Materials for thermal insulation

An experienced craftsman has an extensive selection of materials with which to insulate steel thin-walled bathtubs with his own hands. They differ in thermal conductivity, price and method of application. If the wash tank is thermally insulated prior to installation, almost any material that suits the price-performance ratio can be used. The most popular means of insulating steel products are:

-

polyurethane foam sealant. A sealant based on polyurethane foam, popularly known as polyurethane foam, is the optimal material for thermal insulation of a bathtub. It has a low thermal conductivity and high resistance to moisture, easy to apply, fast drying. Many craftsmen choose polyurethane foam for insulating bathtubs because of the affordable price.

-

Sheet foil polyurethane foam. Another material that effectively maintains the temperature of the water in steel tanks is polyurethane foam in the form of self-adhesive sheets. The layer of foil, which is supplied with polyurethane foam, additionally reflects heat into the bowl. With the help of this material, the outer surface of the bath is pasted over with a self-adhesive layer or glue.

Insulation with polyurethane foam advantages of use, application technology

To achieve optimal energy efficiency of the bathroom will allow the use of liquid polyurethane foam as a heater.

To achieve optimal energy efficiency of the bathroom will allow the use of liquid polyurethane foam as a heater. The advantages of the material include high strength, vapor permeability, heat and sound insulation, fire resistance, moisture resistance. Polyurethane foam has a low weight, so it does not exert additional load on the ceiling and walls of the bathroom. The properties of the material allow, polyurethane foam perfectly adheres to any materials. Due to the structure of the insulation, free circulation of air masses in the heat-insulating layer is ensured, therefore, there is no need to lay hydro and vapor barrier films.

The low coefficient of thermal conductivity of the thermal insulator allows you to apply polyurethane foam in a thin layer. As a result, a monolithic uniform coating is obtained, which completely eliminates the formation of cold bridges and the accumulation of condensate under the heat-insulating layer.

Polyurethane foam is sprayed onto insulated surfaces using special equipment, and the technology of its application makes it possible to insulate even rooms with a complex configuration.

Polyurethane foam is sprayed onto insulated surfaces using special equipment, and its application technology allows. The biological and chemical resistance of polyurethane foam eliminates the destruction of the heat-insulating layer, as well as the formation of fungus and mold.

The polyurethane foam layer is sheathed with moisture-resistant finishing materials, for the fastening of which a frame is equipped. The small thickness of the heat-insulating layer allows you to save the useful area of the bathroom, and you can start finishing the insulated surfaces already 30 minutes after applying the thermal insulator.

The polyurethane foam heat-insulating layer does not lose its characteristics under the influence of high temperatures, therefore, there is no need to additionally shield the places of its contact with heating equipment.

Video on how polyurethane foam is sprayed from Ecotermix:

Tips and tricks for insulating a bathroom with mineral wool mats

Mineral wool consists of mineral fibers, such a composition of the insulation allows the heat-insulating layer to "breathe", therefore, it prevents the formation of condensate on the walls and ceiling of the room.

When insulating with mineral wool, its hygroscopicity should be taken into account, therefore the heat-insulating layer must be isolated from contact with moisture. In order to ensure high-quality waterproofing of the insulation layer, hydro and vapor barrier layers are mounted.

When carrying out thermal insulation work, it is necessary to carefully monitor the integrity of the vapor and waterproofing layers, since a violation of their tightness will allow the insulation to absorb moisture, which will negatively affect the thermal insulation properties of the material.

Mineral wool is used to insulate the walls and ceiling of the room. For thermal insulation, it is better to choose mineral wool mats, and not insulation in rolls. Thermal insulation boards have increased rigidity, and the technology of fixing them between the frame guides will prevent the insulation from slipping from vertical surfaces.

It should be remembered that to create a supporting frame, it is best to use galvanized metal profiles, and not wooden slats, since wood is not highly resistant to moisture and has a shorter service life. Galvanized profiles have high anti-corrosion properties and resistance to deformation, but wood can lead over time, which will lead to a violation of the thermal insulation layer and a decrease in the energy efficiency of the room.

If heating equipment is located in the bathroom, then the contact points of mineral wool and such equipment must be additionally shielded with aluminum foil.

Bathroom floor insulation

In order to prevent heat from escaping into the ceiling, various heaters are used: expanded polystyrene, extruded polystyrene foam and polyurethane foam.

In order to prevent heat from escaping into the ceiling, various heaters are used: expanded polystyrene, extruded polystyrene foam and polyurethane foam. The use of foam boards is extremely rare. This is due to the low density and rigidity of the foam sheets. The material is brittle and may release harmful substances when heated.

Extruded polystyrene foam has slightly improved properties compared to polystyrene: rigidity, hardness, vapor permeability and higher thermal insulation. But these materials, to ensure the required level of thermal insulation, require the application of significant layers of insulation (over 5 cm). This raises the level of the floor significantly, especially when taking into account the layer of heating elements, the leveling layer and the decorative coating (laminate, ceramic tiles, etc.). When applying a leveling concrete screed, to ensure the necessary strength, the floor should be additionally reinforced with a reinforcing mesh.

The most rational would be to create a heat-insulating layer using polyurethane foam. This material has the lowest level of thermal conductivity, so it is enough to apply a relatively small layer of material (2 cm) to ensure the required level of insulation. Moreover, polyurethane foam has the properties of a vapor-conducting membrane, which allows moisture to pass from the base, but does not allow it to penetrate deep into the heat insulator.

Before installing the heat-insulating layer, it is necessary to lay a waterproofing film or prime the surface with penetrating waterproofing agents.

The underfloor heating system has a significant heating capacity due to the relatively large heating area. Due to this, it is not necessary to create high temperatures for heating the room.

The prices for the services of our company can be found in the section

Or order a consultation of a specialist at a convenient time for you!

The application is absolutely free and does not oblige you to anything!

In any apartment or house, the bathroom plays a key role. For some, a bath is comfort and coziness. As you know, the bathroom almost always has high humidity, so the main enemy of comfort and coziness is dampness and, in some cases, cold. It is the cold that creates a temperature contrast that significantly increases the risk of dampness. In the fight against it, there are several methods, for example, installing ventilation, installing a heated towel rail, but this will not fundamentally eliminate the problem of cold.

There is a simple and rational method of warming the bathroom with your own hands. Based on the fact that it is not always convenient to do this from the outside, it should be insulated from the inside. This is exactly what will be discussed in this article. First, we will consider what heaters exist, and then we will analyze how to insulate the floor, walls and ceiling.

If there is a choice between external and internal insulation, then preference should be given to the first, since such insulation is more effective.

Insulation of the bathroom

Many experienced a feeling of discomfort while in the bathroom. This is due to the fact that cool air enters from the sewer shaft and other cracks.

To avoid such unpleasant sensations, the bathroom should be insulated correctly, using only high-quality materials:

- The wall is cleaned and covered with a drug that prevents the occurrence of fungus;

- Penofol or extruded foam is glued to the wall;

- Moisture-resistant drywall is glued over the glued material;

- Ceramic tiles are laid on top of drywall.

There is another way to insulate the walls in the bathroom:

- In addition, bathroom ceiling insulation may also be required, the best option is to install a suspended plasterboard ceiling. The space between the ceiling and drywall is insulated with foam.

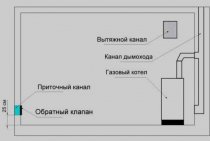

It is also important that the ventilation of the bathroom effectively removes the fumes generated in the house to the outside. In order to insulate ventilation, it is necessary to prevent the penetration of air from the street into the bathroom through it.

This is achieved by installing special grilles with a fan on the ventilation openings, which draws out the vapors, while not letting outside air into the room.

In any case, the sewer shaft should be insulated, since it is a source of drafts that draw heat out and prevent the bathroom from warming up properly.

How to keep warm in the bathroom

Before proceeding with the insulation of the walls, it is necessary to take care of the heat that will need to be stored. Heating by means of radiators in this case is not able to fully cope with this task. In addition, they heat only during the heating season. It is for this reason that experts recommend installing an electric heater in the bathroom, for example in the form of a warm floor.

For the device of a warm floor, a two-core cable is used, which is laid on the floor with a certain frequency. The more often the rings of the heating wire are located, the more efficient the floor heating will be. The laid structure is poured with a concrete screed, only one wire remains outside, intended for connection to the network.

Underfloor heating in the bathroom allows you to enjoy the warmth even after turning off the central heating.

How to insulate a metal font with your own hands

Below is a detailed step-by-step instruction for insulating an iron bath with foil-wrapped polyurethane foam (penofol).

For detailed instructions on thermal and sound insulation of a bathtub using mounting foam, see our special article.

Step 1 Place the bathtub up against the wall or lay it upside down on the floor, first covering it with cardboard or cloth. This is necessary to avoid damage to the enamel.

Step 2. The next step, you will need to degrease the surface.For this, a universal degreaser is perfect. But if it is not there, it does not matter, you can use alcohol or ordinary dishwashing detergent. Thoroughly wipe the entire surface and let it dry for 10-15 minutes.

Step 3. If you have insulation in rolls, cut a piece of the desired length so that the bowl is covered across from side to side, as shown in the photo. Do not forget to peel off the film from the adhesive layer.

After you have glued the sheet to the bathtub, you need to cut off the excess and once again tightly iron the insulation with your hand so that there are no bubbles.

Step 4. Measure the width of the most even sections and cut strips of 15-25 cm. Then glue them to the bowl in the same way, cutting off the excess.

Step 5. Next, glue the remaining empty spaces with the same small strips.

Don't forget to cut a drain hole.

Step 6 Glue the joints of the insulation with reinforced tape.

Step 7. Release the leg attachment points from the insulation.

Wall insulation

The simplest but most effective method of insulating a bathroom from the inside is pasting them with foam boards. First of all, you need to stock up on tile adhesive, foam sheets, a rubber roller, finishing putty, spatulas of various sizes, a trowel with serrated edges and a construction knife.

First of all, it is necessary to prepare the walls, clean them of dust and old coatings, and then apply several layers of antiseptic primer. The adhesive, previously mixed with water, should be applied with a notched trowel to the foam sheets. Then the foam must be installed in such a way at the place of attachment so as not to break the sheets, and then rolled with a rubber roller. Once all the sheets are glued, you can start puttying. The mixed finishing putty is applied evenly on the walls. After it dries, the walls will need to be painted or finished from the inside in other ways.

"Warm" plaster is a cement-based insulation that has recently appeared on the building materials market, so not all craftsmen use it to insulate walls. To reduce the thermal conductivity of the coating, it is advisable to use special additives instead of sand. Warm plaster may have compositions of the following type. Sawdust composition, as a rule, uses sawdust and cellulose, therefore, insulation with this material is best done in dry rooms to avoid mold on the walls. As a filler for the vermiculite composition, a mineral is used that has poor thermal conductivity and low weight - expanded vermiculite. It is better to choose such plaster for wet rooms, as it has antiseptic properties. In the expanded polystyrene composition, expanded polystyrene granules are used as a filler.

Insulation of the bathroom with the help of "warm" plaster occurs quickly, since in this case it is not necessary to level the walls, moreover, the material has excellent adhesion to all materials and does not form cold bridges. But in order to achieve a good effect, the plaster will have to be applied in a thick layer, about 2 times thicker than when applying the composition to the foam. Plaster is not a topcoat, so it must be finished with another material on top of it.

Before applying “warm” plaster to the walls, they must be thoroughly cleaned of dust and old coating and primed. After that, a composition should be prepared from the dry mixture and water, which should be applied to the walls with a wide spatula. Remember that plaster should not be applied immediately in a very thick layer, the optimal thickness should not exceed 2 cm, while each layer should be allowed to dry for 4-5 hours. If you do not adhere to this rule, then soon the plaster will begin to crack and flake off.Insulating the walls of the bathroom from the inside will allow you to stay in the room with comfort, as well as prevent condensation and, accordingly, dampness.

Floor insulation

Insulating the floor in the bathroom is best to start with waterproofing. After all, all the moisture that got on the walls still flows to the floor. And if an accident suddenly happens, then the water will quickly penetrate into the neighboring apartment.

To prevent this, you should use waterproofing materials of a penetrating or pasting type. But it is best to apply liquid rubber to the surface, because as soon as the material dries, it completely isolates building structures from moisture penetration. It is not very practical to insulate the floor in the bathroom with polystyrene foam. The fact is that the floor will rise, and an additional screed will have to be built above the insulating structure in order to lay tiles or laminate. Therefore, it is best to arrange a system of underfloor heating.

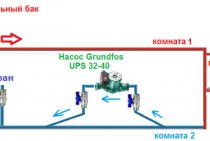

At the moment, there are many options for underfloor heating in the bathroom. For example, you can heat the floor with hot water, you can also install an electric heating cable or special heating mats in the floor base.

It is not very practical to insulate the floor using the first method, because the hot water in the pipes gradually cools. In addition, industrial water is not purified, it contains a lot of impurities that precipitate and clog pipes. When there is no hot water in the system, it will not be possible to heat the floor in the bathroom.

So, in order to insulate the room with electric mats, you first need to level and clean the base under the mats, and in some cases a concrete screed is specially made for the structure. The mats must be laid on concrete, they are already protected from moisture with special materials, after which the system should be poured with concrete. The design includes a thermostat, with which you can adjust the amount of heating of the room, while the entire system operates from a conventional electrical network

It is recommended to entrust the installation of the electric floor heating system to specialists, because it is very important that the electrical wires are insulated correctly. If you have a choice between water floor heating and electric mats, then it is better to give preference to the latter.

Underfloor heating guarantees high reliability and long service life, besides, they are quite cheap.

If you do not have the opportunity to install heated floors, then you can insulate the floor in the bathroom using insulating material. However, in this case, the structure will need to be covered with a concrete screed. To begin with, the floor is leveled and cleaned, then a layer of waterproofing is applied and left to dry. At the next stage, the structure must be poured with concrete, after which tiles or other facing material can be laid.

Remember that, despite the ease of installation of the floor, when performing work, you must be careful and follow all safety requirements.

This completes the insulation of the bathroom from the inside. Properly performed work will significantly improve the feeling of coziness and comfort that arise when taking various water procedures, since it is rather difficult to call being in a damp cold room comfortable.

Materials and tools for bath insulation

We use polyurethane foam and sheet foam 2-3 cm thick as a heater. We calculate the approximate consumption of materials as follows. We find the surface area of the bath, considering it as a rectangular box. To do this, measure the dimensions on the inside. An ordinary steel bath 1.5 m long has internal dimensions of 1.4x0.55x0.4 m. We find the perimeter (1.4 + 0.55) x 2 \u003d 3.9 m. Multiplying the perimeter by the height 3.9x0.4 \u003d 1 .56 m 2, we get the surface area

Of course, due to the curvature, the area will be smaller, but in practice this is not so important, since the foam is sold in meter pieces

We calculate the approximate consumption of foam from a conditional layer thickness of 2 cm, that is, we need about 30 liters of foam (1.56x0.02 / 1000 \u003d 31dm 3). A bottle of 500 ml should be enough with a margin.

Since we will apply the foam twice, if necessary, it can be purchased in addition.

It is better to apply foam with a gun. It is not expensive, about 300 rubles, in addition, given that such a gun saves foam up to 20%, its actual cost will be even lower.

Some pistols are equipped with interchangeable nozzles of various sections and shapes. If you purchased a device without nozzles, you can make a homemade tip from a polyethylene or PVC tube of a suitable diameter. We heat the end of the tube and flatten it, leaving a narrow gap so that the foam comes out not in a stream, but in a strip.

If do-it-yourself insulation of an iron bath is not part of a general home renovation, you can do without a gun using ordinary (“household”) cylinders.

Vibroplast

The vibration-absorbing material consists of a layer of embossed aluminum foil and a sticky polymer layer covered with anti-adhesion paper. Easily adheres to uneven surfaces without additional heat. Vibroplast does not absorb moisture and has the properties of a sealant. Use in the temperature range from -45 to +100 °C is admissible. Good sound and heat insulator.

- a piece of the desired size is cut from vibroplast

- remove protective paper

- put on the surface of the bath, level

- rolling with a roller

Advantages of vibroplast:

Advantages of vibroplast:

- non-toxic

- low price

- withstands a wide temperature range

- moisture resistant

Thermal insulation of the bathroom with polystyrene foam: advantages and disadvantages of thermal insulation material, tips for installing a thermal insulator

Styrofoam is often used to insulate a bathroom.

Styrofoam is often used to insulate a bathroom. The insulation has high moisture-repellent and heat-insulating properties. When using foam, it must be remembered that this material does not differ in vapor permeability, therefore it does not allow the walls to "breathe", therefore, condensate that accumulates under the heat-insulating layer will lead to the destruction of the walls and can cause mold and mildew.

In order to prevent the accumulation of moisture under the heat-insulating layer, it is necessary to ensure its integrity, that is, the seams and joints of the material should be carefully sealed.

The foam plastic installation technology is quite simple, so you can insulate the room yourself with this thermal insulator.

To carry out thermal insulation work, you will need the insulation itself, tile adhesive, putty, spatulas (including a spatula for applying the adhesive composition), a construction knife and a rubber roller. Styrofoam sheets are well processed and cut to the required size.

To carry out thermal insulation work, you will need the insulation itself, tile adhesive, putty, spatulas (including a spatula for applying the adhesive composition), a construction knife and a rubber roller.

Before installing the insulation, it is necessary to thoroughly clean, level and prime the surface. If the ceiling and walls of the bathroom are uneven, then their alignment is carried out by applying rough plaster. It is necessary to prime surfaces for insulation with foam plastic twice; for this purpose, it is recommended to use antiseptic primer.

At the next stage, an adhesive composition is prepared, which is applied to the heat-insulating sheets with a notched trowel. For good adhesion of the insulation to the surface, the adhesive composition must be applied over the entire surface of the sheet.

When installing the foam, it should be remembered that it is a rather fragile material, therefore, the sheets should be pressed against the wall surface carefully, for a good adhesion of the insulation to the surface to be insulated, the sheets of material are rolled with a rubber roller. Do not forget that the contact points of the insulation with heating equipment, as in the case of mineral wool mats, must be shielded with aluminum foil

Do not forget that the contact points of the insulation with heating equipment, as in the case of mineral wool mats, must be shielded with aluminum foil.

After installing the heat-insulating layer, the joints between the sheets of insulation are sealed, then the exterior finish is carried out using finishing putty. In order for the putty surface to be smooth and uniform, the finishing putty should be applied in two layers. The second layer is applied after the first one has dried and grouted, it should also be carefully wiped. A trowel board is used for grouting. Putty surfaces can be painted or finished with moisture-resistant finishing materials.

Features of bathroom insulation

The bathroom is a room with a specific microclimate, characterized by significant temperature fluctuations and a very high level of humidity. Therefore, its thermal insulation requires a special approach and I have no right not to mention some of the nuances.

- The need to destroy the interior of the bathroom. To insulate the bathroom, you will have to dismantle the finish, and then re-tile the walls with tiles, plastic or plaster. All these operations increase the cost of the project, the time for its implementation and labor intensity.

- Reducing the area of the sanitary facilities. It is unlikely that someone has a bathroom in the apartment is spacious. So, an insulating cake will make the room even smaller. So think about whether all the necessary furniture and equipment will fit there after insulation.

- Violation of air infiltration. A vapor-tight insulation does not allow moist air to pass through the walls, therefore, to control the humidity in the bathroom, it is necessary to design not just effective ventilation, but forced ventilation using powerful ones.

- Danger of mold and mildew. This scourge can only be feared if the thermal insulation is not done correctly.

- Reducing the service life of enclosing structures. If you install insulation inside, the walls of the dwelling will constantly freeze and come into contact with atmospheric moisture, which negatively affects their integrity.

However, in my case, I was not able to install insulation on the 20th floor of a city apartment building, since I can’t pretend to be a monkey hanging at a dizzying height. And I didn’t want to hire a specialist either.

Therefore, I resorted to internal insulation. Although there are some nuances that need to be said:

- for internal insulation of the bath, it is necessary to use materials that have hydrophobic properties and do not lose their performance properties when wet;

- it is better to choose materials with the lowest thermal conductivity so that the insulation layer is as thin as possible;

- for internal insulation, materials with great strength are needed in order to maintain integrity during finishing and possible mechanical stress.

Features of a steel bath and indications for its insulation

Steel is often found in bathroom components due to the special properties of the alloy - durability, lightness compared to cast iron, strength, corrosion resistance with auxiliary coatings. Metal bathtubs are sold in an affordable price range, are offered in various colors and configurations, and are easy to install.

There are also disadvantages - the rapid cooling of water, a loud noise when collecting liquid.They are explained by two key characteristics of steel:

- High resonant effect. Since the walls of the products are 2-3 times thinner compared to cast iron, the metal vibrates due to drops falling from a height. These fluctuations exacerbate the noise of water, cause discomfort.

- High thermal conductivity. When the hot water flow is turned on, the steel walls of the bowl quickly heat up, but they also quickly lose heat, helping to lower the temperature of the collected liquid. If you do not take care of the thermal insulation of the steel bath, you will have to finish hygiene procedures faster, you will not be able to soak up the warm water here. Or you need to constantly add hot flow, which leads to increased utility bills.

The thinner the walls of the metal container, the stronger the vibrations, the set of water is accompanied by a fair amount of noise, the liquid cools quickly. According to plumbers, when choosing a bowl, it is better to give preference to variations with a wall thickness of 4 mm or more, in this case, all minor flaws will be smoothed out by elementary hand-made insulation.

Insulation of a steel bath is necessary due to the rapid cooling of water in it

Insulation of a steel bath is necessary due to the rapid cooling of water in it

The low price contributes to the prevalence of steel models, but many put up with the inconvenience of using them, not realizing that they can be eliminated on their own by purchasing the right materials. Experts explain that it is advisable to take all additional measures even before installing the container in the allotted place and connecting it to sewer communications, otherwise you will have to manually dismantle the product, such intervention is accompanied by a number of difficulties.

- steel bath insulation. A special category of materials is attracted to thermal insulation, which are conveniently distributed along the walls and bottom of the bowl from the outside. As a result of the impact, the thermal conductivity of the structure decreases, the container keeps the specified temperature of the liquid longer;

- soundproofing. Here you will need resources of sound-absorbing and vibration-proof types, they are mounted by pasting all the outer surfaces of a steel product. If you want to reduce the cost of purchasing materials, they can be used to process only those areas where the water flow falls.

Hand-made insulation of the bottom of the tank will allow you to get rid of both problems with a minimum cost of money and time.