How to cut foam so that it does not crumble

Expanded polystyrene is a versatile material that is used for heat and sound insulation of buildings under shock and noise loads. When carrying out repair work related to thermal insulation or redevelopment, it is necessary to cut large sheets of insulation. In this regard, the question arises of how to cut the foam to make the line even.

Tools

Consider equipment that finds application for cutting foam at home. These include:

- knife

- hacksaw for metal

- wood saw with fine teeth

- Bulgarian

- soldering iron

- nichrome wire.

Before you start cutting, you need to mark the workpiece with a simple sharpened pencil. If a hacksaw or jigsaw is used as a cutting tool for foam, do not make quick movements. This is due to the good thermal insulating properties of the material, when, when friction occurs, heat is not removed and it heats up, which complicates the process. Use a soldering iron if you need to quickly cut the workpiece. To do this, you need to flatten its end with a hammer and fix a special part, for the manufacture of which you need to take a metal cap of a fountain pen and a blade. After warming up the device, start cutting the sheets.

With the help of a grinder, cut the foam only very thin. It is unlikely that it will be possible to achieve a high-quality cut, the result will be the same as when working with a jigsaw. In addition, with this method of processing the material there will be a lot of debris and noise.

Choosing the right knife

To cut the foam, you can use an ordinary knife, which should be well sharpened and preheated. The clerical version is suitable for cutting soft material, it has a sufficiently flexible blade and is not recommended for processing plates of considerable thickness, since it is difficult to obtain an even vertical cut. The advantages will be a small amount of debris, availability and low cost of the tool. Remember that the thinner the sheet, the more even the cut will be, the optimal thickness should be no more than 5 cm.

The best way to cut

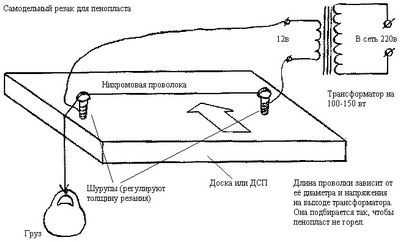

This method can be used if you have a basic understanding of electrical engineering, for the manufacture of fixtures you will need to prepare:

- wire

- transformer

- spring.

The table is placed at an inclination (20-60˚), and a wire is stretched across, one end of which is fixed rigidly, and a spring is used to secure the other. They are connected to the wires of a transformer connected to the electrical network. Current is applied, the workpiece is placed on the table. Sheets are cut as a result of sliding under the action of their own weight.

You can pass current from the power transformer of the old TV. Another option is to include a variable resistance (rheostat) in the electrical circuit. The current strength must be controlled so that strong heating does not occur, which will result in the melting of the foam and the appearance of sagging along the edges of the line.

The attractive side of this method is the ability to cut fragments both in a straight line and along kinks and convolutions, which makes the process universal.

It is important to remember that the wire should not be very hot. It will be enough if it just blushes slightly, otherwise the incision will turn out to be too wide

You should select a strong spring, this will make it possible to adjust the length.

Features of working with large sheets

Do-it-yourself cutting of foam boards is possible using simple but effective equipment, such as steel wire with a diameter of 0.5 mm and wooden handles fixed at the ends. Previously, the block needs to be marked on both sides and start sawing quickly. The thread heats up and melts the material, as a result of which the surface will have a hard, smooth and melted crust. To determine the best way to cut expanded polystyrene (polystyrene), it is necessary to evaluate all the advantages and disadvantages of the listed methods and select a tool based on the characteristics of such cutting.

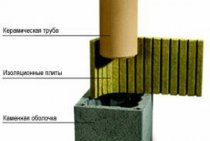

Foam plastering the first stage of wall finishing

Like it or not, but before painting the foam, it should be plastered (with the obligatory creation of a reinforcing layer). The protection performed in this way will ensure the long-term functional suitability of the heat-insulating layer. Regardless of what material the insulated wall is made of, how the final painting on foam plastic will be carried out, the decorative finishing algorithm is as follows:

- A plaster mortar is being prepared, for which the dry mixture is diluted with water in accordance with the manufacturer's recommendations.

- The heat-insulating layer is cleaned of dust and debris to ensure high-quality adhesion of the solution.

- A reinforcing (base layer) is applied to the reinforced heat insulator, namely:

- using a spatula, apply a thin layer of plaster (2 - 3 mm) to an area of \u200b\u200bno more than 2 square meters;

- a reinforcing mesh is embedded in the applied layer of starting plaster (preferably a polymer mesh, since the metal is subject to corrosion and “cold bridges” may appear);

- the operation is performed by smoothing the polymer fiberglass mesh with a spatula;

- the creation of a reinforcing layer begins with the corners - for this, a strip of mesh is folded in half along the length and applied to the corner of the building, so that at least 30 cm of the mesh starts around the corner;

- a sequential recessing of a polymer fiberglass mesh is performed in a thin layer of starting plaster over the entire area of \u200b\u200binsulation.

- The dried surface must be treated with a primer - a primer, which makes it possible to improve the adhesion of the finishing layer of plaster to the base.

- The final layer of plaster is applied, leveled, if necessary - polished.

- Penoplex is painted with facade coloring agents, the choice of which is carried out in accordance with the chemical characteristics of the insulation.

Such a simple scheme for creating a finishing coating, followed by painting the foam, makes it possible to ensure a long service life of the insulation. But you should not rush, since not every paint can be used for foam extruded polystyrene.

How to cut polystyrene so that it does not crumble

Styrofoam or expanded polystyrene refers to a universal material that is used for insulation and sound insulation in building structures. The basis of its structure is formed by foamed plastic. This explains why the foam often crumbles when cutting.

When processing the material, it is necessary to decide how it needs to be cut so that the cut line is even and the crumbs are as small as possible.

Types of tools

Mechanical cutting. The most common tools at hand include a knife, a jigsaw, a saw and a grinder.

Ordinary knife

The main focus when choosing a knife is its blade. If it is sharp, then the cutting process is faster, and less waste is generated.

The knife must be preheated before cutting.

The disadvantage of this method is that the use of a knife is possible with a foam thickness of 1–5 cm.

Disadvantages in use:

- the ability to cut only thin sheets;

- the blade of the knife becomes dull quickly;

Office knife.The clerical version of the knife is best used for soft material. This knife has thin and flexible blades, so it is not practiced for processing thick plates.

Advantages:

- little garbage;

- availability of acquisition;

- low cost.

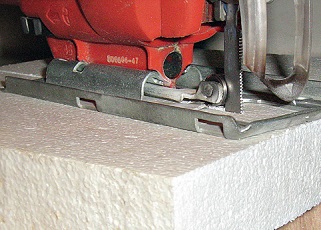

Electric jigsaw. Trimming with a jigsaw is used when cutting foam up to 10 cm in thickness. This method does not require much effort.

Flaws:

- the cut is not perfectly even;

- a sufficient amount of crumb is formed;

- cannot be used in the absence of power supply

Hand saw for wood. If the thickness of the foam reaches 40 mm, then it is better to cut it with a hacksaw for wood. The method is quite simple and fast, without the cost of special physical effort.

A saw with fine teeth is better. This tool is only used for making straight cuts.

"Bulgarian". The advantages of the grinder are that it, as it were, cuts the foam itself, if you use the thinnest circles.

However, it is not recommended to cut thick material with a grinder. You will not get a qualitative result, but there will be an extremely large amount of garbage.

In addition, this option is not very good due to the screeching that occurs when the foam plastic interacts with the circle of the machine. Plus, the noise of the tool's engine is added to it. Therefore, in the case of cutting a large number of foam plates, you should wear headphones from the very beginning. Add to this list also the cost of electricity that you need to pay.

Nichrome wire cutter. The practice of working with foam shows that a high-quality cut is formed when using a tool with a heated wire. The edges are even, smooth, and there are practically no crumbs. The advantages of the method include high cutting speed and productivity in volumes similar to industrial ones.

The active use of the method is hampered by the difficulty of acquiring it due to the lack of it in stores. With an urgent need for a machine, there is only one way out - to make a cutter yourself. This is a separate question, which is devoted to many good articles on the Internet, containing step-by-step instructions and illustrations.

Easy way to cut

Cutting can be done with thin steel wire. It should be fixed on wooden handles. They are located at different ends of the surface intended for cutting. Sawing resembles the process of sawing firewood. You will need an assistant who will take one of the pens. Friction heats the string, so the cut line is even and smooth.

Outcome

From the review, we can make a general conclusion that the process of cutting foam plastic proceeds quite simply and quickly. The processing method is selected depending on the selected tool, the amount of work, the shape (rectilinear, sinuous or volumetric) in which the result is to be obtained.

1 Styrofoam cutting

So, expanded polystyrene, like any other material, needs to be processed before use. Initially, it is supplied in ordinary plates with a certain thickness. However, the shape of the plates is not always enough to use them wherever necessary.

Often the plate has to be cut into pieces, cut, cleaned. Sometimes it becomes necessary to cut off a decorative part on the edge of the slab or make a certain angle.

There are actually a lot of options. But the question remains one. How to cut styrofoam? It would seem, why else invent some additional units, buy a special foam cutter if it’s not something to cut, you can even break it with your own hands. And this is literally.

Here we must turn to the features of the polystyrene itself and. The foam itself consists of small polystyrene beads.

The initial raw material in it is a polymer that is mixed with foam aggregates and air.The result is a rather pliable and very light construction, which is easily cut or broken by hand.

That's just breaking the foam - this is not the best solution. The break line will never be accurate. Styrofoam balls will bend it, making the final design unsuitable for precise work.

However, we still note that it is very easy to break or cut the foam. That is, cutting foam at home is quite real. Another question is how to do this accurately and with minimal damage to the material. This is where a foam cutter or any home-made device will come in handy.