How to wash the heat exchanger of a gas boiler with your own hands

Flushing of heat exchangers is required for gas boilers at intervals of 2-3 years. If this procedure is neglected, over time the boiler unit will become worse at coping with its functions, its efficiency will drop by almost half, and in order to maintain the usual temperature in the house during the heating season, it will be necessary to force the unit to constantly operate at full capacity.

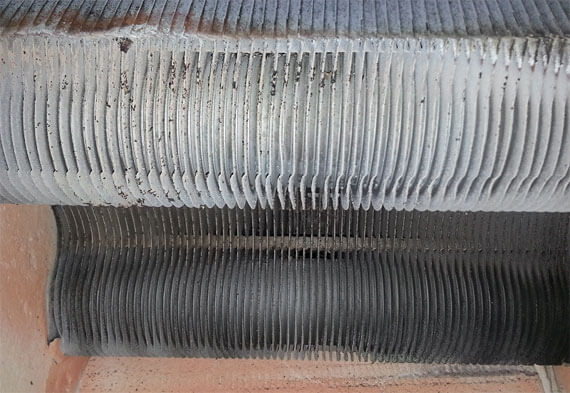

Why is this happening and why is it dangerous? Cleaning the heat exchangers from the outside makes it possible to remove the accumulated layer of soot - the thicker the layers, the worse the boiler works and the higher your energy costs. Flushing the boiler from scale helps to remove scale that has settled on the inner surface of the heat exchanger. Due to scale, the working section of the heat exchanger narrows, the coolant warms up more slowly - this also negatively affects the efficiency of the autonomous heating system and adds load to the boiler.

If preventive maintenance of a gas boiler is not carried out in a timely manner, gas costs increase every month and the risk of boiler breakdown increases. Steel boilers, constantly working at full power, quickly burn out. In the vast majority of cases, boilers fail at the height of the heating season, when they operate at full load. Calling a master to repair a boiler unit with mandatory cleaning and flushing of the heat exchanger will cost a serious amount.

To avoid problems and save money, it is enough to carry out preventive measures every three years. Flushing a gas boiler is a set of works that can be done on your own, spending from 1.5 to 4 hours on everything.

Regular cleaning of the boiler heat exchangers guarantees its efficient operation.

Thanks to the information presented here, you can independently, without the involvement of specialists, carry out preventive maintenance of a gas boiler, single or double-circuit. The work performed by you in accordance with the recommendations below will be of no less quality than the preventive maintenance carried out by qualified personnel of service companies.

In addition, you can save a considerable amount, since the cost of specialist services can reach several hundred US dollars. In addition, waiting for the arrival of the master for several days, or even weeks, may not suit every owner of an individual heating system, especially shortly before the start of the heating season.

Do-it-yourself cleaning of the boiler heat exchanger getting started

Before starting work, firstly, you should disconnect the heating boiler itself from the power source.

In order to access the system heat exchanger, you will need the following tools:

- Phillips screwdriver

- Flat screwdriver

- Wrench.

Perhaps, in your case, to flush the gas boiler heat exchanger, you will not need the entire set of tools from the list above, however, we recommend that you still provide for the presence of each of them as a “reserve”.

For example, to access the heat exchanger of a double-circuit turbocharged boiler with a Hermann SuperMaster 24SE boiler, you will need to do the following:

- remove the front cover from it, after which you will get access to the "insides" of the boiler,

- then remove the cover from the tightly closed combustion chamber, for which you will have to unscrew six bolts.

In turbocharged boilers, as in the case under consideration, the combustion chamber cover must have a rubber seal on all sides. Under the cover is the combustion chamber of the heating boiler.In order to gain access to it, at least a few walls covered with refractory material should be removed. To do this, once again unscrew the next five screws and open the combustion chamber.

At the bottom of a turbocharged boiler, you will most likely find a bunch of air-drawn debris. It will be most convenient to remove it with the help of an ordinary household vacuum cleaner.

The lower part of the combustion chamber is occupied by a number of nozzles that pass gas into the system. All nozzles should be thoroughly cleaned - the holes through which gas is supplied should become transparent.

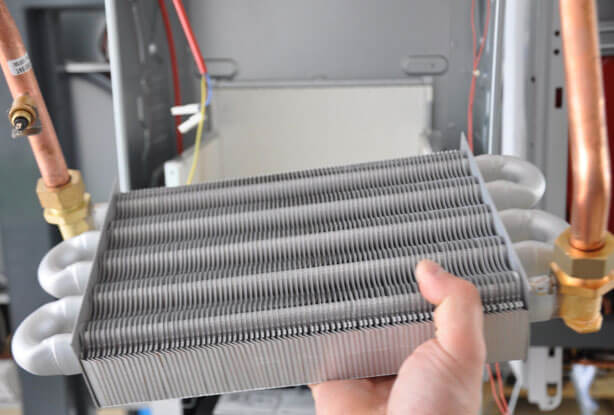

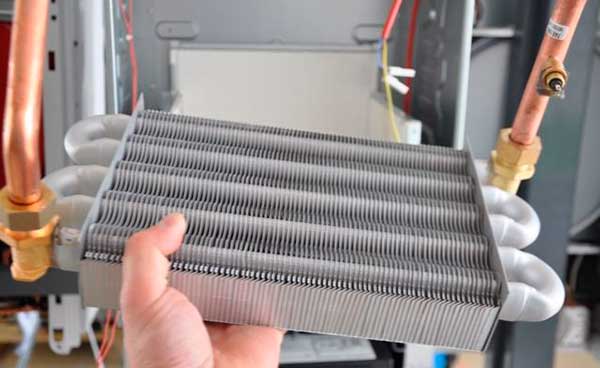

Next, you need to remove the heat exchanger itself. In the model under consideration, there are no threaded connections; the tube through which water is supplied and removed is connected using an adapter. On one side of the heat exchanger is a temperature sensor, from which the wires should be carefully disconnected.

How to clean interior surfaces

Flushing of the inner surface of a plate, fire-tube or bithermic heat exchanger is possible only with the help of special equipment.

- High pressure pump - hydrodynamic flushing. Used to remove small deposits. Advantages - the speed of the procedure and the possibility of cleaning without removing the heat exchanger.

- Booster (acid-resistant pump) - acid (chemical) flushing. Removes even old scale. Benefits - removes scale that cannot be removed by other methods. Disadvantages - with the wrong selection of reagents (acids and neutralizers), it reduces the service life of the heat exchanger.

- Complex "Streamer" for electric discharge cleaning. Used to remove scale of any strength. Advantages - the metal of the heat exchanger is not destroyed, a high degree of purification is provided. Disadvantages - noise and duration of the procedure.

Of all the methods listed at home, only chemical cleaning is possible, since the factory booster can be replaced with a low-pressure pump. The rest of the equipment is both expensive and bulky, so such washing of boilers can only be done by service centers.

How often should the boiler be cleaned

The technical documentation for the boiler indicates how often it needs to be serviced. For closed circuits with the addition of reagents (single-circuit heating boilers), cleaning is required less frequently. It can be performed 1 time in 2-3 years. The bithermic and secondary heat exchangers must be flushed every year, and under difficult operating conditions (“bad” water composition) - twice a year.

Signs that the boiler urgently needs cleaning:

- the boiler is slowly gaining temperature;

- insufficient traction;

- the burner does not ignite or does not burn well;

- with the same gas consumption, the heat output is less;

- traces of soot or partially burnt paint in the area of \u200b\u200bthe viewing window.

Do not neglect preventive measures, because the result of this can be not only broken equipment, but also a threat to the safety of all residents of the house. Clogged chimneys and pipes with growths inside can cause serious accidents.

A little theory or how it all starts

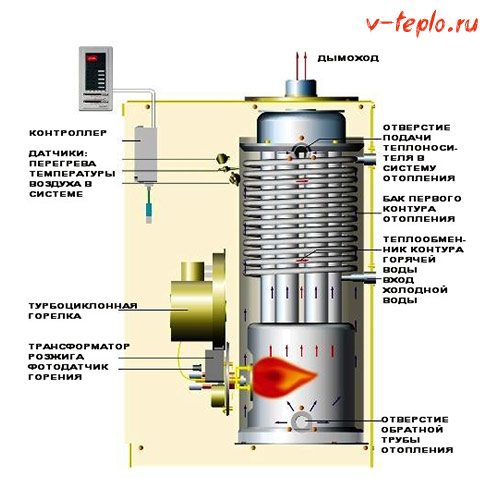

Although the heat exchangers of different heating systems may have some distinctive features, their design and principle of operation are basically the same: a coolant passes through a curved pipe (coil), then the coil heats up with a flame of burning gas, transferring heat to the liquid passing through it, supplied further along pipes to heating radiators. The plate system, in which the tube heated by the flame is located, allows to increase the temperature and make the heating of the coil material more uniform. Outwardly, such a system resembles a radiator installed in a car.

For the manufacture of heat exchangers, materials with good thermal conductivity are most often used. As a rule, these are copper alloys or pure copper.

In order to ensure efficient heating of the coolant in the heating system, it is necessary to monitor:

- Cleanliness of the heat exchanger inside and out

- Cleanliness and absence of blockages in the gas nozzles that release gas to heat the heat exchanger and its surrounding plates

You are unlikely to find specific figures, however, the experience and independent calculations of the owners of individual heating systems indicate that as a result of contamination of the heating system of the coolant, the loss of resources can be quite large.

In this case, the excess consumption of gas can be 10-15%. When converted into a financial equivalent, the amount lost as a result of the inefficient operation of the heating system can be quite large. In accordance with the advice of professionals, for the efficient operation of the heating system, annual cleaning of the heat exchanger of a double-circuit boiler is necessary, however, practice shows that with soft tap water it is enough to carry out this procedure once every three years.

Scale in kettles and taps indicates a high degree of water hardness, in which case we recommend cleaning the heating system every two years.

Features of flushing plate heat exchangers

In this case, the exchanger still needs to be disconnected from the boiler and the external and internal surfaces must be cleaned of scale. It's easiest to start cleaning from the outside. First, the device is filled with warm water, to which some kind of household remedy is added against scale, rust, and so on. After some time, the agent is washed off the surface with clean water. It is most convenient to carry out this operation on the street, using a car wash for washing, supplying high-pressure water pressure. In the absence of such a wash, you can ask the car wash workers to carry out this operation, but do not forget that too much pressure can damage the plates.

After cleaning the outer surface, you can wash the inner walls of the structure (these are the walls of the curved pipe). This flushing of the gas boiler heat exchanger is different in that a fairly thick layer of scale can be on the surfaces, especially if the last cleaning was carried out a long time ago, or was not carried out at all, or if hard water is used in the system. Even dirt can get inside, getting there along with the working fluid, especially in the absence of a cleaning filter.

Video - Cleaning procedure for plate exchangers

Why is it necessary to flush the heat exchanger?

In fact, a heat exchanger is a metal (or made of cast iron) box in which a radiator is installed. This radiator is heated by the fire of a burner located outside and gives off heat to the working fluid circulating inside.

In the case of a clean heat exchanger, it will function with maximum efficiency, and almost all the energy received will be spent on heating. But over time, the walls of the internal channels are covered with various kinds of impurities - salts (scale) dissolved in the liquid. Tellingly, scale is especially actively formed precisely in the secondary exchanger of the boiler for 2 circuits, if hard water circulates in the network.

The consequences of this kind of pollution can be the most unpleasant.

- The heat exchanger is overheating. In accordance with the scheme of operation of gas equipment, the coolant, which is supplied from the "return" pipeline, must cool the internal surfaces of the heating element. And if scale forms, then the heat exchanger overheats and the device, as a result, fails.

- The efficiency of the heater is reduced. Mineral deposits, as you know, have a rather low heat conductivity, which is why more energy is spent on heating the liquid. Consequently, fuel consumption increases.

- Heating equipment fails.Due to mineral deposits on surfaces, the movement of the working fluid is difficult. This forms an excessive load on the circulation pump, which, as a result, quickly exhausts the working resource (in the absence of timely cleaning of narrow passages).

As you can see, if you flush the heat exchanger in a timely manner, you can not only save a lot of money, but also prevent the failure of expensive elements. In addition, a minimum of gas consumption is ensured.

What is the best way to flush the device

Now let's figure out what is best to use for flushing

Despite the fact that there are quite a lot of recommendations and instructions, the choice of a particular fluid should be taken with all caution. Most experts advise using saline for this purpose.

Such a solution really effectively removes growths, but by its nature it is quite aggressive. Therefore, there may be a risk of destruction of the internal surfaces of the structure.

Note! In addition, there is information that the use of hydrochloric acid can lead to metal brittleness. But citric acid, as it turns out, is not so dangerous for heating equipment.

It copes well with various types of scale - no less effectively than the reagents that are popular today, including Sanaks, Sillit, Detex and others.

And if you take care of all elements of the heating system in a timely manner and, more importantly, competently, you can not only increase its performance, but also significantly extend its service life. Cleaning the heat exchanger - one of the most important operations, as we have already found out - will be a significant contribution to this process

But citric acid, as it turns out, is not so dangerous for heating equipment. It copes well with various types of scale - no less effectively than the reagents that are popular today, including Sanaks, Sillit, Detex and others.

And if you take care of all elements of the heating system in a timely manner and, more importantly, competently, you can not only increase its performance, but also significantly extend its service life. Cleaning the heat exchanger - one of the most important operations, as we have already found out - will be a significant contribution to this process

How to flush a gas boiler heat exchanger

Do-it-yourself flushing of the gas boiler heat exchanger is carried out mechanically or chemically, with the second option being more efficient.

mechanical way. In this case, remove the heat exchanger to clean it manually. Dismantling this part is a troublesome task, the complexity of which depends on the design of a particular boiler model. In any case, the result of mechanical washing is lower than that of chemical washing.

Chemical method. Allows you to flush your boiler without dismantling the heat exchanger, but requires the use of special equipment - a booster.

You can mount it yourself :

- a washing solution is poured into a tank with a volume of 15-20 liters;

- hoses connected to the pipes of the heat exchanger are lowered into the tank;

- the boiler turns on for heating (it is necessary to maintain a stable temperature of about 50 degrees);

- a circulation pump (preferably reversible) should be connected to the assembled system, which will force the flushing solution to pass through the heat exchanger.

- if you additionally install a strainer on the supply hose, mechanical impurities will not be cyclically driven through the heat exchanger.

Note! From time to time switch the system to the reverse direction using a reversible pump, or simply by swapping the hoses. The heating of the boiler is switched off

Before connecting the equipment for flushing, it is necessary to relieve the pressure in the heating system to zero using the Mayevsky tap, drain the coolant from the heat exchanger, and clean the built-in mud filter of the boiler (if any).

Flushing the double-circuit heat exchanger

If the double-circuit unit is equipped with a bimetallic heat generator that simultaneously heats the coolant and prepares water for hot water supply, then cleaning is carried out according to the method described above, using a booster.

For models with a secondary heat exchanger, this stainless steel part must be removed and washed separately. For dismantling, remove the front panel, unscrew and slide the control unit. The secondary heat exchanger for the gas boiler is bolted at the bottom. It is removed and boiled on the stove in water with citric acid or a special agent.

How to flush the heat exchanger of a gas boiler?

Citric acid is a popular folk remedy, the solution is prepared at the rate of 20 g of acid per 1 liter of water, but a higher concentration is also allowed. You can also use special products that are safe for metal and heating system seals.

In any case, at the final stage of cleaning, clean water should be driven through the heat exchanger with a booster to remove traces of cleaning agents aggressive to the metal, and only then bring the unit into working condition.

How to perform cleaning and flushing work without removing the heat exchanger using a circulation pump, see the following video.

Mechanical cleaning of plate heat exchangers

It is possible to clean the boiler from soot without removing the heat exchanger. To do this, just remove the cover, arm yourself with a stiff nylon brush and close the gas nozzles so that dirt does not get there. The whole process is clearly shown in the video:

If the soot has stuck to the surface and is not removed during mechanical processing with a brush, then the heat exchanger is removed and soaked in special washing solutions for several hours. Such products are commercially available in a wide range, such as Fauch and MAZBIT +. But you can also use household chemicals - gels for cleaning grills, ovens.

Before dismantling the boiler, you must disconnect it from the gas, and the igniter from the electricity. In addition, it is necessary to drain the water from both circuits and the expansion tank. The secondary heat exchanger is removed first, it is located immediately behind the boiler cover. It is more problematic to remove the primary (main) one, since you will have to disassemble the combustion chamber.

Chemical cleaning

In the presence of a booster, flushing can be performed independently. You can make a booster with your own hands - this is a pump and a 10-liter container with two hoses

In order for the procedure to help remove scale, but not damage the metal surface, it is important to choose the right acid. If the boiler is cleaned regularly, there are small deposits on the pipes, then the best way out is to use citric acid.

The concentration of the solution is up to 200 g of acid per 5 liters of water.

If the scale is old or unprepared water with a high mineral content (hard water) is used, you need to take more radical means - compounds based on orthophosphoric, sulfuric or hydrochloric acid. The use of a hydrochloric acid solution without corrosion inhibitors is not recommended as it may damage the equipment.

After acid treatment, it is imperative to flush the heat exchanger with a neutralizer. The alkaline composition is selected based on the acid used. For example, after citric acid, regular baking soda is fine. If you buy a flushing liquid, then it is better to immediately purchase a neutralizer for it: usually companies that produce acidic formulations also offer alkaline ones for neutralization.

Flushing video:

How to clean the plate heat exchanger

PHE cleaning procedure

Demountable cleaning of the heat exchanger

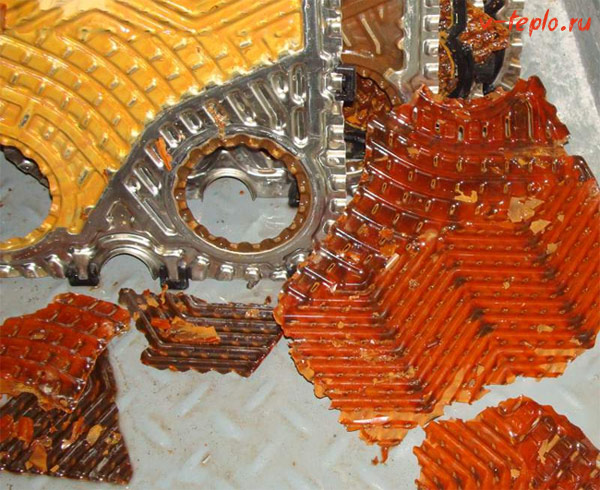

If the heat exchanger is heavily contaminated or completely out of order, collapsible flushing is used.

Wherein:

- the heat exchanger is disassembled

- remove all plates

- plates are soaked in a special solution

- each plate is washed “by hand” and with a high-pressure apparatus.

- the plate pack is inserted into the heat exchanger

- the package of plates is screeded to a certain size (number of plates x screed coefficient)

- the heat exchanger is assembled and pressure tested.

Advantages:

Collapsible flushing provides a 100% quality guarantee. Eliminates any kind of pollution. Everything happens visually and the customer sees the whole process of work.

Flaws:

If the heat exchanger has been operating under critical conditions, or the rubber seals have reached the end of their service life, then there is a possibility that the seals will have to be changed (i.e. the cost and time of service work will increase)

CIP flushing of the heat exchanger

As a prophylaxis and prolongation of service life, in-place washing is used with the help of special washing devices (BOY-C-190, etc.). CIP is used for both brazed and gasketed heat exchangers. Washing is done on site for 4-5 hours.

1. Before connecting the flushing unit, disconnect (hermetically) the heat exchanger from the working media, while the equipment remains under water, i.e. filled.

2. The supply hose of the unit is connected through a bleeder to the lower branch pipe of one of the circuits, and the intake hose is connected to the upper bleeder.

3. Water is poured into the unit and mixed with the flushing composition in a certain ratio based on the total amount of water in the unit and in the heat exchanger circuit.

Before mixing the chemical reagent with water, it is recommended to run the unit only with water, to check the tightness of the connections and equalize the liquid level in the unit (if the water level in the unit rises or falls, check the stopcocks)!!!

4. Then open the launchers and put the flushing equipment into operation.

5. During the operation of the installation after 30 minutes. switch the reverse direction.

6. After flushing, drain the reagent from the heat exchanger and the unit and flush the circuits with water with a neutralizer using the unit. Neutralize the drained reagent, check with a tester and drain into the sewer.

Flaws:

if the heat exchanger is clogged with various kinds of mechanical inclusions (as a rule, these are particles of sludge after welding of the pipeline, etc.), then without collapsible flushing will not be effective enough.

Advantages:

no need to dismantle the heat exchanger (this is important for the rubber seals of heat exchangers, which have come to the end of their service life)