The choice of paint for pipes

The answer to the question: is it possible to paint hot pipes - has already been provided, so we turn to the selection of a dye. Today, there are several types of paint that are a priori suitable for processing hot radiators.

- alkyd enamel - the surface treated with this material can be matte or glossy. The paint creates a durable coating. Among the variety of these dyes, there is a special one for radiators that can be applied to hot pipes. In addition, the enamel will create a barrier against the formation of rust;

- acrylic paint - has proven itself at home, as it is easy to use and does not emit odor when dried due to the fact that it is water-based;

- oil paint - this material is hopelessly outdated due to its characteristics (dries for a long time, has a pungent odor), so we will not consider it;

- spray paint - suitable for use in industrial environments, requires special application skills. This material is not suitable for use in the home;

- silicone-based dye - due to the cost and specifics of the application, such paint is significantly inferior to the first two options;

- dye based on heat-resistant varnish - great for heated pipes, but in a city apartment and a private house the temperature of the radiator is unlikely to rise above 90 degrees, so it is not advisable to use such a dye;

- water-dispersion paint - dries quickly on a heated surface, which interferes with high-quality film formation. In addition, such a dye already has poor abrasion resistance - it is not suitable.

Of all these paints, alkyd enamel and acrylic paint have proven themselves in the best way. But they have two drawbacks: alkyd enamel - exudes a smell, and acrylic - does not protect against rust. In order not to endure the unpleasant smell from alkyd paint, you can use acrylic paint, but before that you need to apply a primer layer on the batteries. Such paint for hot heating pipes keeps quite well and does not darken over time.

Examples of enamels for painting radiators

Among the range of special radiator paints, there are options that suit better than others. For example, among alkyd enamels, the Swedish paint "Elementfard Alkid" surpasses its competitors in its characteristics (it emits very little odor, dries quickly, is used at surface temperatures up to 100 degrees, does not require priming). And also the Dutch paint "Radiator Paint" helps to positively answer the question: is it possible to paint pipes during the heating season? After all, its range of application up to 90 degrees is enough to paint hot pipes.

steel pipe primer steel pipe primer product manufacturers at russian.alibaba.com-page1

The result of searching for information about these products and suppliers has already been translated into languages for your convenience. If you have any suggestion on this page, please help us improve.

Quality and type of steel

Today you can find the following options for heating radiators:

- bimetallic radiators;

- steel;

- cast iron.

Bimetal are made of two types of metals - steel and aluminum. Today, such products are in greatest demand among consumers. Aluminum provides good thermal conductivity, and steel is resistant to stress. The quality characteristics of such products are much higher than those of conventional cast-iron or steel batteries.

Temperature ranges

Let's try to figure out under what conditions it is necessary to use a heat-resistant primer:

- Up to 60°С.This type of composition is suitable for priming central heating radiators and pipes used to supply hot water. If the processing technology is not violated, you can use primers made on a paint and varnish basis. The coating will be applied without streaks, will not crack or fade in the sun.

- Up to 100°C. These materials are popular when working in country houses, this is due to the fact that, as a rule, in such buildings, the owners can regulate the temperature regime and often exceed 60 ° C.

- Soil mixtures, for temperatures above 300°C. Used for priming in industrial production.

Painting pipes of the heating system

Preparation for painting: cleaning and priming the surface of pipes and heating radiators

Before painting, heating pipes must be thoroughly cleaned of rust or old paint.

Pipes for painting are prepared according to the following instructions:

- Before painting the surface, it must be thoroughly cleaned - remove the old layer of paint and primer, clean the places where rust has formed to a metallic sheen. Get rid of dust and dirt with a wet rag and brush. Old paint is removed with a spatula and special cleaning solutions.

- The flushing solution is applied to the surface of the radiator and wrapped with a softening film. After some time, the paint can be easily removed with a spatula or drill, with a metal brush put on it.

- After that, the surface is treated with sandpaper and degreased with white spirit.

- Next, the surface is treated with an anti-corrosion primer. Its purpose is not only to protect against the appearance of corrosion, but also to increase adhesion - the adhesion of paint to metal. An alkyd-based primer is suitable for this.

When choosing a primer, it is imperative to pay attention to whether it has the properties of anti-corrosion protection. This is a prerequisite, otherwise all work may be in vain - rust will appear again

Manufacturers, as a rule, indicate this directly on the primer can.

Now the surface is ready, in fact, for applying paint - it will lie perfectly on such a surface.

Nowadays, the industry offers special two-in-one and three-in-one primers. They usually contain a primer, color pigments and a rust converter. Such primer paints are applied to the surface of a pipe or battery without their preparation for painting.

Instructions for self-coloring heating pipes

Step-by-step instructions for preparing and painting pipes and heating radiators in pictures

Next, consider how to paint heating pipes. You can, of course, invite a professional painter for these purposes, but it is much cheaper, and it will not be difficult to paint with your own hands.

The first thing to remember is that batteries should only be painted cold!

So, how to paint the pipes of the heating system:

- Getting started, first of all, it is necessary to protect the floor from contamination. To do this, they usually use unnecessary newspapers, paper, cloth, which are laid directly under the pipes and batteries.

- Also, before the staining process, you will need to select brushes. Brushes must be small in size with soft straight and curved bristles.

- The paint begins to be applied from above and moves towards the bottom. Cover the battery and pipes with paint from all sides, then apply a second layer of the coloring solution. In this case, you will get a perfectly evenly painted surface. With a two-layer painting, it is necessary to wait until the first layer dries, and only then apply the second.

Coloring can also be carried out using a spray gun and from a spray can. When painting with an airbrush, it is advisable to remove the battery in order to carefully paint over all hard-to-reach places.When using a can of heat-resistant paint, the surface of the pipes and the radiator is painted with high quality and very quickly. Additional instructions on how to paint surfaces with a spray can be found on its packaging. Typically, the balloon is zigzagged from top to bottom at a distance of about 30 cm from the surface.

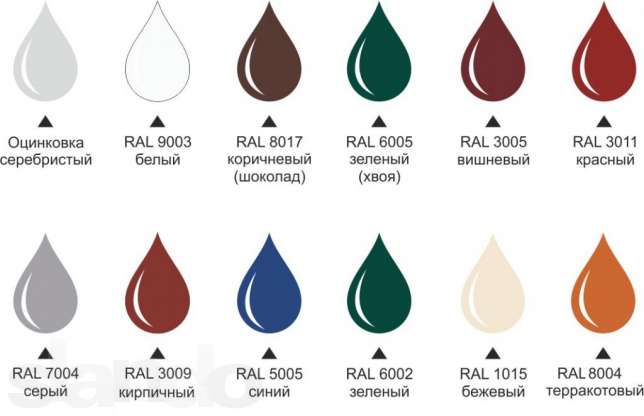

A variety of colors for the heating system

Characteristics of water-dispersion enamel.

In order to paint heating pipes, you can use a variety of paints that have different characteristics from each other. Among this diversity are the following:

- Alkyd enamel. Resistant to various influences, withstands heating temperatures from 100 degrees. The downside of this coating is a very unpleasant odor that occurs during application and until completely dry. Therefore, painting heating systems is often preferred with other types of paint.

- Water-dispersion paint. It dries quickly, has a long service life, but, in order to paint heating pipes, it is necessary to choose only specialized types of paintwork.

- Acrylic enamel based on organic solvents. This paint has a glossy sheen, does not change its color when used. Surface pre-priming required.

Paint manufacturers

Today, manufacturers offer many types of paints with which you can paint heating pipes, but among them the following stand out:

- Radiator Paint. Dutch white enamel is today considered optimal for painting heating systems. Odorless, withstands temperatures up to 90 degrees.

- Alkyd enamel Heitzkorperlak. Differs in the excellent covering ability, it is applied only if systems of heating are cold.

- Millertemp. Anti-corrosion paint with which you can paint any metal surface. It can withstand temperatures up to 600 degrees. When using it, no primer is required, the color is charcoal gray, matt aluminum.

- Elementfarg Alkyd. Paint and varnish from a Swedish manufacturer, which does not require a preliminary primer. Withstands temperatures up to 100 degrees, dries very quickly. It is used as a preparatory layer for applying other paints or as an independent top coat.

You can also paint heating pipes with other compounds, including alkyd Radiator, UNIPOL primer enamel, VD-AK-1179 enamel and many others designed specifically for heating systems.

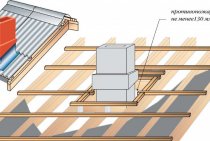

Step by step instructions for painting the chimney

For work you will need the following tools, materials:

- paint brushes or rollers;

- metal brush for surface cleaning;

- acetone or other degreasing liquid;

- primer;

- paint and varnish composition suitable for the material of the chimney.

For chimney painting to be effective, the following steps must be followed:

-

Calculate the area to be painted.

This step is necessary to calculate the amount of materials needed. -

Cleanup.

It is necessary to remove from the base that which can interfere with staining, as well as affect the quality of work: old paint, grease, dirt, etc. -

Primer.

Needed for better adhesion of paint to the surface.

Air Code of the Russian Federation:

- Pipes up to 100 m high are painted with horizontal stripes from 0.5 m to 6 m in white, red (at least 3 stripes should be).

- For structures over 100 m, the size of the strips should be from 1/7 to 1/21 of the entire height of the object. The outer stripes should be red.

The paint is applied in 2-3 layers so that the thickness is 40-60 microns. The consumption for 1 coating layer is 120-150 g/m².

metal surfaces

Metal pipes are usually made of stainless steel, which is the least susceptible to corrosion.Nevertheless, any structure from before painting must be prepared, otherwise painting for metal will not be long-term enough.

The work is as follows:

- Use a wire brush to clean dirt and old paint.

- Wash thoroughly, dry the base.

- Treat with a degreaser.

- Apply a mixture that prevents corrosion.

- Cover with 2-3 coats of primer.

- The last step is coloring. It is better to paint around the perimeter from top to bottom.

The main thing is the anti-corrosion coating, which increases the life of the structure. Also an important condition is the processing of sealing seams - in these places the pipes are most susceptible to destruction.

brick chimneys

Brick for construction is used less frequently. But such structures still exist.

Work algorithm:

- On the connecting clamps, it is worth tightening the bolts.

- Remove traces of old stains.

- Wash off dirt.

- Repair plaster if damaged.

- Apply a primer (from 2 layers or more).

- After drying, you can start painting. It is worth applying 2 layers of paint to the brick so that it is stronger, brighter.

Ceramic pipes

The technology for painting a ceramic pipe depends on what the insulation layer is covered with:

- foam concrete should be painted in the same way as a brick: clean, wash, restore damage (if any), apply a primer and paint;

- the metal layer is processed according to the metal pipe painting scheme: cleaning, anti-corrosion composition, primer and painting itself.

Here you can choose a paint with a lower coefficient of resistance to high temperatures (since the insulating layer that is included in the structure reduces it).

From reinforced concrete

Reinforced concrete pipes are painted in the same way as metal pipes. The main thing is the application of an anti-corrosion compound and the choice of a paint that is resistant to temperatures (otherwise such a coating will not last long).

As with a metal structure, you need to clean it of dirt, apply an anti-corrosion compound, primer and paint.

With proper preparation and painting, a protective layer is formed on the pipe, which protects the structure for 5 years. In addition, the protection period depends on external factors and weather conditions, proper operation of the system and timely repair.

Temperature ranges

At what temperature is the use of special, heat-resistant primers required? Let's analyze the coating requirements for different operating temperatures.

Up to 60С

In this temperature range fit, in particular, elements of autonomous heating systems. Typical for them, the temperature difference between supply and return is 70/50C, which gives no more than +60C on the surface of heating devices.

At temperatures from 0 to +60, general-purpose paints and primers can be safely used. Subject to the painting technology (that is, with high-quality cleaning of the surface and the conformity of the soil to the type of paint and varnish material), you can not be afraid of delamination or fading of the paint.

General purpose paints can be used in an autonomous heating circuit.

Up to 100С

The only significant difference from the previous scenario is the need to use paints with persistent pigments. The binder and primer remain the same as before: all popular types of paints tolerate prolonged heating without destruction.

Practical consequence: cheap and very common GF-021 is a quite suitable primer for heating radiators both in autonomous heating circuits and in central heating systems.

Up to 300C

And here comes the finest hour of heat-resistant soils. If the instruction for the use of temperature-resistant paintwork materials contains an indication of the need for priming, you will have to select special compounds that tolerate prolonged heating and retain their properties over the entire range of operating temperatures.

Over 300C

All paints intended for temperatures above +300 degrees are applied without preliminary priming, directly on a cleaned and degreased surface. A layer of soil at such temperatures will only increase the likelihood of delamination of the coating.

Particularly heat-resistant paints are applied directly to the metal base.

Nuance: we are talking about metal surfaces. Reinforcing primers for plaster or putty for brick fireplaces and stoves are also used at higher temperatures.

Painting radiators and heating pipes technology and stages of work

- The choice of paint for pipelines and radiators

- Some more tips

Painting radiators and heating pipes carries not only an aesthetic function, but also a functional one. Proper painting of pipelines is a guarantee of durability and reliability of heating batteries. How to paint pipes correctly and what should be considered? What paint should you choose? And finally, what does painting heating pipes mean?

Battery paint must be color stable, resistant to high temperatures and resistant to corrosion.

Until recently, pipelines were painted only white. Such a color scheme is not only boring, but also trite. Very often, batteries painted white are somewhat knocked out of the interior. Modern paints allow you to paint batteries in any color you like, the most suitable for the overall design of the room. How to start painting radiators and heating pipes? Base preparation: primer

Painting a radiator and pipeline is a rather painstaking work that requires compliance with a certain technology.

Painting of heating pipes is carried out after the primer composition is correctly selected.

The durability of the coating and the quality of work directly depend on how the primer is selected. It is simply necessary when painting heating pipes, as it significantly improves the adhesion between the battery itself and the paint material. Thus, it serves as the basis for the paint that will be applied over it.

For painting radiators, it is best to choose an alkyd-based primer

It is very important to choose a primer that has anti-corrosion properties: it will protect pipes from rust and damage to pipelines and heating radiators

Modern hardware stores present a wide selection of paints that already contain a primer. Primer paints not only protect batteries from corrosion and rust, but also allow you to paint them in any desired color.

There are also paints that not only protect heating pipes from rust, but also allow you not to clean the surface on which they will be applied.

After the primer for the batteries is selected, the first stage of work can be considered completed. Next, you should decide on the colorful material itself.

Analysis of market offers

What are heat resistant soils? Let's take a look at a few offers of the modern market as examples.

GF-031

Alkyd heat-resistant primer is produced according to TU-2312-030-00206919-2002 and is a suspension of pigments, antioxidants and surfactants in glyptal varnish.

Packaging GF-031.

What can be said about its properties and features?

- The primer is designed for steel, magnesium and aluminum surfaces. In particular, GF-031 is used in civil aviation - for applying coatings to aircraft bodies.

- The maximum operating temperature is +200C.

It is curious: the reservation about the civil aircraft industry is not accidental. The outer skin of the fighter-interceptor at a speed of about 2.5M (2.5 times faster than the speed of sound) is heated up to 300-500 degrees due to friction with the air.

- Solvent - solvent; they also dilute the soil during thickening.

- The method of application is by spraying or using a hand-held painting tool.

- The thickness of a single-layer coating after drying should be 15-20 microns. The primer consumption per one layer is 60-80 g/m2.

- TU stipulates the color of the applied pigments. Produced in accordance with the specifications GF-031 - yellow.

Phosphosoil

The name is a trademark of the Moscow company KrasCo. As you might guess, we have the so-called phosphating primer.

It reacts with the base and forms a thin layer of insoluble phosphates that improve adhesion and prevent corrosion.

Chemical composition of the phosphating agent.

- A mixture of acrylic, formaldehyde and epoxy resins is used as a binder. It is logical to assume that the primer is intended exclusively for open air or industrial conditions: formaldehydes in a residential area will clearly be superfluous.

- The operating temperature range is up to +300 degrees.

- Due to its composition, the primer can be used with all types of heat-resistant and conventional paints. It can be used not only on metal: the manufacturer allows the use of the final coating on fiberglass or ceramics to improve adhesion.

- The primer can be applied not only to previously cleaned, but also to a rusty surface.

However: when applying a primer with your own hands, it is still worthwhile to first remove the sheet and loose rust. Phosphating composition may change its chemical properties, but it will not change the spatial structure of the fragile oxide.

- Phosphosoil is diluted with acetone or toluene.

- Thanks to organic solvents, the composition can be applied at low temperatures down to -10C. Drying time of a single-layer coating at +20 - no more than 30 minutes.

- The average primer consumption is 70-90 grams per square meter.

In the photo - Phosphogrund packaging.

G-77

This heat-resistant primer for stoves and fireplaces impresses with its heat resistance. The operating temperature of 1200 degrees is declared for it, which, you see, is very impressive against the background of the previously described solutions. The composition of the water-dispersion primer is not disclosed by dealers; however, the colossal heat resistance suggests that the main binder in G-77 is heat-resistant silicone.

Grounding has two purposes:

- Improving the adhesion of putties and plasters.

Useful: at high operating temperatures, you can forget about the usual gypsum and cement mixtures. A mixture of clay and sand is used to finish stoves and fireplaces; often skimmed milk is added as a binder: the casein contained in it (milk protein, also known as low-fat cottage cheese), even with temperature denaturation, retains excellent binding properties.

Plastering the oven with clay mortar.

- Strengthening the base. The resins contained in the soil penetrate into its pores and bind the surface layer of the material into a single whole.

What other information about the primer is available to a potential buyer?

- Application is quite traditional - with a roller or brush in two layers.

- Drying time of one layer - no more than an hour. At least two hours must pass before further finishing on the primed surface.

- Priming is carried out at a positive temperature. Water base, remember?

- Consumption is no more than 400 milliliters of soil per square meter of surface.

Heat-resistant penetrating G-77 is supplied in 1 kg plastic cans.

As always, the video in this article will offer the reader more information on the types and applications of heat-resistant primers. Good luck!

>Primer for steel pipes

How to prime pipes

The process of preparing and priming pipes occurs step by step.

The work instructions have some features:

- The walls and floor of the room are closed.

- The surface of the pipes is thoroughly cleaned of old paint and rust. To do this, take metal brushes, brushes. The cleaning process is shown in the photo.

Cleaning pipes with a metal brush

- Old paint is treated with a special solution to soften it.

- Scraped off with a spatula.

- Carefully to a smooth state and gloss, the surface is cleaned with an abrasive cloth.

- The pipe is washed and dried.

- Degreased with a suitable agent.

- The primer is applied in the chosen way, using:

- brush, suitable for small diameters with irregularities. This takes more primer and processing time;

- a small roller that effectively reduces the consumption of the mixture;

- spray gun or pressure canister. The price of paint in a spray can is much higher with a small volume, which is not cost-effective.

Tip: Priming is recommended to carry out at least two layers. At the first coating, small irregularities are carefully filled.

A primer for pipes must be carried out before the final coating, which allows the latter to be well fixed. Processing in progress at room temperature with turned off heating. This ensures proper drying, improves surface quality and reduces primer consumption. The processing process itself is offered on video.

Properly made coating on steel pipes is a guarantee of their long-term use.

Graduated from the Faculty of Architecture of the Penza State Institute of Architecture and Construction. Over the past ten years, he has been a leading specialist in a large construction company in the city of Penza, which is engaged in the construction of multi-storey residential buildings. The total work experience in the specialty is 18 years. Advises on design issues, the choice of materials for interior and exterior decoration, the technology of finishing work.

Once upon a time I read in one Soviet publication that a layer of paint on batteries can significantly reduce heat transfer between the battery and the room, even a figure of 60% loss flashed. The ideal solution would be to chrome batteries and the appearance is excellent and heat will be given without loss. And connecting pipes can, in principle, be primed and painted. This is probably true for those who are cold in winter and who have a centimeter layer of paint on batteries.

Usually, an epoxy primer is not used, but applied to metal pipes and heating radiators GF-021, and then PF-115 enamel is painted on top. The primer consumption is indicated on the can, and the exact surface area of the pipes can be found in the tables.

The choice of thermal paint and the main manufacturers

The Russian construction market has a wide range of liquid heat insulators from various manufacturers, when choosing a paint, you need to read the application instructions, compare prices, because the product belongs to the category of expensive ones. You can determine the required amount of material according to the consumption rates indicated on the packaging for various types of treated surfaces.

Corundum

The manufacturer produces a wide range of paints, the main brands are:

- Classic - used for finishing interior and exterior objects with a working temperature range from -60C to +250C.

- Facade - provides thermal insulation of the outer surface of buildings, has good vapor permeability and moisture resistance.

- Anticorrosive - applied to cleaned metal surfaces or with traces of rust, provides high anticorrosion protection of objects during operation

- Winter is a brand intended for application in frosts at temperatures down to -10 C.

The average price of a 10-liter container of all brands of Corundum is 100 USD.

Fig. 8 Heat insulating paint for pipes - application options

Astratek

Durable paints with a service life of up to 30 years and a temperature of the coated surfaces up to 150 C. The product line consists of several grades of gray and white colors:

- The station wagon is used for thermal insulation of internal and external walls of buildings, the paint can withstand several freezing cycles, it is diluted with water.

- The metal is produced in gray color, during operation the coating performs anti-corrosion functions, it can be used for painting metal objects and roofs of buildings.

- The white facade is used to insulate the facade walls of buildings, it has increased water resistance and vapor permeability, a viscous consistency is designed to work with a spray or spatula.

The average cost of 10 liters. heat paint Astratek is 110 c.u.

Rice. 9 Popular brands of heat-insulating paints

Armor

Liquid thermal insulation Bronya consists of several varieties:

- Classic - performs the functions of a heat insulator in heating and hot water systems, can be used to insulate chimneys. The paint is not subject to solar radiation, protects the treated surfaces from corrosion and condensation, thereby extending their service life.

- Anticorrosive - designed to cover rusty metal objects, further providing their high anticorrosion protection.

- Winter - additive polymers and foam glass granules are additionally introduced into the composition, it can be used in winter at temperatures up to -35 C. and is designed for operation in cold weather, has a rather high price - about 162 USD. for 10 liters.

- Facade - in addition to thermal insulation, it performs protective functions, preventing the formation of condensate, fungus and mold, and has high vapor permeability.

Products under the Bronya brand are among the most budgetary (with the exception of Winter), the average price for 10 liters. is 75 c.u.

Rice. 10 Liquid thermal protection on the roof

Compared with the use of traditional heaters, thermal paint has higher performance properties, its use allows you to quickly and efficiently paint rooms, heating systems, steam pipelines and hot water pipelines. With your own hands, it is easy to paint the insulated object with a roller or a paint brush; to obtain the desired consistency, the paints are diluted with water.

Primer gf-021 gray and red-brown for metal and primer for pipes

Soil GF-021 looks like a liquid-plastic mass, which has a specific smell of solvents used in the production process, regulating additives and a desiccant used to accelerate drying. The composition is a suspension of glyptal or alkyd varnishes and anti-corrosion pigments with additives.

The primer GF-021 has found wide application in outdoor work for the preliminary protective coating of wood, metal or other products with which it has good adhesion, allowing for durable, stable pre-painting anti-corrosion treatment. Before priming, especially if it is done using an airbrush, it is required to dilute GF-021 to reduce the viscosity level. In this case, xylene GOST 9949 or 9410, solvent GOST 10214 or 1928, or any of them together with white spirit (nefras C4 155/200) GOST 3134 are used as a diluent in the recommended ratio of 1: 1, but the proportion of solvents should not exceed a quarter of the mass of the primer itself. Turpentine can be used; when painting in an electrostatic field, RE-4V thinner or its analogue RE-3V should be used. The surfaces to be treated are preliminarily completely cleaned of dirt, dust and old paintwork, traces of possible corrosion are removed, thoroughly degreased and dried. The applied coating retains its declared characteristics in the temperature range from forty-five degrees of frost to sixty degrees Celsius, does not react with sea or fresh water, and is not affected by mineral oils and detergents.

The GF-021 primer is applied by roller, brush, spraying or vacuumization, immersion or other method at an ambient temperature of at least five degrees and not more than twenty degrees Celsius, preferably in two layers.The time required for the first layer to dry at +20°C is an astronomical day. The same conditions must be observed before working with the primer, if it was at sub-zero temperatures during storage or transportation.

It is used as a base for paints and varnishes such as PF, GF, EF, FL and the like, but can also be used as an independent coating. It is produced mainly in accordance with GOST 25129-82 in red-brownish color, or according to TU in light gray tones.

Structures treated with a primer are distinguished by a smooth matte finish or have a dull gloss, they are excellently polished without “loading” abrasive materials. Excellent strength and quality characteristics are primarily due to the use of high-quality high-molecular copolymers in the manufacturing process, and the relatively low cost of GF-021 is due to their domestic origin.

The primer should not be in the area of direct sunlight, the container must be hermetically sealed, limiting the ingress of air and precipitation. When working with it, you should use personal protective equipment that excludes the composition from getting into the eyes and open areas of the body. Painting work is recommended to be carried out either outdoors or in a well-ventilated area, away from possible sources of ignition. It must be remembered that the soil GF-021 is toxic and requires specialized disposal, it is categorically excluded to drain residues into the general sewer system.

CONSUMABLES AND RELATED PRODUCTS:

Paint brushes

flat and fluted

Overalls and

household inventory

Moscow and other regions of Russia can find out the cost of delivery by contacting any nearest terminal of a transport company working with St. Petersburg. For our part, we will ensure prompt delivery of cargo to any carrier you choose.

For wholesale orders there is a system of discounts. Regular customers are always a priority for us, but we are always open to dialogue and mutually beneficial cooperation for new ones. Our product catalog includes the most complete list of products offered, and for the objectivity of your choice, only original photographs are placed on all pages of the site. A price list that reflects prices in real time will help you choose and buy products of interest at the most favorable prices. Any of your feedback, complaints and suggestions will not go unnoticed, we are waiting for them on our e-mail. address: mail@komplektacya.ru

Why Use a Heat Resistant Primer

Is it really necessary to prime a surface that will subsequently heat up? To answer this question, it is necessary to understand the features of the operation of such items. Here are a few of them, which are the most obvious:

- The need to increase the adhesion of the coloring matter to the surface. It's no secret that many primers have a fairly high degree of adhesion. In addition to this, they increase the adhesive characteristics of the painted surface itself. It is thanks to the primer composition that metal elements that are amenable to heating acquire a certain film that is resistant to dissolution when a coloring matter is applied to it on metal.

- Protection against the occurrence of corrosion damage. Heat-resistant primers are not only necessary in terms of preparing the surface for applying paint, but also act as a protective material themselves.

- Reducing paint consumption. After applying a heat-resistant primer, a kind of film appears on the product. When painting the surface with coloring compositions, the absorption process is almost completely absent, which ensures economical paint consumption.This property is relevant when decorating stoves or fireplaces. The fact is that the compositions for painting this type are quite expensive. Therefore, it is better to carry out high-quality priming than to spend money on paint.