Installation of ground heating system

The heating cable or heating mats for the greenhouse should have a power of 75–100 W/m kV.

cable floor

Installation of electric cable heating of the soil in the greenhouse is carried out in the same way as the water circuit:

- A pit is prepared with a depth of 50 cm, a heater is laid on the bottom, but in this case waterproofing made of thick PVC film is necessarily laid.

- Then everything is exactly the same: a layer of sand, a mesh, a cable, again a layer of sand and a protective mesh.

After installation, it remains to connect the cable and thermostat to the control unit and set the desired heating parameters.

Fundamental rules:

- It is permissible to install a stove or boiler both in the dressing room and in the greenhouse itself. However, a foundation is needed. For a brick stove, a concrete foundation is built, and for a metal stove, from a sheet of steel or from an asbestos-cement mixture. The design must be as stable as possible, and it is also necessary to comply with all fire safety measures;

- The seams between the parts of the flue pipe and the gaps at the junctions with the stove or boiler must be sealed so that smoke does not enter the greenhouse.

Clay mortar is used as a sealant, since it is heat resistant.

Regardless of the method of heating in the winter greenhouse, it is necessary to install an air ventilation system:

- Only metal pipes with the same diameter are connected to the outlet and inlet of the boiler, the length may be different. Plastic pipes are installed at a distance of 1-1.5 meters from the boiler;

- Before installing the element for heating the soil, an expansion tank is installed. It is installed at the highest point of the building, close to the stove or boiler.

Instructions for mounting the element for ground heating:

- Lay heat-insulating material (foam plastic, insulators with foil, special mats) in the base of the greenhouse. The use of material contributes to protection against loss of heat and energy, as well as reliable fixation of pipes with hot water;

- Place plastic pipes on the film. Lay pipes start from the walls to the center of the greenhouse. This arrangement contributes to uniform cooling and energy transfer from pipes to the ground throughout the greenhouse. It is not recommended to use steel, because wet soil will cause corrosion, the pipes will collapse and pollute the soil. Also, do not use pipes that have low heat transfer;

- Connect pipes to the heating system. To automatically control the water temperature, it is necessary to install a thermostat on the heater. The optimal temperature regime for cultivated plants is from 35 to 40 ºС;

- Cover water heating pipes with soil (40 to 50 cm thick).

This layer helps prevent thermal damage to the root system.

This option allows you to heat the greenhouse no worse than when using water. Installation takes place as follows:

- It is necessary to remove the fertile layer to a depth of 40-60 cm.

- The bottom is leveled so that there are no protruding elements, and then sand is poured, which acts as a leveling bed.

- The polyethylene film serves as a waterproofing, it is overlapped or adhesive tape is used to connect the sheets.

- On top you need to lay thermal insulation, which does not have a reflective coating.

- Now you can start laying the heating elements. The material must be cut to fit the configuration of the greenhouse. Mounting plates are used to fix cables. The conductors can be placed arbitrarily, but at the same time, a distance of at least 10 cm must be left between the threads.

- It is necessary to connect all the segments into a single chain, insulate the couplings and bring them out on one side. It remains to power the system and ring.

- Polyethylene should be laid on top of the infrared film.

- For heating elements, you will need wet sand, which will serve as a covering layer.

- A mesh of metal with small cells is placed on top of the sand.

- At the last stage, it remains only to return the soil layer to its place and lay pipes equipped with a temperature sensor in its middle.

Features of the first start

Mounting a warm water floor with your own hands in a private house is only half the battle.

The heating system must be able to correctly start and configure, its durability and efficiency depend on it:

- First of all, let the air out. This is done gradually contour by contour. You cannot open all the loops at once. The circulation pump is set to minimum speed.

- The boiler starts up at the minimum temperature (30-40⁰С) with a gradual increase by no more than 1-2⁰С per day. At the same time, the supply and return temperatures on each loop are controlled, and the coolant flow rate is set.

Before the first start-up of the system, the screed must harden and dry. Additional gradual drying of the screed by starting the circuits will avoid temperature shock and cracking.

Knowing the basics of how to make a water heated floor yourself, it is not difficult to bring the idea to life. If everything is done correctly, then the costs and efforts will pay off with a vengeance in just 2-3 years.

I made a site about homemade products myself.

Ground heating cable

Heating the soil in a greenhouse with a cable differs significantly from other methods, since it provides heat not only for the air in the structure, but also for the soil. At the same time, its temperature can change at different stages of plant growth due to the presence of temperature sensors on the cable. This is an important feature that has a positive effect on the state of fruit crops. It ensures their growth and development.

Since the cable is stationary, it is always ready to go. There is no need to carry out its dismantling or other work when the season is over. It is an integral part of the design. If there is no need to use it, then just turn off the device.

The cable is located around the entire perimeter of the greenhouse. This allows him to evenly distribute heat in it. In addition, the cable is completely safe for human health, the environment and the plants themselves. Therefore, this heating method is often used.

Options for heating the soil in the greenhouse

To heat the soil in greenhouse buildings, various types of underfloor heating are used. Equipment is selected depending on the operational features and area of the greenhouse.

water system

Underfloor heating water type is considered a fairly effective and fairly economical option. But its installation requires the presence of a heater and a pumping group. It is not entirely reasonable to purchase such equipment specifically for heating a greenhouse, since its cost is quite high. Therefore, the installation of the water system is carried out mainly in greenhouses located at a distance of no more than fifteen meters from the boiler intended for heating the house.

Water heated floor is not very suitable for a greenhouse

Of no small importance when using a warm floor for greenhouses with a liquid heat carrier is the size of the heated area. Large areas still require a separate installation of a heating boiler

And in order to achieve the required temperature in the winter season, it becomes necessary to combine a warm floor with a radiator system.

heating cable

Electrical cable equipment is widely used for soil heating in greenhouses with a fairly large area. The laying scheme of this floor is quite simple, so you can do the installation work yourself.

During operation, the cable-type heating system does not require manual temperature adjustment, since all control is carried out using a temperature sensor.

When choosing electric heating equipment for a greenhouse, special attention should be paid to the power of the device. For effective heating of the soil, this indicator must be at least 75 watts per square meter

The main condition for the installation of the cable system is the presence of an operating electrical network.

infrared heaters

The film heat-insulated floor has a reliable waterproof covering. The infrared heat emitted by the carbon heating elements has a beneficial effect on plants grown in greenhouses. But its use for large areas has significant drawbacks - a low level of soil heating and low resistance to mechanical stress.

Film floor heating has a low level of ground heating

In this regard, infrared heaters are used in small greenhouses where seeds are germinated or seedlings are grown.

Work order

At the first stage, it is necessary to remove the fertile soil to a depth of half a meter. Then a layer of thermal insulation is laid, while you must not forget to tamp the base. A film and a layer of sand about 50 mm are applied over the insulation.

At the second stage, the pipe is laid, it will need to be covered with the same sand.

The greenhouse soil will warm up as follows:

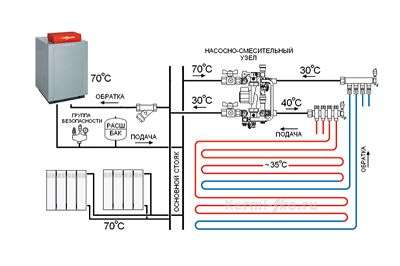

- The mixing unit includes a pump and a three-way valve. If the coolant is run on the radiator, then large financial expenses will be required.

- The water supply to the underfloor heating will be carried out through the return line from the radiators.

Thanks to this arrangement, a polycarbonate greenhouse with a warm floor is obtained.

As for the material for pipes, you can take different options: polymers or steel. When choosing a polymer version, care must be taken. A protective mesh is used to cover the pipes, and only fertile soil is poured over it. The branch pipes remaining outside must be connected to a collector located next to the greenhouse.

How temperature is maintained

The best option for maintaining temperature indicators is the use of thermostats. The optimal indicator for most greenhouse crops is from +15 to +20 °C. Some gardeners use greenhouses to grow plants and then transplant them, then the temperature in the room must be maintained at +30 ° C.

If we talk about the calculation of power and heating in a greenhouse with an electric floor, then by installing thermostats, you can significantly reduce electricity costs by up to 30%. All this is achieved due to the fact that the flow of electricity is not all the time. When the temperature drops to the set value, it will become a signal to turn on the heating. As soon as the desired temperature is reached, the thermostat will turn off.

Warm hollow - a win-win option not only for a large agro-industrial economy, but also for a small greenhouse in a country cottage. Such systems allow you to maintain an optimal microclimate in the room, which has a beneficial effect on the quantity of the crop and its quality.

Most gardeners give only positive feedback about underfloor heating in greenhouses. They help increase yield and promote comfortable plant growth.

Home comfort How to make a warm floor in the bath with your own hands? Do-it-yourself water heated floor in the bath

As an additional means of heating the bath, you can choose a floor heating system. The work involves the implementation of several stages, including preparatory work. In order to lay warm p…

Home and family What is the best air freshener in the car: reviews. How to make a DIY car air freshener

How nice it is to get into a car, the interior of which, instead of the pungent smell of smoke, is fragrant with citrus or your favorite perfume. But not all air fresheners offered in stores do the job. Many…

Home comfort How to make a self-leveling floor for a garage with your own hands?

The self-leveling floor owes its name to the technology of the device. This is a variant of the screed by pouring a self-leveling mixture. As a distinctive feature of the self-leveling floor on a cement basis, the t…

Home comfort Do-it-yourself wardrobe-bed. How to make a bed built into the closet with your own hands

One of the most stylish and ergonomic solutions for unusual bedrooms in private houses and apartments is the purchase of furniture such as a wardrobe bed. In its appearance, it is no different from an ordinary bed,…

Home comfort By what principle are floors assembled in baths with their own hands

The device of floors is one of the important points in the construction of a bath.

With their own hands, they are made quite simply. But it's worth knowing a couple of things. The floors in the bath in most cases are made of wood, but there are also…

Computers How to make a cobblestone generator in Minecraft with your own hands

Today we will talk about how to make a cobblestone generator in Minecraft. Having a characteristic gray tint, this material can become the main one in the construction of most structures. In addition, he is a must…

Home comfort The size of the viewing hole. How to make a viewing hole in the garage with your own hands

An inspection hole in the garage is an invariable attribute for a car owner who independently maintains his own car. Therefore, the construction of a garage often begins with the arrangement of a pit. How to build it for all ...

Home comfort How to make floors in the bath with your own hands: device, stages of work, photo

Arranging your own steam room is a multi-stage process. The bath floor is no exception. In order to ensure the drainage of water, equip ventilation, and also provide the room with waterproofing, ...

Home comfort How to make a floor in the garage with your own hands?

Currently, the requirements for floors in…

Home comfort How to make a warm floor with your own hands: a sequence of work

If you do not know how to make a warm floor with your own hands, in the presented article you can find some useful tips. So, first, let's look at how it happens. The design can be water or electric ...

Along with warming up the air, installing a warm floor in a greenhouse with your own hands will significantly increase productivity. The ground heating system in greenhouses is built on the same principle as underfloor heating in residential buildings, although there are some differences in installation.

Greenhouse floor heating options

Before taking on the organization of work and thinking about how to make a warm floor in greenhouses, you need to figure out how the soil is heated. There are several options:

- Water use. This system works on the principle of how warm water floors work, where hot water goes through a pipe system. In another way, this option can be called soil heating using plastic pipes. The method is quite economical in terms of resource use, but often people encounter problems during installation work. Experts advise using water heating for large greenhouses.

- Film warm floors in the greenhouse are equipped in a similar way to the technologies used for residential buildings.

- The use of heat guns also takes place. These devices are ideal for large greenhouses, but a lot depends on the cost of equipment, and the soil can only be warmed up superficially.

- The use of infrared lamps. They are mounted on greenhouse structures. The option is interesting in that several temperature zones can be created in one greenhouse.

How to make a warm floor in a greenhouse with your own hands, video and photo tips

Sand or slag can be used as thermal insulation material. Before backfilling sand, it is recommended to remove small debris: shells and pebbles. The area on which the insulation is poured is well trampled down, and then filled with water - so that the layer as a result is dense, without air bubbles.

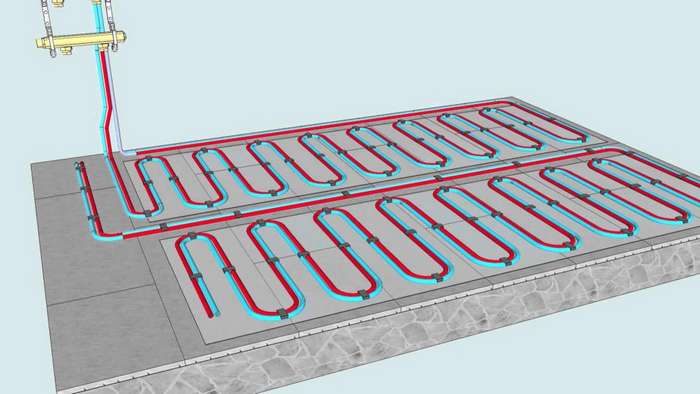

The hose is laid according to the scheme, in the form of a snake. It is worth making sure that these elements are not too close to each other - then they will heat the same area, and the other will remain without heating. The optimal distance is about 80 cm.

To avoid drying out of the soil, a temperature sensor is installed. The wires of the system are brought out. Then a layer of insulation of the same thickness (about 10 cm) is again filled up, watered.

A mesh is laid on the thermal insulation layer (10 cm) (slate can also be used). It will help to securely fix the elements of the system so that they do not change position during operation. In addition, it will protect the elements of the warm floor from damage by garden tools. The price of the mesh can be quite high, but this is the material that should not be saved on.

The mesh is covered with a layer of black soil. The optimal thickness is 25 cm. It is worth considering that after completion of work, it is also necessary to add chernozem to the beds, but the total thickness in any case should not be more than 30 cm.

The last step is to connect the temperature sensor to the thermostat. It will ensure that the temperature in the greenhouse is comfortable for the plants.

A traditional electric (cable) warm floor is connected in exactly the same way, with the exception of one important detail: an electric cable is installed instead of a hose. The infrared film is mounted with your own hands very simply: on a sand screed (later the soil is covered) or simply in the soil

This material has a high efficiency (100%), as it converts electrical energy into thermal energy without loss. At the same time, the film does not burn out oxygen, but ionizes the air in the greenhouse

The infrared film is mounted with your own hands very simply: on a sand screed (later the soil is covered) or simply into the soil. This material has a high efficiency (100%), as it converts electrical energy into thermal energy without loss. At the same time, the film does not burn out oxygen, but ionizes the air in the greenhouse.

How temperature is maintained

The best option for maintaining temperature indicators is the use of thermostats. The optimal indicator for most greenhouse crops is from 15 to 20 ° C. Some gardeners use greenhouses to grow plants and then transplant them, then the room temperature must be maintained at 30 ° C.

If we talk about the calculation of power and heating in a greenhouse with an electric floor, then by installing thermostats, you can significantly reduce electricity costs by up to 30%. All this is achieved due to the fact that the flow of electricity is not all the time.

Warm hollow - a win-win option not only for a large agro-industrial economy, but also for a small greenhouse in a country cottage. Such systems allow you to maintain an optimal microclimate in the room, which has a beneficial effect on the quantity of the crop and its quality.

The most practical way to maintain the temperature is considered to be a thermostat. For the vital activity of plants, the temperature is best in the range of 15-20 degrees. If you plan to use the greenhouse as a nursery, that is, to grow plants for subsequent transplantation, it is better to set the temperature to 30 degrees.

Using the thermostat in automatic mode can significantly save energy - up to 30%. Such efficiency is achieved due to the fact that electricity is not always on: as soon as the temperature drops to a certain level, the regulator turns on and starts heating the soil. When the specified temperature is reached, the thermostat switches off automatically.

The "warm floor" system is ideal not only for large greenhouses in agro-industrial complexes, but also for a small greenhouse in a summer cottage.Installing a soil heating system with a do-it-yourself thermostat allows you to provide the optimum temperature for plants, and hence the yield and quality of products.

Arrangement of the floor in the greenhouse

According to their design and the principle of using the area, greenhouses are of two types: a greenhouse in which the main soil of the site is used, covered with a structure made of a frame covered with polyethylene or polycarbonate, and greenhouses - greenhouses that have a full foundation and are designed for growing crops and seedlings in special containers on shelving or floor.

The latter are often used for growing strawberries according to the Dutch technology, since they provide a crop all year round.

The floor in the greenhouse should not be just soil, since every time after watering it will turn into dirt. It is possible to make an embankment of crushed stone, sand, and even pebbles, but it is rather difficult to move a cart or large bags of soil over such a surface, for example.

In order for such a greenhouse to be not only warm, clean, but also comfortable, the floor is screed with concrete. If funds allow, and the soul requires beauty, you can lay out the floor of the greenhouse with paving slabs, but in the grooves between the tiles, a fungus can form from dampness or ants can start.

In European countries, the floor of the greenhouse is quite often finished with ceramic tiles. Agree, this is very beautiful, and if, for example, you are fond of growing tropical plants, such as palm trees and pineapples, you can even just relax reading a book in such a greenhouse.

When choosing this material, it should be borne in mind that classic tiles for the bathroom floor should not be used, the greenhouse often uses equipment for transporting goods, and the flooring must be quite durable.

The latest innovation in the technical equipment of greenhouses is the use of underfloor heating technology, which not only ensures cleanliness and warmth, but also directly heats the soil in containers. Of course, many will immediately think: “How economical and safe is it?”. As practice shows, the high cost of such a floor lies only in its arrangement. A screed will also be required here, and many farm enterprises, in order to save money, purchase Birss dry mixes at a wholesale price, which also provide waterproofing.

Whatever type of finish you choose, when arranging the floor in the greenhouse, you need to remember about drainage channels and drainage systems, especially if you plan to install automatic irrigation in the greenhouse. To keep the floor level even, the water drainage system can be made using a web of pipelines built into the floor screed.

Water heated floor for greenhouse

This technology is most often used for heating greenhouse soil. Water heating provides heating of soil and air inside the dome of the greenhouse.

Connecting the floor contour rings

Water heating of the soil in the greenhouse is expensive, but only in installation. In operation, it is much more economical and reliable than electrical systems. To ensure automatic regulation of the system, a 220 V power supply is required. Thermostats, ventilation and a circulation pump will be connected to the network.

The boiler is mounted on the foundation, a sandwich pipe is installed for the chimney.

Technology for the implementation of a water-heated floor in a greenhouse on a sand cushion:

- First, a layer of soil 40–50 cm is removed over the entire heated area, equal to the total thickness of the underfloor heating cake. For better thermal insulation, foam can be laid at the bottom of the pit.

- The bottom of the pit is leveled, compacted, 10 cm of sand is poured. Sand is spilled and also compacted.

- Then a reinforcing metal mesh with a large cell is laid. Pipe rings will be attached to it.

- For the water circuit, polymer pipes are usually taken.They are easy to solder, resistant to corrosion and easily bent to a given radius. The rings are fixed on the grid with wire or nylon clamps.

- The contour is filled up flush with sand and covered with a reinforcing mesh. It will protect the circuit from damage by a garden tool.

- At the end, a layer of chernozem is poured with simultaneous laying of temperature sensors in the soil.

In order not to limit the operation of the boiler, in which the fuel burns inefficiently, the heating system is performed according to the Tichelman scheme. In this case, the floor circuit will be a return after the coolant passes through the air heating radiators.

Tichelman scheme

To increase the temperature inertia of the system and avoid sudden temperature changes, a heat accumulator must be provided in the system. For a greenhouse, a home-made welded tank insulated with mineral wool is suitable.

The advantages of such a connection are that there is no need to install a complex manifold group with a three-way valve and a servo drive for mixing cold water into the floor circuit. A coolant cooled to normal will go under the ground.

The use of a water heating system for the soil is more effective when the greenhouse is located next to a house that has a local source of hot water. A water heater or boiler is used to heat water.

When the greenhouse is located at a long distance, pipes are laid from the house to the greenhouse underground. It will take additional effort and resources to isolate the pipes passing along the street. As well as the installation of an additional apparatus for heating the greenhouse. The heating system consists of:

- Heating boiler or furnace;

- pipes;

- expansion tank;

- flue;

- circulation pump.

Types of heating boiler:

- Gas;

- Electric heating;

- For solid fuel;

- Brick or metal stove on coal or wood.

The latter option is easy to install and also the most economical. It is not difficult to build a small brick stove with your own hands, but instead of coal and firewood, use sawdust and other wooden and paper household waste.

According to the selected heating source, a chimney is also selected:

- brick;

- From asbestos and cement mixture;

- metal;

- Double-sided "sandwich" pipe.