney. At a distance of less than 5 mm, a heat-resistant sealant is used. If the gap width exceeds 1 cm, cement mortar, an apron or a special sealant are used.

To close the gap between the pipe and the roof is necessary for:

- ensuring isolation of the attic from atmospheric moisture;

- to improve the efficiency of thermal and waterproofing;

- increase the service life of the truss system and the entire roof structure;

- elimination of cold bridges.

Sealing the chimney on the roof avoids the destruction of the roof itself.

Tape sealant

Tape sealant refers to solid materials. Many builders consider it the most profitable option for roof sealing. Material Features:

- it is based on butyl rubber;

- sealant tape is highly resistant to ultraviolet and high temperatures;

- it has high adhesiveness, due to which it is easy to install;

- ideal for sealing joints between chimney and roofing.

The tape has an aluminum coating, which increases the life of the sealant in outdoor use. The tape is easy to install and operate. The average service life of the product is 10 years. Due to the wide range of colors, the tape can be used for sealing various roof coverings. The sealant has exceptional adhesion to various surfaces. The tape is used when necessary for sealing wooden, plastic, metal surfaces. The tape is also successfully used for sealing translucent roofs.

How it is applied

The surface of the pipe and roof, on which the tape is applied, must be cleaned and dried.

It is important that the area to be treated is level. To apply the tape, you need to cut a piece of a certain length, then remove the protective film and press the product firmly against the joint (slit)

At temperatures below +5, the tape is first kept indoors at a temperature of 15 degrees for 12 hours.

Using the tape in sub-zero temperatures involves heating the treated surface. The tape is not used for surfaces with a working temperature above 80 degrees or with a roof slope of more than 55 degrees.

Sealing seams on a corrugated roof

Work sequences:

- L-shaped abutment strips are applied to the chimney and lines are marked on its walls along the upper edge of the strips;

- according to this marking, strobes with a depth of 10-15 mm are made with an angle grinder with a stone disc;

- the lower junction bar is installed first, while the bend in its upper part is inserted into the strobe;

- then, in the same way, the side strips are installed with an overlap on the bottom and lastly the top.

The strobes are filled with heat-resistant silicone sealant, and the lower horizontal parts of the slats are fixed with self-tapping screws to the crate. To prevent leakage at the attachment points, it is necessary to use special roofing screws with rubberized heads. If there are none, you can cut out gaskets from rubber and put them on a self-tapping screw under the head.

At the final stage, a so-called tie made of waterproof material is installed so that water flows into the drainage system of the house.A corrugated board is laid on top of the structure, another decorative false apron is installed and fixed with self-tapping screws to the pipe.

When sealing in this way, you can do without cutting the strobe, but for this it is necessary to lay out a pipe with a ledge, under which the junction strips will be wound.

Many furnaces are equipped with round pipes, consisting of several layers. To seal the seams around such a pipe, ready-made caps with an apron are produced. They are a galvanized sheet with a hole to which a cone is attached at an angle. The sheet is fixed with self-tapping screws on the crate, the pipe is inserted through a hole in the cap. The upper part of the cone is pressed around the pipe with a metal clamp with a gasket, ensuring the tightness of the connection.

In addition to rigid caps, Master Flash elastic penetrations are available for sale, allowing you to close the seam near the pipe quickly and efficiently. They can be used not only for sealing chimneys, but also for other roof elements - antennas, ventilation pipes. The appearance of Master Flash is similar to a metal cap, only it is made of rubber or silicone. It can be used at temperatures from -50°C to 130°C on any type of coating, especially suitable for use on translucent roofs.

Installation of elastic penetration is not difficult. At its base, a hole is cut slightly smaller than the diameter of the chimney. The penetration is simply pulled over the pipe, the base around the perimeter is smeared with heat-resistant silicone sealant and fixed to the corrugated board with roofing screws. You can additionally glue the junction of the base and the roof with self-adhesive tape. To protect the penetration from ultraviolet radiation, a decorative cap is put on top of it to match the color of the roofing.

How to protect the chimney from moisture

Practice shows that most often water leaks on the roof near the pipe are associated with poor-quality sealing of the roof cut. If the cutting is under the roof, it will flow from below, if on top - from above. To prevent this, by installing insulating aprons, the chimney on the roof is waterproofed.

The work is carried out in several stages:

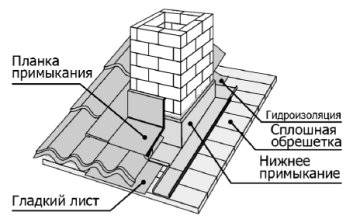

- First of all, a drainage gutter is laid in the waterproofing layer above the chimney, designed to remove moisture from the chimney.

- Then an internal apron is mounted, which ensures complete sealing of the junction of the roofing to the chimney.

- Next, the so-called "tie" is laid. This is an element cut from waterproofing material, placed under the lower edge of the inner apron. The design must necessarily reach the very edge of the roof. If the roof is covered with slate or metal tiles, the edge of the tie is brought out between the bottom sheets of the coating to the roof surface. Along the edges of the structure, a side is necessarily made with the help of pliers, which will not allow water to spread over the roof, but will direct it down the slope.

- Roofing is laid around the pipe.

- An external decorative apron is mounted on top of the roof. It is installed in the same way as the internal one. The only difference is that the top edge is attached directly to the pipe wall.

Insulating aprons are made independently, but if desired, industrially manufactured units designed specifically for this purpose can be purchased. They are used for wiring round chimneys through the roof and are called roof passages. The nodes are an element consisting of a flat sheet of steel in the form of a base, to which an apron is attached, made in the form of a cap. A chimney is passed inside it.

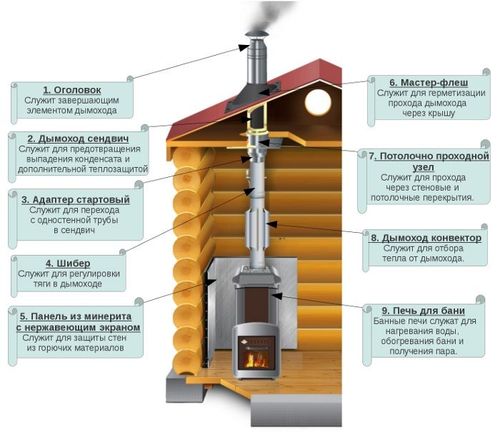

To ensure stove draft, it is necessary to equip ventilation outlets on the roof. They form air currents, protect ventilation from atmospheric precipitation and create traction in heating appliances. The outlets must be fixed strictly vertically and equal in height to the chimney, only in this case the air flows formed in them will be strong enough to ensure the optimal mode of fuel combustion in the heating device.

Pipe waterproofing is a responsible business. Not only the integrity of the roofing pie, but also the safety of using heating appliances depends on the correct implementation of it. Of course, you can do all the work yourself, but you need to calculate your strength and be sure that everything will be installed absolutely correctly. If, nevertheless, there are doubts about your competence, it is better to entrust the installation of waterproofing to specialists and get a unit assembled in accordance with all the rules in a short time.

Decide on the type of waterproofing material

The development of chemical production allows today to produce a large number of insulating materials for the roof carpet. What type of material to choose: rolled, liquid, powder? What composition should it have in order to protect the house for a long time and reliably from the penetration of water under the roof, especially in the places where the pipe exits to it?

waterproofing pipes together with flat roof base carried out using liquid reinforced mastics - mixtures of organic binders with extremely fine fillers. The composition of such mastics is very different, most often these are bituminous mixtures of hot or cold bitumen-gasoline. Today, more and more often on the market there are branded liquid or powdered mastics, intended for subsequent dilution with solvents, with a complex multicomponent composition.

On pitched roofs, rolled mastics, film and non-woven materials are used, which are also glued to the base with mastics or fastened with self-tapping screws. The well-known roofing material belongs to the number of rolled mastics. As a material for waterproofing, a special film, polyethylene and polypropylene, or non-woven synthetic membranes can be used. Rolled waterproofing has many modifications that allow you to purposefully select the one that will most fully meet the functions of a particular roof.

The quality of the waterproofing of the roof depends to a large extent on whether or not the joints formed by the exit of pipes to its surface are correctly made. It is these areas that often give out the unprofessionalism of builders. Based on the foregoing, it should be concluded that contacting specialists at the stage of waterproofing pipes and any exits to the roof will help to avoid unnecessary financial and labor costs in the future.

We sheathe the chimney with corrugated board

The priority of independent heating of a private house is more and more obvious. In addition to significant savings, this is the ability to independently choose alternative heating methods. Among the sufficient number of available options, stove heating is still popular. Despite certain installation difficulties, this is the best way to create a favorable microclimate in the house.

Any autonomous heating, with the exception of electricity, requires the removal of combustion products through the chimney. Today there are enough materials with which it can be organized. In the event that it is a refractory brick, it is best to protect it from the negative effects of aggressive environmental factors through cladding.

Attention.Our readers believe that morning fishing is a myth! The secret of the catch is revealed, you just need to dissolve 1 sachet in 0.5 liters of water more

The chimney lining is a kind of shield that prevents the formation of condensate as a result of the interaction of the temperature difference between the environment and the chimney.

Heat resistant chimney sealants

This type of sealing material has a silicone base to which iron oxides are added. Such additives not only increase the temperature stability of the sealant, but also give it a reddish tint, which makes the composition invisible when processing brick chimneys.

When using heat-resistant silicone sealants, a number of important features should be taken into account, in particular:

- Such materials can release acetic acid, contributing to the formation of an acid reaction. This is the reason that they cannot be used for metal chimneys.

- Some types of heat-resistant sealants are not resistant to solar radiation, which limits their use for roof structures.

- Good adhesion with many substances and materials (brick, ceramics, glass, concrete, etc.) makes the scope of their application quite wide.

- Due to their high water resistance, they can be used to seal the upper sections of chimney structures.

- They have good ductility and strength, as a result of which they can be used in structures that experience significant wind loads.

- The curing process of silicone sealants takes from several hours to several days, and depends on the temperature and humidity of the environment. The optimal values for these indicators are 25 ° C and 50%.

- Silicone sealants are not recommended for deep seams or cracks.

- To improve the quality of sealing, before applying the composition, clean the surfaces of the seams from dust, dirt, grease and other contaminants.

- Application of silicone sealants is possible only on completely dry surfaces.

- Conventional silicone sealants used in construction are not heat resistant and cannot be used to seal chimney structures.

Finishing the chimney choice of materials

Among the negative factors affecting the chimney are:

- atmospheric influences (wind, precipitation, ultraviolet radiation);

- ambient temperature difference;

- high temperature workloads.

Due to the difference between the temperature of the working pipe and the air temperature in the chimney, condensate forms, which provokes the destruction of the pipe during the combustion of heating oil. To avoid the formation of condensate and protect the pipe from external influences, it is required to provide reliable insulation of the chimney due to the cladding.

Various materials are used for sheathing the protruding part of the pipe. When choosing, consider:

- resistance to external factors, wear resistance;

- appearance and color scheme (corresponding to the roofing or wall decoration of the building).

Finishing the chimney on the roof is most often done using:

- clinker bricks or tiles;

- plasters;

- cement fiber boards;

- roofing material (corrugated board, slate).

Characteristics of finishing materials

Finishing the chimney on the roof with plaster is characterized:

- affordable cost;

- simple installation;

- versatility (suitable for any roofing);

- the ability to implement any color solutions (plaster can be painted with silicone paint).

Plastering of pipes is carried out using the same technology as the finishing of facade walls. Traditional cement or lime-cement mortar can be used, but a more durable option is to use mineral, silicone, silicate or acrylic plaster. Painting the dried surface increases the wear resistance and durability of the finish.

Small format fiber cement boards are durable, resistant to ultraviolet, moisture, temperature fluctuations, and are light in weight. It is an environmentally friendly, non-flammable material. For lining the chimney, you can use smooth or structured plates, the material is on sale in a wide range of colors.

If slate is used for roofing, the chimney lining on the roof is usually made from the same material. Slate slabs can be in the form of an arc, scale, rectangle or octagon. The color of this natural material depends on the deposit. It is usually graphite, green or magenta in color.

A fairly simple and budget option for finishing the pipe is the use of corrugated board. It is used if the roof covering is made of the same material. A chimney finished in the color of the roof looks aesthetically pleasing.

Prefabricated chimney elements for the roof passage have an aesthetic appearance and are quite easy to install. They are equipped with a steel chimney channel and can have a ready-made external cladding of any material, or be prepared for self-finishing so that the chimney externally harmonizes with the roof. The modular steel structure is not additionally finished, it is enough to mount it at the point of passage through the roofing pie.

Roof chimney waterproofing

When making a passage through the roof, it is important to comply with SNiP standards. Between the elements of the roof and the chimney, a gap should be left, the size of which is regulated by the documents

At the place of passage through the roof, a box is usually mounted (wooden or galvanized metal), in which all the free space around the pipe is laid with non-combustible material - stone or glass wool.

Sealing the chimney on the roof can be done using improvised means or using unified elements. Around the chimney, a so-called collar should be made, or a salary - a finish made of metal strips, about 40 cm wide, in accordance with the dimensions of the pipe. The bending angle of the steel strips must correspond to the angle of passage of the chimney through the roof. To calculate the length of the section, you need to take into account:

- slope angle;

- chimney dimensions;

- chimney type.

If the salaries are made of galvanized sheet, then they are interconnected with an overlay and soldered. The steel sheet elements are joined by a double standing seam. The lap seam connection is used to seal the passageway assembly on roofs made of corrugated boards and tiles. If the angle of the roof slope is more than 30 degrees, a special beam should be installed behind the chimney - a “bumper” that will protect the pipe from rainwater flows and excessive snow pressure in winter.

The protective elastic apron for the chimney can be made:

- from a flexible metal tape (lead or aluminum);

- made of galvanized metal with a polymer coating.

The apron is installed around the pipe in two layers around the entire perimeter. The bottom layer of the apron is placed under the roofing, and the top layer is mounted on top of the roofing material.To close the top layer of the apron, a waterproofing film and metal profiles are used.

The top folded edge of each apron must fit into a groove cut along the perimeter of the chimney. After mounting the edge into the groove, the joint is filled with polymer sealant or silicone for the roof.

Ready solutions

The sealing of the chimney on the roof is a rather difficult task, the quality of the solution of which depends on the reliability of the thermal and waterproofing of the roof. You can complete the passage assembly yourself, using various materials and special strips, or mount a finished structure, which includes a wide protective apron.

Ready-made roof cutting on the construction market is presented in many versions - the models differ in material and manufacturing method, as well as the angle of inclination of the element that protects the place where the pipe passes through the roofing pie from water. The angle of inclination can be from 15 to 55 degrees, therefore, the cutting of the chimney on the roof is designed for the most popular slope slope options.

For the installation of such a design, a hole of the appropriate size is made in the roofing pie. A seal made of rubber is attached to the structure from the outside with the help of silicone. The distance between the pipe and the collection passage is filled with non-combustible insulation. The roof penetration covers the passage assembly, after which the penetration can be attached to the roof with self-tapping screws. It is recommended to use a sealant to seal the connection.

When choosing the option of how to close the chimney on the roof, you can use other ready-made solutions, for example, Master flash roof penetrations.

https://youtube.com/watch?v=rL-_Irakk4s

Possible problems with poor-quality sealing of the passage on the roof

Decking is a high-quality roofing material that has a complex layered structure. Layers are applied to the outer base of the steel sheet:

- zinc;

- additional anti-corrosion;

- primers;

- polymer (polyester);

- mounting protection.

And on the inside, galvanizing, primer and corrosion protection are also applied. Thanks to this structure, the corrugated board has an excellent bearing capacity, protection against rust, fire and decay. The building material retains its properties over a wide temperature range.

On the roofs of houses, it is customary to create various openings for ventilation and smoke. This naturally leads to a violation of the waterproofing and other protective layers. Therefore, sealing the joints of the pipe with the roof surface is of great importance. This process should be carried out in the right way, otherwise problems may arise:

- Leakage. When the pipe is led through the roof, the presence of uninsulated slots leads to the penetration of water into the house, living quarters, dampening of walls, including load-bearing ones, the appearance of mold, etc.

- Destruction of rafters. The roof structure consists of wooden rafters. Moisture, getting through the joints, contributes to the decay of the tree and the destruction of the entire structure.

- corrugated board corrosion. Despite the fact that the roofing material is protected by anti-corrosion layers, the internal protection is weaker than the external layer. Corrosion gradually destroys corrugated board, reduces its protective characteristics and attractive appearance.

- Reducing the level of roof insulation. When water penetrates into the layers of thermal insulation, the latter lose their ability to retain heat and protect against external cold. The insulator loses about 50% of its ability to effectively retain warm air in residential areas.

To be sure of the quality of your roof, you should repair the joints in a quality manner. Various sealing methods have now been developed that allow high-quality waterproofing of the gaps between the pipe and the flooring.

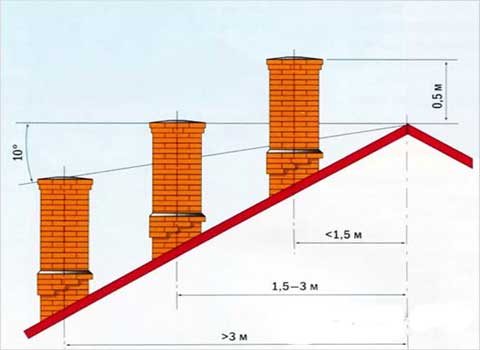

How to choose the right location for the chimney on the roof

The best option, according to boilermakers and roofers, would be a chimney device on the roof near the ridge.

- This makes it possible to ensure minimal accumulation of snow around the chimney in winter, the absence of snow pockets near the ridge, that is, leakage in the junction zone is excluded.

- Height of chimney above roof at the same time, it is small, which leads to a decrease in the impact of external unfavorable external factors on its design.

- The low height of the chimney relative to the ridge creates favorable conditions for the formation of the least amount of condensate.

It should be borne in mind that the lower the chimney is located along the roof slope, the greater the height of the chimney above the roof according to building codes.

If there is a common wall with a multi-storey building, then the pipe is brought out above the roof of the high-rise building.

Where it is not recommended to install a chimney

It is better not to install passage nodes in the following places:

- next to the skylights, since any gust of wind will bring carbon monoxide and smoke into the attic;

- valleys, the junction of two slopes that form an internal corner, where it will be difficult to ensure a good connection to the pipe, in addition, a huge snow pocket is formed there.

The chimney must not be rigidly fixed to the roof, since if the integrity of the roof is violated, there is a risk of destruction of the chimney, respectively, and fire.

Conclusion

The arrangement of the outlet of the pipe through the roof should be approached with the utmost responsibility. If the work is done poorly, moisture will regularly enter the attic. This will entail dampening of the rafter system and insulation.

High humidity adversely affects the condition of the wood. As a result, many load-bearing elements of the attic are deformed. This can lead to sagging of the roof and the appearance of cracks in it. High humidity in the attic room has a devastating effect on the internal facing material. The durability of the roof depends on the correct choice and installation of the sealant.