Device and principle of operation

Structurally, the instrument may have a different principle of formation of the gas-oxygen mixture. Some torches use an oxygen cylinder to supply air, while modern devices take oxygen directly from the atmosphere. More functional devices are equipped with automatic piezo ignition, a protection system, including wind protection, various tips and adapters.

Roof gas burner

Roof gas burner

The propane burner is made of simple structural elements:

- Handle for secure holding of the unit;

- gas pressure regulator;

- gas tube for fuel supply;

- metal distribution nozzle;

- gas hose systems supplying gas with nipples from 6 to 9 mm;

- propane tank.

- oxygen balloon;

- clamps for fastening.

The principle of operation of a propane burner for roofing:

- The burner is connected to the oxygen and propane cylinder reducers using a supply hose system.

- Reducers are mounted on cylinders to create a working welding pressure.

- After assembling the circuit for gas and oxygen, checking the tightness of the connection and fixing the nodes, the gas is opened on the cylinders by means of valves.

- Set the gas pressure to the regime value, and open the valve.

- Fuel is fed through hoses to the propane burner.

- The mixing process is carried out in the injector with the formation of a gas-air environment.

- The working flame leaves the device with a temperature of more than 2000 * C.

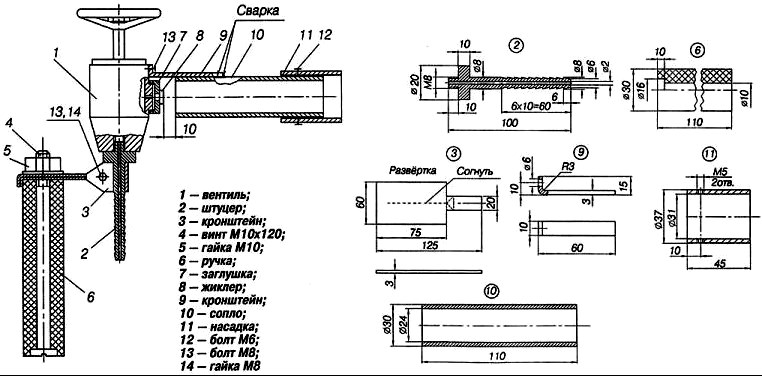

Propane burner device

Propane burner device

Varieties of burners

All devices can be classified according to two parameters: technology of operation and scope.

According to the principle of operation, the following types of devices can be distinguished:

- diffusion, in which the process of mixing gas and oxygen is carried out during combustion;

- injection, where even before the gas enters the combustion chamber, it is enriched with oxygen;

- atmospheric, which, according to the principle of operation, resemble injection, but oxygen is supplied to them to a lesser extent;

- recuperative, where a special device - a recuperator - heats up the gas before mixing it with air;

- regenerative - similar to recuperative ones, but heating to the required degree is carried out by another unit - a regenerator, which first heats up gas and oxygen, and only then supplies it to the combustion chamber;

- inflatable, where air is forced into the combustion chamber using a fan;

- pre-mixed, where oxygen is added near the outlet;

- with incomplete premixing.

Devices are also classified according to their purpose:

- Household appliances characterized by low power. Most often we are talking about atmospheric devices, since their operation is associated with the least number of problems.

- Industrial equipment used in boiler rooms, factories and for heating a large number of residential units. The most common are injection, fan and diffuse devices.

Homemade gas burners

The main components for the manufacture of powerful gas burners are industrial valves. They may be new, but for a homemade device, it is sufficient to use used ones in the absence of a gas leak. They are designed to work in tandem with a 50-liter propane gas cylinder with an angle valve and a reducer.

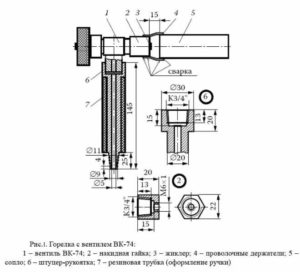

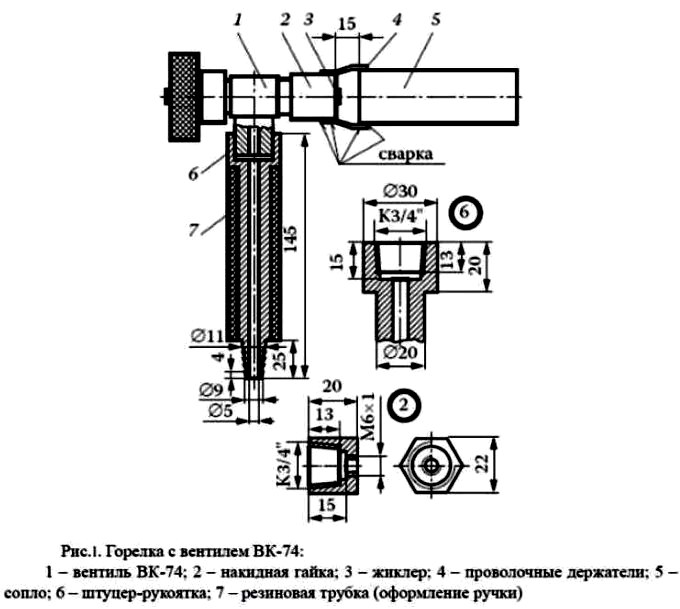

Burner with valve VK-74

The device of this burner is shown in fig. 1. The valve of the oxygen cylinder VK-74 is taken as the basis. A fitting-handle machined on a lathe is installed to the outlet end, to the corrugated part of which a hose from the cylinder is connected.A cap with a prepared threaded hole for the jet is screwed onto the part of the valve with a K3 / 4˝ conical thread, with which it was connected to the gas cylinder. You can use a ready-made version of a blowtorch or gas stove.

The nozzle is made from a piece of steel pipe 1/4˝ 100 mm long and welded to the cap on two pieces of wire ∅5 mm. A distance of 15 mm should be left between the cap and the nozzle for air to enter the combustion zone. By bending the wire holders, the position of the nozzle is adjusted to achieve the center position of the flame.

The sequence of actions for ignition of the burner:

- Open the cylinder valve;

- Bring a lit match to the nozzle and slowly open the burner valve;

- Control gas ignition;

- Regulate the flame with the burner valve

A home-made gas burner of this design has one drawback associated with the peculiarity of the location of the valve. The gas flow is directed in the opposite direction to the normal position. Stuffing box seals experience constant gas pressure (including when the valve is closed), so it is necessary to constantly monitor the tightness of the seals.

Burner converted from acetylene gas cutter

If you have an acetylene torch with a defective oxygen supply valve, do not rush to throw it away. It will also fit for the manufacture of a burner (Fig. 2.). Gas mini burner

Mini gas burners are more suitable for working with small parts. The mini burner is based on a ball inflation needle. It is necessary to make a cut in it, a little further than the middle of the needle. Some needles already have a similar hole, which greatly speeds up the work process. Next, you need to take a syringe needle, and bend it about 45 degrees in the middle.

The pointed end of the syringe needle is best sharpened so that it is straight. After that, it must be inserted into the ball needle in such a way that one end of it comes out through the hole, and the other protrudes from the large needle by several mm. The resulting mini design should be fixed with soldering. After that, droppers must be attached to the bases of the two needles. Clamps - Dropper regulators should be moved as close to the needles as possible. In the resulting burner, they will act as regulators for the supply of gas and air. They also need to be fastened together, and this is best done with a thermal gun. It remains only to connect a source of compressed gas to the finished device, the burner is ready for use. Such a homemade gas burner can heat objects up to 1000 degrees.

It must be handled with care and safety precautions.

Principle of operation

The essence of the working principle of the device is simple: prepare a mixture of gas and oxygen for combustion, ensure a stable supply of the mixture and its combustion.

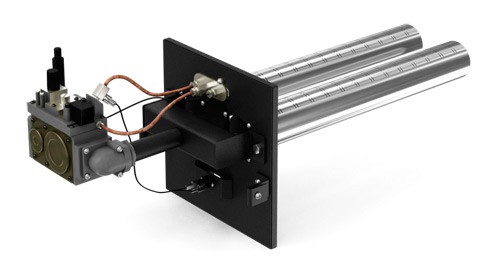

The gas burner is also equipped with additional features aimed primarily at automating and maintaining the safe operation of the equipment. These functions are provided through the use of nodes such as:

- Automation. Due to its use, the gas supply to the burners is stopped in case of an emergency. For example, such a shutdown can occur if the temperature of the igniter falls below the set level.

- Ignition. The device works on electricity or on a piezoelectric element. The ignition operation scheme looks like this: natural gas is supplied to the igniter, where it ignites from a spark (mechanically or automatically), after which the ignition is heated to a certain level, opens the valve and allows the gas to go to the burner.

The device can work on electricity or on a piezoelectric element.

The equipment that is used in boiler rooms is not much different in terms of the principle of operation from household appliances. However, such devices tend to withstand high gas pressure.In addition, industrial equipment is equipped with filters to filter out all kinds of resins and small dust particles. Filtration improves the economy and technological efficiency of equipment operation.

Burner classification

The essence of the operation of gas burners is to ensure stable and continuous combustion of fuel in the combustion chamber of the boiler. The classification of equipment is based on the four main functions of the device, such as:

- the flow of gas and air in proportions that provide the optimal ratio in the mixture;

- direct mixing of gas and oxygen;

- creation of stable combustion;

- ensuring uniform ignition and avoiding an explosion when ignited.

Modulated equipment is classified as a separate class. A distinctive feature of such devices is the ability to automatically adjust to the current needs of the room and the ability to change the combustion power depending on the temperature regime inside and outside the building. In view of these capabilities, this type of equipment is highly economical.

Safety

Gas metal cylinders are explosive, even five-liter cylinders can become a source of a powerful explosion. They were replaced by safer metal-composite and composite materials, which reduced the explosiveness of gas cylinders to zero, since such containers do not explode.

General safety requirements for the use of propane burners

- Personnel are allowed to work when they reach 18 years of age. The welder must have certification and obtain permission to start working with propane equipment, undergo a medical examination and not have medical prohibitions. Prior to the start of work, the personnel are given introductory and primary briefings.

- The welder must know and follow the safety rules when using a propane torch and methods of assistance.

- The welder must have special clothing and footwear and protective equipment.

- Before starting work, tools and equipment are selected and checked for their performance.

- Remove the steel cap with a key.

- Perform an internal inspection of the fittings, remove dirt and purge the valve by sharply turning the valve in the “open-close” direction. If it does not unscrew, then the vessel is considered non-working, it is sent for repair to the gas repair service.

- The propane cylinder is installed in a well-ventilated area with an air temperature above 0C to prevent freezing.

- Before turning on the gearbox, purge its fitting.

- The reducer is attached to the vessel with a closed valve.

- Maximum distances from the place of work: from heat sources - more than 1 m from open flames - more than 10 m.

When working with propane vessels, it is forbidden:

- Carry out inclined installation of cylinders.

- Place the vessels in passage and low-light places, as well as under the sun.

- Work without gear.

- Use hoses from different pieces connected with wire.

- Leave working cylinders unattended.

- Repair a burner connected to a propane tank.

- Warm up the reducer using an open flame.

Criterias of choice

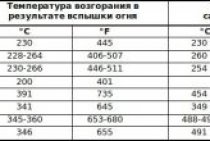

The correct choice of device is carried out, having full knowledge of the technical properties of the metal and the gas used, the former being of paramount importance, especially the refractoriness of the materials being welded.

For soldering copper or cable, you will need a specialized burner, which can be purchased from the distribution network of large cities, for example, in Moscow.

Technical features:

- The power of the flame differs depending on the type of work: desoldering electronic parts is the minimum value, and heating the metal for forging is the maximum value.

- The shape of the flame is also related to the type of operation: shrink work or heat treatment of large surfaces requires a wide flame, and soldering uses a high-precision contour flame in the form of a needle.

- The plastic case is budgetary, it is used for work with a low regime temperature and with short processing periods, otherwise the plastic may melt.

- The stability of the flame is determined by the ability to work at an angle of up to 45.

- The presence of interchangeable nozzles is a desirable equipment for users to be able to perform different tasks.

- Special requirements: form of construction, stability, presence of protective functions, for example, wind protection.

- Options for connecting to spray cans, threaded connections, the most reliable and common with maximum tightness.

- Containers are selected based on the amount of welding work: from 5 to 50 liters.

- The hose must be such that its length is sufficient to reach the place of work.

- A propane reducer is used with a pressure gauge to monitor the presence of gas.

Do-it-yourself propane burner manufacturing technology

In addition to the handle, all components of the propane torch are made on a lathe. The preferred material is brass. The needle for adjustment is made from a knitting needle. Sealing gland for threads, made of PTFE. With these materials, it is quite possible to make a propane burner.

Tools and materials

Manufacturing begins with the selection of tools and parts for work. The body is made in the form of a steel cup, this design provides protection against separation of the torch. A handle is attached to the body, which is made of any material. with length within from 70.0 to 80.0 cm. A gas hose is installed in the holder, which makes the device rigid. The length of the torch is regulated in 2 ways - gear and valve.

Standard propane torch package:

- Metal case.

- Reducer, purchase a ready-made device.

- Nozzle for creating a gas torch.

- Fuel regulator.

- Nozzle (nozzle) for various tasks.

Necessary tools for making a burner with your own hands:

- Hacksaw for metal.

- Electric drill with a set of drills.

- Pliers, files, screwdrivers of various configurations.

- A set of keys, dies and taps.

- Vice locksmith.

Blueprints

A large selection of different designs for soldering metals allows you to find the right option for the user's tasks. For this, you do not need to contact the trading network at all. If the performer has all the necessary materials and tools and is familiar with the manufacturing technology, then the propane burner can be assembled with your own hands, saving on assembly.

Having a detailed drawing, creating a propane burner is not so difficult. You can find a verified drawing on the Internet or use a simple version of the VK-74 model. For reliable operation and fire safety, it is recommended to use a material approved for use in domestic gas supply systems.

Burner manufacturing steps

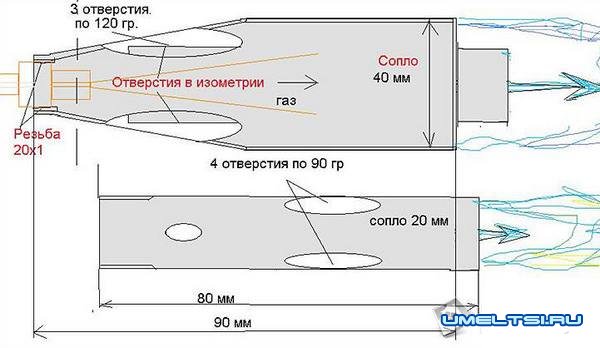

A fitting with a handle function is screwed to the side thread, so a suitable tube is used. An internal thread is cut on one side, and a shank is made on the other for connection to a gas hose. On the thread, connections with the cylinder, screw the plug. At its end, a threaded hole is made for the jet. A nozzle is welded on a plug on steel knitting needles, with the function of an injection chamber.

The body is made of steel, and the divider is made of brass rod. More than 4 holes are made in the divider to circulate oxygen at the cutter outlet.

The divider is installed in the housing with a small gap of 5 mm for the flange. This design provides the necessary deceleration of propane movement to the igniter, which allows for more reliable operation of the torch.

The nozzle is made from a rod. A blind 2mm hole is made in the body, then a jumper with a 4mm hole is made, then it is riveted, ground and connected to the gearbox output.

To give the device a presentable appearance, the metal surfaces are polished. The outlet part of the nozzle is also subject to grinding, to ensure a torch without jerks.

A handle is made and mounted on a propane torch. Handle options are many. You can cut out boards from 5 mm or adapt the handle from an ax and process it to the desired size and attach the base to the tube by making a recess along the width of the drive, and fix it with 2 metal brackets.

When the propane burner is ready, it is connected to a gas vessel and tested. The hose is connected to the gas vessel using a reducer and fixed with a clamp. The free end is inserted into the adapter and is also fixed with a clamp. After completing the assembly of the propane burner, set the working pressure in the vessel. Only after the quality of work is completed, the burner is lit.

Homemade propane burner

Homemade propane burner

The main advantage of using propane fuel is that it is relatively cost effective. For the money, it generates more power than many other fuel sources. It is an efficient combustion fuel, and propane appliances have a much shorter payback period than many other fuel sources. This means that the initial investment in propane combustion equipment pays off faster. Propane is plentiful, but its potential is limited as it is a by-product of oil refining. Properly made propane burner will reliably serve for a long time, will be able to perform many household tasks, without the use of expensive tools.

Nuances and instructions for use

A propane burner is a dangerous device, and therefore, when working with it, you must follow the rules of operation and fire safety

Roofing propane burner, instructions for use:

Carefully and tightly screw the nozzle onto the nozzle.

Connect a hose to the cutter fitting, securing it with a special clamp. Usually they are not supplied in the kit and will need to be purchased separately.

Attach the other end of the hose to the gas vessel.

Check the tightness and reliability of the connections, with the flame regulator closed.

Using soapy water, check the tightness of the connection and gas-air leaks, and with the gas valve on the cylinder open.

Slowly turn the gas regulator counterclockwise and ignite the burner.

It is forbidden to point the torch at flammable materials.

After finishing work, close your gas valve on the vessel.

When the burner flame is out, close the torch flame regulator and allow it to cool.

Dangerous and harmful production factors when working on a roof with a propane burner:

- The occurrence of a fire hazard;

- explosion of a gas tank;

- burns from open fire;

- thermal burn from hot torch surfaces.

The principle of operation of the spark generator, spark block

The principle of operation of the ignition transformer is simple. A voltage doubler is assembled on diode VD1 and capacitor C. With one half-cycle of the mains voltage, the diode is open, the capacitor is charged to the amplitude value of the mains voltage (310 V). At the other half cycle, the diode is closed. The voltage on it, and hence on the thyristor, gradually increases until the moment when the current through the resistor R1 becomes sufficient to open the thyristor. Thyristor opens. A current pulse occurs, which is transmitted through an isolating transformer to the ignition coil. A high voltage and a spark are generated on the high voltage wire. The capacitor is recharged by a voltage of reverse polarity. As soon as this happens, the current drops below the closing current of the thyristor and it closes. The circuit is ready for the next supply voltage cycle.

Making a gas burner from improvised materials in stages

List of materials and tools:• drill; • grinder; • hammer; • sandpaper; • blanks made of brass for the splitter nozzle; • thin brass tube with a diameter of 15 mm; • wooden blocks; • vice; • silicone sealant or FUM tape; • hoses for connection; • valve for adjustment.

How to make a nozzle and a handle

First of all, we take a brass tube and attach a handle to it - for example, from an old burner, or from a wooden block, having processed it before that. In the bar, we drill a hole for a brass tube with the appropriate diameter. Putting the tube into the timber, we fix it with silicone or epoxy.

Next, we proceed to a more time-consuming and lengthy stage of work - the manufacture of the nozzle. The hole size should preferably be 0.1 mm.

With a drill, you can make a slightly larger hole, and then adjust the edges to 0.1 mm. The hole must have the correct shape so that the flame is even.

After that, we fix the workpiece in a vise, take a hammer and carefully, in a vertical plane with a “branch” to the middle of the workpiece, strike the future nozzle. We evenly scroll the product to form an ideal hole.

Then we take sandpaper with fine grit and skin the nozzle head. To connect to the tube, a thread is applied to the back of the product, and the elements can also be simply soldered - but in the future the repair of parts will be more difficult.

Now we attach the device to the gas cylinder and set it on fire - the do-it-yourself burner is ready to go. However, here you can see that to adjust the gas flow, you can only open and close the valve of the gas cylinder, and in this way it is very difficult to obtain the desired flame. What we can do?

How to improve flame control

For the normal operation of our home-made unit, we will install a divider and a crane on it. It is better to mount the faucet near the handle, at a distance of about 2–4 cm, but it can also be mounted on the inlet pipe. As an option, take a burner tap from an old autogen or another similar tap that is threaded. To seal the connection, we take the FUM tape.

The divider is installed on a pipe with a nozzle, it is made of brass, diameter 15 mm. The best option is a cylindrical part, where there is a hole for a tube with a nozzle. If it doesn't exist, do this:1. We take a brass pipe with a diameter of 35 mm and cut off a piece of 100–150 mm.2. We take a marker, step back from the end and mark 3-5 points, with an equal distance between them.3. We drill holes of 8–10 mm in the pipe, take a grinder and make cuts to them evenly.4. We bend everything to the center and weld it to the burner pipe.

Choice of gas burner

When choosing a burner, you need to look at its technical parameters, the method of fuel supply and the principle of mixing gas and oxygen, as well as compatibility with certain devices. Below we briefly describe the five most popular burner models among consumers.

Burner KCHM

Typically used in boilers converted from solid fuel to natural gas or LNG. Equipped with three nozzles and automation. KChM is often used in boilers "Kontur" or similar equipment.

Burner "Hearth"

This is a pneumomechanical device with an automatic mode of operation. The security system automatically stops the combustion process in three cases:

- if the flame went out;

- if there is no necessary traction;

- if the natural gas supply is interrupted.

The "hearth" is equipped with a gas pressure controller, which allows you to achieve uniform combustion even in the event of system failures. Ochag burners are easy to maintain due to the fact that soot does not accumulate in the convective part of the equipment.

Ochag burners are easy to maintain due to the fact that soot does not accumulate in the convective part of the equipment

Burner "Cooper"

This equipment can operate on almost any type of energy carrier.The advantages of this burner include the possibility of its installation without plumbing and welding.

Burner for boilers DKVR

This is a block device where forced oxygen supply is used. Such a device is used in steam equipment for industrial purposes and the corresponding power. The efficiency of such devices reaches 94%. The principle of operation of such burners is inflatable or diffuse. Powerful fans can be used to increase the functionality of the equipment.

Burner for KVS boilers

Such boilers are used for domestic purposes and run on solid fuel. Since there is no need for high power equipment for heating domestic premises, injector or atmospheric devices are most applicable in this case. When choosing a burner for a KVS boiler, you need to look, first of all, at the required power and safety of the device.

The article provides only brief introductory information about gas burners. It will be quite difficult for an unprepared consumer to independently understand all the intricacies of this topic. Therefore, before buying, you should seek detailed advice from a representative of a company selling such equipment.