Finishing

The setting of the solution may take time, so it is better to wait 2-3 days. Finishing is cleaning mortar bricks and give it an even tone.

It is more convenient to remove excess solution with a drill with a brush-type nozzle. The work is dusty, so use a respirator and goggles.

After cleaning, patches of non-uniform color may remain on the bricks. To even out the shade, use a solution of laundry soap with water and a hard, dense brush. After that, the brick "fur coat" is washed with water. The result is a beautiful shade without blemishes.

The first furnace after lining, do it slowly, allowing the brick to gradually absorb the heat.

That, perhaps, is all. I think that you will immediately feel the comfort from the lined stove. The heat will become more balanced, and the heat source will please you with a pleasant view and pleasure from independent work.

Wisdom Quote: The greatest happiness in life is the certainty that you are loved (Hugo Victor Marie).

Protective screens around the oven

Protective screens are insulation shields that cover the side surfaces of the furnace and reduce the intensity of thermal radiation. Screens are metal and brick. As a rule, they are used for metal furnaces.

Method #1 - metal screens

The most common protective screens are factory-made steel or cast iron sheets. They are installed around the furnace, at a distance of 1-5 cm from the walls of the firebox. Depending on the need to insulate one or another side of the furnace, you can purchase side or front (front) screens. Many metal furnaces are initially made with protective screens in the form of a protective casing.

Protective screens reduce the temperature of external metal surfaces to 80-100°C and, accordingly, reduce the fireproof distance to 50 cm. The total distance from the firebox to the wall (together with a gap of 1-5 cm) will be 51-55 cm.

Installing protective screens is not difficult. Due to the presence of legs, metal shields are easily attached to the floor with bolts.

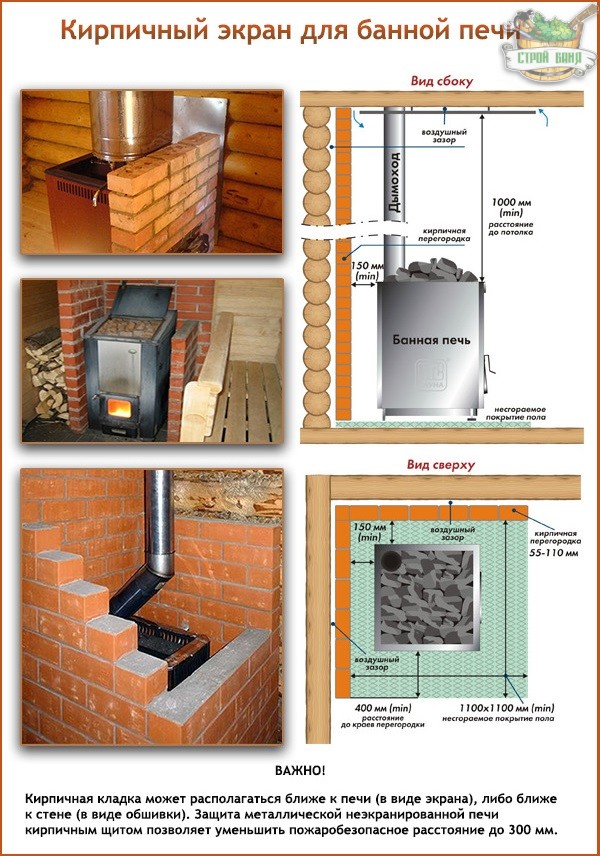

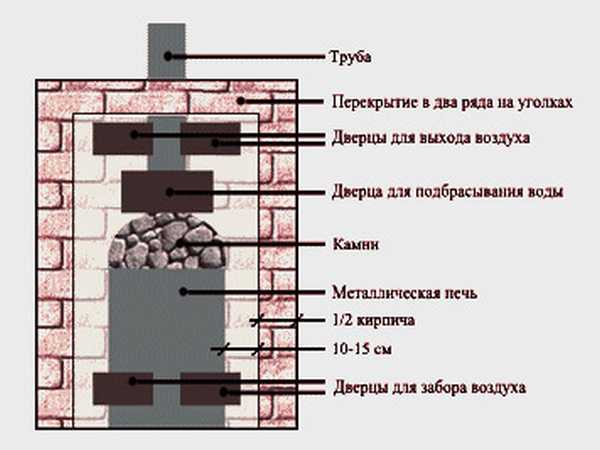

Method # 2 - brick screens

A brick screen can cover all the side surfaces of a metal furnace, representing its outer skin. Then the stove will be in a masonry casing. In another case, a brick screen is a wall that separates the furnace and the flammable surface.

For laying a protective screen, a full-bodied fireclay brick is used. The binder is cement or clay mortar. It is recommended to lay in half-brick (thickness 120 mm). But, with a lack of material, it is possible to allow the wall to be made a quarter of a brick (60 mm thick), although in this case the heat-insulating properties of the screen will be reduced by half.

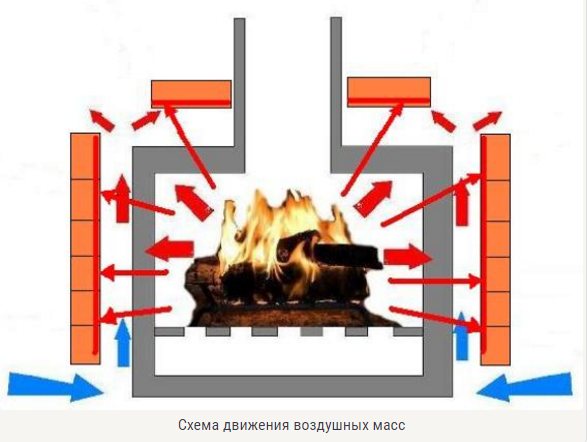

Small holes are left in the lower part of the shield (sometimes with furnace doors) for air convection between the brick wall and the stove.

The brick walls of the screen must end at least 20 cm above the top surface of the furnace. Sometimes laying is carried out to the very ceiling.

The brick screen is not installed close to the walls of the furnace, the optimal distance is 5-15 cm. The acceptable distance from the brickwork to the flammable wall is 5-15 cm. Thus, the use of a brick screen allows you to reduce the distance from the furnace to the wooden wall to 22-42 cm (oven - ventilation gap 5-15 cm - brick 12 cm - ventilation gap 5-15 cm - wall).

Advantages of using a metal stove in a bath

Today, a metal stove in a bath is already a standard equipment, without which it is difficult to imagine a wellness procedure loved by many. Compared to other types of ovens, it has several advantages:

- Ease of installation. It is easy to make with your own hands.

- Easy and simple operation.

- She melts quickly.

- Has good traction.

- High performance.

- Economical in fuel consumption and democratic in price.

But in order to really appreciate all these advantages as much as possible, you need to learn how to use it correctly!

Furnace in the steam room

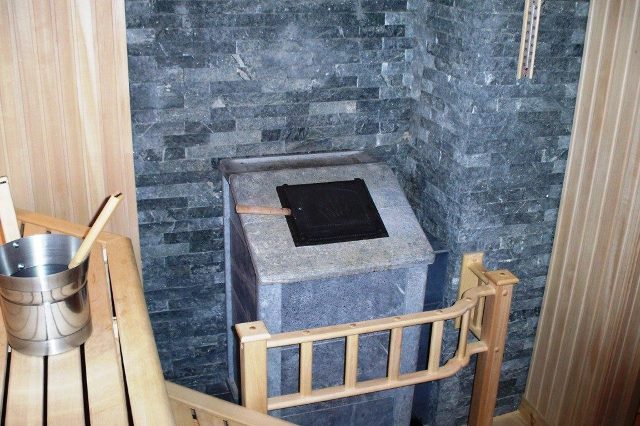

Of course, no one will argue that a stone stove is ideal for a bath. But it needs to be melted for at least 5 hours so that it really begins to give off its heat, imagine how much firewood will go away during this time. And this, in turn, does not suit everyone. And the price of a brick structure will be many times higher than that of a metal stove lined with stone.

Scheme of the movement of air masses

In addition, in order to fold a brick stove for a bath, you need to have the initial skills and knowledge of a stove-maker, since in this design you need to take into account many nuances that are invisible, but play a decisive role!

brick oven

A metal furnace can be bought ready-made, and the lining will not entail large financial costs.

Even if the metal stove itself, bought ready-made in the store, is already a decoration for the steam room, it is better to make a small stone apron around it. This will greatly increase the efficiency and productivity of the oven. Yes, and people who are in close proximity to the metal structure will be more comfortable, because the metal “fries” more than stone or brick!

Metal oven without brick lining

What are the necessary parameters should a metal stove for a bath have?

- It should be small in size so as not to clutter up the space.

- You should not choose too much power, as the sauna room is usually small. It will be difficult to control the optimal temperature.

- The characteristics of the furnace must clearly comply with fire safety regulations.

In addition, it is necessary to take into account the place where the furnace is located. According to the norms of SNiP, the metal unit should be located at a distance of at least 15 cm from the wooden floors.

Sauna oven

The most optimal way to fire a metal furnace in a bath is small but frequent fuel deposits.

This is interesting: Instructions for soldering polypropylene pipes - we tell you point by point

The process of lining a metal furnace with bricks

The whole process of lining an iron stove can be divided into several stages.

Stage 1 Foundation

The order of the foundation device:

- After the issue of the installation site of the furnace has been resolved, it is necessary to cut out the floorboards around the perimeter of the structure, given that the size of the foundation should be 10–15 cm larger on each side.

- Next, you need to dig a pit up to 40 cm deep.

- Then it is necessary to build a wooden formwork according to the size of the pit and the planned structure.

- The next step is to waterproof the foundation.

- Then we pour a pillow of sand and crushed stone of the middle fraction, in order to be able to retain moisture.

- We fill the foundation with cement mortar and be sure to lay a layer of reinforcing mesh on top. We check the evenness of the surface made with a building level.

- Then you need to wait a while for the concrete screed to completely harden.

Stage 2 Foundation device

- After the foundation mortar has completely solidified, you need to lay out the base in one row of brickwork.

- We check again the horizontal level of the surface with the building level.

- We lay a layer of roofing material for the waterproofing of the base.

- From above it is necessary to lay a sheet of iron, which should exceed the size of the brickwork by 10 cm around the perimeter.

- Then we install a metal furnace.

Step 3 Solution preparation

A mixture of cement and clay will serve as an ideal mortar for bricking a metal firebox. Experienced stove-makers advise the proportion of these components to be determined by appearance. It is believed that it is necessary to take the same amount of cement and clay, while adding up to 30% river sand to the solution.

The main thing, when preparing the solution, is to achieve a homogeneous mass, without pebbles and lumps, resembling thick sour cream in appearance. To check the quality of the prepared masonry mortar, you need to apply a little mixture to the brick. A high-quality mortar should not flow and slide off the brick. If the mixture is not very thick, then you can add a small amount of sand.

Stage 4 Brick preparation

To complete this stage of work, it is necessary to soak the selected number of bricks for masonry in water for 12 hours. Carrying out this action is required so that the brick does not absorb moisture from the mortar during laying. When using old brick, it must be cleaned of sand and old mortar.

Stage 5 How to line a metal furnace

The average size of the structure in height will occupy 13–15 rows of masonry. Therefore, it is desirable to divide the whole process of work into two stages. First you need to lay 7-8 rows and let them dry. The next day, after checking the shrinkage, we lay the remaining section of the structure.

Brick finishing process:

- You need to lead the row starting from the corner of the structure, not forgetting to control the horizontal laying with the building level. Control of the correctness of the angle must be carried out with a plumb line or goniometer.

- On the second row, it is necessary to spread a reinforcing mesh to increase the strength of the structure.

- On the same row, you need to start arranging air gaps through which heated air will enter the room. This operation must be repeated on the 6th and 8th row. It is not desirable to make many holes. Two at the top and two at the bottom will suffice.

- The third row is laid out in the same way as the first.

- In the place where it is planned to install a door for fuel and a blower, you need to lay a metal corner.

- The last row fits randomly.

Stage 6 Pre-fired furnace

Is it really worth lining the oven with bricks?

The answer to this question is very simple. First of all, brick lining of furnaces is carried out so that its base does not cool down for a long time, and the furnace does not overheat during operation.

It is important that the selected material is well fired, so raw brick is not suitable for such purposes. For such work, it is also not allowed to use silicate, hollow and slotted bricks.

If the brick lining of the bath stove is carried out, then the user receives certain advantages over the use of metal units:

- Since the brick warms up gradually, the heating of the room is carried out evenly and not much. Such a structure will be pleasant to fill the room with warmth and will not give a sharp heat.

- The base of the brick keeps heat for a very long time, so a constant fire is not required.

- The use of ovens lined with bricks is much safer than metal ones, because there are no surfaces with maximum temperatures. It also reduces the risk of fire from heated metal surfaces.

- The laid stones in the bath will warm up more strongly due to the construction, decorated with bricks.

All these positive aspects will provide a pleasant microclimate in the bath with the right humidity. Many perform such work not only for convenience, but also to achieve certain design solutions. If you choose the right material, then the room with a brick firebox will change, it will look stylish and comfortable.

When it's required

It happens that there is no need to protect the walls. If the furnace is located at a safe distance from the wall in terms of fire safety, the arrangement of protective screens and other measures can be neglected. The distance from the walls that is required to reduce the heat from the source is different:

- A stove laid out in a quarter of a brick should be located no closer than 35-40 cm from the wall;

- A metal furnace without a lining should be placed a meter away and not closer;

- A metal one with a footed crucible can be installed 70-75 cm from the wall.

However, not every steam room has the opportunity to fulfill these requirements, due to the small area. The layout of steam rooms with an area of 6-8 m² hardly accommodates the necessary set of items for the soaring procedure. Therefore, the need to isolate the walls with special skins is relevant.

Wrapping methods

In essence, stone cladding is used to act as a heat shield for the furnace. Due to the fact that such a structure is not amenable to the main thermal effect, it can be constructed in the form of:

- Solid lining, which is characterized by rapid heat transfer, which causes a decrease in the performance of the furnace. In this embodiment, the lining is rarely performed, and most often to give the metal stove decorative elements. At the same time, the quality of heating is in the background.

- A heat shield that will look like a small stone fence. This option is quite comfortable for others and helps to increase heat transfer.

- Facing-convector with the presence of products. This structure is the most optimal for bathing needs and is suitable for any metal structure, regardless of the size of the steam room.

How to assemble a protective screen yourself

The essence of the assembled protective structure is its multi-layered structure. After everything is mounted, you get a kind of pie, if you count from the wall surface: a ventilation gap directly at the partition, non-combustible heat-insulating material, decorative trim. It is this wall decoration in the bath around the stove that allows you to maintain a single design style for the entire room and protect the wooden partitions from fire as much as possible.

Assembling the structure is easy. Pieces of refractory material are mounted on the walls as the base of the entire structure. Next, a sheet of heat-insulating material is attached, for example, a glass-magnesium sheet. After that, the outer surface of the sheet is decorated with decorative material - tiles, porcelain stoneware or soapstone.

The last option is the most beautiful and durable, but it costs more than the others.

If the wall of the sauna or bath near the stove is finished with a material such as ceramic tiles or porcelain stoneware, one of its properties must be taken into account: the material itself practically does not change its size from heating, but the solution in the seams between the tiles can significantly expand. Therefore, the joints should not be very thin - when expanding, the composition can cause the glued tiles to peel off from the base.

In addition, porcelain stoneware should be used with caution - if it gets splashed with water while soaring, it can crack

Why are ovens lined with bricks?

Despite the fact that many metal stoves in their original form can serve as a decoration for a bath, you should not avoid lining them with bricks, especially since with the application of ingenuity, the design of the stove can be very advantageously beaten with this.

The lining of a metal furnace is usually done for the following number of reasons:

- Fast heating iron structure. This is dangerous for human health, as the body needs more time to adapt to the new bath temperature.

- Rapid temperature loss. Due to the high thermal conductivity, an unlined metal furnace also rapidly loses its accumulated temperature. To maintain it, constant supervision will be required and firewood and coal have grown, which greatly increases the consumption of materials.

- Air drying. The metal heats up and dries the air much faster, making it less comfortable to be in the steam room.

- Potential for severe burns. Momentary skin contact with a metal surface will result in a high degree burn. Very often the oven is touched by hands.

You can get rid of these problems separately, for example, a metal shield finish will help to quickly lose temperature, but other indicators also increase significantly for the worse, which ultimately makes the usefulness of such a shield doubtful. Furnace lining can eliminate this set of disadvantages. Most of the models currently being produced were originally designed in such a way that it would be convenient to lay their lining in the future.

The lining allows you to reward the furnace with the following number of advantages:

- long and smooth heat transfer;

- reducing the amount of fuel needed to maintain the desired temperature;

- pleasant not overdried heat;

- safer use;

- giving an attractive appearance to even the cheapest and simplest stoves.

The main criteria for choosing a brick for facing

To answer the question of how to brick an iron door in a bath, you need to take into account some points. In such a room there are very high temperature loads. Most often, the user chooses from several options.

- Plain red brick. Due to its heat resistance and excellent heat capacity, this type of material can be used to create a screen. The best option is a red solid brick, but the hollow version should not be used. The latter heats up very quickly, but also cools down quickly. This option is also characterized by an excellent appearance; with proper masonry, you can create a very attractive device that can decorate a visit to the bath.

- silicate brick. It is not recommended to use it for lining a bath stove, since the components that make up its composition do not tolerate high temperatures very well, especially critical ones. The appearance of the finished product will require additional lining.

- fireproof brand. This option is the most optimal option in terms of operation, but it is much more expensive than regular red. This is the most desirable type of brick, if the question is how to overlay the stove in the bath.

Refractory bricks are great for lining a furnace, but they are much more expensive than regular bricks.

Refractory bricks are great for lining a furnace, but they are much more expensive than regular bricks.

When the main material is selected, you should start preparing auxiliary tools and materials that will help you overlay a metal furnace in a bath.

Successful lining of the furnace will be guaranteed if prepared before work:

- Furnace brick;

- A mixture of clay and cement;

- metal corners;

- Asbestos based cardboard;

- Special tools: pickaxe, trowel, plumb line and others.

Sheathing the walls of the bath with non-combustible insulating materials

To prevent the walls from overheating, you can use materials with the properties of increased thermal insulation and inertness to high temperatures.Two types of materials are used:

- reflective;

- fireproof with lining.

The first type includes materials for wall sheathing, consisting of thermal insulation with fireproof properties and a metal coating in the form of a sheet.

Wall insulation with reflective sheathing

Protective cake with reflective materials do so. First, the thermal insulation is fixed with ceramic bushings directly to the wooden walls, then it is sewn up with a stainless steel sheet.

Advice! It is better not to use galvanized metal, since when heated, it is possible to release heavy metals harmful to the human body.

Stainless steel with a polished surface reflects the heat flow into the steam room, reduces heat loss. In this case, reflected heat is more useful than direct heat. For thermal insulation use:

- basalt cardboard or cotton wool, the only material with increased hygroscopicity, non-combustible, environmentally friendly;

- asbestos cardboard, which reliably protects against the occurrence of a flame, characterized by long service life;

- minerite, an artificial material made specifically for this purpose.

The protective sheathing assumes the presence of ventilation gaps of 2 cm from the wall to the insulation, 2 cm from the insulation to the steel sheet. If it is necessary to install the stove as close as possible to the wall, make a double sheathing of non-combustible insulation, with the help of ceramic bushings withstand gaps of 2-3 cm and sew up with a steel sheet.

Insulation with cladding

Measures to protect the walls with cladding are necessary in order to preserve the interior decoration of the room. They are more expensive, but no one has canceled the aesthetic advantages of the bath. It is based on tiling, which is laid on a refractory lining of GKLO, non-deformable gypsum-based cardboard with fiberglass, mineralite, non-combustible cement-fiber material, moisture resistant and resistant to biochemical attack, LSU, material made of fiberglass bonded with magnesia additives, resistant to impact high temperatures, high humidity. Heat-resistant glue is used for installation.

Advice! Use heat-resistant reinforced Terracotta glue, made from chamotte dust bound with kaolin additives, designed for tiling stoves, fireplaces, all heated surfaces.

The recommended facing materials are quite diverse, the best of them are:

- terracotta tiles, it is made from special firing clay, which gives increased heat resistance and durability;

- clinker, more dense clay tiles with a surface of various colors, similar to facing bricks;

- tiled tiles, also made of clay, with an original embossed surface;

- porcelain stoneware made from a mixture of clays, kaolins, quartz sand, feldspars by high-temperature firing under pressure of 400-500 kg / cm², with imitation of stone, wood, durable artificial material;

- talc chloride, a rock mineral consisting of talc, magnesite and chlorite, is an environmentally friendly natural material that absolutely does not absorb moisture, has an attractive appearance, does not crumble, and is not afraid of high temperatures.

Advice! Use talc chloride to finish the steam room, this mineral has a healing effect on the human body, regulates blood pressure, stimulates cerebral circulation, expels viruses and microbes, due to the release of vitamin D when heated.

All of the listed tiles are a protection element that rearranges the cake, the basis of which is a refractory material. As well as a screen, the sheet material is installed on ceramic bushings with a gap of 2-3 cm from the wall. The minimum distance to the heat source from the tiles should be 20cm.

Protection with cladding decorates the room, creates a positive mood, improves the efficiency of procedures. And most importantly, properly installed insulation prevents the occurrence of overheating of wooden walls, their ignition. Light steam!

Why fence the heater in the steam room

Homeowners who want to equip a steam room cheaper in the house purchase an iron or cast-iron stove, or even order a home-made one. Heaters of the middle and highest price categories are equipped with special convection screens that protect people in the steam room from hard infrared radiation coming from the hot steel walls of the furnace.

There are 3 reasons why the owners have to brick the stove in the bath:

- budget and home-made heaters made of metal are devoid of protective screens;

- the need to protect the wood paneling of the steam room from ignition when the stove is installed close to the walls;

- wood-burning stoves with steel walls are not able to retain heat for a long time, the temperature in the steam room drops quickly after the wood burns out in the firebox.

The lining of a metal furnace immediately solves 2 tasks: it protects against burns with infrared radiation and accumulates heat, like a battery. Due to the good heat capacity of brickwork, such a screen will give off heat to the bath for a long time after the furnace is attenuated.

Isolation methods

There are several tricks that allow you to reliably isolate wooden structures from the heat of the stove. Some of them involve a fairly large amount of work, while others are much simpler.

- Creating a protective box of brick or stone.

- Installation of a special screen, manufactured in an industrial way.

- Creating a protective structure with your own hands from non-combustible materials.

The construction of a box of brick or stone will require the greatest investment of time - it will be necessary to lay out several walls that will protect the tree from heating. In addition, this protection option assumes a gap between the tree and the brickwork from 5 to 15 centimeters. About 10 centimeters should remain between the casing being erected and the walls of the stove. All this eats up usable space and requires some bricklayer skills for work.

Factory screens are mounted quite simply and are not so expensive. They could be an ideal solution if they did not require even larger technological gaps between different surfaces. Therefore, such wall decoration near the stove is possible only in a fairly spacious bath. If you need to save space, it is better to look for another solution that allows you to reduce all the indents from the wooden partitions.

The third option allows you to reduce distances to 15 centimeters, which is already more acceptable

At the same time, this method allows you to create the most beautiful design, which is important. However, there will be a lot of work and the costs in this option may be much higher than in the previous ones.

In addition, this method of isolation requires more detailed consideration due to the features of the assembled structure.

List of refractory materials for wall decoration around furnaces

According to the fire safety rules, the arrangement around stoves, fireplaces and fuel boilers should be carried out using refractory special materials that can simultaneously protect a residential or utility building (bath) from possible fire on the walls, and at the same time not harm health.

Any stove or fireplace to create a favorable home atmosphere is very hot, strong heat spreads from them, which in turn can be a source of ignition or fire

Therefore, it is important to carefully choose the right materials when arranging a heat source in a house, bathhouse or basement, when it comes to a fuel boiler.

Foundation arrangement

Now on the Internet you can find a lot of drawings, photos, schemes for building a foundation for lining a furnace in a brick bath. What is this building?

The foundation is made in the form of a quadrangular well, the height of which is equal to the height of the furnace. To close the metal walls, a solid or masonry with windows is used, through which not only fuel is thrown, but also ventilation around the heated surface is enhanced.

According to experts, wooden floor beams can withstand up to 650-700 kg of load. Although in practice, it is not recommended to give a load of more than 400 kg per 1 m². Therefore, it is desirable to further strengthen the existing frame with an iron structure from a corner (50 mm), or screw piles, provided that approximately 180-200 bricks weighing 3.5 kg will go to the screen.

Foundation construction algorithm

- Cut a square in the floor (if it is already installed) of a certain size, dig a pit about 35-45 cm deep.

- Fill the bottom with crushed stone of a large fraction, lay waterproofing, install formwork.

- Place pieces of reinforcement in the foundation frame, apply the required amount of mastic waterproofing, pour the structure with concrete about 15-20 cm above the ground.

- Bring a “cushion” with an ordinary brick to the floor level, on which the furnace and lining will be placed.

- Wait about 3 weeks for the concrete to shrink, then lay the thermal insulation, a steel sheet (thickness 3-5 mm) under the oven.

Solution preparation

In order to qualitatively overlay an iron stove in a bath, it is best to use a classic clay-sand mortar. You can add a small amount (about a sixth) of grade 400 cement to it. This ingredient can only strengthen the whole structure, since the temperature of the future screen will not be high enough.

Since clay requires little, it is best to buy it at a building materials store. For rural residents, such a problem as the purchase of clay should not exist.

To prepare the solution, it is necessary to take the sifted sand and mix it with clay in equal proportions. Add water gradually to get a thick mixture that could easily slide off the trowel.

What other materials are used for lining the furnace in the bath

It turns out that not only bricks can be lined with sauna stoves. Granite or marble slabs are a wonderful substitute. They also tolerate temperature changes well, have a large mass and high thermal conductivity. In addition, this finish will give the bath room an unusually beautiful and unique look. Not everyone can afford such a luxury, from a financial point of view. But if you have any leftovers, then you can use them to build a furnace partition.

True, with the installation of such plates is a little more difficult, in comparison with brickwork. To ensure a beautiful appearance of the lined stove, it is necessary that the work be performed by a specialist. At the very least, the owner should at least consult with such a person.

Minerite slabs are also used to equip the heat shield. With their help, the wall is mounted much easier and faster, even in comparison with masonry, and is able to withstand temperatures of 360-400⁰С. But the heat capacity of this material is low, so it can be used as a good partition that cannot accumulate heat.

Some Helpful Tips

In order for the brick lining to be correct and last for more than one year, you should use the following recommendations:

- masonry is carried out in the usual way with dressing in half a brick;

- it is impossible to associate the structure with bath walls;

- withstand a seam with a thickness of 5 mm;

- leave a gap of 3-5 cm between the metal walls of the stove and the screen;

- in the lower rows, it is imperative to make openings through which cold air would freely enter.Accordingly, in the upper ones there are the same holes for the hot outlet. And from below and overthrow there should be no more than 2-3 openings, otherwise the wall, like a heat shield, will not fulfill its immediate function;

- after laying each row, it is necessary to check it with a level: verticality and horizontality must be observed everywhere;

- carefully remove the remains of the solution both from the inside and from the outside.

Selection criteria for full or partial furnace lining

Many owners of baths, having decided to overlay the stove with bricks, doubt what type of cladding to choose. If you surround the device with brick walls on all four sides, you will get a complete one, otherwise - a partial one.

Whichever option is chosen, the difference will be in the control of convection. In simpler terms, lovers of the Russian bath may have problems. If a controlled convention is organized, then it is possible to close it, in this case the hot air heats not the steam room, but the brick casing, transferring the heat to the steam room softer.

To control the flow of warm air in the direction from the bottom to the top, special openings should be provided. If necessary, they are closed or opened using special doors or pieces of brick.

But open cladding, when the furnace is not closed on one or more sides, is most likely an aesthetic side and a safety issue, since it is less likely to get burned from a brick than from hot metal.

Material selection

A zealous owner always strives to use the building materials available on the farm. But it is impossible to overlay the sauna stove with any kind of brick, since it will be exposed to high temperature and humidity.

This means that white silicate and similar varieties disappear immediately. It is also not recommended to line a steel heater with used material; it will quickly crumble under the influence of the microclimate of the steam room. The following types of bricks remain:

- ceramic corpulent;

- red hollow;

- fireclay (fire resistant).

Most of all, a red full-bodied stone, from which stoves are laid, is suitable for erecting a screen around a bath heater.

A ceramic facing brick (for example, a bassoon) will also fit. It will not only perform its functions, but also give the partition a remarkable appearance. The size of the products does not play a role, here you can use both a standard stone 25 x 12 x 6.5 cm, and one and a half 25 x 12 x 8.8 cm.

It is not recommended to use a hollow stone, unless it is lying around on your farm and the appearance of the masonry does not play a special role. But the service life of a hollow brick inside the steam room will be short-lived.

According to its characteristics, refractory bricks are perfect for overlaying a stove in a bath. But it is more expensive than ceramic, and it has less heat capacity. Finishing bath heating units with fireclay stone, as a rule, is not practiced.