Do-it-yourself installation of a septic tank correct installation of the Universal, Bio and other models

Initially, you need to choose a place to install the cleaning system. This requires the following conditions to be met:

- the lowest possible level of groundwater;

- the distance from the residential building should not be less than 5 m;

- to the septic tank, it is necessary to ensure unhindered access of sewage equipment.

Compliance with these conditions guarantees a long and trouble-free operation of the installed equipment for 50 years.

Installing a septic tank tank is no different from installing other septic tanks

Do-it-yourself installation of a septic tank Tank includes the following works:

- digging a pit. The pit needs to be dug with dimensions exceeding the dimensions of the structure by 25-30 cm. When calculating the depth, the height of the sand cushion is taken into account, the optimal height of which is 30 cm;

- laying sand on the bottom of the pit - this allows you to level it;

- it is necessary to equip a trench along which sewer pipes will pass;

- lowering the equipment into the pit. Before you install a septic tank Tank, you need to check the integrity of the tank;

- connect sewer pipes;

- backfilling of equipment located in the pit. Every 30 cm of soil must be compacted. In order to balance the pressure on the walls of the container, it is necessary to fill it layer by layer with water;

- filling the septic tank with water completely - it should be 30-35 cm higher than the backfill level;

- insulation of the upper part of the treatment plant. The container is closed with a heater, after which the neck is filled.

Installation of infiltrators: secrets of the manufacturer

The antiseptic Tank for giving is ready for operation. If you want to install infiltrators, then the order of work is as follows:

- we measure 1 m from the cleaning system - at this distance it is required to dig a pit to equip the infiltrator;

- a geofabric is laid on the sides of the pit, and a layer of crushed stone is backfilled at the bottom - its height is 40 - 50 cm;

- on top of the crushed stone pillow, an infiltrator is installed;

- pipes coming from the septic tank are connected - water will flow through them;

- installation of a ventilation riser at the outlet;

- the infiltrator is backfilled with a sand mixture, the top of the equipment must be covered with isolon as an insulating layer. You need at least 3 layers of isolon.

To properly install a septic tank with your own hands, it is necessary to install it in accordance with the technical requirements. The main difficulty is the alignment of the equipment when placed in the pit, as well as backfilling the device. During these operations, mistakes are usually made, as a result of which damage to the equipment case occurs. This nullifies all efforts, since untreated drains begin to penetrate the soil, an unpleasant odor appears, which should not be with proper installation quality.

There are also difficulties in the installation of the pipe system - the pipes should go with a slight slope towards the drain. If you are not confident in your abilities, it is better to entrust the installation of a septic tank to specialists. Septic tank is a great option for a country sewer!

A few words about septic tanks Tank

Septic tanks "Tank" are produced from high-strength plastic, the body is reinforced with additional stiffeners, which ensure the reliability of the structure.

Externally, the equipment looks monolithic, but it is a multi-chamber cleaning system, where the sewer drain goes through several stages of processing. The liquid first settles, then fractional separation occurs when solid particles settle to the bottom, and the rest of the mass flows into the compartment inhabited by microorganisms. As a result, the drain is cleaned by 75%, to increase this indicator, infiltrators are installed that perform the function of a post-treatment soil filter.

The advantages of Triton Plastic products are reliability, performance, durability and relatively low cost.

Design and principle of operation

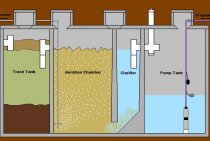

A septic tank looks like a large plastic cube with a ribbed surface and a neck (or two) sticking out above the surface. Inside, it is divided into three compartments, in which wastewater is treated.

The body of this septic tank is one-piece cast, it has no seams. There are seams only at the neckline. This seam is welded, almost monolithic - 96%.

Septic tank: appearance

Although the case is plastic, it is definitely not fragile - a decent wall thickness (10 mm) and additional even thicker ribs (17 mm) add strength. Interestingly, when installing a septic tank, the Tank does not require a plate and anchoring. At the same time, even with a high level of groundwater, this installation does not emerge, but this is subject to the installation requirements (more on them below).

Another design feature is the modular structure. That is, if you already have such an installation, and found that its volume is not enough for you, just install another section next to it, connect it to the already working one.

The modular structure allows you to increase the capacity of the Tank septic tank at any time

Principle of operation

A septic tank works in the same way as many other similar installations. The procedure for wastewater treatment is as follows:

- Water draining from the house enters the receiving compartment. It has the largest volume. While it is filling, the waste decomposes, roams. The process is carried out with the help of bacteria that are contained in the waste itself, and good conditions are simply created in the tank for their vital activity. During the cleaning process, solid sediments fall to the bottom, where they are gradually pressed. Lighter fat-containing dirt particles rise up, forming a film on the surface. The more or less pure water located in the middle part (purification at this stage is approximately 40%) enters the second chamber through the overflow hole.

- In the second compartment, the process continues. The result is a cleansing of another 15-20%.

-

The third chamber has a biofilter at the top. In it there is an additional treatment of effluents up to 75%. Through the overflow hole, water is discharged from the septic tank for further purification (into the filter column, into the filtration fields - depending on the type of soil and groundwater level).

Not a bad exit

As you can see, there are no difficulties. With proper installation and operation, the Tank septic tank works flawlessly - it does not depend on electricity, so it is not afraid of frequent power outages in rural areas. Also, the installation tolerates an uneven usage schedule, which is typical for summer cottages. In this case, the flow of effluents on weekdays, as a rule, is minimal or absent, and reaches a maximum on weekends. Such a work schedule does not affect the cleaning result in any way.

The only thing that is necessary for dachas is conservation for the winter, if accommodation is not planned. To do this, it is necessary to pump out the silt, fill all the containers with water by 2/3, insulate the top well (fill in leaves, tops, etc.). In this form, you can leave to winter.

Operation features

Like any septic tank, the Tank does not respond well to a large amount of active chemicals - a one-time supply of a large amount of water with bleach or a chlorine-containing drug kills bacteria. Accordingly, the quality of purification deteriorates, an odor may appear (it is absent during normal operation). The way out is to wait until the bacteria multiply or add them forcibly (bacteria for septic tanks are commercially available).

| Name | Dimensions (L*W*H) | How much can clear | Volume | Weight | The price of a septic tank Tank | Installation price |

|---|---|---|---|---|---|---|

| Septic Tank - 1 (no more than 3 people). | 1200*1000*1700mm | 600 sheets/day | 1200 liters | 85 kg | 330-530 $ | from 250 $ |

| Septic tank - 2 (for 3-4 people). | 1800*1200*1700mm | 800 sheets/day | 2000 liters | 130 kg | 460-760 $ | from 350 $ |

| Septic Tank – 2.5 (for 4-5 people) | 2030*1200*1850mm | 1000 sheets/day | 2500 liters | 140 kg | 540-880 $ | from 410 $ |

| Septic Tank – 3 (for 5-6 people) | 2200*1200*2000mm | 1200 sheets/day | 3000 liters | 150 kg | 630-1060 $ | from 430 $ |

| Septic tank – 4 (for 7-9 people) | 3800*1000*1700mm | 600 sheets/day | 1800 liters | 225 kg | 890-1375 $ | from 570 $ |

| Infiltrator 400 | 1800*800*400mm | 400 liters | 15 kg | 70 $ | from 150 $ | |

| Cover D 510 | 32 $ | |||||

| Extension neck D 500 | height 500 mm | 45 $ | ||||

| Manhole for pump D 500 | height 600 mm | 120 $ | ||||

| Manhole for pump D 500 | height 1100 mm | 170 $ | ||||

| Manhole for pump D 500 | height 1600 mm | 215 $ | ||||

| Manhole for pump D 500 | height 2100 mm | 260$ |

Another of the features that must be taken into account is not to flush waste into the sewer that does not decompose by bacteria. As a rule, these are wastes that appear during repairs. Not only can they clog the sewer, and you will have to clean it, but these particles significantly increase the amount of sludge, and you will have to clean the Tank septic tank more often.

Description

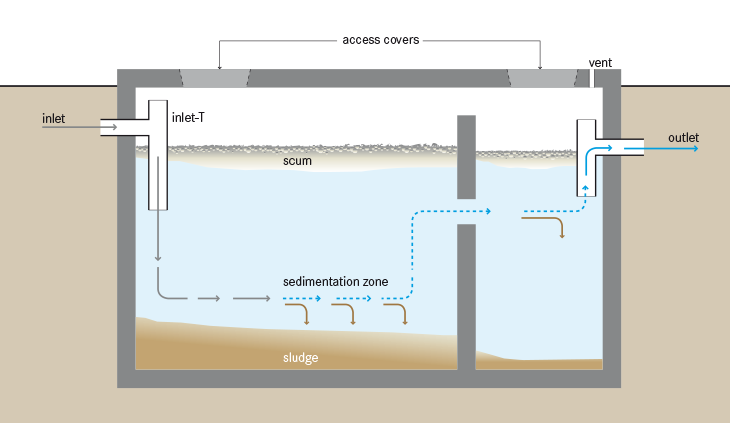

Schematic of a septic tank

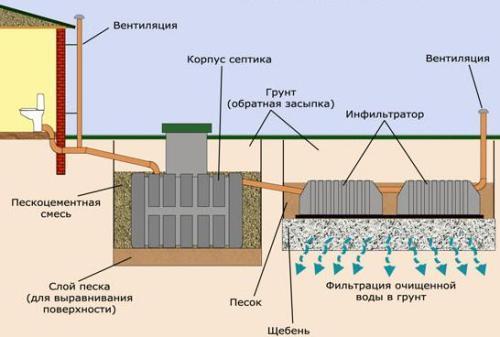

Septic tank and septic drain field

A septic tank consists of one or more concrete or plastic tanks of between 4000 and 7500 liters (1,000 and 2,000 gallons); one end is connected to an inlet wastewater pipe and the other to a septic drain field. Generally these pipe connections are made with a T pipe, allowing liquid to enter and exit without disturbing any crust on the surface. Today, the design of the tank usually incorporates two chambers, each equipped with a manhole cover, and separated by a dividing wall with openings located about midway between the floor and roof of the tank.

Wastewater enters the first chamber of the tank, allowing solids to settle and scum to float. The settled solids are anaerobically digested, reducing the volume of solids. The liquid component flows through the dividing wall into the second chamber, where further settlement takes place. The excess liquid, now in a relatively clear condition, then drains from the outlet into the septic drain field, also referred to as a leach field, drain field or seepage field, depending upon locality. A percolation test is required prior to installation to ensure the porosity of the soil is adequate to serve as a drain field.

The remaining impurities are trapped and eliminated in the soil, with the excess water eliminated through percolation into the soil, through evaporation, and by uptake through the root system of plants and eventual transpiration or entering groundwater or surface water. A piping network, often laid in a stone-filled trench (see weeping tile), distributes the wastewater throughout the field with multiple drainage holes in the network. The size of the drain field is proportional to the volume of wastewater and inversely proportional to the porosity of the drainage field. The entire septic system can be operated by gravity alone or, where topographic considerations require, with inclusion of a lift pump. Certain septic tank designs include siphons or other devices to increase the volume and velocity of outflow to the drainage field. These help to fill the drainage pipe more evenly and extend the drainage field life by preventing premature clogging or bioclogging.

An Imhoff tank is a two-stage septic system where the sludge is digested in a separate tank. This avoids digested sludge with incoming sewage. Also, some septic tank designs have a second stage where the effluent from the anaerobic first stage is aerated before it drains into the seepage field.

A properly designed and normally operating septic system is odor-free and, besides periodic inspection and emptying of the septic tank, should last for decades with minimal maintenance.

A well designed and maintained concrete, fiberglass, or plastic tank should last about 50 years.

Pros and cons of a septic tank Tank

The considered septic tanks are installed on the site at any time of the year. Problems will arise except with digging frozen ground. The place for the "Tank" can be chosen right next to the house at a distance of 2-3 meters from it

It doesn’t matter if the strip or column foundation is used for the construction of housing, moisture from the sealed housing will not seep into the ground and affect the concrete

But the infiltrator should be removed from the base of the building, on the contrary, further away. The humidity around it is always high. If you put it next to a residential building, then even rain-resistant facade plaster from the walls of the house will sooner or later begin to fall off.

Effluent in the anaerobic VOC "Tank" is treated only up to 80%. Without the use of an infiltrator, such water cannot be discharged into a reservoir or used for watering beds. In this regard, this septic tank is somewhat inferior to competitors of the same factory design.

Environmental concerns

A septic tank before installation, with manhole cover on top

The same tank partially installed in the ground

While a properly maintained and located septic tank does not pose any more environmental problems than centralized municipal sewage treatment[citation needed], certain problems could arise with a septic tank in an unsuitable location. Since septic systems require large drainfields, they are unsuitable for densely built areas.

Odor and gas emissions

Some constituents of wastewater, especially sulfates, under the anaerobic conditions of septic tanks, are reduced to hydrogen sulfide, a pungent and toxic gas. Methane may also be released. Nitrates and organic nitrogen compounds can be reduced to ammonia. Because of the anaerobic conditions, fermentation processes take place, which may generate carbon dioxide and/or methane.[citation needed]

Nutrients in the effluent

Septic tanks by themselves are ineffective at removing nitrogen compounds that have the potential to cause algal blooms in waterways into which affected water from a septic system finds its way. This can be remedied by using a nitrogen-reducing technology, or by simply ensuring that the leach field is properly sited to prevent direct entry of effluent into bodies of water.[citation needed]

The fermentation processes cause the contents of a septic tank to be anaerobic with a low redox potential, which keeps phosphates in a soluble and, thus, mobilized form. Phosphates discharged from a septic tank into the environment can trigger prolific plant growth including algal blooms, which can also include blooms of potentially toxic cyanobacteria.

The soil’s capacity to retain phosphorus is usually large enough to handle the load through a normal residential septic tank. An exception occurs when septic drain fields are located in sandy or coarser soils on property adjacent to a water body. Because of limited particle surface area, these soils can become saturated with phosphates. Phosphates will progress beyond the treatment area, posing a threat of eutrophication to surface waters.

Ground water pollution

In areas with high population density, groundwater pollution beyond acceptable limits may occur. Some small towns experience the costs of building very expensive centralized wastewater treatment systems because of this problem, due to the high cost of extended collection systems. To reduce residential development that might increase the demand to construct an expensive centralized sewerage system, building moratoriums and limitations on the subdivision of property are often imposed. Ensuring existing septic tanks are functioning properly can also be helpful for a limited time, but becomes less effective as a primary remediation strategy as population density increases.

Surface water pollution

In areas adjacent to water bodies with fish or shellfish intended for human consumption, improperly maintained and failing septic systems contribute to pollution levels that can force harvest restrictions and/or commercial or recreational harvest closures.

Model range of products LLC Triton Plastic

The range of manufactured products is very wide. It includes treatment systems and peat dry closets, water tanks and grease traps for washing, caissons for wells and deep cleaning stations.

Product range

The range of products consists of several modifications, differing in size, volume and productivity per day. These are products marked: from 1 to 4.

In addition to this model, the company produces septic tanks of the following samples:

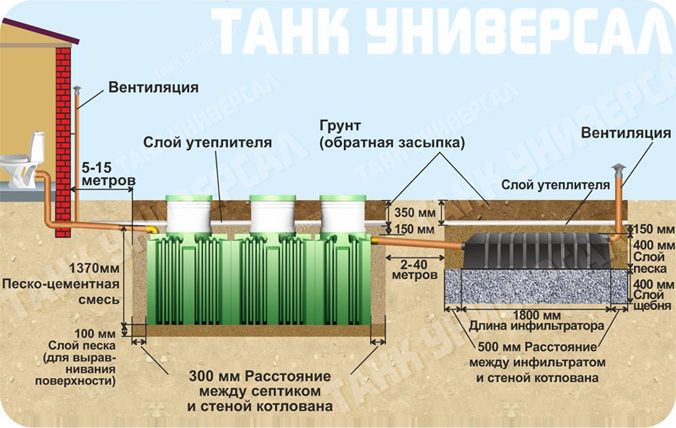

- Tank station wagon

- Triton -T and Triton - H

- Microbe

Let's start with the smallest design. Tank microbe septic tank is a series of miniature devices for use in guest houses or summer cottages, and can also be used as a reservoir for storm sewers and installation in places of temporary residence. The body of the treatment plant of the Universal model is made of durable low-pressure polyethylene and can be operated at low temperatures.

Model Triton H

The triton septic tank is available in two models: accumulative and three-chamber. Triton H is not a treatment plant, but is used only as a wastewater collection tank.A three-chamber septic tank has a principle of operation that allows you to organize an autonomous sewage system in a country house.

It consists of three chambers inside which the wastewater treatment process takes place. Here, slowly flowing from one section to another, they are gradually cleaned and as a result, suspended particles settle to the bottom. The station wagon is a new series of products.

It is designed for use in suburban households and allows you to buy the missing sections if you want to increase the amount of wastewater. This Tank 3 model combines the best characteristics of Tank brand products with high manufacturability and the ability to complete the required configuration.

Emptying

A vacuum truck used to empty septic tanks in Germany

Waste that is not decomposed by the anaerobic digestion must eventually be removed from the septic tank. Otherwise the septic tank fills up and wastewater containing undecomposed material discharges directly to the drainage field. Not only is this detrimental for the environment but, if the sludge overflows the septic tank into the leach field, it may clog the leach field piping or decrease the soil porosity itself, requiring expensive repairs.

When a septic tank is emptied, the accumulated sludge (, also known as ) is pumped out of the tank by a . How often the septic tank must be emptied depends on the volume of the tank relative to the input of solids, the amount of indigestible solids, and the ambient temperature (because anaerobic digestion occurs more efficiently at higher temperatures), as well as usage, system characteristics and the requirements of the relevant authority. Some health authorities require tanks to be emptied at prescribed intervals, while others leave it up to the decision of an inspector. Some systems require pumping every few years or sooner, while others may be able to go 10–20 years between pumpings. An older system with an undersize tank that is being used by a large family will require much more frequent pumping than a new system used by only a few people. Anaerobic decomposition is rapidly restarted when the tank is refilled.

Services for de-sludging tend to empty a septic tank completely, i.e. take out all septage, although the actual removal of settled solids is left purposefully incomplete, so as to leave at least some of the microbial populations in place to continue the anaerobic degradation processes that take place in a septic tank. An empty tank may be damaged by hydrostatic pressure causing the tank to partially "float" out of the ground, especially in flood situations or very wet ground conditions.

Description

Schematic of a septic tank

Septic tanks and

A septic tank consists of one or more concrete or plastic tanks of between 4000 and 7500 liters (1,000 and 2,000 gallons); one end is connected to an inlet pipe and the other to a . Generally these pipe connections are made with a T pipe, allowing liquid to enter and exit without disturbing any crust on the surface. Today, the design of the tank usually incorporates two chambers, each equipped with a manhole cover, and separated by a dividing wall with openings located about midway between the floor and roof of the tank.

Wastewater enters the first chamber of the tank, allowing solids to settle and scum to float. The settled solids are anaerobically digested, reducing the volume of solids. The liquid component flows through the dividing wall into the second chamber, where further settlement takes place. The excess liquid, now in a relatively clear condition, then drains from the outlet into the , also referred to as a leach field, drain field or seepage field, depending upon locality. A is required prior to installation to ensure the porosity of the soil is adequate to serve as a drain field.

The remaining impurities are trapped and eliminated in the , with the excess water eliminated through into the soil, through , and by uptake through the system of and eventual or entering or . A piping network, often laid in a stone-filled trench (see ), distributes the wastewater throughout the field with multiple drainage holes in the network. The size of the drain field is proportional to the volume of wastewater and inversely proportional to the porosity of the drainage field. The entire septic system can be operated by gravity alone or, where topographic considerations require, with inclusion of a lift . Certain septic tank designs include or other devices to increase the volume and velocity of outflow to the drainage field. These help to fill the drainage pipe more evenly and extend the drainage field life by preventing premature clogging or .

An is a two-stage septic system where the sludge is digested in a separate tank. This avoids digested sludge with incoming sewage. Also, some septic tank designs have a second stage where the from the anaerobic first stage is aerated before it drains into the seepage field.

A properly designed and normally operating septic system is odor-free. Besides periodic inspection and emptying, a septic tank should last for decades with minimal maintenance, with concrete, fiberglass, or plastic tanks lasting about 50 years.

Why Tank

About the advantages of septic tanks Tank

If during the construction of a house the question arises of choosing a suitable sewerage system, an autonomous sewage system for giving a Tank can be considered as a contender for this role, since it has a number of advantages compared to similar devices:

- The polypropylene ribbed molded body is highly durable, which provides the septic tank with a long time of operation without damage.

- The installation of a septic tank is much faster than the construction of reinforced concrete rings that have already become traditional or the laying of brick walls of a wastewater pit.

- Combined purification of domestic wastewater using biological and chemical processes, as well as post-treatment on the infiltrate, allows for particularly high-quality purification of waste water.

- Multi-stage cleaning allows you to increase the service life of the drainage system many times over.

- The ability to perform mandatory cleaning of the septic tank not every year, but once every 5-8 years.

The scheme of the Tank

How do tank septic tanks work?

According to its design, the autonomous sewerage of a private house Tank, consisting of several sections, is quite understandable and simple. Consider the principle of its work:

- The pipe entering the first section directs all drains discharged from residential and utility rooms into it. Here, a mechanical separation of the solid phase from the liquid occurs: solid particles sink to the bottom, water accumulates above the sediment, and the fat present in the drains collects on its surface.

- Water that has undergone primary clarification is transferred through the overflow pipeline system to the second section of the installation, where it is purified using chemical reagents.

- The third section of the septic tank is a biofilter, where water undergoes biological treatment.

- Country sewerage The tank includes a filtering platform, located near the installation. After passing through three stages, water enters the infiltrator for post-treatment.

Autonomous sewer sections Tank

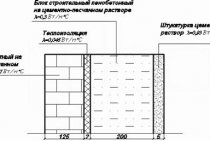

Septic installation diagrams

With well-absorbing soils, a standard installation scheme is used. In this case, a hole is dug 50–60 cm deep more than the height of the main body. In terms of width and length, this pit should also exceed the dimensions of the station by 60 cm.

Further, a sand cushion 10 cm thick is formed at the bottom and a treatment structure is installed on top of it. It is not necessary to pour an “anchor” under it or lay concrete or aerated concrete blocks. After installation in place on top and sides, the septic tank is covered with a sand-cement mixture. In the northern regions, insulation is additionally laid on top.After that, everything is sprinkled with a layer of earth of 30–35 cm.

Installation diagram of a septic tank Tank for absorbent soils

The filtration field on absorbent soil is formed behind the septic tank at a distance of 2–40 meters from it. Between themselves, they are connected by a straight pipe at a slope of 1-2 degrees. The drainage filter under the infiltrator is made from a 40-cm layer of crushed stone. In addition to the latter, you can take a brick, broken tiles or other moisture-resistant building materials.

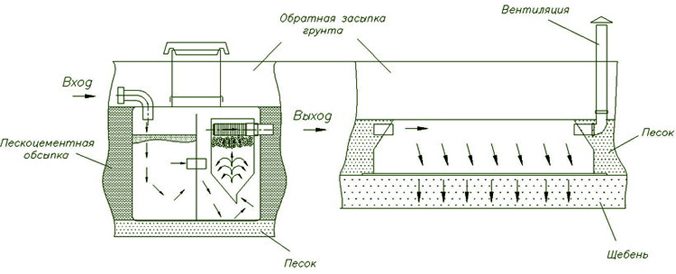

If the soils in the area are clayey or the GWL is high, then the “Tank” will have to be installed according to the scheme with a filtering trench and a storage well. Purified water in this case will gradually accumulate in a special reservoir, and then pumped out to the ground or for removal by a sewage barrel.

Installation diagram of a septic tank Tank for non-absorbent and poorly absorbent soils

With this installation, the outlet from the septic tank does not go into the plastic infiltrator, but directly into the filter layer of crushed stone. Below, under this filter, another one is equipped with a receiving pipe, which is already connected to the drive.

General scheme of the principle of operation

Environmental concerns

A septic tank before installation, with manhole cover on top

The same tank partially installed in the ground

While a properly maintained and located septic tank does not pose any more environmental problems than centralized municipal sewage treatment, certain problems could arise with a septic tank in an unsuitable location. Since septic systems require large , they are unsuitable for densely built areas.

Odor and gas emissions

Some constituents of wastewater, especially , under the anaerobic conditions of septic tanks, are reduced to , a and gas. may also be released. and can be reduced to . Because of the anaerobic conditions, processes take place, which may generate and/or .

Nutrients in the effluent

Septic tanks by themselves are ineffective at removing compounds that have potential to cause in waterways into which affected water from a septic system finds its way. This can be remedied by using a nitrogen-reducing technology, or by simply ensuring that the leach field is properly sited to prevent direct entry of effluent into bodies of water.

The fermentation processes cause the contents of a septic tank to be anaerobic with a low potential, which keeps in a soluble and, thus, mobilized form. Phosphates discharged from a septic tank into the environment can trigger prolific plant growth including algal blooms, which can also include blooms of potentially toxic .

The soil’s capacity to retain phosphorus is usually large enough to handle the load through a normal residential septic tank. An exception occurs when are located in sandy or coarser soils on property adjacent to a water body. Because of limited particle surface area, these soils can become saturated with phosphates. Phosphates will progress beyond the treatment area, posing a threat of to surface waters.

Ground water pollution

In areas with high population density, beyond acceptable limits may occur. Some small towns experience the costs of building very expensive centralized wastewater treatment systems because of this problem, due to the high cost of extended collection systems. To reduce residential development that might increase the demand to construct an expensive centralized sewerage system, building moratoriums and limitations on the of property are often imposed. Ensuring existing septic tanks are functioning properly can also be helpful for a limited time, but becomes less effective as a primary remediation strategy as population density increases.

Surface water pollution

In areas adjacent to water bodies with fish or intended for human consumption, improperly maintained and failing septic systems contribute to pollution levels that can force harvest restrictions and/or commercial or recreational harvest closures.

Principle of operation

The septic tank works like this:

- drains enter the first chamber - it is the largest in size and is called the reception room. The processes taking place in it are characterized as settling, designed to divide the effluent into heavy particles that settle to the bottom, and into light fats that concentrate in the upper part;

- in the second chamber, where the water from the first part of the Tank septic tank enters already clarified, additional clarification takes place in the sludge mode;

- the third chamber, where clarified effluents enter through a pipe system, has a cyclone-shaped bio-purification filter. Its purpose is to ensure the decomposition of organic matter. Floating loading gives the chance to detain suspensions inside;

- provided that the sewerage tank is equipped with an infiltrate, the pipes leaving it deliver effluents purified up to 75% to the infiltrate, where the purification efficiency is up to 100%;

- from the infiltrate, the treated water flows directly into the ground; in this case, a drainage trench, well or filtration field is not required. In the absence of infiltration, it is necessary to equip a trench for drainage or a filtration field, which requires additional space.

The septic tank is suitable for both summer cottages and cottages.

Emptying

A vacuum truck used to empty septic tanks in Germany

Waste that is not decomposed by the anaerobic digestion must eventually be removed from the septic tank. Otherwise the septic tank fills up and wastewater containing undecomposed material discharges directly to the drainage field. Not only is this detrimental for the environment but, if the sludge overflows the septic tank into the leach field, it may clog the leach field piping or decrease the soil porosity itself, requiring expensive repairs.

When a septic tank is emptied, the accumulated sludge (septage, also known as fecal sludge) is pumped out of the tank by a vacuum truck. How often the septic tank must be emptied depends on the volume of the tank relative to the input of solids, the amount of indigestible solids, and the ambient temperature (because anaerobic digestion occurs more efficiently at higher temperatures), as well as usage, system characteristics and the requirements of the relevant authority. Some health authorities require tanks to be emptied at prescribed intervals, while others leave it up to the decision of an inspector. Some systems require pumping every few years or sooner, while others may be able to go 10–20 years between pumpings. An older system with an undersize tank that is being used by a large family will require much more frequent pumping than a new system used by only a few people. Anaerobic decomposition is rapidly restarted when the tank is refilled.

Services for de-sludging tend to empty a septic tank completely, i.e. take out all septage, although the actual removal of settled solids is left purposefully incomplete, so as to leave at least some of the microbial populations in place to continue the anaerobic degradation processes that take place in a septic tank.[citation needed] An empty tank may be damaged by hydrostatic pressure causing the tank to partially "float" out of the ground, especially in flood situations or very wet ground conditions.

Some information about the manufacturer

The most popular Tank model in the domestic market is produced by Triton Plastic LLC. This company is today one of the largest manufacturers of energy-independent cleaning structures. She also produces various plastic products, without which it would be difficult to achieve a comfortable environment in a country house.

With a well-developed dealer network,as well as its own warehouses in many regions of the country, the company was able to ensure the supply of its products to the most remote corners of Russia. One of its brainchildren is the Tank 3 product, which appeared thanks to the professionalism of the employees and the extensive experience in the production of such products.

watch the video, the production of this model:

The company's own design department allowed us to quickly process all requests and calculate the cost of products. At the same time, the quality of each product is checked in the technical control department, so the company's models are highly reliable and efficient. The presence of modern equipment at the production facilities allows us to produce plastic products of any complexity.