Infrared heaters

Infrared heating is ideal for greenhouses, as it is much more economical and efficient than cable heating, which until recently was considered the most reliable. The infrared heater has created a worthy competition to the cable one, heating not the air, but directly the objects inside the greenhouse.

Thanks to this type of heating, the development and growth of plants is accelerated, and the crop ripens faster and pleases with its abundance.

Here are the main advantages of infrared heating:

- the entire area of the greenhouse is heated evenly;

- humidity is at the same level, the air does not dry out;

- due to infrared radiation in the greenhouse, the occurrence of pathogenic fungi and bacteria is inhibited;

- heat spreads from bottom to top, slowly heating the room;

- plant growth is accelerated;

- dust does not circulate in the greenhouse;

- mobility and compactness of heaters. They do not occupy the usable area of the greenhouse, as they are installed on the ceiling, they are easily mounted and dismantled without assistance;

- silent operation of heaters, which has a beneficial effect on both humans and plants.

Due to the mobility of infrared heaters, it is easy to create different temperature zones in the greenhouse, and grow vegetables with different needs for warmth in this room. This is achieved by raising or lowering the heaters. To grow seedlings, the heaters are lowered lower to the ground so that the soil warms up faster, and when the seedlings grow, they are raised higher.

Infrared heaters are not afraid of condensate, so they can be safely used in greenhouses with high humidity.

The principle of operation of heaters is similar to natural heating by the sun - the soil immediately heats up, and then the surrounding air, which creates an atmosphere similar to natural, natural. At the same time, plants feel great, because the air does not dry out, and the heat comes in soft, not burning. The temperature switch is mounted together with an infrared emitter, the minimum temperature on it does not fall below +5 degrees, which is very good for greenhouse conditions.

Infrared heaters come in a variety of spectrum of action. Older models have a flat radiant surface, while newer models have a spherical surface that allows the heat rays to diffuse in a range of 120 degrees, which improves and balances the heating of the greenhouse, and also saves half the electricity. This is due to the fact that the soil is heated directly, and not the air, and the heat from the soil spreads through the greenhouse, rising up

It is important that each heater is controlled by a thermostat, then the difference in temperature in the center and along the edges of the greenhouse will be very small.

In order to correctly calculate the intensity of the infrared heater, you need, for example, to take a greenhouse 6x3 m in size. For such a greenhouse, two heaters 1.7 m long and 1000-1350 W in power will be enough, which will evenly heat the entire room. The main heating zone will be approximately 2.5 m long and 3 m wide. For longer greenhouses of 8-9 m, three heaters will be needed.

Infrared heaters weigh very little, which is also one of their advantages. They are thinner and neater than their predecessors, easy to install, radiate very gentle heat, favorable for plants that respond gratefully to growing conditions with a healthy look, fast growth and rich harvests, delivering an abundance of vitamins necessary for our body to the dinner table!

Biological heating of the greenhouse with biofuel

The essence of the biological heating of the greenhouse is that aerobic bacteria that decompose organic materials (manure, sawdust, garbage) with air access release heat in an amount sufficient for heating.

Biofuel refers to any organic material that can be consumed by microorganisms, releasing thermal energy. The temperature of biofuel can reach +72°C, so the process of decomposition of biofuel with the release of heat is called combustion. Hot biofuel is used in greenhouses to maintain the temperature at the optimal level for plants.

The following are used as biofuels:

- animal manure mixed with loosening materials (straw, sawdust, horse peat, leaves), see table 2

- waste from woodworking enterprises (bark, shavings, sawdust, chips), see table 3,

- urban waste, consisting of organic waste, see Table 3.

| Characteristics of biofuel | Manure | |||

|---|---|---|---|---|

| Horse | Bovine | Pork | Sheep | |

| Weight 1m3, kg | 350-450 | 400-500 | 400-500 | 550-700 |

| Acidity, pH | 8-9 | 6-7 | 7-8 | 6-7 |

| Humidity, % | 65-70 | 75-80 | 65-67 | 73-77 |

| Max. stack temperature, °C | 60-72 | 40-52 | 55-60 | 20-30 |

| Interruption period, days | 7-9 | 18-20 | 9-10 | 20-30 |

| Avg. temperature, °C | 33-38 | 12-20 | 30-35 | 14-16 |

| Duration of burning, days | 70-90 | 75-100 | 90-120 | 60-70 |

| Characteristics of biofuel | Household waste | |||

|---|---|---|---|---|

| Sawdust | Bark | household waste | Garbage compost | |

| Weight 1m3, kg | 150-200 | 400-500 | 700-750 | 650-750 |

| Acidity, pH | 5-6 | 5-7 | 7-9 | 7-8 |

| Humidity, % | 30-40 | 60-75 | 35-60 | up to 50 |

| Max. stack temperature, °C | 30-40 | 40-50 | 60-65 | 50-60 |

| Interruption period, days | 20-25 | 10-15 | 10-12 | 5-7 |

| Avg. temperature, °C | 15-20 | 20-25 | 36-48 | 30-35 |

| Duration of burning, days | 40-60 | 100-120 | 80-100 | 120-180 |

Read more about the characteristics of biofuels in the article: Manure and straw; wonderful greenhouse! Biofuel for greenhouse heating

If necessary, to protect the biofuel from combustion, it is stacked and compacted. In the compacted state, biofuel will not burn or will burn weakly.

To warm up the biofuel, it is interrupted and placed loosely in a stack, hot stones or burning coal are placed inside the stack. After 3-5 days, the biofuel starts to burn and can be used to heat the greenhouse.

Biofuels heat up well in the presence of nitrogenous nutrients. Therefore, sawdust is watered with slurry or animal urine. Mixing manure with wood waste has a good effect. Active activity of microorganisms is possible with sufficient moisture content. Therefore, biofuels are moistened if necessary.

The temperature of the biofuel reaches a maximum a week after heating, and then begins to decrease. The release of heat continues for 2-3 months, gradually fading.

Heating the greenhouse with biological waste helps to dispose of it, rationally using the energy stored in biofuels, and also improves the air-gas environment in the greenhouse by releasing a large amount of carbon dioxide, which plants need for photosynthesis.

The spent biofuel is suitable as an organic fertilizer both in the greenhouse and in the open field.

Biofuel stacking. Hot biofuel is laid in the greenhouse loose, evenly distributed over the area and slightly compacted with a pitchfork. Fertile soil is poured onto biofuel with a layer of 15–18 cm for growing seedlings; if seedlings are grown in pots, then the layer of earth is reduced to 7–8 cm. When growing vegetable plants, the thickness of the earth layer should be increased to 20 cm.

Sowing and planting of plants begin after the soil warms up to the optimum temperature.

The disadvantage of biological heating is that it is impossible to control the thermal regime if it is necessary to raise the temperature to the required level.

Option 3 heating with gas

The main advantage of gas is that it is more stable in terms of supply, but the final cost of products from the greenhouse can surprise.Therefore, if heating a greenhouse in winter with gas lasts only a few weeks, then it is not necessary to pull it from a residential building and purchase expensive pipes for this. It will be enough to take a couple of cylinders for this purpose - they will last for a long time.

It is only important to remember that an excess of carbon dioxide can adversely affect the condition of plants, and therefore such a greenhouse must be well ventilated. And to remove combustion waste, it is necessary to use an exhaust device so that a constant flow of oxygen into the greenhouse is ensured.

And so that the lack of oxygen does not lead to the cessation of the combustion process and the release of gas into the air, it is advisable to use heating devices with an automatic protective device - the sensors will immediately work as soon as the gas supply to the burner stops.

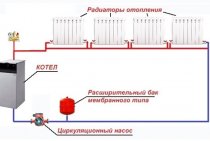

Heating the greenhouse with water heating

When growing a large volume of marketable products, when there is an economic benefit, it is advisable to use water heating in the greenhouse.

Water heating in the greenhouse allows you to operate the building all year round, supplementing with sodium lamps to compensate for the short duration of daylight hours.

The boiler is selected based on the area of the greenhouse and the volume of air in the room, and then installed in the vestibule so that the flue gases do not enter the greenhouse. Heating pipes are located longitudinally, along the walls, under the racks, under the roof, etc.

Heating pipes can pass under a layer of nutrient soil, for example, in excavated greenhouses. A layer of sand 10 cm thick is poured at the bottom of the pit, pipes for hot water are laid on it. From above, they are covered with sand by 10–15 cm, and nutrient soil is poured on the sand with a layer of 25 cm.

Soils for greenhouses and greenhouses

In greenhouses and hotbeds, the root nutrition conditions differ from the open ground nutrition conditions. Frequent and abundant watering contributes to the leaching of nutrients, and repeated top dressing - to the accumulation of ballast formations in the soil. These features require the creation of special soils that can provide favorable conditions for plants.

Greenhouse soils must have:

- fertility

- good air and water permeability,

- to be loose

- have good moisture capacity and retain nutrients well.

For greenhouses, soils that have a neutral environment are considered the best, in which the ratio between solid, liquid and gaseous phases is 1:1:1. This means that they contain a large amount of loosening materials.

As the main components for creating soil soils, low-lying peat, soddy and field lands, manure humus, old (used) greenhouse-greenhouse soil, sand are used:

- low-lying peat of a weak or medium degree of decomposition - 75% + soddy medium loamy soil - 25%;

- lowland peat 60% + sod land 20% + manure 20%;

- field medium or light loamy soil 50% + manure humus 30% + lowland peat 20%;

- soddy medium loamy land 50% + old greenhouse-greenhouse (2 years after use) land 50%;

- chernozem soil 80% + humus 20%; lowland peat 70% + manure humus 20% + sand 10%.

Materials intended for greenhouse soils are passed through a screen and mixed well.

A good component for soil soils are composts and leafy soil, for the preparation of which the leaves that have fallen from trees are put in a wooden box in autumn and watered with water, slurry or urine. Within 2–3 months, the leaves decompose and turn into an earthy mass; it is passed through a screen and added to the soil (up to 30% of the total volume).

As a loosening material, composts from the waste of woodworking enterprises (chips, sawdust, bark, small chips) can be added to the soil.When composting, 44 grams of urea and 15 grams of superphosphate are added to a bucket of fresh waste, thoroughly mixed, moistened and placed in a pile or pile for 2-3 months. Ready compost can be added to peat soil (up to 30%).

The layer of soil for growing plants in a greenhouse should be 25 cm, or 0.25 m3 per 1 m2 of useful area of the greenhouse.

In film greenhouses where plants are grown on natural soil, manure (15–20 kg/m2) or lowland peat (20–25 kg/m2) are added to it if the soils are light; on soils of heavy mechanical composition, add another 10–15 kg of composted wood-shaving materials or sand - a bucket per 1 m2.

Mineral fertilizers are also applied to the greenhouse soil:

- ammonium nitrate 60–90 g/m2;

- superphosphate - 30-40 g / m2;

- potassium chloride - 10-15 g / m2.

In autumn, after applying fertilizers and loosening materials, the soil is dug up to a depth of 25 cm so that organic fertilizers and loosening material begin to decompose, and pests that have prepared for wintering die.

Recommendations

When choosing an infrared heater, it is important to pay attention to its power. Devices should be selected taking into account the size of the room. Usually, for heating 10 m2, a device with a power of 1000 W is required, but it is better to purchase units with a margin

If a wall-mounted heater is chosen, it is important to find out the thickness of the radiator foil layer. Its performance should not be lower than 120 microns. Otherwise, a significant part of the energy will be spent on heating the ceiling.

Usually, for heating 10 m2, a device with a power of 1000 W is required, but it is better to purchase units with a margin

If a wall-mounted heater is chosen, it is important to find out the thickness of the radiator foil layer. Its performance must be at least 120 microns

Otherwise, a significant part of the energy will be spent on heating the ceiling.

Manufacturers produce models of heaters with various functions. It is necessary to think in advance whether they will be used during operation, otherwise there are great risks of overpaying for something that will not be useful in the future.

Devices can have the following options:

- regulation of temperature parameters;

- automatic shutdown of the device when it is turned over (mobile variations);

- shutdown of equipment in case of its possible overheating;

- turning the unit on or off at the right time.

Before buying a device, you should carefully inspect its case. It can be made from steel or aluminium. The first options are more durable, the second - stylish design. On any of the cases there should be no traces of mechanical stress or rust. Corrosion can reduce the life of the device, declared by the manufacturer.

Possibilities of a heated greenhouse

A heated greenhouse has more potential than a conventional building that is not equipped with such a system. Using a heated room for growing greens, berries, fruit or vegetable crops, the grower will be able to harvest throughout the year (subject to the arrangement of the lighting system). In a heated greenhouse, optimal temperature and humidity levels are maintained, despite frosts. Thanks to the creation of an artificial microclimate, it is possible to increase the percentage of seed germination, protect seedlings from various fungal diseases, and also harvest earlier than others.

By heating the greenhouse, you can get berries and vegetables throughout the year, collecting them several times. Thanks to the greenhouse, it is possible to create a winter garden or a flower greenhouse during the cold season, increase the duration of flowering of crops or grow exotic plants that are not adapted to the local climate. The above factors can significantly increase the profitability of the site and increase the amount of revenue if the greenhouse is used to grow plants for sale.

How can you heat

In early spring, you can heat greenhouses in several ways, the choice of which will primarily depend on the purpose of the room. If you plan to heat a small building in which vegetables are grown for yourself, it makes no sense to purchase expensive industrial plants. In this case, various furnaces or boilers are suitable.

Stove heating in greenhouses was used 20-25 years ago, but it is still relevant today. For these purposes, gardeners and gardeners use specialized boilers or barbecues designed to maintain optimal temperature indicators. When using furnaces, heat is generated by burning fuel. The advantages of such a system are its simplicity and low costs for maintaining the temperature, and its disadvantages are low productivity and labor-intensive operation.

Heating of overall polycarbonate greenhouses can be carried out using water or electric heating. In the first systems, it is necessary to use boilers, pumps and pipelines through which the hot coolant will move. With water heating, heat is generated by burning gas or by using electric current.

Electric heating involves the use of electrical appliances to heat the air in the greenhouse.

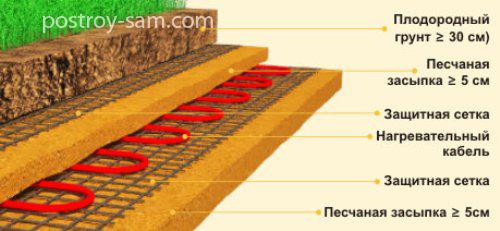

Heating with cables. The principle of operation of such a system is simple: a heat cable is installed under the ground (similar to the installation of a warm floor) and connected to power sources. When turned on, it will heat the soil, and heat from it will spread throughout the room. The system is economical and efficient. Most often it is used in greenhouses for growing plants in early spring or late autumn. For heating the room in the winter season, this method of heating is ineffective.

Year-round greenhouses can be heated using gas systems. For these purposes, summer residents and gardeners often use catalyst burners connected either to the main gas pipeline or to household cylinders. Gas heating is suitable for warming up in the winter season, both large-sized and small greenhouses. The best heating systems are those that use infrared (IR) heaters. They have many advantages over other heating options.

The principle of operation of IR devices is similar to the effect of sunlight on plants. The equipment emits heat, which is absorbed by surrounding objects and subsequently transferred to the air. Depending on the type of installation, the room can be heated from above or below. Some growers organize high-quality heating from all sides. However, this heating method is one of the most expensive.

Often, heaters are placed on the ceiling surface above the beds. The weight of one device is relatively small - its mass does not exceed 5 kg. Most modern greenhouses allow you to place any number of such units. The installation of IR equipment is not difficult, thanks to which the installation can be done by hand without the involvement of hired craftsmen.

Cable heater

This heater consists of a specially insulated cable made of polypropylene, braided armor made of galvanized steel wire and a special sheath. Cable diameter 6 mm, bending radius 35 mm.

The main advantages of a cable heater are:

- relatively easy installation;

- acceleration of plant growth;

- extension of the vegetation period of vegetable crops;

- increase in the number of plant species grown;

- a bountiful harvest;

- the ability to control soil heating.

Typically, cable heating consumes 75-100 W/sq.m of electricity. Special thermostats are designed to control the temperature.

The optimum temperature for the soil is 15-25 degrees, and for seedlings in peat pots - 30 degrees. When heating the soil with an electric cable, the heating element itself is also located in the soil or under the soil in an asphalt concrete monolith. When heating the air, the heating elements are suspended in a special way, and then voltage is applied to them. Heating elements can be hidden in pipes, which perfectly protect them from various damages and moisture. True, such pipes will need a lot.

The safest cable accumulators are made in the form of an asphalt concrete sheet or an asphalt expanded clay concrete slab. They have excellent accumulative properties and warm the soil much more evenly. And most importantly, they are absolutely electrically safe.

Advantages and disadvantages

Every year more and more growers refuse to use outdated systems for heating cold greenhouses. Today, it is rare for anyone to heat rooms with the help of "bourgeois stoves", fan heaters or coal-fired or wood-burning boilers. All these methods are a thing of the past, since they have a significant drawback. These systems heat the air, which, according to the laws of physics, rises, leaving the crops grown cool.

Infrared heaters managed to solve this and many problems of space heating once and for all.

Compared to other systems, they have a number of advantages.

- Optimally distribute heat around the perimeter. Most types of thermal devices on the modern market cannot boast of such an effect.

- Rapid heating of the room. The spread of heat is felt already in the first minute after turning on the device. The devices work in a direction, thanks to which it is possible to evenly heat a specific area. Due to this feature, heat-loving plants and crops for which thermal energy is not so important can be grown in one greenhouse.

- Economical consumption of electrical energy. With the correct installation of the equipment, it is possible to achieve energy savings of up to 40%.

- Exclusion of the occurrence of drafts and the movement of warm air currents, which not all plants like.

- Silent operation of devices.

- Exclusion of "burning" of oxygen in the air. Thanks to this feature, optimal humidity is maintained indoors. This is one of the most important conditions for good growth and fruiting of plants.

- The durability of devices and their uninterrupted operation. The fact is that IR equipment does not include moving mechanisms and rubbing parts that need frequent replacement.

- Small dimensions and weight of the units, which make them easy to transport and install.

Unfortunately, not a single thermal equipment is without drawbacks. There are also disadvantages to infrared heaters. These include the high cost of organizing an IR heating system and the low fire safety of some models (mostly mobile units). In addition, there are counterfeits of equipment from well-known brands on the market, because of which the buyer runs the risk of purchasing low-quality goods.

Gas, oil and primitive types of heaters

To choose the right heater for a greenhouse, you need to immediately determine what exactly will be grown in it, what size of the greenhouse, its thermal conductivity, in what season the heating will be performed.

If seedlings freeze in the greenhouse, then it may be enough to install a few lighted candles. Another thing is a greenhouse 2.5 meters high and with an area of 20 sq.m. For such a greenhouse, completely different dimensions of the heater are required. Without heating, the greenhouse can withstand temperatures down to -1 degrees, and below that additional heating is already necessary.For this purpose, you can use fan heaters equipped with a timer, in which you can specifically adjust the duration and power of operation, as well as automatic shutdown.

The advantage of fan heaters is its ability to quickly heat the air, and the disadvantage is the unevenness of the heat supplied and the drying of the heated air.

The worst of all greenhouse heaters is the gas heater. It consists of a gas pipeline and a regulating gas supply system. The heat generator heats the air and transfers it to the greenhouse. The disadvantage of this heater is also the overdrying of the air in the greenhouse, which is detrimental to plants.

Sometimes greenhouses use oil heaters, which is very irrational. They eat up too much electricity, which, with prolonged use, will not pay off with any crops. In addition, such heaters take up too much space and are not protected from the effects of condensate.

This applies to all electric heaters connected to the network. The slightest short circuit - and a fire cannot be avoided. If dew has fallen in the greenhouse, then it will settle on all surfaces, including the outlet. If a drop hits a current line, a short circuit may occur. It's good if the fuse blows. In the worst case, the socket may catch fire when the owners are not at home.

Therefore, every precaution must be taken to prevent this from happening. The outlet should be outside the greenhouse, preferably in the house, it should be sealed so that water cannot get on it

The heater should not be left on if there is no one in the country house for a long time. For a heater, it would be nice to install a circuit breaker with a small margin of power, so that in the event of a short circuit, it would turn off the voltage. For a 500-watt heater, a 3-amp machine is required, which can operate with a current leakage of 0.03 amperes.

Battery heater

The best option for heating a greenhouse is an autonomous heater that has its own source of energy that does not depend on external factors, such as power surges or power outages. It can be built with your own hands, remade from a car battery, attaching smoldering peat to it.

A car battery has 55Ah and the entire greenhouse needs at least 500W. Therefore, experienced gardeners came up with the idea of using a battery in a pulsed mode, which operates as follows: burning is turned on with the help of a clockwork, the spiral burns out and the contact breaks, after which the tinder in the peat is set on fire. After a while, the next spiral is connected. This mode saves battery power, which is enough for a whole week and even more.

Samopal

The simplest and most primitive way to heat a greenhouse is a "samopal". It works as follows: garbage is burned in the stove, in which two bricks and a bucket of water are heated. In the evening, a bucket of water is placed on a wooden stand in the greenhouse, and hot bricks are placed on a sheet of iron.

Some summer residents use candles, which are installed in the middle of the greenhouse along the path and set on fire. This is an inefficient way of heating, but it looks very nice.

Types of infrared heaters

Infrared heaters of the following types:

- light;

- longwave.

In infrared light heaters, the surface heats up to 600 degrees. Such equipment is suitable for very large greenhouses. Long-wave devices heat up much less and are better suited for small greenhouses.

Infrared devices can work from:

- electricity;

- gas;

- liquid fuel.

Infrared heaters for greenhouses are able to heat a greenhouse with an area of 18 square meters. m. When working on gas during the winter, they consume only two cylinders of liquefied gas.

The shape of such heating devices is different. They are issued as:

- lamps;

- film (tape) panels.

Borovoe greenhouse heating

The pine forest heating of the greenhouse is carried out by hot flue gases coming from the brick oven along the hog on the way to the chimney. In fact, hogs are the beginning of the chimney, located almost horizontally, along the greenhouse.

During the passage of hot gases through the chimney, heat is accumulated by the walls of the hog and then, with slow cooling, heats the greenhouse.

The furnace is arranged in the end part of the greenhouse so that the furnace door goes into the vestibule, and the furnace itself is in the greenhouse. A burr runs from the stove along the greenhouse, laid on brick trenches, so that there are air passages in its lower part and there is no contact between the burr and the ground. From the furnace to the pipe, a small rise of the hog is made (at least 1:100) to prevent smoking.

In shed greenhouses, hogs are placed along the southern wall under the rack. In gable greenhouses, two hogs (respectively, two furnaces) are laid under racks running along the side walls. The riser must be of sufficient height to provide good traction.

Furnaces are heated in the evening, and in case of severe cooling - in the morning to maintain the thermal regime at a sufficient level.

How to do it yourself and save on heating

To reduce the financial costs of heating a greenhouse located in a garden or in a personal plot, it is recommended to organize stove heating. This method of heating the room will allow you to heat the building to the optimum temperature, despite the weather conditions. In order for the heating system to be effective, it is necessary that the thermal power of the furnace is appropriate for the volume of the greenhouse.

Stove heating is in demand among gardeners due to the following factors:

- fast heating of the stove;

- affordable cost of the fuel used;

- easy installation and operation;

- the possibility of building a furnace with your own hands from improvised materials.

The main disadvantage of stove heating is the inability to make the heating process automatic. To ensure the optimum temperature, the grower will have to be constantly present in the greenhouse and put fuel in the furnace, since when it cools down, the risks of crop death are high.

For the arrangement of furnace heating, the following types of furnaces can be used.

"Burgeon". Metal stove with a straight chimney. The design includes a combustion chamber, an ash pan and a door for loading fuel. During the combustion of coal or firewood, the metal walls of the furnace heat up, giving off heat into space. The advantages of using such a furnace include unpretentiousness to fuel (even garbage can be used for these purposes), rapid heating. Its disadvantages are low efficiency, rapid cooling, uneven heating of the space and the impact on humidity indicators.

To install a brick capital oven, you should consider a number of recommendations:

- the structure is mounted on a solid, horizontal, concrete base;

- parts exposed to strong heat should be at a distance from polycarbonate greenhouse walls (at least 70 cm);

- the outlet of the chimney can be laid through the roof or wall (in this case, the passage points are equipped with heat-insulating materials).

How to make heating for a winter greenhouse with your own hands, see the next video.