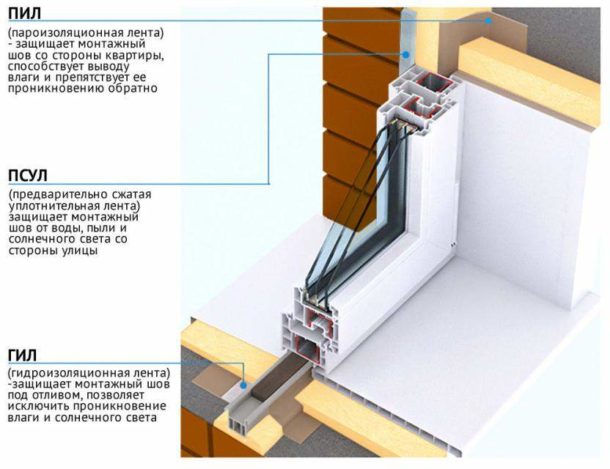

A special PSUL tape for windows will help to ensure high-quality and reliable sealing of seams and joints during the installation of window and other structures. PSUL is a pre-compressed sealing material presented in the form of a self-adhesive tape. Let's consider the main characteristics and scope of this sealant, find out how to understand its marking and get acquainted with step-by-step instructions that will help to carry out trouble-free installation in accordance with all the rules.

Tape Description

Self-expanding tape is a black or gray rectangular strip of elastic porous material resembling foam rubber - porous polyurethane elastomer. It is impregnated with an acrylic-based composition that provides resistance to adverse external influences. One side has an adhesive layer protected by a film.

After opening the roller, unwinding the tape and placing it in the seam, the thickness increases to the parameters indicated in the marking, while the width of the product remains unchanged.

Purpose, scope

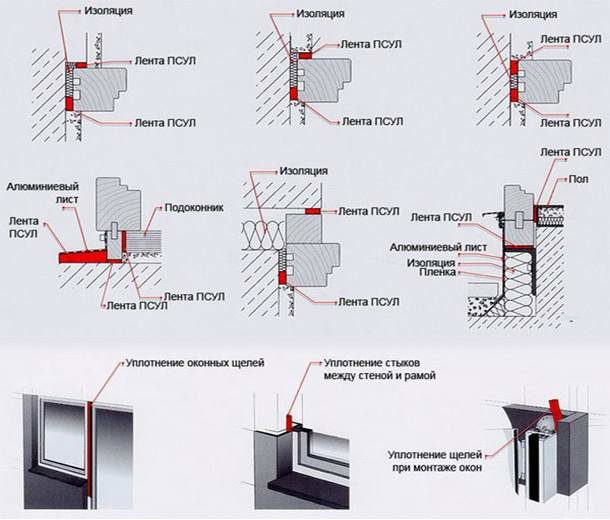

According to GOST 30971-2012, PSUL sealing tape is used to create ventilated assembly joints when installing window blocks. Such a product solves a wide range of tasks:

- protects the mounting foam from moisture and sunlight;

- serves as an obstacle to the development of fungus and mold;

- due to vapor permeability, it removes moisture formed in the pores of the foam due to condensation during temperature changes, to the outside;

- increases the service life and reliability of the seam;

- prevents freezing and seepage of water, penetration of air from the street and dust into the building.

In addition to insulation and protection of seams during the installation of plastic windows in accordance with GOST, PSUL tape is used for the following purposes:

- sealing the seams of concrete parts, window sills, gaps between the wall and window and door frames;

- sealing dormer windows, openings, roof structures;

- isolation from noise and vibration during the installation of air conditioners, fans;

- sealing joints of parts of prefabricated structures, roof elements, non-pressure pipelines (sewerage, storm drains);

- external insulation of wall panel joints;

- sealing the joints of wall beams made of wood and other building elements;

- filling cracks and gaps at the junction of the chimney to the roof, the joints of the ventilation duct.

Due to the specific properties of the material, self-expanding tapes can seal joints with uneven surfaces.

Technical characteristics and properties PSUL

The PSUL sealing tape has the following properties:

- resistance to various natural factors - precipitation, ultraviolet radiation, etc.;

- resistance to deformation;

- compatibility with any materials;

- maintaining elasticity throughout the service life;

- chemical neutrality;

- water-repellent properties;

- resistance to mold and mildew;

- the ability to withstand pressure up to 600 kPa for several hours;

- high heat and sound insulation characteristics.

Specifications of the self-expanding material in the form of polyurethane foam tape with acrylic impregnation:

- operating temperature - from -50°С to +90°С (varies depending on the brand within 5°С);

- resistance to deformation - from 14%;

- dimensions in thickness in a compressed form - from 2 mm, in an expanded state - up to 8 cm;

- thermal resistance - up to +1000°С;

- fire resistance class according to GOST 30402-96 - B1 (flammable building materials).

Indicators of water resistance and frost resistance according to GOST

The state standard GOST R 53338-2009, which contains a description of the material and its classification, divides self-expanding tapes into 3 classes according to the limit of water tightness in a state of working compression:

- Class A - over 600 Pa.

- Class B - not less than 400–600 Pa.

- Class B - not less than 200–399 Pa.

Also, the specified GOST provides for the division of products into types of execution:

- I - optimal for regions with an average monthly air temperature in the coldest season of up to -10°C. The minimum operating temperature is -25°C.

- II - for regions with an average monthly January temperature of up to -20°С. Minimum operating temperature - -45°С

- M (frost-resistant option) - for regions with an average monthly temperature in January below -20 ° C. Minimum operating temperature - -55°С

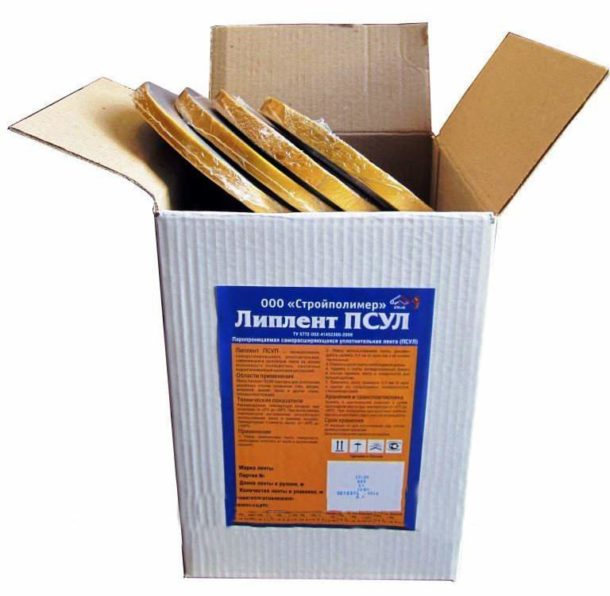

Tape marking

Tape labeling should include:

- Trademark name.

- Sealant class in terms of water tightness limit.

- The numbers represented by a fraction, where the numerator is the width of the product, and the denominator is the range of the optimal width of the sealed gap.

- GOST number.

Example:

Liplent PSUL A 20/8–20 GOST R 53338-2009

Tape of the brand "Liplent PSUL", class "A" in terms of water resistance, 20 mm wide, suitable for sealing joints with a thickness of 8–20 mm.

The type of product for frost resistance is indicated additionally.

Manufacturers

PSUL and the technology for its application were developed by the German company Illbruck, which is its first manufacturer. The most famous domestic products are Profband PSUL and Liplent PSUL. Decent quality has Belarusian products PSUL-EUROBAND.

Ribbon selection

When choosing a self-expanding sealant, it is necessary to focus on the following parameters:

- The width of the adhesive layer - the strength of gluing depends on it. When installing windows, you should choose a tape with a width of 2 cm or more.

- The degree of expansion of the product - determines the density of filling the gap. The optimal value is 20–30% of the initial compressed state, but not more than 60%.

When buying, do not forget to ask the seller for a certificate of conformity.

Installation

PSUL is completely ready for use, its installation does not require the use of special tools and devices. The sealant is selected according to the width of the seam.

The installation of the pre-compressed sealing tape proceeds as follows:

- The PVC window and window opening are being prepared for installation. To do this, dirt and loose plaster are removed, the surface is cleaned of dust with a vacuum cleaner, wiped with a damp cloth.

It is recommended to treat the surface of joints and seams with a special dedusting compound.

- The surface of the quarter is covered with an acrylic primer for outdoor use.

- Marking is done, fasteners are installed.

- A few centimeters (3-5) from the beginning and end of the roller are cut off and not used. A piece of sealant of the desired length is cut off, the paper layer is removed.

- The tape is mounted on the outer side of the frame facing the street, so, with an indent from the outer edge of the quarter by 3-5 mm. The product is pressed against the surface.

Gluing PSUL occurs end-to-end, there should be no overlap. Vertical seams are filled without tape breaks at cross seams. Do not bend the seal at the corners.

- After filling all the gaps between the window and the wall, you must wait until the tape expands to its free state.

The rate of increase in the thickness of the self-expanding material to the working state:

- at a temperature of 0°C, the tape expands to the optimal size in 48 hours;

- at an outside air temperature of +18–20°C, the expansion process lasts 2–3 hours;

- at +30°C expansion occurs in 0.5 h.

Advice. You can speed up the expansion process of PSUL with a hair dryer.

The last steps after the tape has taken the final dimensions will be the sealant treatment of the joint of the frame and the window opening and its closure with a flashing and drainage.