Building regulations

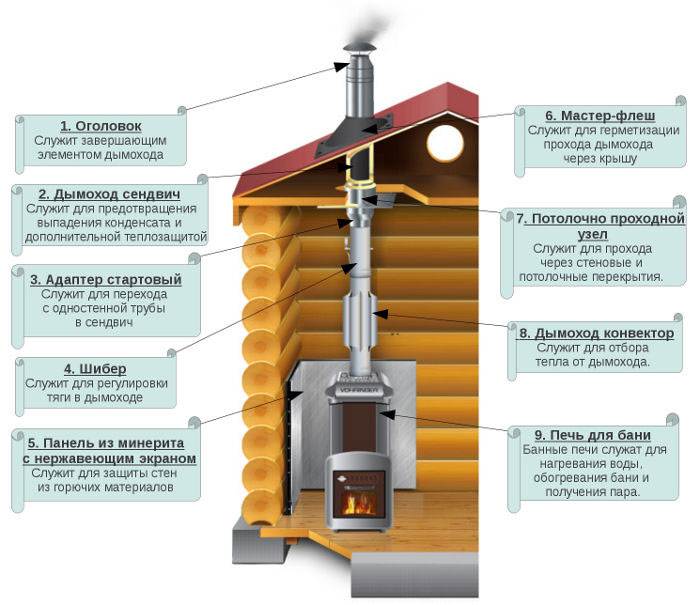

Pipes are allowed to be laid in the outer walls of the building, but the diameter of the outer casing should not be less than the thickness of the fence. The vertical deviation is allowed no more than 30 °, the horizontal deviation is 1 m. A cut is made at the points where the pipe passes through the ceiling structure.

Norms of chimney distances:

- to fireproof structures - 5 cm;

- to slow-burning (plastered walls and wood ceilings) - 25 cm;

- to slow-burning, upholstered with asbestos sheet and galvanized - 10 cm, if the insulation protrudes 15 cm beyond the edge of the channel on both sides.

The chimney is checked for tightness if the device uses the principle of self-manufacturing. The chimney outlet above the roof is closed. If smoke accumulates in adjoining ducts or adjacent rooms, then the chimney is loose or not isolated.

The requirements for smoke channels are:

- the density is sufficient to keep gases and smoke out;

- the diameter matches the outlet pipe of the heating unit;

- when arranging, permitted materials are used;

- chimneys provide the required draft force;

- there should be no blockages, blockages inside the pipes;

- are not installed in the area of wind backwater.

Types of convectors

The supply of clean air is required for the operation of supply and exhaust ventilation. The traction force removes the products of combustion outside the building, draws clean air into the chimney channel. The functioning of the chimney depends on the outdoor temperature and the degree of heating of the smoke, the height of the pipe above the roof and other conditions. Equipment for the removal of carbon monoxide is divided into types:

- system for heating one room - chimney-1;

- device for heating in neighboring sectors of the house - chimney-2.

The chimney convector-1 is used for efficient heating of 1 room. The installation is used in private buildings, saunas and baths for alternative replacement of water heating, electric heaters. The standard height ranges from 70 to 100 mm.

2 coaxial pipes are provided in the design of the chimney-2. They depart from the central channel and extend through the wall openings into the adjacent rooms. The outlets heat the air as heating radiators. Factory products are taken with an inner channel diameter in the range from 105 to 115 mm, the outer diameter is in the range from 215 to 305 mm.

The convector is being upgraded to improve the heat exchange between the indoor air and the pipe. Stainless steel sheets are welded to the outer casing, sometimes they are replaced with pipes with a diameter of 30 to 50 mm. The heated air is trapped in the pockets and transfers heat more efficiently.

The principle of operation of the device

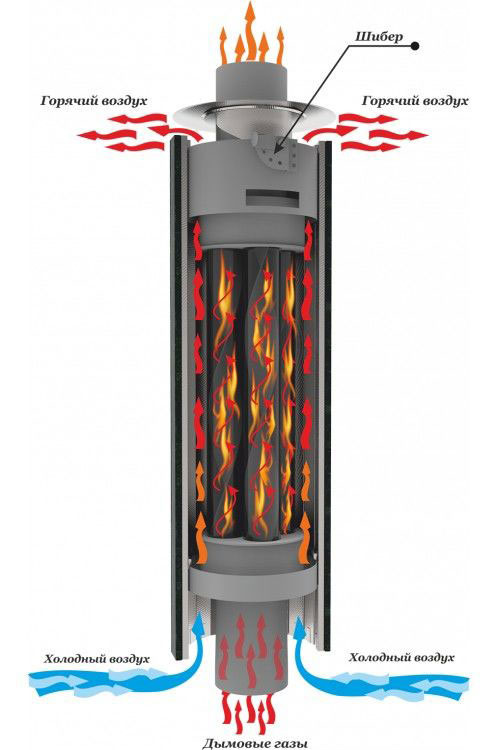

A chimney-convector is a component of a stove or boiler heating system in a house or bathhouse, operating on the principle of convection.

In fact, this is a coaxial pipe consisting of two pipes, one of which is inside the other. The outer pipe acts as a convector and a protective cover that absorbs infrared radiation. The inner part of the structure serves to remove exhaust gases and combustion products, while the outer part is designed to supply fresh air to support the combustion process. in the combustion chamber.

The operation of such a chimney is based on the principle of convection: passing through the inner pipe, hot smoke, gas and water vapor heats the metal pipe.

The increased area of the metal casing, like a radiator, promotes heat exchange and heating of the air as it passes through the air pockets.Due to the large surface area of the metal, the convector effectively transfers internal heat to the air, thereby heating the room.

The main purpose of installing a chimney-convector is to increase the productivity of boiler or furnace equipment, as well as save energy.

Mounting Features

The economizer for the chimney is located in the lower area of \u200b\u200bthe collector. The device exits the channel, then is again in the pipe, working as an intermediate section of the gas exhaust system. The length of the convector is chosen depending on the height of the ceiling or the distance to the wall. The farther the economizer is from the building envelope, the higher the heating temperature of the air passing through it.

Prefabricated converter tubes are completed with modules to make up the required length. Corrugated sections are used if there are no set elements in the kit. Above the hearth, the installation and installation of the lower section of the convector is carried out. Part of the pipe is sealed with gaskets, the joints are treated with a heat-resistant sealant.

The pipe is covered with a layer of insulation if flammable materials are nearby. Warm air cools evenly, decreases and is drawn into the lower section. It raises the temperature, getting into the convector, and heats the pipelines for adjacent rooms.

Errors occur when installing a chimney-convector in case of an incorrectly selected length or diameter. The chimney does not work efficiently if the economizer is located high or low relative to the floor. Poor sealing does not allow for the correct redistribution of heat fluxes.