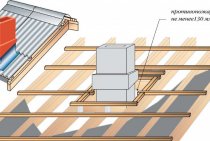

The choice of location and type of foundation for the stove

Scheme of laying the foundation for the furnace

Before starting the laying of the furnace, pay due attention to finding a place to place it. For example, if the unit is placed in the middle of the room, it will be able to give off much more heat, warming up from all sides and evenly heating the air around

If you place the stove against the wall (and this option is used most often), cold air will constantly “walk” near the floor. Therefore, in this regard, you need to make your own decision.

Pre-determine the installation location of the furnace door. This element must be installed so that in the future you can load fuel into the stove as conveniently and quickly as possible without spreading garbage from firewood or coal throughout the house. Usually the furnace door is located on the side of the kitchen or some little-visited room.

The finished brick stove will have a fairly impressive weight. In order for the device to stand as reliably and for a long time as possible, an individual concrete foundation must be prepared for it.

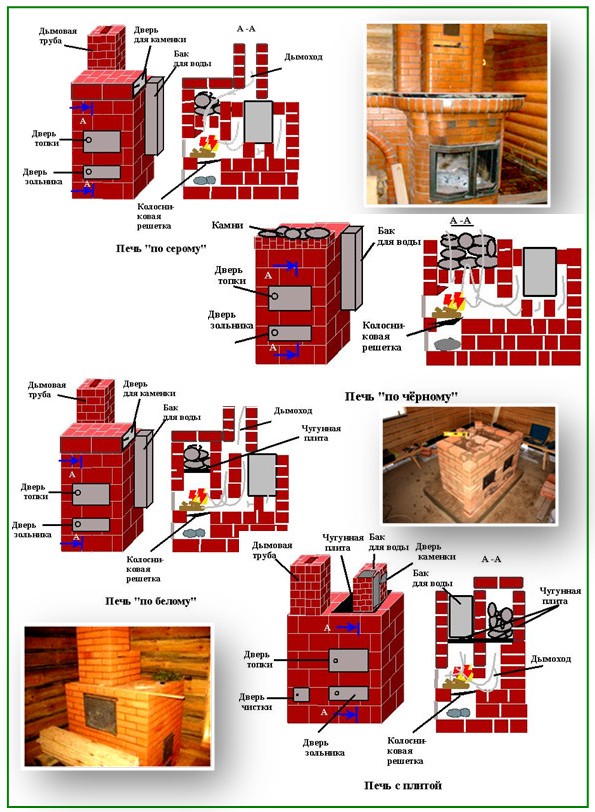

Furnace Design Features

Traditional brick ovens have a fairly simple design. However, the apparent simplicity at first glance allows achieving very high rates of productivity and efficiency.

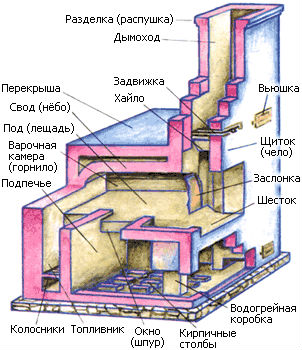

The main elements of the body of a brick oven are the firebox and the chimney. Cooking ovens are additionally equipped with stoves and / or ovens, it is also possible to install a tank for heating water.

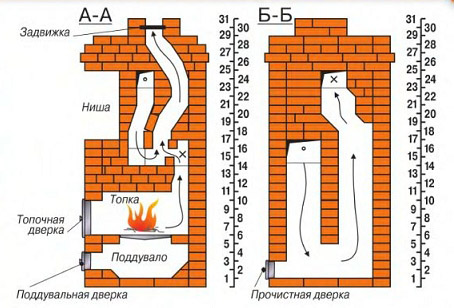

Scheme of the Russian stove

The firebox is the main part of the furnace unit. It is in the firebox that firewood or other fuel used for heating is loaded. The firebox can be of various sizes. When determining the appropriate dimensions, several important factors must be considered, such as:

- type of fuel used. If you will heat the stove with wood, make a firebox 50-100 cm high;

- required performance;

- required volume.

To equip the firebox, use refractory bricks. The wall thickness of the structure under consideration cannot be less than half a brick.

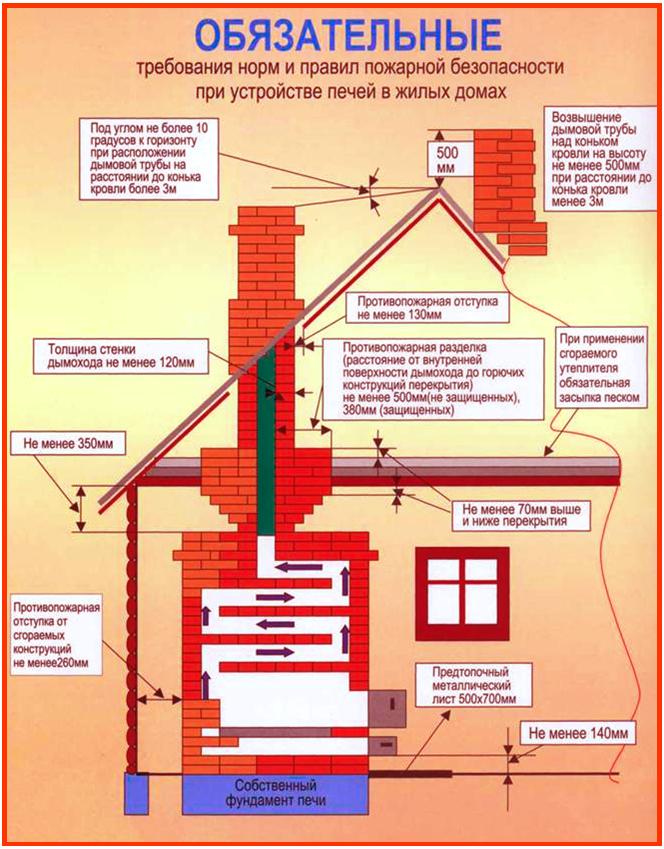

The chimney is also one of the main elements of any heating furnace. The chimney is designed to remove flue gases with various harmful inclusions formed during the operation of the furnace.

Rules for installing a brick chimney

At the design stage of the chimney, try to think through everything so that its design has a minimum number of bends and turns. Ideally, the chimney should be completely vertical. Any kind of bends will lead to a deterioration in traction and a decrease in the efficiency of heating the room.

An ash pan chamber is one of the important structural elements of a brick oven. Ash will collect in this compartment. Also, air is supplied through the ash pan to the inside of the unit, to the fuel. The ash chamber is arranged under the grate of the grate and is equipped with its own door. Traditionally, the height of the ash pan is 3 bricks.

The purpose of the stove in the house

It consists in a set of activities carried out daily or once or twice a year.With intensive use, the rough needs to be cleaned from accumulated ash. Its large amount will interfere with normal air circulation, which is why the firewood will not burn completely.

Another nuance in using a brick oven is the cracking of its finish. Experienced users advise not to overheat the surface. The normal temperature is considered to be 17-18 degrees, and the features of the brick allow you to keep moisture inside the room. Such a microclimate is provided only by the use of a stove, other heating devices often dry out the air, and lower temperatures make the room feel damp and cool.

Main types of ovens

Before proceeding with the self-laying of the furnace, familiarize yourself with the features of the existing varieties of such units. The ovens are:

- heating. Designed exclusively for heating. Such furnaces have an extremely simple design and are laid out in the shortest possible time and with the least effort compared to other types of structures;

- heating and cooking. The most popular and demanded option. At the same time they heat the house and allow cooking;

There are also improved varieties of heating and cooking stoves with a built-in stove or even a full-fledged oven.

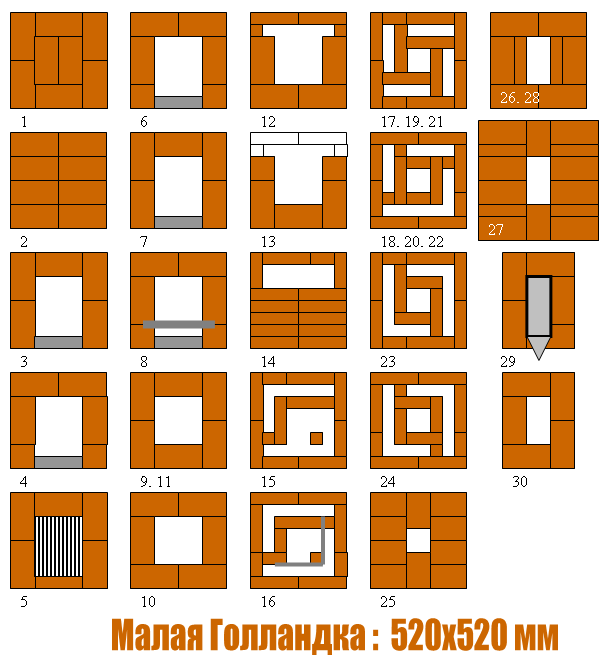

Do-it-yourself Dutch masonry

Fireplace stoves belong to a separate category. This is a great option for a modern private home. Such designs perfectly cope with the tasks of space heating and have an attractive appearance. A properly laid out and finished fireplace stove will be a worthy addition to the interior of both a small country house and an expensive private villa.

These are the stones

Schemes of modern furnaces distinguish them not only by purpose, but also by the features of the form. Most often, units of rectangular and square shape are installed in private houses. But if you wish, you can lay out a round oven. Select the specific option taking into account the characteristics of the room and your own preferences.

The figure shows a simple brick oven for heating and cooking.

The oven, of course, can be laid out with your own hands and numerous schemes will help you do this in the shortest possible time. However, when performing such work, remember that any furnace, regardless of its purpose, shape and other characteristics, must fully comply with current fire safety standards.

Varieties of oven-coarse

Rough (or coarse) is one of the variants of the Russian-Dutch stove. Appeared in Russia more than 200 years ago, "Dutch women" have established themselves as an economical and reliable heating unit that takes up little space in the house. However, domestic stove-makers, having decided to expand the functionality of the existing structure, added a stove bench to it. The original model has undergone significant changes: the height and location of the beds were constantly changing, materials were being improved, the rough began to perform not only heating and cooking functions, but also decorate the house, playing the role of a kind of fireplace.

It is possible to decide whether the house needs a rough one, or whether it is worth looking at another option, only after carefully weighing all the pros and cons of the design in question.

- It is easier to build a rough than most known channel power furnaces. This can be done both during the process of building a house, and in an already landscaped room. No large-scale construction work or alterations are required;

- the cost of materials "affordable" for almost any person;

- the stove is easy to operate, compact and takes up little space;

- its appearance depends on the taste of the owner, who, at will, selects the shape and size of the bricks, the colors of the plaster and the design of the constituent elements;

- thanks to the installed hob, it is easy to cook on coarse.

the heat efficiency of such a stove is extremely low: it can warm up a room with an area of only. If the owner certainly wants to use coarse wood to heat a larger room, he will be unpleasantly surprised by the amount of kindling material leaving.

The extension of a heated bed is another plus of coarseness. But this option is only possible with wood heating. Coal heats the surface of the couch too much.

Types of acceptable designs:

Attaching a shield to the outside allows you to give the stove a more decorative look, making it look like a fireplace. If the work is done carefully, using tiles or decorative ceramic tiles, such a stove will give the room a special charm. But it will be a very costly work: both in terms of the efforts made and in terms of the volume of materials. Such a furnace is more difficult and harder to fold; a foundation is a must. Both wood (up to and coal) are suitable as a heating material (up to However, the thermal power of such a unit is much greater than that of a stove with a built-in shield.

With built-in shield

Outwardly, it looks like a conventional hob. Such a unit is easier to build, and materials are spent many times less compared to the first option. This is a compact stove of small size, the amount of thermal energy of which is limited. Therefore, this option is only suitable for rooms in which they live from spring to autumn, and visit occasionally in winter. A rough house can be built without a foundation, but the bearing capacity of the floor should be from 500 kgf / sq.m.

What mortar to use for masonry

The quality of the masonry mortar directly affects the reliability and durability of the finished furnace. Masonry will be carried out using a sand-clay mortar.

There is nothing difficult in preparing the solution. Take clay, fill it with water and soak it. Sift the mixture through a sieve and then stir into "clay milk". Finally, add some water to get a sufficiently viscous and plastic solution.

Remember, the reliability and strength of the furnace directly depends on the correct preparation of the masonry mortar. Do everything right - the stove will effectively heat your home for many years. Break the technology or decide to save a lot on materials - the thermal unit is unlikely to be able to fully reveal its potential and stand for at least a long time.

The mortar used for laying the stove

How to make a rough oven with your own hands

The oven consists of the following parts:

- A firebox is a working chamber into which fuel is loaded. Equipped with a door.

- Blower - a chamber attached below the firebox. Serves to improve traction. A door is also attached here to regulate the air supply. A grate is installed between the firebox and the blower.

- A chimney is a pipe that removes carbon dioxide from a home. Equipped with a soot cleaning door and damper.

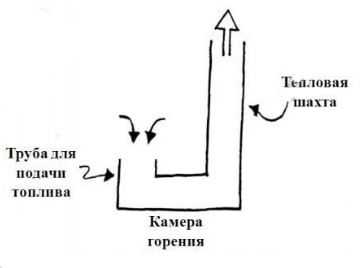

- Smoke circulation (convector) - vertical (sometimes horizontal) channels through which hot gases from the furnace pass. They connect the firebox to the chimney and accumulate thermal energy.

Firebox, shield and chimney

The main differences between a rough stove and a solid fuel stove are a more powerful firebox and the absence of a pass (smoke tooth) in the furnace part. The tooth retains hot gases under the hob, which in the summer stove allows you to reduce fuel consumption for cooking. In rough it is not needed, because. excess heat will be used for heating.

The coarse furnace should have a more powerful firebox because the shield provides additional resistance to the flow of flue gases. A chimney with enhanced draft will not help here: the gases in the shield will immediately expand and cool down. Their thermal energy will turn into mechanical energy, which will successfully fly out into the pipe. Figuratively speaking, a firebox with a chimney in a stove with a shield works according to the push-pull principle, and “push” here is a firebox of greater power.This is the reason for the special requirements for the firebox and furnace fittings of coarse, see below.

Depending on the purpose, heating shields for them are of different types. Schemes of heating shields for furnaces are given in fig. below; the fuel part is shown conditionally everywhere.

Schemes of heating shields for furnaces

- Consistent stroke with short vertical channels. The least material-intensive and the easiest to build. The resistance to the current of gases is the greatest. The compactness and heat efficiency of the furnace are average. The most commonly used scheme;

- Sequential course with horizontal channels. The mass and dimensions of the furnace are the same as in the previous. case, but building a shield with horizontal channels is much more difficult. Gas flow resistance approx. 1.5 times less. As a result, the heat efficiency of the furnace is higher. It is possible to arrange a couch, i.e. the upper channel does not get very hot;

- Consistent stroke with long vertical channels. Thermal efficiency is like that of a shield with horizontal channels, technological complexity is like that of a shield with short vertical channels. It occupies the smallest area, but requires a lot of materials and a good foundation (see below) due to the high specific pressure on the support. The best option for a house heating stove for 2-3 rooms, see below;

- Parallel move. The highest thermal efficiency, the smallest mass per unit of thermal power. The occupied area and technological complexity are the greatest. Use with a fire chamber of the reduced power is possible. Optimum for an extension to an existing slab without altering it.

Note: there are also series-parallel or chess shields. The most complex, but also the lightest, resistance to the flow of gases is the least. The only possible option for being rough in a house with a heated attic, see below.

Furnace materials

To make a rude with your own hands, you will need to prepare materials. Try to take all the components for the manufacture of a stove with a stove bench of good quality, because the design will serve you for more than one year.

- The brick is ceramic. This will be the facing of the product. Take without chips and one color. It is available in various configurations, so first you should draw up a drawing of the product and decide what appearance it will have. Instead of lining the stove with a stove bench, decorative or ordinary plaster can be used. If plaster is used, then the surface can be painted.

- The brick is refractory. It is able to withstand high temperatures. Calculate how much you need to make a do-it-yourself furnace compartment.

- Clay and sand will be required in the manufacture of mortar for masonry structures.

- Fireclay powder will be used as an additive to the solution.

- Grids. It is advisable to take made of cast iron. Metal, when using coal, will burn out very quickly.

- Furnace door.

- Blower door.

- Smoke damper.

- For waterproofing, you should take roofing material.

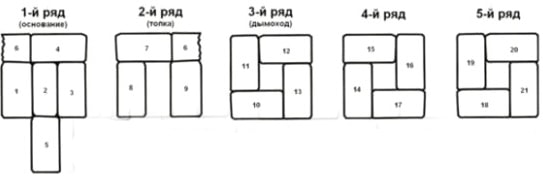

An even simpler version of the stove

If the previous option seemed complicated to someone (although it is not), you can offer an extremely simplified heating design. This oven with your own hands can be laid out in just an hour, even if the hands are generally far from being called golden.

Figure 4. The simplest version of a brick oven

The principle of operation of the structure is simple. Solid fuel burns below, here it settles under the influence of its own mass. Temperature differences create a thrust that carries hot air currents upward. At the same time, firewood burns almost without residue - the smoke is minimal.

For masonry, you only need two dozen whole bricks and two halves. The stove consists of five rows. The design is so simple that it makes no sense to describe the order. The procedure is clearly shown in the illustration.

For those who want an intermediate option, we can recommend a slightly more complicated option.

Figure 9. L-shaped stove

The creation of this design will also require 20-30 bricks. This option can be mastered by yourself in a couple of hours, if the skills of a bricklayer are completely absent. The construction will obey the specialist in a matter of minutes.

Advantages of the simplest furnace designs

- very high installation speed - from a day to several minutes;

- does not require a foundation; the stove can be folded anywhere; and if you do not use a binder mixture, the stove comes out collapsible and easily moves;

- as fuel - everything that burns: logs, branches, cones, corn stalks, leaves, chipboard, furniture remnants, etc .;

- fuel consumption is several times less than, for example, in the case of a potbelly stove;

- the simplest option - without the use of clay - allows you to get more heat transfer than from a fire; therefore, such structures are a godsend for those who do not want to constantly maintain a fire on a hike;

- almost complete absence of smoke - fuel burns with a minimum of waste;

- the temperature of the bricks reaches 1000 degrees - good heating and fast cooking are provided.

Special Requirements

We repeat: the advantages are rude - compactness and the possibility of building in an existing house without capital construction work. But it is not so easy to place a more powerful furnace in the structure of the furnace in general of the same dimensions, it will quickly become unusable from excessive heat load. If special requirements are not met for:

- Furnace foundation.

- Masonry solutions.

- Ways of laying the structure of the furnace.

- The choice and methods of installation of furnace fittings.

The design of the foundation for the rough is given in Fig. The crushed stone pillow without sand filling is leveled into the horizon before pouring. Filling mortar M150 - cement M300 and sand 1: 2. The gap between the rubble foundation and flooring is 30-40 mm. Do not forget to support the cut logs! Leaving their ends hanging is a common but gross mistake. The dimensions of the foundation in the plan should protrude on the contour of the furnace by at least 100-150 mm.

The device of the foundation of the furnace-coarse

Note: the brick bed on the foundation for the stove is laid out with dressing in rows and between rows in the same way as the first 2 rows of masonry of the stove structure, see below.

To fold the rough, 3 types of solutions are used, see fig. below. The bed on the foundation and the chimney are laid out on a lime mortar, as it combines sufficient heat and moisture resistance, but the rubble must be laid only on a completely moisture-resistant cement-sand mortar. Sand for clay mortar is highly desirable to take mountain or ravine, with rough grains. Ordinary clay - purchased oven, guaranteed fat content and, most importantly, purity. Self-digging clay, brought to the desired fat content with sand, is of little use for rough masonry.

Compositions of masonry mortars for a coarse oven

For masonry, a stove is used and, if the order (see below) is provided, fireclay bricks; the red worker is suitable for the highest quality - light red in color (completely annealed), without burn marks, warping and swelling. Dry molded brick is absolutely unsuitable. The masonry of the structure is rough. rules:

- If you are an inexperienced stove-maker, each row of masonry is first laid out dry; detected defects in trimming / chipping of bricks are eliminated.

- Before laying on the mortar, each brick is soaked until the release of air bubbles stops. It is impossible to plump all the bricks into a barrel indiscriminately!

- A layer of mortar 5 mm is applied to the bed and poke of the brick being laid.

- The brick being laid is laid with a smooth movement slightly with an inclination and moved to the previous one so that there are no air bubbles left in the seam.

- The brick is pressed until the seam converges to 3 mm; can't be tapped!

- Between fireclay and ordinary masonry, the initial seam is 8-10 mm; after pressing - 6 mm.

- The seam between bricks and metal embedded parts (see below) is 10 mm.

- Excess mortar squeezed out of the seam is removed with a trowel (trowel).

- The recesses in the seams found after cleaning the excess mortar are filled with mortar by indentation without transverse movements, but not by rubbing!

Those who prefer to learn visually can watch a video tutorial on laying heating and cooking stoves below:

Video: laying a heating and cooking stove

Incorrect oven door installation

Fittings and grates for coarse need cast iron; doors and latches - with an installation skirt and holes in it for diagonal wire whiskers. Welded steel or cast iron fittings with eyelets for straight whiskers (laid along the corresponding furnace wall) are unsuitable in this case. However, install the doors/latches as in fig. on the right, it’s impossible to be rude; It's not by oven rules at all. For a country Dutch woman 2.5 bricks in plan, which is heated once or twice a season, maybe it will work, but not for being rude.

It is necessary, firstly, to compress the whiskers (wire - galvanized 2-3 mm) with wrapping so that they do not move. Press at first not tight, set at the desired angle (at least 12 mm should remain from the far end of the mustache to the inside of the masonry). Then gently tighten, shake the door/latch lightly. Haven't left? Good. Then, secondly, you need to wrap the skirt tightly with asbestos cord (or from basalt fiber), and only now put it in place. You can also watch the following videos about installing accessories in the oven.

The main stages and important features of laying the furnace

From the moment the foundation is poured to the start of construction, 3-4 weeks should pass. During this time, the base will gain the necessary strength and be able to withstand the weight of a brick oven. The work in question requires maximum responsibility and concentration on the part of the performer. Any mistakes can lead to irreparable consequences, so tune in to work in advance and allocate enough time to complete it.

DIY brick oven

The laying of the furnace is carried out in several stages.

First stage. Lay out the ash pan and the lower part of the first cap from the brick. Carry out masonry using the previously discussed sand-clay solution.

Second phase. Install the ash pan door into the masonry. Use galvanized wire to fix the door.

Install the ash pan door into the masonry

Third stage. Install a grate above the ash pan chamber.

Install a grate above the ash pan chamber

Fourth stage. Mount the firebox. Surround the inside of this compartment with refractory bricks. Bricks lay out "on edge". At this stage, you need to use a special masonry mortar. It is prepared in the same way as the standard one, but instead of simple clay, refractory clay is taken, i.e. fireclay. Secure the combustion chamber door with a steel plate and the wire you already know.

Fifth stage. Continue the standard laying until you reach the 12th row. Having reached this row, close the combustion chamber and evenly lay the tiles with burners. This plate must be made of cast iron. Check the evenness of the laying using the building level.

Sixth stage. Lay out the first cap. It is built in the left edge of the stove. At the same stage, a canal for the summer course is being equipped.

Seventh stage. Install the stove and lay out the walls of the cooking compartment. Keep the calculation of the lower cap mentioned earlier.

Eighth stage. Install a gate valve for the mentioned summer run channel. This valve is located in the inner corner of the brewing compartment.

Ninth stage. Lead the laying to the 20th row. Having reached this row, close the cooking compartment and the first hood. Be sure to leave in the solid masonry the required number of openings for the summer run and the lifting channel, as well as the vents of the cooking compartment.Place bricks on steel corners - this way you will ensure higher strength and reliability of the stove.

Tenth stage. Close the portal of the brewing compartment with hinged fireplace doors. It is better that the doors have heat-resistant glass inserts. This solution will allow you to monitor the process of fuel combustion and admire the flame.

Eleventh stage. Install cleaning doors for easy soot removal. For installation, choose a place to which it will be easiest for you to get to.

Twelfth stage. Lay out the walls of the cap almost to the top edge of the wall opening. At the top, block the stove with a couple of rows of bricks. Fill the gap between the top of the stove and the jumper with mineral wool. This will provide additional thermal insulation and slightly increase the heating efficiency.

Thirteenth stage. Lay a decorative band around the upper perimeter of the unit.

Fourteenth stage. Proceed to the device of the chimney pipe. It is better that the chimney was brick. This design will last much longer than the same metal or asbestos pipes.

In the end, you just have to lay out the chimney to the end and, if desired, finish the exterior of the stove. The easiest option is plastering. Otherwise, be guided by your own preferences and available budget.

Thus, laying the stove, although not a simple event, but it is quite possible to do it yourself. It is enough to simply understand the technology and follow the instructions in everything. Remember, the materials for work should be of the highest quality. And the schemes of furnaces tested over the years will allow you to independently build a unit that will heat your house with high quality for many years without any problems and complaints.