What is a closed cooling system and what are its advantages

A closed system is a water-cooling system with a steam-air valve that is hermetically separated from the surrounding atmosphere. It reduces the evaporation of water from the radiator, which prolongs the operation of the tractor between topping up water and reduces the formation of scale.

When the pressure in the system rises more than 1.25-1.30 atm, the steam valve opens, which releases the excess steam formed. As the system cools, the steam condenses and the volume of water decreases. In this regard, a vacuum is created, under the action of which the air valve opens and the pressure in the system becomes equal to atmospheric.

What are the features of the tractor engine cooling system?

Tractor diesel engines dt 20, D-108, AM-01 and 238NB have a closed cooling system with a thermostat. The D-108 and 238NB engines have two thermostats installed in parallel. The thermal regime is regulated for the tractor engine of the tractor dt 20 by a curtain, and for the engines D-108, AM-01 and 238NB with the help of blinds.

The open cooling system of the D-28, D-48 and D-50 engines has a thermostat, and the thermal regime is controlled by means of shutters.

The tractor engines XTZ, SMD-7 and SMD-14 have an open cooling system without a thermostat, and the thermal regime is regulated by a curtain. For tractor engines dt 20, D-28, tractor dt 20, D-50, SMD-7 and SMD-14, the water pump is installed coaxially with the fan and is driven by a common belt drive from the crankshaft. The water pump for diesel tractors xtz, D-108 and 238NB is placed at the bottom of the block.

The fan of the 238NB tractor engine is driven by a gear transmission.

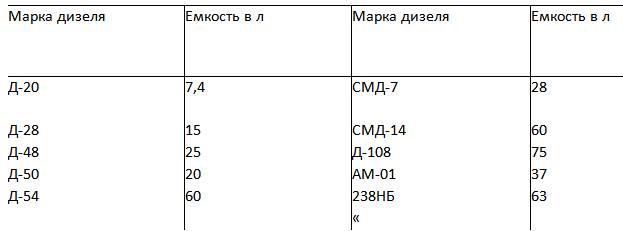

The capacity of the tractor engine cooling system is shown in Table 21.

table

Cooling capacity

What is the maintenance of the cooling system?

Care cooling system consists in the timely topping up of water, flushing the system and removing scale from it, checking the belt tension and lubricating the fan bearings. Fill the system with clean water that does not contain a large amount of mineral salts. This requirement is best met by rain or snow water. If you have to use water with a high content of mineral salts (hard), then it must be boiled or add 6-7 g of caustic or 10-15 g of washing soda per 10 liters of water. Water containing chlorine or sulfate salts must not be poured into the cooling system, as it quickly destroys the thin brass tubes of the radiator. Such water should be neutralized by adding 100 g of liquid glass to 10 liters of water. It is necessary to add water to an overheated diesel engine gradually, without stopping the diesel engine.

Rinse periodically for 5-10 minutes with clean water cooling systemby opening the drain cocks on the block and the lower manifold pipe.

It is necessary to regularly remove scale from the cooling system, for which you need to prepare a solution of 50-60 g of washing or caustic soda per 1 liter of water, drain water from the cooling system of a preheated tractor engine, pour 2 liters of kerosene and the prepared solution and start the diesel engine for 5- 10 minutes, and then leave the cooling system filled with the solution for 10-12 hours. After that, restart the diesel engine for 5-10 minutes, then stop, drain the solution and thoroughly rinse the system with clean water.

The correct belt tension is determined by the amount of deflection by pressing the belt with your hand, or by the amount of force required to turn the fan blade when the crankshaft is stationary. When pressed by hand with a force of 6-8 kg in the middle of the belt, the deflection should be within 15-20 mm.

Always watch for water leaking through the water pump seal.

It is necessary to periodically lubricate the bearings of the fan shaft and the water pump.It is also necessary to monitor the strength of the radiator mounting. The core of the radiator must be clean. It should be cleared of blockages and washed with water.

Water-deal what will happen if you mix filled antifreeze with water and a direct answer to the question

Experts warn - you should not rush, you need to look through the factory booklet for information about the filled emulsion and how to restore its level. Then the question of what will happen if you mix antifreeze with water will disappear by itself. We will give multilateral situations when it is possible to add a natural chemical liquid, and when it is impossible.

A little liquid is gone

Let's say that in the tank the nominal level has shifted down by 100 ... 300 milliliters. In this case, you can pour water with confidence and do not worry about the state of the system. The balance of additives will not change, since the evaporated liquid is just water. It is worth knowing:

- Antifreeze is half water.

- You can only add distilled composition.

- Ordinary water cannot be added due to the fact that the outcome of the interaction of the natural chemical composition with coolant additives is unknown.

- The solution from the tap is harsh and can lead to corrosion of the cooling system channels.

There is not enough coolant

The best option would be topping up ready-made antifreeze or diluted concentrate. If the situation with a leak arose far from the points of sale, and it is summer outside, then you can safely pour the distilled composition. As a last resort, filtered water will do.

Diluted with a large amount of water, the coolant must be replaced. Moreover, this should be done before the onset of the first cold weather. Naturally, in winter it is forbidden to resort to excessive dilution of the coolant. After all, it can freeze and the engine will need partial repairs.

Additive classification

The well-known classification of antifreezes was invented by Volkswagen to facilitate the separation of liquids by composition. To this day, it is widely used, used in the certification of coolants.

Antifreeze classification table:

| Antifreeze class | Description |

| G11 | Hybrid antifreeze (G11) is a green, turquoise, blue or yellow liquid containing silicates or phosphates as inhibitors. Service life - 3 years. Type: inorganic. Produce "hybrids" since the 90s. Subclasses G1+ and G11++ differ in the percentage of carboxylic acids.

G11 antifreezes (Tosol) are designed for old cars with a large volume of the cooling system. They create a protective film throughout the cooling system that protects parts from corrosion, but this protection has a drawback - this protective film reduces thermal conductivity. Therefore, in a modern car with thin channels of the cooling system, the G11 is not suitable, because. engine cooling deteriorates. In addition, the boiling point of G11 antifreeze is 105 degrees. The maximum service life of such coolants is 2-3 years or up to 50-80 thousand km. mileage |

| G12 | Carboxylate antifreeze (G12) is a red organic liquid (various shades). It has been serving for 5 years and protects metal from rust and cavitation much better than G11 class refrigerants. Red antifreezes are adsorbed only in the centers of corrosion, forming a layer with a thickness of 0.1 microns. That is, the inner surface of the cooling system is not completely covered, but only where necessary. This has a positive effect on heat transfer: the cooling efficiency of the engine is not reduced. |

| G13 and

G12+ |

Lobrid antifreeze G13 (formerly G12 +) - organic base supplemented with mineral inhibitors. Such antifreeze forms an ultra-thin protective film on the metal, which reacts only with a corrosion center. The composition of lobrid fluids includes organic acids and silicates. The service life of such antifreeze is unlimited, provided it is poured into a new car. Color - red (first lineups), orange and yellow (new lineups), purple (post-2012 lineups). The compositions were developed in 2008 and are actively used by the manufacturer Peugeot and Citroen.

G13 2008 - orange or yellow coolant, created, unlike its predecessors, based on propylene glycol steel. Because of this property, antifreeze is much better than other classes, but the price is also the highest. So you can determine the G13 not even by color, but by the price tag in a car dealership. |

It is quite easy to draw an analogy between the color of a liquid and its composition. Class G11 antifreezes are usually blue and green. G12 is usually red. And G13 refrigerants received purple, red and yellow colors.

Red antifreeze G12

Red antifreeze G12

Technical characteristics of antifreezes:

| Name of indicator | Standards for antifreeze g11 | Standards for antifreeze g12 |

| 1. Appearance | Homogeneous transparent colored liquid without green mechanical impurities. | Homogeneous transparent colored liquid without red mechanical impurities. |

| 2. Density at 20°C within | 1.065 – 1.085 g/cm3 | 1.065 – 1.085 g/cm3 |

| 3. The temperature of the beginning of crystallization is not higher | Minus 37 °С | Minus 37 °C |

| 4. Boiling point at a pressure of 101.3 kPa (760 mm Hg) not lower than | 108 °С | 108 °С |

| 5. Mass fraction of water, no more | 50 % | 50 % |

| 6. Alkalinity reserve not less than | 10 cm3 | 3 cm3 |

| 7. Foaming:

foam volume after 5 minutes no more foam disappearance time no more |

30 cm3

3 min |

30 cm3

3 min |

| 8. Hydrogen index (pH) at a temperature of 20 ° C, within | 6,5-11,0 | 6,5-11,0 |

| 9. Corrosive effect on metals, g/m3 per day, not more than:

copper M1 (GOST 859-78) brass L68 (TU 48 - 2 1-5005 - 80) solder POS-35 (TU 48 - 13 - 10 - 84) aluminum AK-6M2 (OST 48-178-80) cast iron GN-190 (according to FIAT VAZ 52205) or Sch-25 (GOST 1412-85) steel ST-20 (GOST 1050) |

0,1

0,1 0,2 0,1 0,1 0,1 |

0,1

0,1 0,2 0,1 0,1 0,1 |

| 10. Impact on rubber at a temperature of 100 ° C for 72 hours. Volume change no more than:

standard rubber samples 57-5006 (TU 38 - 105 - 250 - 77) class TRP-100-60 standard rubber samples 57-7011 (TU 38 - 105 - 262 - 78) class TRP-100-60 |

5%

5% |

5%

5% |

| 11. Hard water resistance | not defined | not defined |

| 12. Fractional data:

distillation start temperature not lower than mass fraction of liquid distilled to a temperature of 150 °C, not more than |

100 °С

55% |

55 °С

5% |

Test tasks for diagnostics and maintenance of the car

The hole in the bottom of the coolant pump housing serves to

|

2

- Navigation on this page:

|

The hole in the lower part of the coolant pump housing is used for:

|

2

How to properly replace the coolant

Now let's move from theory to practice. It is necessary to carry out a scheduled replacement because even during normal operation in antifreeze, the content of additives decreases over time, and corrosion of engine parts increases. The fluid begins to foam more, and therefore it is worse to transfer heat and the engine may overheat. Scheduled replacement, as a rule, is recommended every two years, and in conditions of intensive use, every 60 thousand km of the vehicle's run.

If exhaust gases enter the cooling system, early replacement may be required. This happens, for example, through a faulty cylinder head gasket, or air in leak areas, which provokes accelerated aging of the fluid. So, the signs of the need for this may be the following signs: - a jelly-like mass is formed on the inside of the surface of the expansion tank; - antifreeze in light frost (up to minus fifteen ° C) becomes mushy, which leads to the formation of sediment in the tank; - the electric fan of the radiator of the cooling system begins to work more and more often.

In emergency situations, for example, when replacing a broken hose on a long journey, you have to fill the cooling system with water from a random source. As a result, hard water with impurities activates corrosion and causes the formation of foreign suspension, which leads to inhibition of the circulation of the liquid and can cause difficulty in the operation of the water pump. In addition, scale appears in the hones of strong heating, which impairs the operation of the cooling system. When the antifreeze turns brown, it means that active corrosion of the cooling system components is taking place. And the “cooler”, diluted with low-quality water, should be replaced as soon as possible, and at the same time, be sure to flush the cooling system.

About the procedure for replacing the coolant - it must be carried out on a cold engine: - remove the cap of the expansion tank and / or radiator; - then, open the heater radiator valve - this is so that there is no liquid left in it or in the supply hoses; - unscrew the plugs in the radiator and BGC of the motor, drain the old coolant into a previously substituted container, then install the drain plugs back; - pour a thin stream of new coolant slowly through the expansion tank and close its cap; - start the engine, warm it up, then turn it off, and after it cools down, top up the liquid to the desired level as necessary.

We find out whether it is possible to interfere with antifreeze of different brands and colors recommendations of experts

Having found that there is not enough coolant in the expansion tank, it is worth asking what type of composition is filled. This may be stated in the user manual. It is possible that this information is printed on the container itself in the form of a pasted sticker.

It is a completely different matter when mixing compositions of different brands. As a result of this activity, anti-corrosion additives may conflict. The result is the formation of a solid precipitate or flakes. It is quite obvious that this state of affairs will greatly reduce the resource of the pump.

To avoid a curious case, expressed in the mixing of antifreezes of different classes, it is worth familiarizing yourself with their classification. There are two types of bases:

Ethylene glycol and propylene glycol in their composition are polyhydric alcohols. The more their content in the cooling mixture, the greater the frost resistance it has.

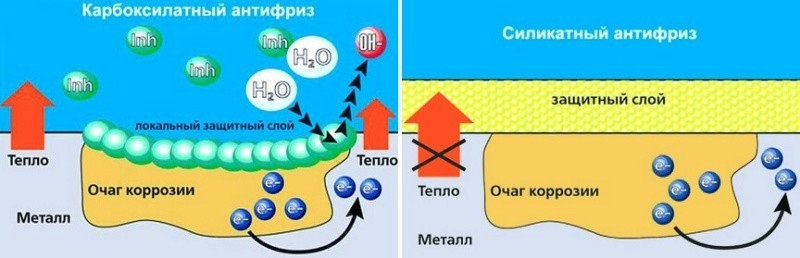

- Traditional (Silicate). They include corrosion decatalysts from inorganic substances - borates, phosphates, nitrates. They cover the working surfaces with a thin protective layer that impairs the heat transfer of the nodes.

- Carboxylate. They are based on organic acids or, in other words, carboxylates. Such additives locally resist corrosion, creating a protective layer one micron thick in a certain place.

- Hybrid. They contain organics (carboxylates) and inorganics (nitrates, borates, phosphates). Excellent suppression of corrosion areas and counteract liquid boiling.

- Lobrid. A significantly increased concentration of carboxylates and a deliberately low mass fraction of inorganic silicates are the main difference from hybrid compositions. It is an advanced blend and is used on new vehicles.

Note. The classification from VW helps to separate the types of coolants by additives:

- G11 - hybrid.

- G12, G12+ - carboxylate.

- G12++, G13 - lobrid.

Is it possible to mix antifreezes of different brands and types with organic and inorganic additives

The operator must be aware of the type of antifreeze that is in the cooling system of his machine. If coolants with organic and inorganic additives are accidentally mixed, as a result of mutual poisoning, they will not be able to provide adequate protection for engine parts.

In an emergency situation where coolant needs to be topped up and the type of antifreeze is not available, water can be added to keep the cooling system running until the correct type of coolant can be topped up. Please note that water, especially mineralized water, is a corrosive substance and is more dangerous for heavily loaded diesel engines than, for example, for gasoline engines of cars. Therefore, it will be necessary to bring the content of additives in antifreeze to normal as soon as such an opportunity arises.

Antifreezes with organic additives (OAT) and coolants with organic and inorganic additives (NOAT) can be mixed in an emergency, but it must be borne in mind that as a result of mixing, inhibitor additives in the composition of both fluids neutralize each other. How to proceed further, the opinions of the experts we interviewed differed. Some experts advise in this case to measure the level of additives in the resulting antifreeze and bring it back to normal with the help of additional (reducing) SCA additives. Others believe that, given the considerable cost of modern engines, if you spoil the liquid by adding coolant of a different grade to it, drain everything without sparing and fill in a new one recommended by the engine / machine manufacturer, and in the future try not to do such errors.

It is usually believed that in the coolant "with an extended service life" you can safely add up to 10-25% of the usual coolant (not "long-playing"). If the amount of antifreeze added is more than 25%, the antifreeze obtained in the cooling system should be checked: whether it contains enough organic additives (OAT) so that it is able to protect engine parts.

You should not draw a conclusion about the type of coolant by its color, you can easily make a mistake. For example, both coolant without nitrites and with nitrites can be painted red. If there is any doubt about the compatibility of two antifreezes, it is recommended to at least approximately check their compatibility in this way: mix in a 1: 1 ratio, mix thoroughly and observe for an hour whether there will be liquid and sediment stratification. Such a check will help to reject at least the lowest-quality counterfeit antifreezes.

Dilution of antifreeze concentrate

Antifreeze concentrate is a substance that does not contain distilled water. The remaining components, such as dye, additives and ethylene glycol, are present in full.

In order for the antifreeze to fulfill its functions and not have to be poured out due to improper mixing, the correct proportions must be observed. The procedure itself is not complicated and consists in mixing the concentrate with distilled water according to the table values.

Table: proportions of water and antifreeze concentrate

| Percentage of water | Concentrate percentage | Freezing threshold, °С | Boiling threshold, ° С |

| 87,5% | 12,5% | -7 | 100 |

| 75% | 25% | -15 | 100 |

| 50% | 50% | -40; -45 | +130; +140 |

| 40% | 60% | -50; -60 | +150; +160 |

| 25% | 75% | -70 | +170 |

Video: how to dilute antifreeze concentrate

In order for your car's cooling system to last as long as possible, only antifreeze should be used as a heat sink. Its topping up and dilution with water can be performed by each car owner, adhering to the above recommendations.

Good day, dear readers of my AUTOBLOG, the winter season is coming, and, accordingly, severe frosts will come. Your vehicle's coolant must be prepared for these tests. But there is such a situation, especially in summer, when water is added to the expansion tank, that is, antifreeze is mixed with water, they do this because of the low liquid level. And is it right? Let's think today about the question of whether it is worth diluting antifreeze like that ...

You can mix antifreeze and water, there's nothing wrong with that. The main thing in this matter is not to overdo it. Antifreeze itself consists of 70% water, and therefore adding a small amount of liquid will not cause much harm. The main thing to remember is concentration. At high temperatures, for example in summer, water evaporates from antifreeze, leaving only the active layer of additives, that is, the liquid becomes more concentrated. It is even recommended to add a little water to such a liquid in order to reduce the concentration to a normal state.

Now let's consider another situation. For example, your hose from the expansion tank broke, about a liter of antifreeze leaked out, then you fixed the leak and decided not to buy more liquid, but to add water. In the summer it can and will work, but in the winter it is by no means impossible to do this. Because the concentration of such coolant is very low. Such a liquid will freeze already at - 5 - 10 degrees Celsius. And if your liquid is frozen, then this is fraught with serious breakdowns, it can break the radiator of the stove and engine, and also damage the pipes. I remember a radiator leaking on my Ford Fusion precisely because my antifreeze was very diluted to -28 degrees, and that night it banged - 35 degrees. The antifreeze did not freeze, but began to crystallize, and this was already enough for the radiator to leak. Therefore, in winter, do not mix antifreeze with water, but on the contrary, you need to add concentrated antifreeze in order to increase the temperature threshold.

And the last thing - you should not greatly dilute the liquid, also because the anti-corrosion properties of antifreeze, with a large dilution with water, decrease or even disappear altogether. But the water inside the system can cause rust of metal pipes, adapters and all kinds of metal valves. And where there is rust, there is also sediment, sediment will be deposited on the walls of metal pipes and clog the passages, and this is not very good. Of course, all this will not happen quickly, but why take the risk.

Summing up, I want to say - you can mix, but within reasonable limits. And it is best to add to antifreeze - only antifreeze. Moreover, in red antifreeze, add red, and in green it is green. Read useful articles - antifreeze red or green, and also - is it possible to mix antifreeze and antifreeze. And today everything.

(8 votes, average: 4.50 out of 5)