High-quality ventilation in the kitchen allows you not to breathe the fumes that inevitably accompany the cooking process, and ensures the safety of furniture. The hood is mounted directly above the stove, and the ventilation shaft may be at some distance. To connect them, special pipes are used - air ducts. Let's find out how to choose, assemble and disguise a plastic kitchen hood duct.

Plastic pipes are distinguished by a long service life and ease of installation. In addition, PVC products are safe in terms of environmental friendliness and hygiene.

Varieties

Air ducts used for kitchen hoods differ in material, shape and level of rigidity.

Exhaust pipes are made of several types of plastic:

- PVC;

- fluoroplast;

- polypropylene;

- low pressure polyethylene.

The first 3 types are suitable for connecting to an exhaust device in the kitchen: they are resistant to high temperatures.

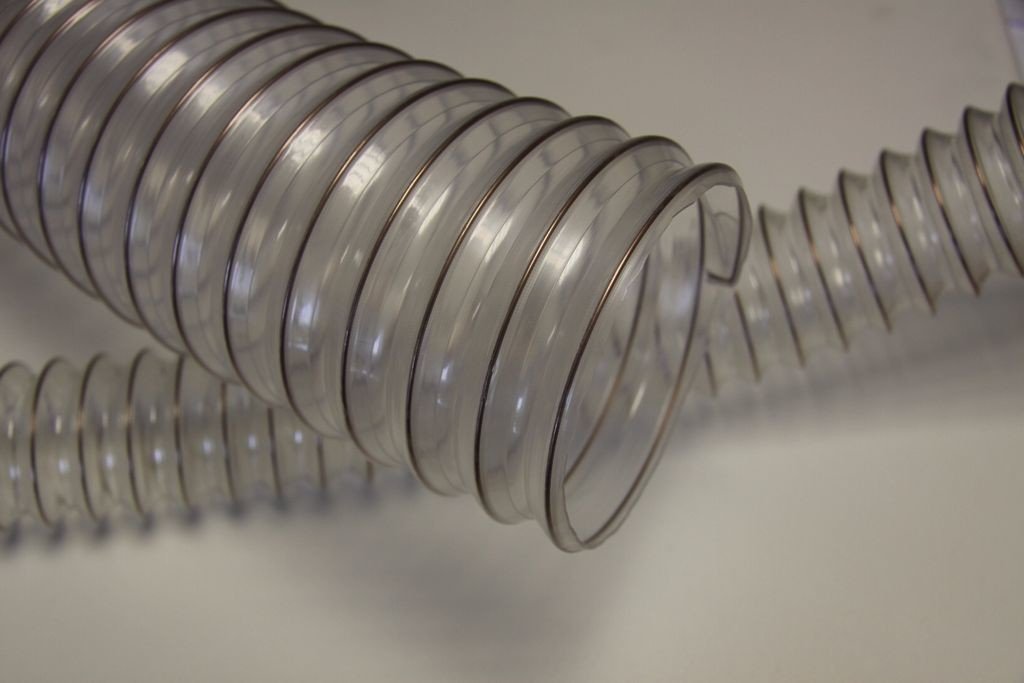

Products for kitchen hoods can be corrugated (flexible), as in the following photo, or made of hard, smooth plastic.

Allocate air ducts with a rectangular or round section.

- Rectangular plastic channels are compact, easily hidden under a false ceiling, more convenient in terms of installation.

- Round exhaust pipes are characterized by greater throughput and lower noise levels.

Design features and dimensions

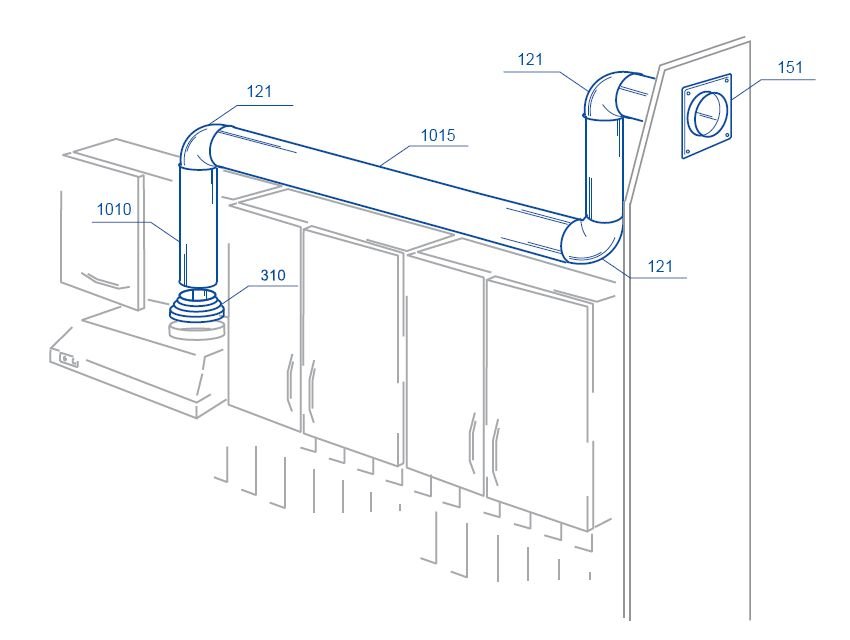

Remember that when purchasing PVC air ducts, you need to stock up on adapters that will be needed to connect the plastic pipe and the hood. Adapters are also used for duct bends and connection to general house ventilation. If a corrugated product is used for the hood, then you can save on adapters for bending the pipe.

Important! The length of the PVC pipe should not exceed 3 meters. Otherwise, the performance of the hood will drop with each additional meter.

Any bend also negatively affects the functionality of the hood. When installing the duct in the kitchen, try to avoid 90 degree angles. This will overload the hood, which will significantly reduce the life of the product.

It is allowed to make no more than 3 knees and bends.

The diameter of the plastic pipe is selected according to the cross section of the ventilation hole. The sizes of rectangular and square PVC kitchen ducts are standard. The following values are most often used: 110 × 55, 120 × 60 and 204 × 60 mm. The sizes of round plastic pipes vary from 110 to 150 mm in diameter.

You can buy these products in almost every hardware store. It should be noted that the price of flexible ducts is slightly higher than flat PVC ducts.

Installation

The most practical and easy to install pipes are corrugated. They are cut into pieces of the desired size and connected to the elements of the hood and ventilation shaft in the kitchen. It is recommended to replace the standard ventilation grill with a special one - with a built-in connecting pipe. Clamps are used as fasteners. For greater reliability, the joints are treated with sealant.

Note! Corrugated pipes are installed in the most stretched position. This approach ensures the nominal throughput of kitchen ventilation.

Smooth PVC air ducts are mounted in the same way. The pipe is cut with a hacksaw into pieces of the desired size and attached to the hood elements using adapters. The pipe should go deeper into the nozzle by about 50 millimeters. Attachment points are treated with silicone.

Advice! Installation of the hood is carried out taking into account the direction of air movement.Otherwise, the service life of the PVC product will be significantly reduced.

If you have installed a powerful hood, a backdraft effect may occur. In other words, the kitchen will have aromas from the common ventilation shaft. This applies to powerful models, whose performance is about 600-700 cubic meters of air per hour. To avoid this phenomenon, it is recommended to install a check valve. These devices are available in two versions:

- membranous type;

- in the form of a plastic disk on the axis.

The valve must be installed vertically, otherwise it will operate under its own weight.

You can do it differently: bring the hood directly to the street. To do this, a hole of the desired diameter is made in the wall of the house. You should be aware that before starting such work, it is necessary to obtain permission from the housing and communal services and the BTI.

To avoid such difficulties, it is recommended to consult the seller about the power of the hood and correlate these parameters with the area of \u200b\u200bthe kitchen room. For the needs of an average family living in a typical high-rise building, a low-power hood is enough.

How to hide the air duct in the kitchen

Plastic channels fit more organically into the design of the room than metal ones. But even they can spoil the look of the kitchen, so most owners prefer to hide this element. There are several ways to do this masking.

- Air duct pipes are hidden under multi-level, suspended or stretch ceilings. For this, a special box is made of drywall, which hides almost the entire system. But this method is only suitable when a major overhaul is started in the kitchen with the replacement of the ceiling. If the hood is installed after finishing, then it is unlikely that it will be possible to hide it under the ceiling covering.

- To mask the pipe duct, you can purchase or make a special PVC or GKL box. This decorative element is easily matched or designed to match the finish. In addition, additional lamps can be inserted into the box.

- If custom-made furniture is purchased for the kitchen, you can place the hood in it. To do this, it is enough to inform the furniture installation master about your desire. The air duct can be permanently built into kitchen cabinets or made in a retractable version.

- Finally, you can simply paint the air pipe. If you show imagination, you can get a completely original decoration for the kitchen.

To ensure that all elements of kitchen ventilation are of the same color, it is recommended to purchase ready-made kits. Some manufacturers sell their products according to the scheme: hood + air duct + additional element = effective ventilation in the kitchen.

Particular attention should be paid to the quality of materials. Remember that hoods made from low-grade raw materials or in violation of production technology will last no more than 5 years. At the same time, PVC products from trusted manufacturers are designed for at least 30 years of operation.

Step-by-step instructions for installing a plastic channel for the hood are in the video below. Ask questions about selection and installation in the comments.