Flat roof device technology and materials

A flat roof has a smaller area than a pitched one, and for this reason alone it is cheaper. Funds are also saved, due to the absence of a truss structure, and the rolled waterproofing materials themselves are less expensive than tiles or metal.

For domestic private housing construction, flat roofs are not typical. Many homeowners consider them as attributes of industrial architecture and high-rise buildings. However, it is worth moving a little further west, for example, to Poland, as cottages with flat roofs appear before your eyes in large numbers. And this is not surprising, because the Poles are the closest neighbors of the Germans, and they are well aware of the economy. In Germany, there is indeed a huge number of private houses of post-war development with a flat roof.

Recovering from the devastation, the Germans were forced to count every penny. And although houses with flat roofs were not traditional for them at that time, they began to build them. First of all, there were economic advantages. The construction time was also reduced due to less complex and time-consuming installation.

As for the climatic factor, the only restriction for the construction of a flat roof may be regions for which heavy snowfalls are typical. There it is better to have a gabled pitched roof, such as one sees in the Alps.

Key Recommendations

After the decision was made to complete the roof pie of the house using soft tiles, you need to think about laying it yourself. Installation is not difficult, but the technology has some features. The following work recommendations can be made:

Material after purchase is stored indoors. Sheets are stacked in a horizontal position in pallets, the height of which is taken no more than 16 rows. The underlayment carpet, which is used for priming and leveling the surface under the tiles for storage, is placed in a vertical position.

To create favorable temperature conditions in the under-roof space, thermal insulation will be required. The selection of the type of insulation is carried out depending on the preferences and financial capabilities of the owner of the house. Most often, mineral wool is installed

The laying technology of this material assumes the presence of reliable waterproofing and vapor barrier

In addition, to remove liquid vapors from the surface of the insulation, a ventilated air gap is provided between it and the roofing, the width of which is on average 5 cm.

When buying roofing material, it is important to pay attention to the batch of goods. The roof will look better if you use materials made at the same time in one place.

In this case, an exact match in color and physical characteristics can be guaranteed.

Installation of soft tiles is not carried out at negative temperatures

This is due to the fact that the material becomes brittle in the cold and can be easily damaged when fixed in a cake.

For laying the material with your own hands, the minimum slope angle should be 15 degrees.Installation at a lower level does not guarantee waterproofing, since the liquid moves rather slowly over the surface and can easily flow into small gaps. In this case, it is worth considering the rule that the roof slope cannot be too large for bitumen and remember that the more the roof is tilted, the more material is required for the cake.

Do-it-yourself installation of soft tiles is carried out without the use of a burner. This material does not belong to the class of built-up materials. For additional fixing (with strong wind loads), special adhesive solutions are used.

Peel off the transparent protective film from the inner surface immediately before laying on the cake.

When doing work with your own hands, it is important to remember that it is not allowed to walk on the roof without special devices in sunny warm weather. This is because the material melts slightly when exposed to sunlight, and the installer may leave shoe marks on the surface that cannot be removed without replacing part of the coating.

A solid material is used as a base for tiles. The pie may include a solid crate or a sparse one, followed by laying moisture-resistant plywood on it. Installation directly on the heater is prohibited.

If you follow these recommendations, then the roof with flexible tiles will delight its owner for many years.

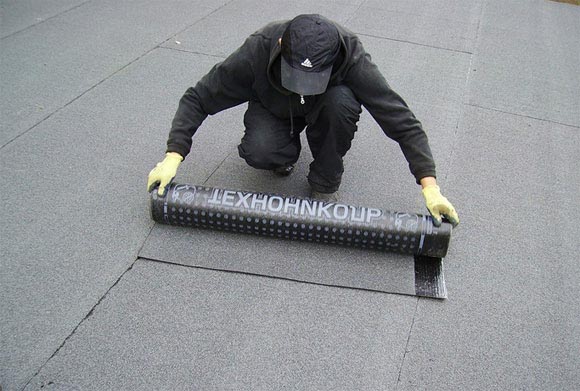

Roof covering with roll materials

The device of flat roofs allows the use of rolled materials, the strips of which are overlapped, and in the same direction:

- when the slope of the flat roof is more than 5%, then the outer width of the overlap is 10 centimeters, and the inner one is 7 centimeters;

- when the slope does not exceed 5%, the width of the overlap for all layers is at least 10 centimeters.

If during the process of sticking the panel deviated from its location, you should try to return it to its place without peeling off the material. But if it is impossible to move, the glued piece is cut off and the panel is glued again, observing a 10-centimeter overlap.

When a flat roof is being installed, strips of rolled material are laid in layers (for more details: “Roll roofing device - coating properties“). If the installation is carried out on a liquid mastic, each layer is glued at intervals that cannot be less than 12 hours.

Features of the device of flat roofs, detailed video:

How to make a soft roof

The arrangement of the roof is a complex task, which includes a number of specific steps.

As a foundation on which a soft roof will be laid, moisture-resistant plywood, OSB-plate or edged board is used. It is also allowed to use other building materials with a flat surface and humidity not more than 20%. The seams of such sheathing must necessarily have a certain gap. For plywood and OSB boards, a minimum gap of 2-3 mm is allowed, for edged boards, a gap of 5 mm must be left. This is necessary so that when expanding under the influence of temperature and moisture, the base does not begin to deform. On edged boards, annual rings are centered down.

This system is designed to ensure proper air circulation quality, which prevents condensation from forming on the back of the base. If this stage is neglected, then soon the rafter system may begin to rot, and in winter ice and icicles may form on it.

Roof ventilation includes the following elements:

- vents in the overhangs of cornices;

- ventilation outlets;

- the gap between the waterproofing and the base is at least 5 mm.

In order for the attic to be properly ventilated, soft tile manufacturers recommend that the ventilation holes be distributed evenly along the entire ridge.

The arrangement of a soft roof includes the organization of the lining layer.It is mounted on the cornice overhangs, ends and valleys of the roof from top to bottom. With roof slopes over 18 degrees, you can make a lining layer only in those places where there is the greatest likelihood of leaks. Skates and valleys are covered with a layer 25 and 50 cm wide, respectively. At the same time, the valleys are equipped with a lining layer on both sides.

With roof slopes from 12 to 18 degrees, the lining is placed over the entire roof area, starting from the bottom, moving upwards parallel to the eaves. The overlap between the lining strips in the longitudinal direction should be 15 cm, in the transverse direction - 10 cm. The lining is fixed with special nails at a distance of 20 cm from each other. To achieve better tightness of the lining layer, the overlap points are lubricated with bituminous mastic.

Installation of cornice strips

The elements are made of metal. They are mounted on the overhangs of the eaves directly on the lining. Wooden planks are necessary to protect the edge of the crate from rain and wind. Fasteners are made with mounting nails with a wide hat with an interval of 100 mm. At the junction of the cornice strips, an overlap of at least 2 cm is made.

Installation of gable slats

As in the previous case, the slats are made of metal. They are laid on the ends of the roof over the lining layer. The purpose of these strips is to protect the edge of the crate from the ends. Fastening is carried out similarly to the strips on the cornices.

It is necessary for additional protection of the roof from rain and snow. Choose it according to the color of the roof. Fix the carpet with nails with a wide hat. The overlap is carefully glued with bituminous mastic.

Installation of cornice tiles

When laying soft tiles, it should be remembered that before starting work, it is necessary to remove the protective film from the back of the tiles. Cornice tiles are laid at a distance of 10-20 mm from the edge of the cornice (more details: “Soft tiles - laying technology: “six rows” method“). At the same time, each element of the tile is laid exactly end-to-end.

Inverted flat roof installation technology

An inverted roof is more reliable and durable than a traditional roof, it does not leak for several decades.

When constructing this type of structure, the order of the layers is changed, thereby improving the quality of the roof. Unlike the first method, such a structure can be operated.

- For minimum loads, porous-insulating, heat-insulating, and waterproofing materials are used. As a final coating, roll-type materials are used.

- For medium loads, it is necessary to use stronger and denser thermal insulation. As a final coating, paving slabs or other types of similar material are used.

- For significant loads, reinforced material is installed between the main layers of insulation. And as a final coating, a reinforced concrete slab is used.

Installation of an inverted flat roof is carried out in the following sequence:

- First, the base is prepared, a reinforced concrete slab is laid, then it is coated with a primer to ensure that the waterproofing is well attached.

- Laying waterproofing material is somewhat different from the traditional method. First, a waterproof material is laid, it can be PVC or rolls, which include bitumen.

- Then proceed to laying the insulation material.

- Then the geotextile is spread, which should be located between the insulating materials of the internal composition, and the final coating.

- At the end, the final coating is laid; for roofs with a minimum load, roll-type materials or gravel are used, which is applied to the entire surface. For a roof with an average load, you can lay paving slabs or use other durable materials.For significant loads, a reinforced concrete slab of a monolithic type is used.

Types of soft roof structures

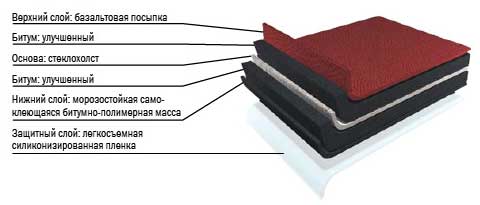

Roofing cake is a generalized technical term that combines a number of structures with a similar "layered" structure. The combination of layers should protect the owners of the house from atmospheric attacks and protect the internal filling of the cake from premature spoilage.

The standard structure of a roofing pie includes the following mandatory components:

- Vapor barrier. Prevents the penetration of evaporation from the interior of the house and the condensation of moisture on the building materials used in the construction of the roof;

- Thermal insulation. Contributes to the preservation of heat, protects from noise coming from outside, winds, cold temperatures;

- Waterproofing. Prevents the penetration of rainwater and melted winter precipitation into both the roof structure and the building;

- Decorative coating that simultaneously performs the work of wind protection.

The category of soft roofs includes materials with excellent waterproofing qualities. Among them are bituminous roll representatives, piece analogues, mastics and a new generation of membranes. A couple of decades ago, they only served as a barrier against water, and now they also successfully play the role of decorative coatings. This is due to the ennobled outer surface and the development of laying methods that allow attaching super-thin materials to any type of base.

The combination of insulating and decorative properties made it possible to reduce the number of main layers in the roofing cake to 3, if one of the types of rolled materials is used to equip the roof.

When laying bituminous tiles, waterproofing is not completely abandoned. However, it is laid as an additional waterproof layer and covers the roof either completely if the slope of the slopes does not exceed 18º, or partially in strips along the overhangs, along the ridge and valleys, around the pipes and at the junctions on roofs with slopes steeper than 18º.

The above list of the main roofing layers has the nature of general recommendations. In fact, it is being finalized by reducing or adding functional elements, because a number of significant circumstances influence the formation scheme of an ideal roof structure, such as:

- the type and purpose of the object being equipped, i.e. a residential building or household building;

- temporary or permanent use, determining the use or rejection of thermal insulation;

- the shape of the roof and the steepness of its slopes, directly related to the choice of materials for roofing;

- type of base for arranging a pie and laying a soft roof;

- the presence of an operated or non-operated attic;

- regional climatic features, according to which the thickness of thermal insulation is determined;

- compatibility of structural layers, as in case of incompatibility, separation or migration layers will be required.

A well-arranged pie for a soft roof is constructed taking into account the full range of the listed conditions. Without information about the specifics of the project, no one will give exact recommendations, but it is worth familiarizing yourself with the principle of construction, regardless of whether the cake will be arranged with your own hands or hired roofers will be engaged in laying it.

Flexible tile device

In general, flexible tiles can be thought of as fiberglass that has been impregnated with bitumen. Its main layer is enclosed between layers of oxidized bitumen containing polymer additives. Thanks to these layers, the material acquires strength and ductility. It gets its color from the granulates of different colors that cover the top layer. They simultaneously perform a protective function, protecting the material from UV radiation and exposure to the atmosphere. Recently, manufacturers supply the material with a bottom adhesive layer, which is most often covered with a mounting film.Such a device of the material not only simplifies its installation, but improves the quality of installation, as it increases adhesion to the base and better seals the coating.

Mounting tools

A flexible roof can be laid by 1 person, the only requirement for the roof surface is that its slope must exceed 12º. The maximum slope angle is not limited. Work requires the following materials and tools:

- knife,

- hammer,

- sealant,

- mastic,

- roofing nails,

- work gloves,

- trowel for applying mastic,

- ridge cornice strip,

- trim and eaves,

- waterproofing underlayment.

Surface preparation

The base to which the material is attached must be solid. This distinguishes the device of roofing from soft tiles from roofs for which other materials are used. For comparison: a metal tile is laid on a crate, between the bars of which a gap is allowed. This is due to the high rigidity of the metal tile. A soft roof does not have it, therefore it requires preliminary installation of a solid base.

For it, OSB boards (oriented strand boards), moisture-resistant plywood with a thickness of 9 mm or more, as well as edged or tongue-and-groove boards are used for it. Any of these materials are laid with a shift of the seams, that is, apart, while leaving a gap of 1 cm between them.

For it, OSB boards (oriented strand boards), moisture-resistant plywood with a thickness of 9 mm or more, as well as edged or tongue-and-groove boards are used for it. Any of these materials are laid with a shift of the seams, that is, apart, while leaving a gap of 1 cm between them.

The surface must be clean, smooth and dry. The quality of installation and the service life of the coating depend on these conditions.

The roofing cake should also have the following layers:

- first, vapor barrier material is laid on the rafters;

- if an attic is planned, a mineral wool insulation is laid on top;

- from the outside, on the base, for example, OSB boards, a waterproofing roofing carpet is attached using the overlap method using roofing nails; each of its strips is unfolded horizontally from the bottom up with an overlap of 15 cm.

The lining carpet, in addition to protecting it from moisture, protects the roof from destruction if the installation of soft tiles is not temporarily carried out.

What is a green roof and how to build it

Green roofing allows you to give the building an original look and design. Such a roof has several advantages:

- Thanks to space savings, various vegetables and berries, ornamental plants can be grown on the roof, and a comfortable area for relaxing or business meetings can be placed in a green atmosphere.

- With the help of plants, more oxygen will appear on the site, that is, they favorably affect the environment. Also, plants are able to absorb various toxic substances if the city has a large gas content.

- The layer of soil located on the roof cools the room inside in summer and warms the room in winter.

- Thanks to this construction, the level of sound insulation increases.

If it is planned to build such a roof, then it is necessary to strengthen the structure, since a significant load will be placed on it.

Green roofing can be of two types:

The extensive type of roofing is covered only with ornamental plants or lawns, while the soil layer is up to 15 centimeters. Watering is carried out only when the grass begins to grow, and other plants are in pots. At the same time, lawns are periodically cut, as needed.

The intensive type of roof allows the placement of soil up to 60 centimeters, that is, you can plant not only decorative, but also fruit plants that have shallow roots. On the roof of this type, you can place a garden or vegetable garden, while the structures of the supporting type must withstand a significant load. This type of roofing is expensive.

The installation of a green roof is carried out according to the principle of a conventional reinforced structure. First, a reinforced concrete base is laid, then a waterproofing material is placed. After that, polystyrene foam is laid, it serves as an insulating material.Spread geotextiles, and perform drainage from crushed stone or gravel. Then the geotextiles are laid again, and the soil is placed. After all the layers are laid, you can plant the necessary plants.

Such a roof is built at a slight slope so that excess water can freely go down. Otherwise, it is necessary to install a drainage system, otherwise, in case of stagnant water, the roof cake will deteriorate. Moisture will begin to penetrate into the room, this is fraught with the destruction of the flow, and subsequently the walls.

Thanks to this solution, the roof can be given an original look, as well as usefully growing various vegetable and fruit plants. Among such an atmosphere, you can make a play complex for children, a site for recreation, tea drinking, and other events.

When arranging a green roof, water should not be allowed to stagnate on the surface. It is better to plant plants that do not require frequent watering. It is also necessary to take into account the load exerted by the soil located on top, the structure must be reinforced to withstand all the expected weight. All miscalculations are desirable to be completed before work begins on the construction of the roof.

Do-it-yourself euroruberoid soft tile

This rolled material belongs to the category of built-up type. It can be safely laid on roofs with zero slopes

It is only important to realize how to lay a soft roof correctly. For laying euroroofing material, it is necessary to properly prepare the base

It must be clean and dry. In addition, the base must comply with all fire safety requirements. The basis for laying such a soft roof can be any monolithic floor, but at the same time it must be equipped with slopes for water drainage. In addition, roofing material can also be welded onto oriented strand board. If the roof is laid on an old roof that already has a tar cake, it will only enhance the properties of the new roof.

The prepared base is treated with a special bituminous mastic. It is available on the market in the form of a concentrate and already in finished form. If there is already a layer of resin on the base, then there is no need to apply mastic here.

When buying it in a store, pay attention to the instructions on the package. There must be indicated the time required for the complete drying of the mastic

It is strictly forbidden to fuse roofing material before this time, as this negatively affects the quality of the resulting roof. Well, then you can make a roof from roofing material with your own hands. following the instructions.

Work always begins from the point of the roof, where the installation of the drain is done by hand. Due to the fact that the runoff line runs parallel to the slope, the water will not enter the joints between the individual strips of roofing material.

The roll of roofing material must be unwound in such a way that it does not have folds, that is, it is absolutely even. After that, you need to pull it well and fix one edge. To do this, the roofing material is heated with a burner until the indication film on its surface melts (for more details: “Euroroofing material - laying technology: installation process“). The edge of the material is glued to the base. After alignment and docking of the attachment point, the roll of roofing material is tightly rolled up.

This is followed by the process of fusing the roofing material onto the base. In order for this operation to be carried out correctly, it is necessary to adhere to several rules of work:

Do not overheat the material. If, nevertheless, this could not be avoided, then you will have to buy a new roll of roofing material, since overheating leads to damage to the material and inability to stick.

The finished surface is covered with a protective powder

It is important to exclude "bare" spots without protection.

Roofing material strips are welded with an overlap of at least 10 cm. For orientation, there is a special line on the material strips.

Soft roof device, detailed instructions on the video:

Particular attention should be paid to the junction of the roofing material to the ventilation channels and other roof elements. For the treatment of such problem areas, mastic for soft roofing is used.

After drying, it acquires the same protective properties as the euroroofing material itself.

Often, snow is able to penetrate into places where water does not get, which is why it is so important to properly process the adjunctions. If work is carried out on a roof with a large slope, then it is imperative to install snow retainers (read: “Soft tile roof - device“)

In addition, it is necessary to take measures to prevent icing in winter, as well as properly install drips and drainage systems.

As you can see, the technology of laying roofing material is slightly different from the process of installing bituminous tiles (for more details: "Bitumen tiles: do-it-yourself installation - fastening standards"). But in both cases, upon completion of work, it is necessary to clean the roof of any debris and foreign objects. If this procedure is not given due attention, then in places of contact with foreign objects, the coating may become unusable.