The aroma of freshly prepared food in the kitchen is great, but not very good when the smell is scattered around the apartment and things are saturated with it. In order to avoid the spread of odors and steam during cooking, as well as the settling of fat and soot on walls and furniture, you need to install kitchen hood. This appliance allows you to maintain a healthy atmosphere in the room and is absolutely necessary if you often cook at home. In order for the hood to perform its functions efficiently, it must be supplemented with an air duct. Air ducts designed for a kitchen hood can vary in shape, diameter, material, so the choice of this element must be approached no less responsibly than the purchase of the hood itself.

Why is it better to choose a hood with an air duct?

This question may arise for anyone who chooses a hood for the kitchen. The fact is that there are devices that do not need to install an air duct, since they have a different principle of operation. Such hoods are called filtering or circulating and purify the air from impurities using carbon filters. Unfortunately, this type of device is not efficient enough, expensive to operate, since it requires frequent filter changes, and is not available in stores in a large assortment.

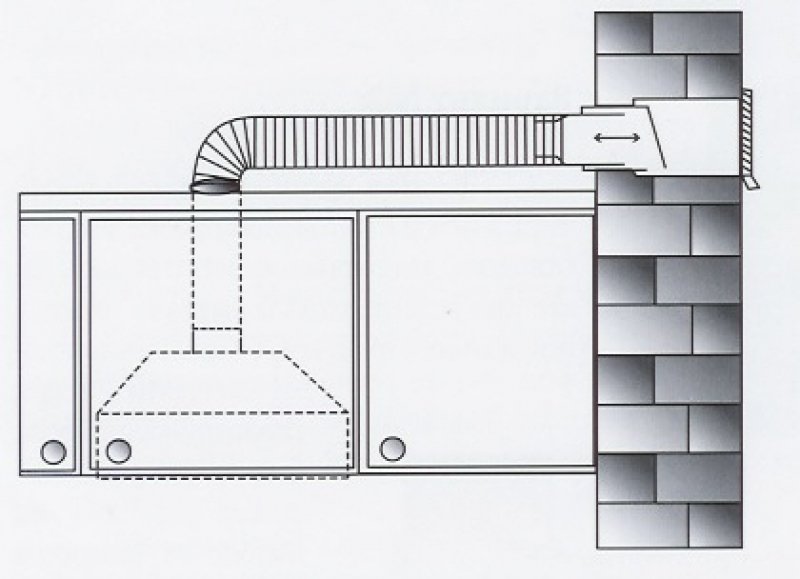

Pull-in or evacuation hoods are more efficient and more successful in cleaning the air in the kitchen. The principle of their work is to draw in polluted air from the room and remove it through the duct into the ventilation system of the house. The throughput of such an extract depends not only on the power, but also on the parameters of the duct, which can differ significantly.

Types of air ducts

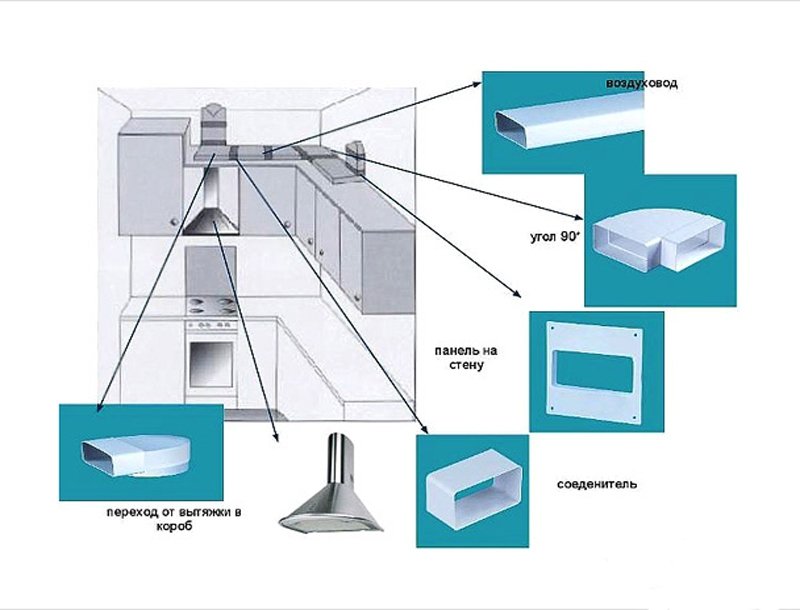

Air ducts for evacuation kitchen hoods may differ in several ways:

- in shape, configuration and diameter;

- according to the material from which they are made.

In its form, the cross section of the duct can be:

- round;

- oval;

- rectangular.

The choice of air duct shape depends on the parameters of your kitchen. Round and oval channels take up more space than rectangular ones, so for small kitchens with a low ceiling, it is better to prefer the latter option. A flat rectangular duct for air outflow during installation can be hidden by laying it in strobes or disguised with the help of special structures. However, it should be noted that its performance is lower than that of round and oval counterparts.

In the manufacture of air ducts, one of several types of materials is used:

- plastic (polyethylene, PVC and fiberglass);

- aluminum;

- steel.

Each of these materials has its own advantages and disadvantages.

Plastic air ducts

Usually plastic air ducts have a rectangular or round cross section. Rectangular flat pipes look more aesthetically pleasing, round ones are easier to install, since they do not require adapters to connect to the exhaust pipes and ventilation grilles.

Advantages

- smooth inner surface that prevents the accumulation of dirt and grease;

- resistance to corrosion;

- light weight;

- ease of installation and connection of parts;

- good sound insulation - during operation of the hood, air noise is almost inaudible;

- affordable price.

Flaws

- the need for additional purchase of adapters and connecting elements;

- low resistance to high temperatures.

Steel ducts

Can be made from galvanized or stainless steel. Stainless steel air ducts are practically not used at home.Galvanized pipes are used for kitchen hoods, but today they are no longer popular with the townsfolk.

Advantages of galvanized ducts

- smooth surface that does not interfere with the passage of air flow;

- high temperature resistance;

- low price.

Flaws

- greater weight compared to analogues from other materials;

- the need to use sealing compounds to seal the channel;

- when installing a system of complex configuration, it may be necessary to cut metal;

- high noise level.

Aluminum ducts

Advantages

- versatility and ease of installation;

- due to the flexibility of the pipe, installation does not require rotary fittings;

- corrugated material can be stretched to a greater length;

- high temperature stability;

- the cost is lower than that of analogues.

Flaws

- corrugated surface prevents the free movement of air flow;

- fat and other deposits can accumulate in the grooves of the corrugations;

- unpresentable appearance requiring disguise;

- instability to deformations and external influences.

Operating parameters of the duct

Regardless of the chosen type of duct, there are several important points to consider when planning and installing the system.

- One of the most important parameters to consider when choosing a duct is its diameter. To select the desired diameter, you need to measure the hole on the hood. The diameter of the air outlet pipe should be the same or slightly larger.

- The total length of the drainage system should not exceed 3 meters, otherwise its efficiency will decrease.

- The number of bends in the system should be minimal, with each turn the efficiency of the hood drops by 10%. If the number of elbows is more than three, it is better to choose a flexible channel.

- The installation of a polluted air exhaust system requires special measures to restore natural ventilation, since the air passage is closed. The best solution would be to install a special valve at the ventilation outlet, the so-called "cracker". During operation of the hood, the damper closes one of the two openings - this ensures forced draft. When the appliance is turned off, the damper closes the second opening, which allows natural ventilation.

- If corrugated material is used, it should be stretched as much as possible to improve flow by reducing the grooves in the corrugation.

- It must be remembered that the system may require cleaning over time, so this should be provided for during installation and made collapsible.