Preparation and choice of one of the methods

After acquiring all the necessary materials and tools, they proceed to the initial stage. In order to do everything correctly, there are small secrets, namely, these are the masonry rules and preparatory steps that should not be missed. Before laying the wall with silicate or ceramic bricks, choose the method of masonry. When building the outer layer of the wall, if plastering or other decorative finishing is not planned in the future, the bricklayer lays the bricks against or against them with undercutting. If the master has good skills and building experience, this is a serious plus, but every person can master the basic simple masonry techniques. The main thing in work is accuracy. How to lay a brick correctly learn from Internet resources or learn from an experienced developer.

Before laying the bricks, you need to learn how to make the mortar correctly so that it can be easily applied to the wall with an even layer of the required thickness, and also master the techniques for hemming or trimming bricks of the required shape and size using a pickaxe or grinder. It should be remembered about the need to pre-soak building materials prepared for work. Dry brick too quickly sucks the liquid out of the cement composition.

Masonry rows of lighthouses at the ends of the wall

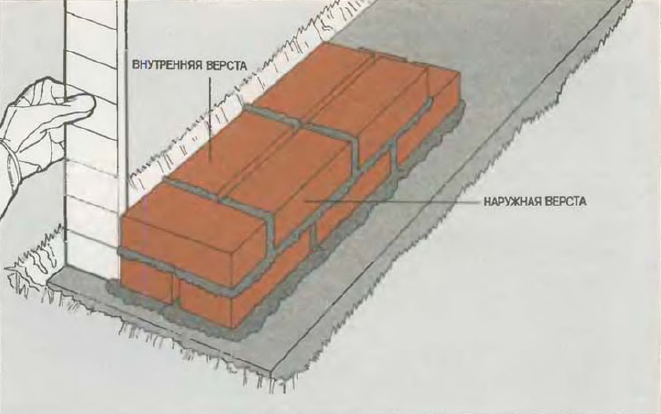

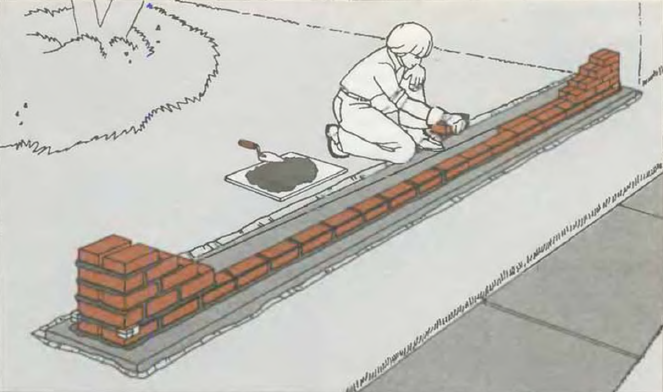

1. Installation of the first bricks of the outer verst (front row)

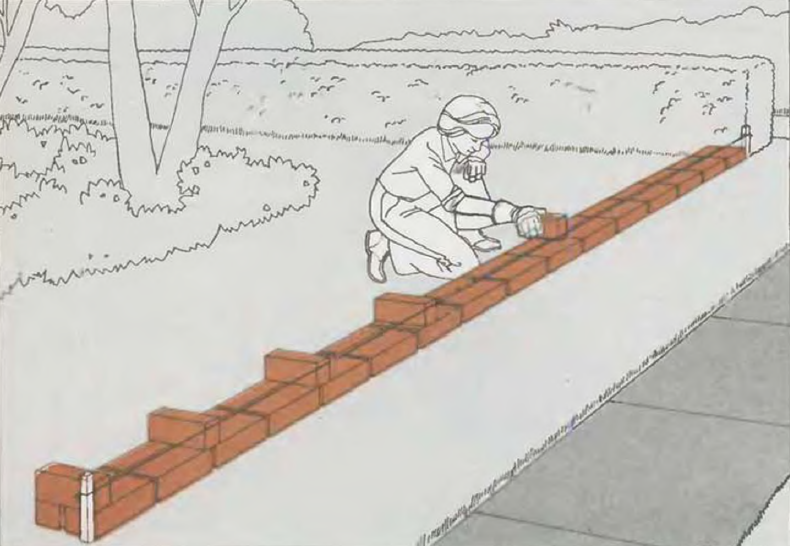

Wet about 25 bricks with a hose and let the surface moisture evaporate. (Always do this procedure before laying bricks.) Prepare 0.01 cubic meters of mortar. Remove the soil from the surface of the foundation, moisten with water about a meter of its length and wait until the moisture evaporates from the surface. Lay a strip of mortar next to the chalked line, then place three bricks on the mortar. (below in the image) These bricks will be the beginning of the corner or edge of the wall.

Carefully align the position of these three bricks with respect to the chalk line, as well as in height relative to the foundation (10 mm). To do this, you can use the level and order. Check the order of the height of each brick when laying subsequent rows.

2. Masonry of the inner verst (inner row)

Lay a strip of mortar parallel to the three bricks you laid in the outer row, about 10 mm short of them. Install the brick at the end of the mortar strip at a distance of 10 mm from the first brick of the front row or at a distance determined during test laying. Lay two more bricks. Align the row of three bricks with a level, ensuring that the surfaces of the bricks of both rows are in the same horizontal plane.

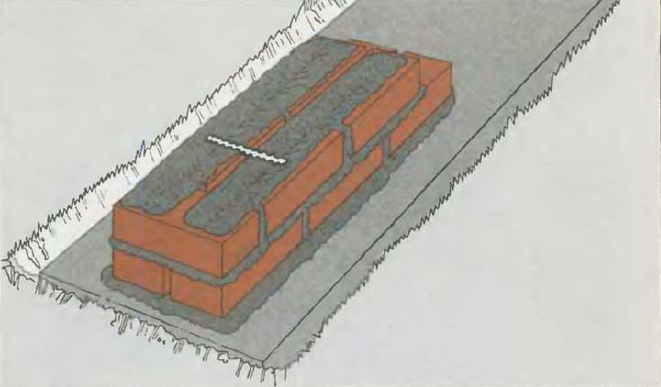

Lay the second row of front and inner versts, starting with bonded bricks. (Every second row starts with an extreme bonder brick). Lay two bricks of the spoon rows so that a step forms between the first and second rows of masonry.

3. Laying the first metal strips

Accordion-shaped metal strips for connecting rows are laid along the entire wall for every second row. Lay a layer of mortar on the second row and place the strips into it at a distance of about 450 mm, pressing them down with the end of the trowel. Then put two spoons on the strips, which will begin the third row of the front and inner mile.

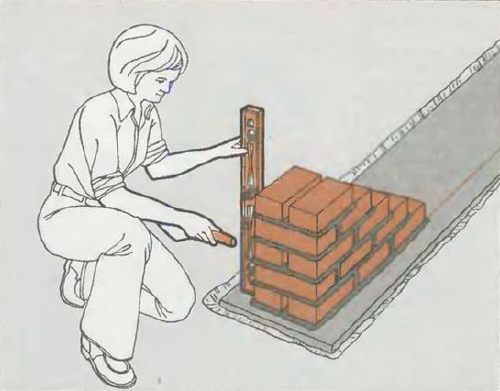

4. Finishing the laying of the first edge of the bricks

Lay five rows of front and back versts, establishing links between the fourth and fifth rows. The end should be stepped with a step width equal to the width of the brick. Check the masonry level. When you find a protruding brick, tap the level with the end of the trowel handle to push the brick into place. If the brick is too deep in the wall, knock it forward.Do not pay attention to minor inaccuracies, correct only if they are gross enough.

5. Masonry of the second edge

At the opposite end of the foundation, repeat steps 1 through 4 to make a five-row end

At this stage, it is especially important to carefully check the masonry level and order. The two ends must be exactly the same, otherwise the wall will be unstable and the only way to fix the problem is to dismantle the wall

Mortar for masonry

The brick is laid on a cement-sand mortar. Cement is used not lower than M400, sand is clean, ravine. The proportions for the specified brand are 1 to 4 (for m500 - 1: 5). The batch is done manually or with a concrete mixer, but the order does not change.

First, sand is sieved, a binder is added to it, everything is mixed in a dry state until a uniform color is achieved. Then water is added. Its amount is 0.4-0.6 parts, but they look at the plasticity of the solution. It is more convenient to work with a plastic mortar than with a rigid one, but when laying a hollow brick, in this case the consumption of the mortar greatly increases: it fills the voids. In this case, it is more practical to make a hard solution.

To improve plasticity and more convenient work, lime, clay or liquid detergent are added to the composition (you can use hand soap, there are in large flasks). The number of additives is quite small - no more than 0.1 parts, but the characteristics of the solution improve significantly: it is easier to stack, it does not delaminate for longer.

Immediately it is worth warning: do not knead large volumes at once. The batch must be used within two hours. And in the last half hour it can be difficult to work with it: the separation of water may begin, or it may begin to seize. It depends on the weather conditions and the quality of the cement, on the thoroughness of the kneading. If do-it-yourself bricklaying is your first experience in this area, it will turn out slowly. Therefore, it is better to make portions of the solution small.

Often for beginners planning to lay bricks on their own, the question arises: at what temperature can you work. It is possible to work at positive temperatures without special additives. In the best case - not lower than + 7 ° C. This is the threshold at which the cement normally sets. At lower temperatures, the hardening process practically stops, as a result, the mortar may crumble, and the strength of the wall will be low. To lower the bar, there are special antifreeze additives, but the cost of such a solution is already high: the price of these additives is considerable.

Brick laying technique

Before use, the solution is stirred, as heavy particles can sink down, and water can rise to the top. The mixed solution is placed in buckets and transferred to the masonry site, where it is distributed. Immediately put a strip of mortar - a bed - for one row. Under the tychkovy row, the width of the bed is 200-220 mm, for the spoon row - 80-100 mm. If the seam is completely filled, about 10-15 mm recede from the edge, the mortar height is 20-25 mm, which during laying provides a seam of 10-12 mm. Before installing the brick, the mortar is leveled with a trowel.

There are three techniques for doing brickwork. On a hard, low-plastic solution, the "press" technique is used. In this case, the seams are completely filled. If the solution is plastic, use the "butt" technique.

Brickwork technique "butt"

As already mentioned, this method of laying bricks is used with a plastic mortar. It should be mobile, easy to apply and move. This is achieved by adding additives. You can spread the solution immediately on the entire surface of the wall: additives allow you to extend the time before setting begins.

The bed is laid with a thickness of about 20 mm, an indent of about 15-20 mm remains from the edge. Such an indentation avoids squeezing the solution onto the front surface, but at the same time, the edges of the seams often remain unfilled.This significantly reduces the strength of the wall, therefore, in regions with seismic activity, the laying of verst rows (outer and inner) by this method is prohibited.

When laying a spoon row, they take a brick, holding it with a slight slope. Bringing to the already laid, at a distance of 8-10 cm, they begin to rake up the solution with an edge (poke). When docking, it turns out that the seam is already partially filled. The brick is pressed down a little (sagging), pressing it to the bed. The excess is removed with a trowel and sent either to a bucket or to a wall.

With this technique, it often turns out that the vertical seams are only partially filled. Therefore, this method is also called "wasteshovka". They are filled when laying the bed for the next row. If the technique is not yet very well developed, it is better to fill the seams before laying the next row: voids reduce strength and thermal insulation characteristics.

When laying the bonder row, everything is exactly the same, only the solution is raked with a spoon edge. The backing is laid, like the tying rows, and then pressed with the palm of your hand. It is necessary to ensure that all the stones are on the same level. This is done using the building level, and the verticality of the wall is checked with a plumb line every 3-4 rows.

Technique "squeeze"

When working with hollow bricks, as a rule, hard mortars are used. In this case, a brick is used with the “press” technique. In this case, you also have to work with a trowel.

The bed is laid at a distance of 10 mm from the edge, the thickness is still about 20 mm. Since such a composition does not stretch well, it is raked to the edge of the laid brick with the edge of the tool. They take a brick with their left hand and press it against the trowel, while pulling it up. At the same time, they continue to press with a brick, achieving the required thickness of the seam (10-12 mm).

Excess solution is picked up with a trowel. Having laid several fragments, they take the level, checking the horizontality of the row, by tapping the handle of the trowel, straightening the position. The solution squeezed out is selected. It turns out dense masonry, but the process takes longer: more movements are required.

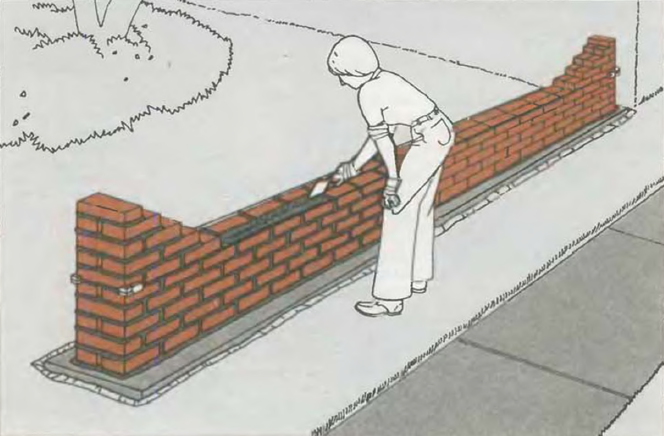

Butt with undercut

The average performance method - butt with cutting seams. With this method, the bed is laid out close to the edge (10 mm), as when laying, pressing it, and the laying technique is close-fitting: they raked the mortar with a brick, put it down, pressed it down, and removed the excess. If the wall is subsequently not planned to be finished with anything, after several rows it is necessary to take the jointing - a special tool and give the seams the required shape (convex, concave, flat).

As you can see, this is a kind of symbiosis. To make it more convenient to work, the solution is also made with "intermediate" plasticity. If it is too liquid, it will flow down the wall, leaving streaks, so it needs to be kneaded a little tighter than when laying back to back.

Hand tool

Most often, when brickwork is used, hand tools are used; without a set of a bricklayer, it is impossible to perform this type of work. Masonry tools:

A trowel (trowel) is a metal flat spatula, triangular in shape, attached to a plastic or wooden handle. A trowel is necessary for a bricklayer to apply cement mortar for laying on the surface of a brick, followed by its leveling. And also with the help of this tool, grouting and filling of joints between bricks is carried out, followed by removal of the remnants of the plastic cement mass.

It is very convenient to use a manual trowel when leveling the laid bricks by tamping with the back of the handle. A pickaxe differs from a standard tool in the shape of metal impact surfaces. On the one hand, there is a striker, shaped like a standard chisel or chisel, on the other side of the striker, there is a striker in the form of a rectangular bar. The blunt end of the hammer splits a brick or block into two parts or evens out the masonry.

But the sharp end of the hammer serves as a convenient device for chipping small parts from the brick. Jointing serves as a special device for decorative seams in brickwork. The use of jointing mainly involves working with facing bricks. Depending on the type of brickwork, jointing of various sizes and shapes is used.

There is another group of tools that is actively used in the construction of brickwork, which can be called measuring.

Laying rows of bricks between the edges of the wall

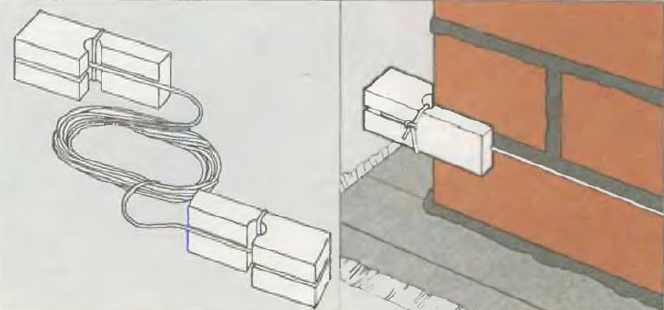

1. Mooring line

When laying bricks between the edges of a wall, use a mooring cord, a device consisting of two blocks of wood or plastic to which a cord is attached. If you did not buy such pads in the store, make them yourself. Tie a nylon or other synthetic cord to the shoe by inserting it into the groove.

Hook the shoes on the outermost brick of the first row, aligning the cord exactly with the top edge of the brick. Pull the cord to the other end of the wall, attach it to the second block and hook the block to the brick of the first row. Align the string with the edge of the first brick.

2. Laying a row of bricks between the ends of the wall

Lay out the first outer verst row between the edges of the wall along the cord, which should be located at the level of the edges of the bricks and at a distance of one to two millimeters from the wall surface. Lay the masonry on both sides and lay the closing brick in the center, on both ends of which a layer of mortar has been applied. Then lay out the first inner row along the cord installed on the inside of the wall.

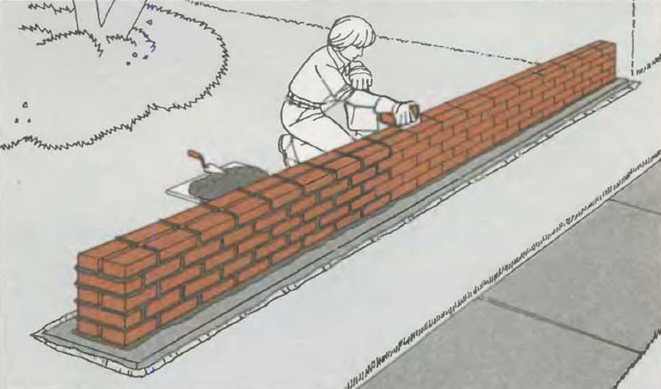

3. Masonry to the top of the ends of the wall

Always lay the masonry from the ends to the center and thus lay the next four rows of bricks of the outer and inner mile. After laying each row, move the cords up one row. On the second and fourth rows, lay the row dressing strips with an interval of 450 mm between them. After installing the end bricks in the last row, the wall will have a height of approximately 375 mm - the exact height depends on the size of the bricks. If this height is sufficient, lay the last row on edge on top and fill the seams between the bricks of the upper row with mortar.

4. Continuation of brickwork

If you want to build a higher wall, make five rows of new edges and then lay rows between them from the ends to the center of the wall. As before, when laying the outermost lighthouse bricks, check their height in order, and lay out the rows between the outermost bricks along the cord. The next five rows will give a total wall height of about 750mm. Laying five more rows, you will get a height of 1.125 m. Another row of bricks - and you will get a wall 1.2 m high.

DIY brickwork tools, order and features

Now, how to lay a brick with your own hands, you have an idea, you need to talk about the procedure as well as some technical nuances.

Let's start with the tool. You will need:

- mason's trowel - apply and level the mortar on the bricks;

- concrete mixer or container for mixing mortar;

- mortar shovel - for kneading and periodic mixing;

- two or three buckets for the solution;

- plumb - check the verticality of walls and corners,

- building level - to check the horizontal laying of the row;

- mooring cord - for beating rows;

- jointing (for forming seams);

- hammer-pick for beating undersized bricks (halves, 3/4 and checks - 1/4);

- the rule is a metal or wooden flat bar to check the plane of the wall.

Next, we talk about the features of the technology. First: it is advisable to soak the brick before use. This is especially true in hot dry weather. Then it will “pull” less moisture from the solution. If there is not enough moisture, the cement will not be able to gain the required strength, which will affect the strength of the building.

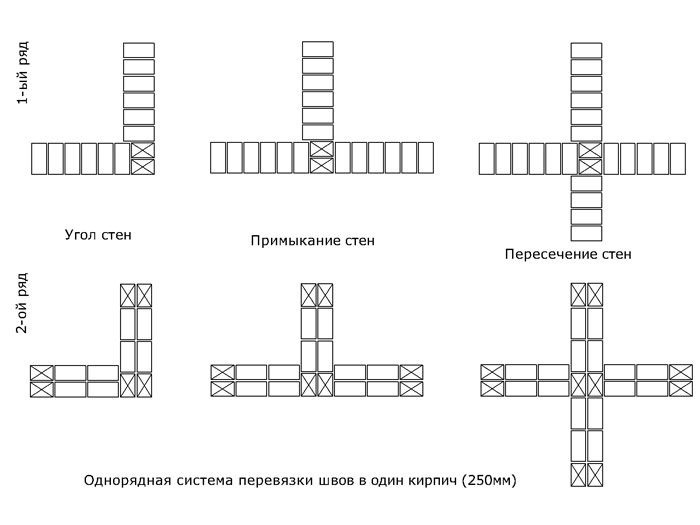

Second: the corners are driven out first. First two first.They are connected with 2-3 rows of bricks according to the chosen masonry pattern. Then the third corner is expelled. The second and third are also connected by several full rows. After the fourth corner is placed and the perimeter closes. This is how walls should be erected, bypassing them around the perimeter, and the walls will not be kicked out one by one. This is one of the most common mistakes.

Third, there are two row control technologies. The first is that nails are inserted into the seams of the corners, to which fishing line laces are tied. It must be stretched so that it marks the upper edge of the brick, and also limits the outer (and, if necessary, inner) surface of the wall.

The second way is to use wooden or metal orders. This is a flat bar or corner, on which marks are made every 77 mm - risks on wood or cuts on metal. They mark the required row thickness: brick height + seam. They are installed using flat mounting brackets that are inserted into the seam. If necessary, they are then simply removed and rearranged higher.

There is another way - a bricklayer's corner. It has a slot on one side into which the mooring is inserted. "Sits down" on the corner on the solution.

The disadvantage of this method is the same as just a nail in the seam: the height of the row must be controlled "manually" when deriving corners. With a lack of experience (and where to get it if brickwork is being done for the first time with your own hands), this is difficult. Having (having done it yourself) ordering is easier.

Fourth: preparation of incomplete bricks. As you saw, when laying, they use halves, three-quarter bricks and checks - 1/4 of the part. So that the work does not slow down, before starting the masonry, it is required to prepare them. This is done with a pickaxe. When preparing, high accuracy in size is required, otherwise the dressing will fail. To make it easier to control the length, marks of the appropriate length are made on the handle. Having attached the pen to the brick, marks are made on it on both sides of the spoon. Then, having applied the pick blade to the mark, they beat on the reverse side with a hammer, making notches. Having made notches on both spoons, the picks break the brick with a strong blow.

Features of forcing corners

Scheme of ligation of longitudinal sutures.

First, two bricks are taken (or a brick and an insert) and placed in a corner in a clamp on the mortar. Laid, they should form a right angle. Lightly tap them with the handle of the trowel, and then fill the gap between them with mortar. Be sure to align the horizontal lines with a level.

Further laying is carried out according to the chosen scheme. The thickness of horizontal joints between rows after the mortar has hardened should not exceed 10-15 mm, vertical joints between individual bricks - 6-8 mm. On each side of the corner, you need to put 3-4 bricks, be sure to control the evenness of their horizontals and verticals. Then, following the dressing scheme, 2 rows are laid on top, then 3, etc.

Do not forget about the alignment of the seams. It is done by scraping and jointing while the mortar is still soft. The easiest way is to slightly drown the seams into the masonry, for which it is enough just to draw a joint along them, and wipe off the excess mortar from the wall.

The direction of the work does not really matter, do it in the way that is more convenient for you. For right-handers, it is better to distill a brick house from right to left, for left-handers - vice versa. If a team of masons is working, then 5-6 rows are simultaneously driven out in all 4 corners, and then the walls are built up row by row, observing the initial gap (the corners should be 5-6 rows ahead of the wall) until the work is completed.

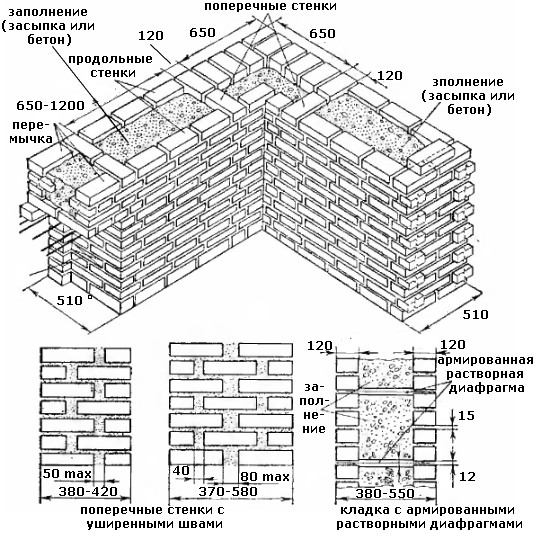

Well brickwork of walls according to the system of A.S. Vlasov.

But alone with such a volume of work at the same time will not cope. Therefore, use the following order: first, drive out 2 corners to the desired height, then put 1-2 rows of bricks between them, drive out the 3rd corner and connect it with the same number of rows with 2, then drive out the 4th corner and connect it with 3 and with 1 corners.And so continue to work, after each circle, raising the walls of the brick house along the entire perimeter by 1-2 rows, until the masonry is completed.

When driving corners, you will inevitably have to make stepped cliffs, the so-called. fines. Partly this will be due to the fact that you will have to use trimmed bricks - tabs, partly - to ensure a stronger connection of corners and walls in the future.

For a future brick house, it is extremely important that the corners are straight and strictly vertical. The angle is checked with a square, the brick must adjoin it tightly

The verticality of the corners, especially above 7-8 rows, is controlled with a plumb line, and the horizontal - with the help of a building level. Professionals take measurements every 4-5 rows, but if you do not have enough experience, do not be lazy to take them more often.

brick wall construction

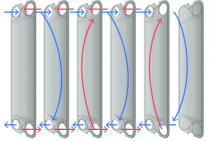

The brick wall shown here is a combination of several simple structures. Like all walls, it rests on a foundation - in this case, strip concrete 250 mm deep and 400 mm wide. The top of the foundation is 100 mm below the ground so that soil can be laid next to the wall and plants can be planted. Some walls consist of a single row of bricks; for added strength and better proportions, this wall consists of two parallel rows of bricks separated by a narrow air gap and bound together with metal strips. Both rows are spoon-shaped, that is, the bricks are laid end to end with seams 10 mm thick. The upper row of bonded bricks, laid on edge, connects both rows together.

Basic terms

Let's start with general concepts. Everyone knows exactly what a brick looks like, that it is ceramic, and there is silicate - too. But not many are aware of how the edges of this material are correctly called. And in the description of masonry technology, they are very common.

The largest face is called "pastel", the middle - side - "spoon", and the smallest - "poke".

The dimensions of a brick, in principle, are standardized (250 * 125 * 66 mm - single and 250 * 125 * 88 mm - one and a half), but the technology for its production is such that they can differ significantly from different manufacturers: by 2-3 mm in each of faces, and this is a rather significant difference, given the number of pieces in one row. Therefore, before ordering a batch, it is advisable to measure samples from several firings in order to determine how accurately the technology is maintained.

It is also important to pay attention to the geometry: the edges must be located strictly at 90 °. Otherwise, bursting loads will occur, and the wall may crumble.

Masonry marking

Test laying of the first two rows

Mark the line of the outer surface of the wall, using the wall of your house, a path or a red line as a horizontal reference line. Hammer stakes at the ends of this line and stretch a cord between them. Then lay the first front (front) row of bricks on the ground along the cord with 10 mm gaps between them. If necessary, move the stakes so that an integer number of bricks fit exactly between them.

Lay the inner (back) row of bricks with a gap between it and the front row of 10 mm. After laying several bricks, lay one brick on edge across the parallel rows. If it does not fit exactly on both rows, change the gap between them. Fully lay out two rows of bricks, checking the gaps.

Summarize

As you can see, making bricklaying devices with your own hands is very simple and not expensive. Although it will serve you for a very long time.

Bricklaying is a job that should be done with at least some experience. If you do it haphazardly, then the strength of the walls will not be sufficient, and this is fraught, as you yourself understand. In addition, the quality of the masonry will depend on how the house will look from the outside.

It is necessary to use various devices and tools to control the work being carried out.It is not reasonable to think that if you can do without them, then you are a professional. Mechanical devices are designed to make our lives easier.

- two horizontal strips 11x25 mm; two horizontal strips 19x40 mm; four vertical strips 19x40 mm; two studs with a diameter of 10 mm with winglets, bolts and nuts, with which the vertical strips are connected; two screws with caps with a diameter of 20 mm with nuts and washers; finishing 40 mm nails for fastening parts (the ends of the nails on the inside will need to be bitten off with wire cutters).

The total length of the structure is 850 mm. Horizontal strips are fastened in the shape of the letter G. Sections from the edge to the vertical strips - 130 mm. The height of the vertical bars above the level of the entire structure is 100 mm. This height is chosen so that when laying bricks, the thread passes 15 mm above the vertical slats and does not interfere with the use of the fixture. To install vertical strips on the inside of the device, you will need to select two grooves in a horizontal strip 11x25 mm with a chisel. All wooden parts are made of glued pine lumber. To prevent the absorption of moisture from the solution, the surface is varnished. Note: with the help of winged studs, you can adjust the width of the structure and work with wider or narrower bricks. The inner part is fixed tightly, only the outer side of the device can move.