Many residents of city apartments have had to make sure from their own experience that it is impossible to create a favorable microclimate in an apartment without high-quality ventilation. It's great when ventilation provides an influx of clean winter air into the apartment from the street, it's bad that we lose the same volume of heated air. In order to get enough fresh oxygen and at the same time prevent heat loss, it is necessary to use a heat exchanger. There is a huge selection of recuperation systems on the market, however, if you wish, you can easily make and install a recuperator with your own hands.

Efficiency and principle of operation of recovery systems

Recuperator (recuperator) in Latin - "returning" or "receiving back." In our case, it plays the role of a heat exchanger, the task of which is to detain the thermal energy that tends to leave the room together with the outgoing air in the cold season, and block the flow of the same thermal energy (in the form of hot air) into the room in the summer.

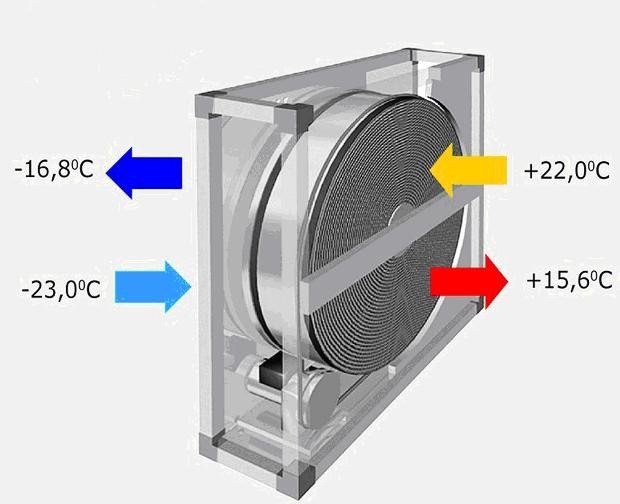

The air recuperator consists of several channels through which, without mixing with each other, the air flows entering and exiting the ventilated room pass. If the temperature of the air streams differs, they begin to exchange thermal energy, and, accordingly, the hot air cools down, and the cold air heats up. In addition, air is dried in the process, this is due to the condensation of liquid on the channels of the heat exchanger. The use of recuperation systems helps to reduce heat loss by up to 70%.

- have a constant high-quality heat exchange;

- compensate for the inefficiency of natural ventilation due to the installation of sealed windows and doors;

- refuse to use energy-consuming heaters and air conditioners;

- save on heating;

- maintain the cleanliness of the air in the apartment - it will be free of street dust and plant pollen.

The ventilation system with a heat exchanger allows for constant renewal of the air in the room and creates comfortable temperature conditions inside the room.

Types of recuperators

Recovery systems can be divided into several types.

- Direct-flow, counter-flow, cross-flow heat exchangers differ in the way air flows are moved.

- Depending on the design features, recuperators can be ribbed, tubular, plate and plate-ribbed.

- According to the material of manufacture, heat exchangers are metal, plastic, membrane.

- According to the principle of action, there are:

- plate (cross-flow) heat exchanger - the most popular type of simple design used in houses and apartments;

- rotary heat exchanger - for operation, a source of electricity is required that rotates the rotor element, they are large and have high efficiency (up to 87%);

- roof heat exchanger - industrial level installation;

- coaxial recuperator - easy to perform even without experience;

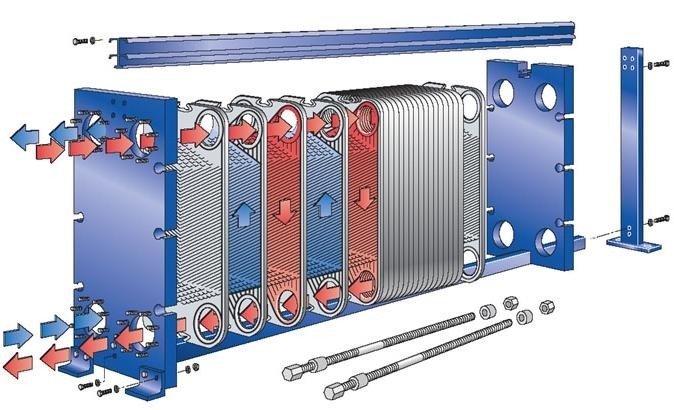

- recirculation (liquid) heat exchanger - transfers heat to air using water or antifreeze, has a complex design and efficiency comparable to that of a plate heat exchanger.

Plate heat exchanger

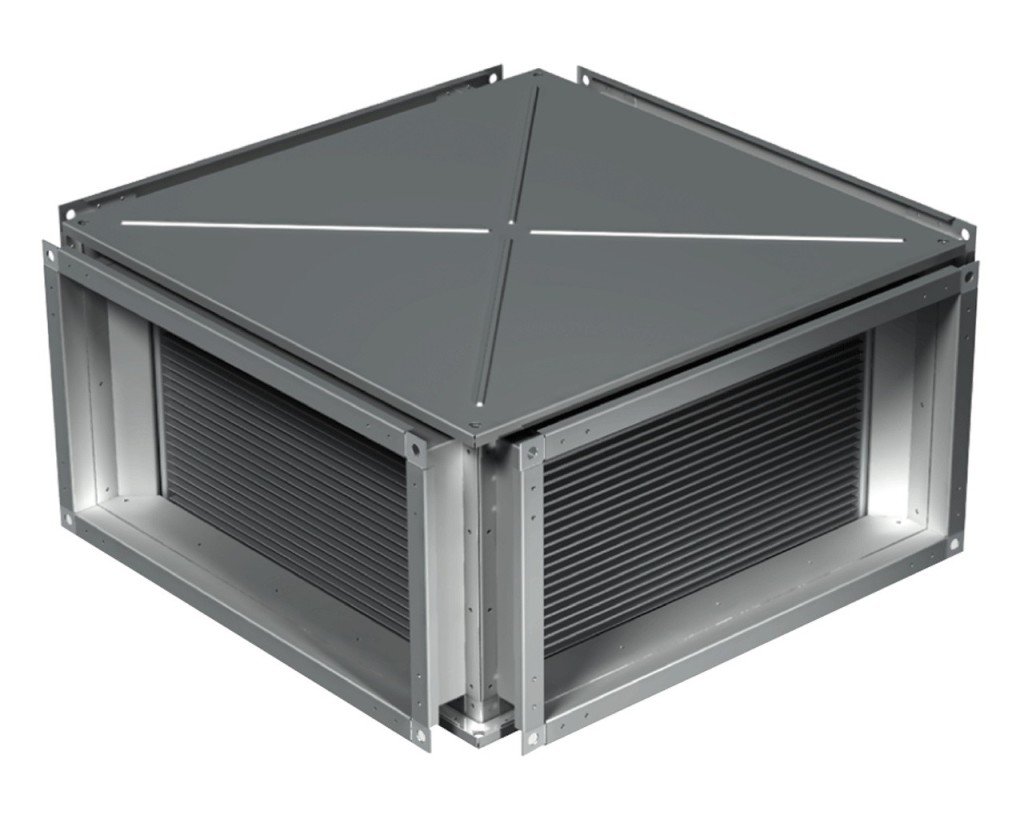

Plate heat exchangers are most often made in the form of a tank, divided inside by strips of galvanized steel, which create channels for the movement of air flows. Moving through the channels, the air jets do not mix, but they can exchange thermal energy, which leads to the equalization of the temperatures of the incoming and outgoing air flows.

Ventilation systems based on plate heat exchangers have a number of advantages:

- high efficiency - up to 65% efficiency;

- simple design and compact size;

- ease of manufacture and maintenance;

- ease of adjustment;

- the possibility of installation on any section of the duct;

- no need to use electrical energy;

- lack of moving and rubbing parts.

Such heat exchangers also have their disadvantages:

- The risk of freezing at low temperatures due to moisture condensation in the heat exchanger channels, which reduces the efficiency of the device.

- Impossibility of regulation of air humidity.

To date, the use of plate-type heat exchangers in supply and exhaust ventilation systems is considered the most effective solution for an apartment.

Independent production of a plate-type heat exchanger

Since the average cost of a plate heat exchanger is $300. That is, it makes sense to make this easy-to-make air recuperator with your own hands.

In order to make a recuperator yourself, you will need:

- sheets of galvanized metal (4 sq. m.);

- technical cork 2 mm thick;

- silicone sealant with a neutral reaction;

- a tin box for the body or sheets of MDF, metal or plywood for its manufacture;

- glue;

- 4 cm thick insulation (mineral wool or polystyrene foam);

- corners for racks;

- plastic flanges;

- jigsaw or grinder.

Stages of work:

- We cut the material into small squares with a side size of 200 to 300 mm. The plates should be the same and perfectly even, it would be better to cut the sheets folded in a bundle with a grinder than to use metal scissors. There should be about 70 such plates serving as blanks for the recuperator cassettes.

- In order to create a gap between the sheets, we use a technical cork. The bottom line is to make such a section at which the air flow velocity will be 1 m / s. We glue the cut cork along two opposite edges of the square blanks, without touching the latter.

- After waiting for the glue to dry, we create a heat exchanger cassette, gluing the sheets in such a way that each subsequent one is located at an angle of 90 degrees to the previous one. In the cassette, alternating channels are obtained, perpendicular to each other. The last sheet will be the one on which we did not glue the cork.

- After connecting all the plates with the help of a corner, we tighten the structure with a frame.

- All cracks are carefully sealed with sealant.

- On the walls of the cassette we have fasteners for flanges having a diameter corresponding to the pipes of the air ducts. It is advisable to place the cassette vertically, then condensate will collect at the very bottom. In the same place, a drainage channel is being prepared: a hole with a tube for draining fluid.

- In order for the cassette to be removed from the case, guides from the corner must be installed inside it.

- The case with the cassette is placed in a box made of thick plywood or tin. An important point will be the use of heat-insulating materials (mineral wool or foam plastic), with which all sides of the box are glued from the inside.

Note! The width of the heat exchanger body must correspond to the width of the cassette, the height and length must correspond to the diagonals of the square plates.

For more reliable operation of the recuperation system in conditions of negative supply air temperatures, when the heat exchanger plates can freeze, a bypass is added to the system, through which, if necessary, the supply air flow is directed. At this time, only warm exhaust air will pass through the heat exchanger, and under its influence, the iced heat exchanger plates will thaw.

The efficiency of a home-made heat exchanger will be about 60–65%, which will ensure that the optimal microclimate in the room is maintained.