Regulation of gas supply to the boiler and water circulation in the system

Thus, depending on the type, class and model of the boiler, it can be installed:

- pump;

- control system;

- safety system;

- protection and diagnostic systems.

Single and double circuit boilers

Despite the fact that the heating boiler is a complex device, its basic scheme is clear to everyone who wants to figure it out. For example, the answer to the question what is a double-circuit gas boiler is quite simple. The boiler is designed for home heating, providing the circuit (pipe system throughout the room) with heat. If a water heating system is also connected to the boiler, which is carried out approximately according to the same principle, then the boiler serves two circuits and is equipped with two heat exchangers. Depending on this, boilers are divided into single- and double-circuit.

How the boiler room works

A boiler room is a complex, high-precision engineering system consisting of a large number of elements.

The boiler room is closely connected with a number of other engineering networks of a house, enterprise, etc., therefore its stable operation is an important safety requirement. So that you can better understand what this system is, you should describe how the boiler room works

Gas boilers

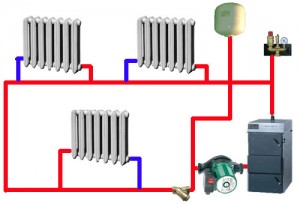

The principle of operation of a gas boiler is as follows: fuel from a gas pipeline or from a gas tank is supplied to the boiler burner. That, in turn, ensures the combustion of gas in the corresponding chamber. In the process, heat is released, which heats the coolant passing through the boiler heat exchanger.

The hot coolant is sent to the distribution manifold, where it is distributed among the heating circuits available in the system (these can be heating radiators, underfloor heating, a hot water boiler, etc.). When the coolant travels all the way along the circuits, it cools down and is sent through the return line to the boiler for heating. Thus, a vicious cycle is created.

The distribution manifold includes various equipment that circulates the coolant and controls its temperature.The removal of combustion products is provided by a chimney. The boiler house is controlled by automation.

Diesel boilers

The principle of operation of diesel boilers is somewhat similar to gas systems. When the boiler is turned on, two devices begin to function at once - pressurization and a fuel pump that supplies fuel to the nozzle. This creates the optimal pressure, which is set by the manufacturer, this guarantees a uniform supply of diesel fuel. Pressure indicators in the nozzle reach 10–16 bar.

Then two operations take place simultaneously - spraying fuel through the nozzle and applying voltage to the ignition electrodes. The ignition of the fuel mixture follows, the operation of the boiler room begins in normal mode.

If you need installation or repair of boiler equipment, please contact EnergoStroyTechService LLC.

Principle of operation

The double-circuit boiler heats the coolant in the heat exchanger. The entire heating process works thanks to a thermostat that starts a double-circuit boiler if the temperature of the coolant drops to a certain level. When the thermostat starts, it gives a command to the circulation pump. The pump, in turn, also begins to function and produces the movement of the coolant in the return pipeline. As a result, the coolant, which is heated in the heat exchanger, begins to circulate through the system.

After starting, the gas appliance starts at low power, but during the heating process it increases to maximum. But in the case when the operating mode is set, the boiler heats up to the desired temperature. This process is controlled by automation, with very rapid heating, it turns off the boiler, that is, it shuts off the gas supply to the burner.

The heat exchanger is heated by the released thermal energy from gas combustion. Thus, the combustion chamber with the burner is located below, and already above it is a heat exchanger.

When the coolant in the heating system has reached the set temperature, the burner gradually fades out, and then the gas does not flow at all. Further, the double-circuit gas boiler is in standby mode, until a new thermostat command.

As for the second function of the two-circuit unit - the supply of hot water, it is carried out using a three-way valve. It blocks the path of the coolant to the heating system, while water enters the secondary heat exchanger, which is designed for hot water supply. This heat exchanger is located above the primary. The three-way valve is activated when the water tap is opened, and after it is closed, the double-circuit boiler continues to work to heat the coolant for the radiators.

Ignition of gas boilers can be of two types:

- Electric - this type of ignition is in appliances that run on electricity. Thanks to the control unit, such ignition occurs automatically;

- Piezo ignition - inexpensive boilers are equipped with this type of ignition, this is a non-volatile system. Ignition occurs by pressing a button on the body. In this case, the igniter is constantly on.

Thermal control devices

To automatically adjust the operation of the boiler, many built-in devices are used.

The thermostat or programmer is responsible for temperature control.

Proper use of thermostat settings allows you to achieve savings on energy consumption of 20-30%, which will significantly reduce heating costs. Having reconsidered the need to purchase this device, you can buy a programmer for a gas boiler, even if you already have a boiler.

If it gets cooler or warmer outside the window, a different water temperature in the pipes is required and new settings have to be made. Such systems can be equipped with an electronic scoreboard and automatic adjustment. But the principle of their work is to constantly bring the system into such a mode in which the desired water temperature will be reached by starting / turning off the boiler every few minutes. In this mode of constant readiness for switching on the burner, the pump runs constantly. It wears out the equipment.

A more justified option is a programmer that controls the temperature of the air in the room, and not the water in the pipes, when the desired comfortable temperature is set and the boiler is controlled, also turning it on and off, while starting and turning off the pump only when the air temperature change sensor is triggered. The air cools and heats up more slowly, so starts are less frequent, minimizing energy costs and reducing equipment wear. Those who want to get more significant savings and a comfortable temperature buy a room programmer for a gas boiler, they are widely represented on the market.

The principle of operation of the boiler and its device

Image 1. Hydraulic diagram of a double-circuit boiler in heating mode.

Gas appliances with two heating circuits have the following principle of operation. The heat of the burnt natural gas is transferred to the heat exchanger, which is located above the gas burner. This heat exchanger is included in the heating system main, that is, the heated water in it will circulate through the heating system. Water circulation is carried out by means of a pump built into the boiler. For the preparation of hot water, the double-circuit device is equipped with a secondary heat exchanger.

The presented diagram in PICTURE 1 shows the ongoing work processes and equipment arrangement:

- Gas-burner.

- Circulation pump.

- Three-way valve.

- DHW circuit, plate heat exchanger.

- Heating circuit heat exchanger.

- D - input (return) of the heating system for heating;

- A - supply of ready-made coolant for heating appliances;

- C - cold water inlet from the main;

- B - output of ready hot water for sanitary needs and domestic use.

The principle of preparing water for domestic hot water is as follows: the heated water in the first heat exchanger (5), which is located above the gas burner (1) and is designed to heat the heating circuit, enters the second plate heat exchanger (4), where it transfers its heat to the domestic hot water circuit.

As a rule, double-circuit boilers have a built-in expansion tank to compensate for changes in the volume of the coolant.

The scheme of a double-circuit boiler allows you to produce hot water and heat it for heating only in certain modes.

The design of a double-circuit gas boiler.

Using the boiler for both domestic hot water and heating at a certain point in time is not possible. For example, during operation of the device, the heating system is heated at a given temperature, the process of maintaining the temperature is controlled by the automatic boiler, and the circulation of the coolant through the heating network is carried out by a pump.

At a certain moment, the hot water tap for domestic needs is opened, and as soon as the water begins to move along the DHW circuit, a special flow sensor installed in the boiler is activated. With the help of a three-way valve (3), the water flow circuits in the boiler are reconfigured. Namely, the water heated in the heat exchanger (5) ceases to flow into the heating system and is supplied to the plate heat exchanger (4), where it transfers its heat to the DHW system, that is, the cold water that has arrived from the pipeline (C) is heated through the pipeline (B) served to consumers of an apartment or house.

At this moment, the circulation goes in a small circle and the heating system does not heat up during the use of hot water. As soon as the tap on the DHW intake is closed, the flow sensor is triggered and the three-way valve opens the heating circuit again, further heating of the heating system occurs.

Most often, the scheme of the device of a double-circuit gas boiler implies the presence of a plate heat exchanger. As already mentioned, its purpose is to transfer heat from the heating circuit to the water supply circuit. The principle of such a heat exchanger is that sets of plates with hot and cold water are assembled into a package where heat transfer occurs.

The connection is made in a hermetic way: this prevents the mixing of liquids from different circuits. Due to the constant change in temperature, processes of thermal expansion of the metal from which the heat exchanger is made occur, which contributes to the mechanical removal of the resulting scale. Plate heat exchangers are made of copper or brass.

Connection diagram for a double-circuit boiler.

There is a double-circuit boiler scheme, which includes a combined heat exchanger.

It is located above the gas burner and consists of double tubes. That is, the heating circuit pipe contains a hot water pipe inside its space.

This scheme allows you to do without a plate heat exchanger and slightly increase the efficiency in the process of preparing hot water.

The disadvantage of boilers with a combined heat exchanger is that scale is deposited between the thin walls of the tubes, as a result of which the operating conditions of the boiler deteriorate.

Types of gas burners

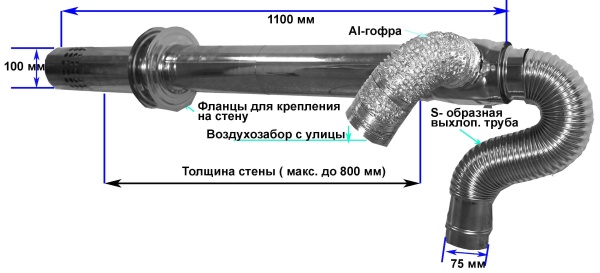

Double-circuit wall-mounted boilers are produced with an open type of gas burner and with a closed one. An open gas burner in the boiler requires the supply of the necessary amount of air for combustion of gas from the room where the gas boiler is installed. For example, the usual scheme of a typical geyser for heating water.

The device with a closed burner has an isolated space for combustion of gas from the room. Air intake for the combustion process is carried out outside the building. Most often, such devices are connected using a coaxial chimney that goes to the outer wall of the building. It consists of two pipes located one in one. Combustion air is taken in through the outer pipe, and combustion products are removed through the inner pipe.

It is possible to connect with the emission of combustion products into the provided chimney of the building and air intake with a lateral pipeline supply. Boilers with a closed burner are called turbocharged, as they have a built-in turbine-type electric air blower.The advantage of such gas appliances is the safety of operation. Their work does not require constant monitoring of the air supply, ventilation of the room, the ingress of combustion products into an apartment or house is excluded. Due to the excess traction, more efficient combustion and faster heating of the water occur.

The device of a wall-mounted gas boiler.

Double-circuit gas appliances can be connected in boiler mode. This mode of operation involves heating the water and its subsequent accumulation in the boiler, and from it the water is already supplied to the water intake points.

Condensing gas heaters are distinguished by the fact that their design allows the water vapor contained in the products of gas combustion to condense. During the condensation process, additional heat is released, which is used either for the heating circuit or for the DHW circuit. The scheme may include the formation of condensate on a specially shaped primary heat exchanger or on an additional device that is located above the primary heat exchanger.

All double-circuit gas boilers must include an automation unit and control sensors for proper and safe operation. Automation monitors the set parameters of water heating in the circuits, can be used in conjunction with remote sensors for indoor air temperature. Traction sensors, control of emergency shutdown of gas supply allow you to operate the boiler in the safest way.

For long-term use of a gas appliance, a competent installation should be made, including power calculation, installation in accordance with safety standards, and high-quality commissioning operations.

Work on the installation of gas equipment should be carried out only by special gas services that have a certificate for its implementation.

The principle of operation of the boiler part 2

But it doesn't end there. After switching on, the boiler starts to work on the rise. First at minimum power, and eventually reaches its maximum. When a double-circuit gas wall-mounted boiler heats up the media to a predetermined temperature at some stage, the unit goes into modulation mode. If at the first start-up the power exceeds the allowable one, the microprocessor sends a signal to turn off the burner. Reactivation is carried out after three minutes. The combustion chamber is metal and has a special heat-resistant winding. Above it is a heat exchanger, below it is a burner. The latter lights up exactly at the moment when the temperature of the carrier in the system drops and the water needs to be heated. Turns on with it in operation and circulation pumpdesigned to drive water through a closed system. When the set temperature is reached, the gas wall-mounted double-circuit boiler goes into standby mode. In some models, the burner burns, but at a minimum, in others it goes out and lights up when gas is supplied.

The principle of operation of a double-circuit gas boiler

Now we will begin to analyze the principle of operation of a gas double-circuit boiler. We found out the purpose of individual nodes and modules, now this knowledge will help us understand how all this equipment works. We will consider the principle of operation in two modes:

- In heating mode;

- In hot water generation mode.

In heating mode, the boiler provides your home with heat.

Immediately, we note the fact that operation in two modes is immediately impossible - for this, double-circuit boilers have a three-way valve that directs part of the coolant to the DHW circuit. Let's look at the principle of operation during heating, and then find out how the technique works in hot water mode.

In heating mode, a double-circuit boiler works in the same way as the most common instantaneous heater. When first turned on, the burner works for a rather long time, raising the temperature in the heating circuit to the set point.As soon as the required temperature is reached, the gas supply will turn off. If an air temperature sensor is installed in the house, then the automation will take into account its readings.

The operation of a gas burner in double-circuit boilers can also be affected by weather-dependent automation that controls the temperature of the outside air.

The heat from the operating burner heats the coolant, which is forced through the heating system. The three-way valve is in such a position to ensure the normal passage of water through the main heat exchanger. Combustion products are removed in two ways - independently or with the help of a special fan located in the upper part of the double-circuit boiler. The DHW system is in the off state.

Hot water operation

As for the hot water circuit, it starts at the moment when we turn the handle of the water tap. The appeared current of water leads to the operation of a three-way valve, which turns off the heating system. At the same time, the gas burner is ignited (if it was turned off at that time). After a few seconds, hot water starts flowing from the faucet.

When switching to hot water mode, the heating circuit is completely switched off.

Let's look at the principle of operation of the DHW circuit. As we have already said, turning it on leads to the shutdown of the heating operation - only one thing can work here, either the hot water supply or the heating system. It's all controlled by a three-way valve.

It directs part of the hot coolant to the secondary heat exchanger - note that there is no flame on the secondary. Under the action of the coolant, the heat exchanger begins to heat the water flowing through it

The scheme is somewhat complicated, since a small circle of coolant circulation is involved here. This principle of operation cannot be called the most optimal, but double-circuit gas boilers with separate heat exchangers can boast of normal maintainability. What are the features of boilers with combined heat exchangers?

- A simpler design;

- High probability of scale formation;

- Higher efficiency for DHW.

As we can see, the disadvantages are closely intertwined with the advantages, but separate heat exchangers are valued more. The design is somewhat more complicated, but there is no scale here.

Please note that at the time of DHW operation, the flow of coolant through the heating circuit stops. That is, its long-term operation can disrupt the heat balance in the premises.

As soon as we close the tap, the three-way valve is activated, and the double-circuit boiler goes into standby mode (or the heating of the slightly cooled coolant immediately turns on). In this mode, the equipment will be until we open the tap again. The performance of some models reaches up to 15-17 l / min, which depends on the power of the boilers used.

Having dealt with the principle of operation of a gas double-circuit boiler, you will be able to understand the purpose of individual components and even be able to independently understand the issues of repair. At first glance, the device seems very complicated, and the dense internal layout commands respect - after all, the developers managed to create an almost perfect heating equipment. Double-circuit boilers from companies such as Vaillant. are actively used for heating buildings for various purposes and for generating hot water, replacing two devices at once. And their compactness allows you to save space and get rid of the need to purchase a floor boiler.

What can you save when using a gas boiler

Competent installation

Experts also agree that efficient, reliable and economical operation of the boiler is possible only with the proper organization of not only the installation of the boiler itself, but also the entire heating system.

In addition, it is important to take into account all measures that prevent equipment failure, since repair, maintenance of gas boilers are also significant material costs, which, in turn, can also be reduced by contacting a gas boiler service center in a timely manner, as well as drawing up a service agreement gas boiler

Do-it-yourself boiler cleaning

Choosing a gas boiler

The choice of the boiler itself is also a means of saving

Cheap, more expensive, with or without automation, on which you can win at the very beginning and in subsequent operation - all this is important to take into account and calculate. A striking example of the ambiguity of calculating savings on heating can be the purchase of a boiler of the AGV type (gas water heating apparatus), which means the cheapest type of boiler of the old, Soviet, sample with primitive automation

As a standard, the AGV gas boiler has a very low price, but also low efficiency, but they do not need electricity. Only an accurate calculation will help determine the degree of savings when using this device. You can read about domestic gas boilers in our article “Russian-made gas boilers: varieties and properties”.

It is also important to determine the potential problems of certain boilers when choosing the optimal model. For example, a MORA gas boiler will constantly suffer malfunctions up to failure in conditions of electrical voltage instability, with the slightest setting errors and lack of water in the system.

And the reviews on the Master Gas Seoul gas boiler are contradictory at first glance, but they provide information about the vulnerabilities of this model - the accumulation of combustion waste in the boiler, which leads to noisy fan operation, leaks and unstable water temperature during supply, while with its main function, heating, this model copes properly.

- How to pour water into an open and closed heating system?

- Popular Russian-made outdoor gas boiler

- How to correctly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes in case of malfunction

Recommended reading

How to correctly calculate the power of a gas boiler? What to do if the gas boiler blows out with wind? How to properly connect a gas boiler to the heating system? Installation of a gas boiler: what you need to know?

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited.Any copyright infringement entails legal liability. Contacts

The design of a two-circuit device

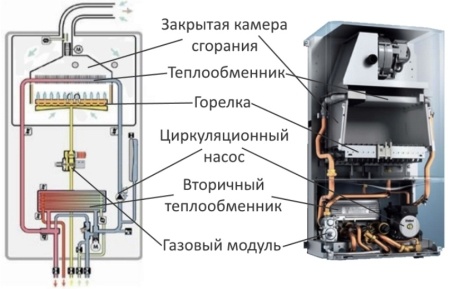

The device of a double-circuit gas boiler (Fig. 4) consists of three main nodes that are in all types of the device:

Also, an invariable part of the gas heating unit is a housing with a layer of thermal insulation.

The gas burner is a design with perforations along the entire body, and there are nozzles inside. Nozzles deliver and distribute gas for a uniform flame. The burner can be of several types:

- Single-stage - this burner is designed so that it cannot be regulated, it works in one mode;

- Two-stage - this device has 2 power adjustment positions;

- Modulated - the power of such a burner can be adjusted, due to this, the boilers consume fuel more economically.

Heat exchanger. In double-circuit gas appliances there are 2 heat exchangers:

- Primary - the coolant for the heating circuit is heated in it. Made from steel or cast iron;

- The secondary is a heat exchanger in which water is heated for the hot water circuit. It is usually affected by a temperature slightly less than the primary, so it can be made from materials such as copper, stainless steel, etc.

Automation is a node that controls the operation of a gas device. It includes an electronic circuit and a sensor system. Sensors give indications of the operation of a double-circuit boiler to an electronic circuit that sets the operating mode or turns off the device.

Circulation pump - this device is needed for a forced circulation heating system. This is a component part for a volatile system. Such a pump provides the desired pressure indicator.

The system for removing combustion products can be with:

- natural traction. In this case, the combustion products are discharged into the chimney, which must rise above the roof by at least 1 meter;

- forced traction. Boilers with such a system have a fan in their design to discharge combustion products into a coaxial chimney (pipe in pipe). Such boilers are called turbocharged.

Expansion tank. When the coolant is heated to a high temperature, it expands, and its excess temporarily enters the expansion tank. The volume of the tank can be different, it depends on the volume of the coolant in the system and the power of the boiler.

The combustion chamber looks like a container made of metal with thermal insulation. It is above it that the primary heat exchanger is located, and at its bottom there is a burner. The combustion chamber of a gas device can be:

A double-circuit gas appliance with an open chamber is a device that can be non-volatile, since it takes combustion air directly from the room in which it is installed. It is recommended to install such units in separate rooms - boiler rooms. They must be arranged according to all the rules, namely, have good ventilation and a window. If a double-circuit boiler with an open combustion chamber does not have enough air, it will emit carbon dioxide.

A double-circuit gas appliance with a closed chamber is a device that takes combustion air from the street through a coaxial chimney. The principle of the coaxial gas exhaust system lies in its special design - "pipe in pipe" (Fig. 6). That is, a pipe with a smaller diameter is in a pipe with a larger diameter. Combustion products exit through a small pipe, and air is taken into the gas boiler through a large one. The advantage of a coaxial chimney is that it can be installed both horizontally and vertically.