Choosing a heater

The main reason for the freezing of pipelines is the insufficient circulation rate of the energy carrier. In this case, at sub-zero air temperatures, the process of crystallization of the liquid may begin. So high-quality thermal insulation of pipes is vital.

Fortunately, our generation is unspeakably lucky. In the recent past, the insulation of pipelines was carried out using only one technology, since there was only one insulation - glass wool. Modern manufacturers of thermal insulation materials offer simply the widest selection of pipe insulation, which differ in composition, characteristics and method of application.

It is not entirely correct to compare them with each other, and even more so to say that one of them is the best. So let's just look at the types of pipe insulation materials.

By scope:

- for pipelines of cold and hot water supply, steam pipelines of central heating systems, various technical equipment;

- for sewer systems and drainage systems;

- for pipes of ventilation systems and freezing equipment.

In appearance, which, in principle, immediately explains the technology for the use of heaters:

- roll;

- leafy;

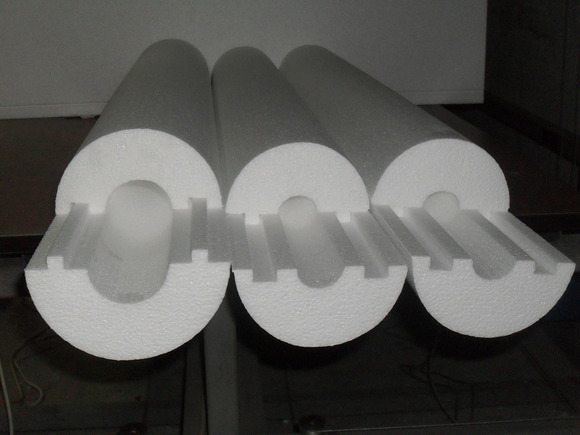

- casing;

- pouring;

- combined (this rather already refers to the method of pipeline insulation).

The main requirements for the materials from which pipe insulation is made are low thermal conductivity and good resistance to fire.

The following materials fit these important criteria:

Mineral wool. Most often sold in the form of rolls. Suitable for insulation of pipelines with high temperature coolant. However, if mineral wool is used to insulate pipes in large volumes, then this option will not be very profitable in terms of savings. Thermal insulation using mineral wool is produced by winding, followed by its fixing with synthetic twine or stainless steel wire.

In the photo, a pipeline insulated with mineral wool

It can be used at both low and high temperatures. Suitable for steel, metal-plastic and other polymer pipes. Another positive feature is that expanded polystyrene has a cylindrical shape, and its inner diameter can be selected to fit the size of any pipe.

Penoizol. According to its characteristics, it is closely related to the previous material. However, the installation method of penoizol is completely different - its application requires a special spray installation, since it is a component liquid mixture. After the penoizol hardens, an airtight shell is formed around the pipe, which almost does not allow heat to pass through. The advantage here is also the lack of additional fastening.

Penoizol in action

Foil foam. The latest development in the field of insulation materials, but has already won its fans among Russian citizens. Penofol consists of polished aluminum foil and a layer of polyethylene foam.

Such a two-layer design not only retains heat, but even acts as a kind of heater! As you know, the foil has heat-reflecting properties, which allows you to accumulate and reflect heat to the insulated surface (in our case, this is a pipeline).

In addition, foil penofol is environmentally friendly, slightly flammable, resistant to temperature extremes and high humidity.

As you can see, there are plenty of materials! There is plenty to choose how to insulate pipes with. But when choosing, do not forget to take into account the characteristics of the environment, the characteristics of the insulation and its ease of installation. Well, it would not hurt to calculate the thermal insulation of pipes in order to do everything correctly and reliably.

Insulation laying

The insulation calculation depends on which laying is used. It can be external or internal.

External insulation is recommended to protect heating systems. It is applied along the outer diameter, provides protection against heat loss, the appearance of traces of corrosion. To determine the volume of material, it is sufficient to calculate the surface area of the pipe.

Thermal insulation maintains the temperature in the pipeline, regardless of the impact on it of environmental conditions.

Internal laying is used for plumbing.

It perfectly protects against chemical corrosion, prevents heat loss from hot water routes. Usually this is a coating material in the form of varnishes, special cement-sand mortars. The choice of material can also be made depending on which gasket will be used.

Channel laying is in demand most often. For this, special channels are preliminarily arranged, and the tracks are placed in them. The channelless laying method is less commonly used, since special equipment and experience are required to carry out the work. The method is used when it is not possible to perform trenching work.

Installation of insulation

The calculation of the amount of insulation largely depends on the method of its application. It depends on the place of application - for an internal or external insulating layer.

You can do it yourself or use the program - a calculator for calculating the thermal insulation of pipelines. Coating on the outer surface is used for hot water pipelines at high temperatures in order to protect it from corrosion. The calculation with this method is reduced to determining the area of \u200b\u200bthe outer surface of the water supply system, to determine the need per linear meter of pipe.

For pipes for water mains, internal insulation is used. Its main purpose is to protect the metal from corrosion. It is used in the form of special varnishes or a cement-sand composition with a layer several mm thick.

The choice of material depends on the laying method - channel or channelless. In the first case, concrete trays are placed at the bottom of the open trench for placement. The resulting gutters are closed with concrete covers, after which the channel is filled with previously excavated soil.

Channelless laying is used when digging a heating main is not possible.

This requires special engineering equipment. Calculating the volume of thermal insulation of pipelines in online calculators is a fairly accurate tool that allows you to calculate the amount of materials without fiddling with complex formulas. Material consumption rates are given in the relevant SNiP.

Published: December 29, 2017

(4 ratings, average: 5.00 out of 5) Loading…

- Date: 15-04-2015Views: 139Comments: Rating: 26

Proper calculation of the thermal insulation of the pipeline can significantly increase the life of the pipes and reduce their heat loss.

However, in order not to make mistakes in the calculations, it is important to take into account even minor nuances.

The thermal insulation of pipelines prevents the formation of condensate, reduces the heat exchange of pipes with the environment, and ensures the operability of communications.

Pipeline insulation options

Finally, consider three effective ways of thermal insulation of pipelines.

Perhaps one of them will appeal to you:

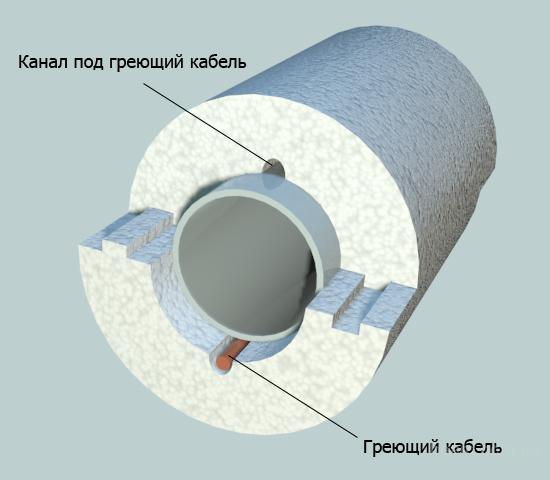

- Insulation with heating cable. In addition to traditional isolation methods, there is such an alternative method. Using a cable is very convenient and productive, given that it takes only six months to protect the pipeline from freezing. In the case of heating pipes with a cable, there is a significant saving of effort and money that would have to be spent on land work, insulation material and other points. The operating instructions allow the cable to be located both outside the pipes and inside them.

Additional thermal insulation with heating cable

- Air warming.The error of modern thermal insulation systems is this: often the fact that soil freezing occurs according to the “top-down” principle is not taken into account. The flow of heat coming from the depths of the earth tends towards the process of freezing. But since insulation is carried out on all sides of the pipeline, it turns out that I will also isolate it from rising heat. Therefore, it is more rational to mount a heater in the form of an umbrella over the pipes. In this case, the air layer will be a kind of heat accumulator.

- "Pipe in a pipe". Here, another pipe is laid in polypropylene pipes. What are the advantages of this method? First of all, the pluses include the fact that the pipeline can be warmed up in any case. In addition, heating is possible with a warm air suction device. And in emergency situations, you can quickly stretch the emergency hose, thereby preventing all the negative points.

Pipe-in-pipe insulation

Calculation of the volume of pipeline insulation and laying the material

- Types of insulating materials Laying insulation Calculation of insulating materials for pipelines Elimination of insulation defects

Insulation of pipelines is necessary in order to significantly reduce heat loss.

Preliminary calculation of the volume of pipeline insulation is required. This will allow not only to optimize costs, but also to ensure the competent performance of work, maintaining pipes in proper condition. Properly selected material can prevent corrosion, improve thermal insulation.

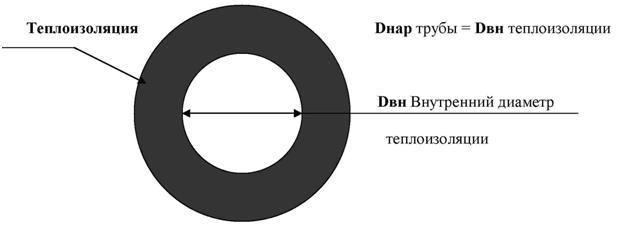

Pipe insulation scheme.

Today, different types of coatings can be used to protect tracks. But it is necessary to take into account exactly how and where communications will take place.

For water pipes, two types of protection can be used at once - internal coating and external. For heating routes, it is recommended to use mineral wool or glass wool, and for industrial ones, purchase polyurethane foam. Calculations are performed by different methods, it all depends on the type of coating chosen.

Characteristics of network laying and normative calculation methodology

Performing calculations to determine the thickness of the heat-insulating layer of cylindrical surfaces is a rather laborious and complex process.

If you are not ready to entrust it to specialists, you should stock up on attention and patience to get the right result. The most common way to calculate the thermal insulation of pipes is to calculate according to the normalized indicators of heat loss

The fact is that SNiP established the values of heat loss by pipelines of different diameters and with various methods of laying them:

Scheme of pipe insulation.

- open way on the street;

- open in a room or tunnel;

- channelless way;

- in impassable channels.

The essence of the calculation is the selection of heat-insulating material and its thickness in such a way that the amount of heat loss does not exceed the values prescribed in SNiP. The calculation methodology is also regulated by regulatory documents, namely, by the relevant Code of Rules. The latter offers a slightly more simplified methodology than most existing technical references. Simplifications are concluded in such moments:

The heat loss during heating of the pipe walls by the medium transported in it is negligible compared to the losses that are lost in the outer insulation layer. For this reason, they are allowed to be ignored.

The vast majority of all process and network pipelines are made of steel, its resistance to heat transfer is extremely low. Especially when compared with the same indicator of insulation

Therefore, the resistance to heat transfer of the metal wall of the pipe is recommended not to be taken into account.

Thermal calculation of the heat network

For thermal calculation, we will take the following data:

· temperature of water in the supply pipeline 85 °C;

· temperature of water in the return pipeline 65 оС;

· average air temperature for the heating period of the Republic of Moldova +0.6 °C;

Calculate the losses of uninsulated pipelines. An approximate determination of heat losses per 1 m of an uninsulated pipeline, depending on the temperature difference between the pipeline wall and the ambient air, can be made using a nomogram. The value of heat loss, determined by the nomogram, is multiplied by the correction factors:

where: a - correction factor taking into account the temperature difference, a=0,91;

b is the correction for radiation, for d=45 mm and d=76mm b=1.07, and for d=133 mm b=1,08;

l — pipeline length, m.

Heat losses 1 m of uninsulated pipeline, determined by the nomogram:

for d=133 mm Qnom=500W/m; for d=76mm Qnom=350 W/m; for d=45mm Qnom=250 W/m.

Considering that heat losses will be both on the supply and return pipelines, the heat losses must be multiplied by 2:

kW.

For heat loss of suspension supports, etc. 10% is added to the heat losses of the most uninsulated pipeline.

kW.

Normative values of average annual heat losses for a heat network during above-ground laying are determined by the following formulas:

where: , - normative average annual heat losses, respectively, of the supply and return pipelines of the above-ground laying sections, W;

, - normative values of specific heat losses of two-pipe water heating networks, respectively, of the supply and return pipelines for each pipe diameter for above-ground laying, W / m, determined by;

l - the length of the section of the heating network, characterized by the same diameter of pipelines and the type of gasket, m;

— coefficient of local heat losses, taking into account the heat losses of fittings, supports and compensators. The value of the coefficient in accordance with is taken for above-ground laying 1.25.

Calculation of heat losses of insulated water pipelines is summarized in Table 3.4.

Table 3.4 - Calculation of heat losses of insulated water pipelines

|

dн, mm |

, W/m |

, W/m |

l, m |

,W |

, W |

|

133 |

59 |

49 |

92 |

6,79 |

5,64 |

|

76 |

41 |

32 |

326 |

16,71 |

13,04 |

|

49 |

32 |

23 |

101 |

4,04 |

2,9 |

The average annual heat loss of the isolated heating network will be 49.12 kW/an.

To evaluate the effectiveness of an insulating structure, an indicator called the insulation efficiency factor is often used:

where QG ,Qand - heat losses of uninsulated and insulated pipes, W.

Insulation efficiency factor:

Method for calculating a single-layer heat-insulating structure

The basic formula for calculating the thermal insulation of pipelines shows the relationship between the magnitude of the heat flux from the existing pipe, covered with a layer of insulation, and its thickness. The formula is applied if the pipe diameter is less than 2 m:

The formula for calculating the thermal insulation of pipes.

ln B = 2πλ [K(tt - tо) / qL - Rn]

In this formula:

- λ is the thermal conductivity of the insulation, W/(m ⁰C);

- K is the dimensionless coefficient of additional heat loss through fasteners or supports, some values of K can be taken from Table 1;

- t is the temperature in degrees of the transported medium or coolant;

- to is the outside air temperature, ⁰C;

- qL is the value of the heat flux, W/m2;

- Rn - resistance to heat transfer on the outer surface of the insulation, (m2 ⁰C) / W.

Table 1

| pipe laying conditions | The value of the coefficient K |

| Steel pipelines openly along the street, along channels, tunnels, openly indoors on sliding supports with a nominal diameter of up to 150 mm. | 1.2 |

| Steel pipelines openly along the street, along channels, tunnels, openly indoors on sliding supports with a nominal diameter of 150 mm or more. | 1.15 |

| Steel pipelines openly along the street, along channels, tunnels, openly in rooms on suspended supports. | 1.05 |

| Non-metallic pipelines laid on suspended or sliding supports. | 1.7 |

| Channelless laying method. | 1.15 |

The value of the thermal conductivity of the insulation λ is a reference, depending on the selected thermal insulation material. The temperature of the transported medium t is recommended to be taken as the average during the year, and the outside air t as the average annual.If the insulated pipeline runs indoors, then the ambient temperature is set by the design specification, and in its absence it is assumed to be +20°C. The index of resistance to heat transfer on the surface of the heat-insulating structure Rn for laying conditions along the street can be taken from Table 2.

table 2

| Rn, (m2 ⁰C) / W | DN32 | DN40 | DN50 | DN100 | DN125 | DN150 | DN200 | DN250 | DN300 | DN350 | DN400 | DN500 | DN600 | DN700 |

| tt = 100 ⁰C | 0.12 | 0.10 | 0.09 | 0.07 | 0.05 | 0.05 | 0.04 | 0.03 | 0.03 | 0.03 | 0.02 | 0.02 | 0.017 | 0.015 |

| tt = 300 ⁰C | 0.09 | 0.07 | 0.06 | 0.05 | 0.04 | 0.04 | 0.03 | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 | 0.015 | 0.013 |

| tt = 500 ⁰C | 0.07 | 0.05 | 0.04 | 0.04 | 0.03 | 0.03 | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 | 0.016 | 0.014 | 0.012 |

Note: the value of Rн at intermediate values of the coolant temperature is calculated by interpolation. If the temperature index is below 100 ⁰C, the Rn value is taken as for 100 ⁰C.

Indicator B should be calculated separately:

Table of heat losses for different thicknesses of pipes and thermal insulation.

B = (dout + 2δ) / dtr, here:

- diz is the outer diameter of the heat-insulating structure, m;

- dtr is the outer diameter of the protected pipe, m;

- δ is the thickness of the heat-insulating structure, m.

The calculation of the pipeline insulation thickness begins with determining the ln B index, substituting in the formula the values of the outer diameters of the pipe and the heat-insulating structure, as well as the layer thickness, after which the ln B parameter is found from the table of natural logarithms. It is substituted into the main formula along with the normalized heat flux index qL and make a calculation. That is, the thickness of the thermal insulation of the pipeline should be such that the right and left parts of the equation become identical. This thickness value should be taken for further development.

The considered calculation method applied to pipelines with a diameter of less than 2 m. For pipes of a larger diameter, the insulation calculation is somewhat simpler and is performed both for a flat surface and using a different formula:

δ \u003d [K (tt - tо) / qF - Rn]

In this formula:

- δ is the thickness of the heat-insulating structure, m;

- qF is the value of the normalized heat flux, W/m2;

- other parameters are the same as in the calculation formula for a cylindrical surface.

Method for calculating a multilayer heat-insulating structure

Insulation table for copper and steel pipes.

Some transported media have a sufficiently high temperature, which is transferred to the outer surface of the metal pipe almost unchanged. When choosing a material for thermal insulation of such an object, they face such a problem: not every material is able to withstand high temperatures, for example, 500-600⁰C. Products capable of contacting such a hot surface, in turn, do not have sufficiently high thermal insulation properties, and the thickness of the structure will turn out to be unacceptably large. The solution is to use two layers of different materials, each of which performs its own function: the first layer protects the hot surface from the second, and the latter protects the pipeline from the effects of low outdoor temperatures. The main condition for such thermal protection is that the temperature at the boundary of the layers t1,2 be acceptable for the material of the outer insulating coating.

To calculate the thickness of the insulation of the first layer, the formula already given above is used:

δ \u003d [K (tt - tо) / qF - Rn]

The second layer is calculated according to the same formula, substituting the temperature at the boundary of two heat-insulating layers t1,2 instead of the pipeline surface temperature tт. To calculate the thickness of the first layer of insulation for cylindrical surfaces of pipes with a diameter of less than 2 m, a formula of the same type is used as for a single-layer structure:

ln B1 = 2πλ [K(tt — t1,2) / qL — Rn]

Substituting the value of heating of the boundary of two layers t1,2 and the normalized value of the heat flux density qL instead of the ambient temperature, the value of ln B1 is found. After determining the numerical value of the parameter B1 through a table of natural logarithms, the thickness of the first layer insulation is calculated using the formula:

Data for calculation of thermal insulation.

δ1 = dout1 (B1 - 1) / 2

The calculation of the thickness of the second layer is performed using the same equation, only now the temperature of the boundary of two layers t1,2 acts instead of the temperature of the coolant tt:

ln B2 = 2πλ [K(t1,2 - t0) / qL - Rn]

Calculations are made in a similar way, and the thickness of the second heat-insulating layer is calculated using the same formula:

δ2 = dout2 (B2 - 1) / 2

It is very difficult to carry out such complex calculations manually, and a lot of time is lost, because throughout the entire pipeline route, its diameters can change several times. Therefore, in order to save labor costs and time for calculating the insulation thickness of technological and network pipelines, it is recommended to use a personal computer and specialized software. If there is none, the calculation algorithm can be entered into the Microsoft Excel program, while quickly and successfully obtaining results.