Open heating systems

Open heat supply systems are characterized by the fact that hot water for the needs of the consumer is drawn directly from the heating network, and it can be either full or partial. The hot water remaining in the system continues to be used for heating or ventilation.

The water consumption in the heating network with this method is compensated by the additional amount of water that is supplied to the heating network. The advantage of an open heating system lies in its economic benefits. During the Soviet period, almost 50% of all heat supply systems were open.

At the same time, one cannot discount the fact that such a heat supply system also has a number of significant drawbacks. First of all, it is the low sanitary and hygienic quality of water. Heating devices and pipeline networks give water a specific smell and color, various impurities appear, as well as bacteria. Various methods are usually used to purify water in an open system, but their use reduces the economic effect.

An open heat supply system can be dependent on the method of connection to heat networks, i.e. connected through elevators and pumps, or connected according to an independent scheme - through heat exchangers. Let's dwell on this in more detail.

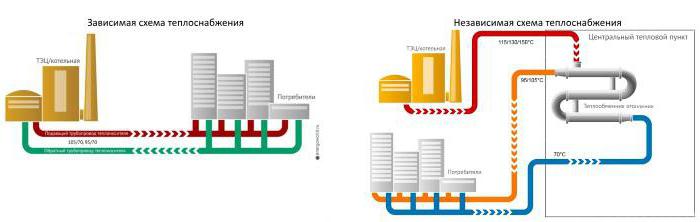

Dependent heating systems

Dependent heat supply systems are such systems in which the coolant through the pipeline enters immediately into the consumer's heating system. There are no intermediate heat exchangers, heat points and hydraulic isolation. Undoubtedly, such a connection scheme is understandable and structurally simple. It is easy to maintain and does not require any additional equipment, such as circulation pumps, automatic control and monitoring devices, heat exchangers, etc. Most often, this system attracts with its, at first glance, efficiency.

However, it has a significant drawback, namely, the inability to adjust the heat supply at the beginning and end of the heating season, when there is an excess of heat. This not only affects the comfort of the consumer, but also leads to heat loss, which reduces its initial apparent efficiency.

When energy saving issues become relevant, methods are being developed and actively implemented for the transition of a dependent heat supply system to an independent one, this allows saving heat by about 10-40% per year.

Independent heating systems

Independent heat supply systems are systems in which the heating equipment of consumers is hydraulically isolated from the heat producer, and additional heat exchangers of central heating points are used to supply heat to consumers.

An independent heating system has a number of undeniable advantages. This:

- the ability to control the amount of heat delivered to the consumer by regulating the secondary heat carrier;

- its higher reliability;

- energy-saving effect, with such a system, heat savings are 10-40%;

- it becomes possible to improve the operational and technical qualities of the coolant, which significantly increases the protection of boiler plants from pollution.

Due to these advantages, independent heat supply systems have become actively used in large cities, where heat networks are quite long and there is a wide range of heat loads.

Currently technologies for the reconstruction of dependent systems into independent ones have been developed and are being successfully implemented. Despite the significant investment, this eventually gives its effect.Naturally, an independent open system is more expensive, but it significantly improves water quality compared to a dependent one.

Closed circuit heating systems, what is it

The difference between this scheme of centralized heating of houses and the previous one is that hot water is used exclusively for heating. Hot water supply is provided by a separate circuit or individual heating devices.

The circulation of the coolant occurs in a vicious circle; minor losses that occur are compensated for by automatic pumping in case of pressure loss.

The temperature of the supplied water is regulated directly in the boiler room. The volume of boiling water in this system remains the same. Thus, the intensity of space heating directly depends on the temperature of the liquid circulating through the pipes.

Heat points play an important role in this home heating scheme. In them, water comes from the CHP, and already there, with its help, the coolant is heated, which is supplied to consumers.

Legal basis of relations in the field of heat supply

Relations between energy companies and consumers are regulated by the Federal Law on heat supply No. 190, which entered into force in 2010.

Chapter 1 outlines the basic concepts and general provisions that define the scope of the legal foundations of economic relations in heat supply. It also includes hot water supply.

General principles for the organization of heat supply are approved, which consist in the creation of reliable, efficient and developing systems, which is very important for living in the difficult Russian climate.

Chapters 2 and 3 reflect the broad scope of powers of local authorities that manage pricing in the heat supply sector, approve the rules for its organization, accounting for heat energy consumption and the standards for its losses during transmission. The completeness of power in these matters allows you to control the heat supply organizations related to monopolists.

Chapter 4 reflects the relationship between the supplier of heat energy and the consumer on the basis of an agreement

All legal aspects of connection to heat networks are considered.

Chapter 5 reflects the rules for preparing for the heating season and repairing heat networks and sources. It describes what to do in case of non-payment under the contract and unauthorized connections to heating networks.

Chapter 6 defines the conditions for the transition of an organization to the status of a self-regulating in the field of heat supply, the organization of the transfer of rights to own and use a heat supply object.

Users of thermal energy must be aware of the provisions of the Federal Law on heat supply in order to assert their legal rights.

Features of an open system

The advantage of an open system is its economy. Due to the long length of pipelines, the quality of water deteriorates: it becomes cloudy, acquires color, and has an unpleasant odor. Attempts to clean it make the method of application expensive.

Heating pipes can be seen in big cities. They have a large diameter and are wrapped in a heat insulator. Branches are made from them to individual houses through a thermal substation. Hot water is supplied for use to heating radiators from a common source. Its temperature ranges from 50-75°C.

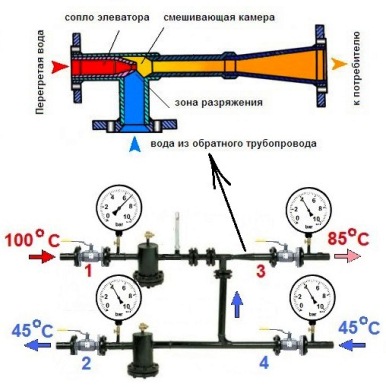

Connection of heat supply to the network is carried out in dependent and independent ways, implementing closed and open heat supply systems. The first is to supply water directly - using pumps and elevator units, where it is brought to the required temperature by mixing with cold water. An independent way is to supply hot water through a heat exchanger. It is more expensive, but the quality of water at the consumer is higher.

Coolant efficiency

The cycle passed by the heat carrier is a little more complicated than in an open mechanism.The cooled coolant, through the return line, enters the heating heaters or boiler rooms, where it receives the temperature from the hot process steam of turbines, condensate or is heated in the boiler. Losses, if any, are made up by the make-up liquid, thanks to the regulator. The device always maintains the set pressure, keeping its static value. If heat is received from CHP, the heat carrier is heated by steam having a temperature of 120° - 140°C.

The temperature is pressure dependent and sampling is usually done from medium pressure cylinders. Often there is only one heat extraction at the plant. The removed steam has a pressure of 0.12 - 0.25 MPa, which is increased (with controlled extraction) during seasonal cooling or steam consumption for aeration. When it gets cold, the liquid can be heated up by a peak boiler. An aerator can be connected to one of the turbine outlets, and chemically treated, treated water enters the feed tank. The heat removed for consumers, obtained from steam condensates and steam, is regulated qualitatively, that is, with a constant volume of the carrier, only the temperature is regulated.

Through the network pipeline, the coolant enters the heating unit, where the heating circuits form the required temperature. The water supply circuit does this with the help of a circulation line and a pump, having received water heated by a heat exchanger and mixing it with tap water and cooling water in the pipes. The heating one has its own control valves, which make it possible to qualitatively influence the heat extraction. The closed system assumes independent regulation of heat extraction.

However, such a scheme does not have sufficient flexibility and must have a productive pipeline. In order to reduce investments in the heating network, a coupled regulation is organized, in which the water supply flow regulator determines the balance in the direction of one of the circuits. As a result, the heating demand is compensated from the heating circuit.

The disadvantage of such balancing is a somewhat floating temperature of heated rooms. The standards allow temperature fluctuations within 1 - 1.5 ° C, which usually occurs until the maximum consumption for water exceeds 0.6 of the calculated one for heating. As in an open heat supply system, it is possible to use a combined quality control of heat supply. When the flow rate of the coolant and the heat transfer networks themselves are calculated for the load of the heating and ventilation system, increasing the temperature of the carrier to compensate for the need for hot supply. In such a case, the thermal inertia of buildings acts as heat accumulators, leveling out temperature fluctuations caused by uneven heat extraction from the connected system.

Open heating system

In this format, boiling water is sent to the water supply directly from the heating pipes, which allows you to completely avoid full consumption even if all of its volume is taken. In Soviet times, the work of about half of all heating networks was based on this principle. Such popularity was due to the fact that the scheme helped to use energy resources more economically and significantly reduce the cost of heating in the winter and hot water supply.

However, this method of supplying residential buildings with heat and boiling water has many disadvantages. The thing is that very often heated water, due to its dual purpose, does not meet sanitary and hygienic standards. The heat carrier can circulate through metal pipes for quite a long time before it enters the taps. As a result, it often changes its color and acquires an unpleasant odor. In addition, employees of the sanitary and epidemiological services have repeatedly identified dangerous microorganisms in it.

The need to filter such water before supplying it to the hot water supply system greatly reduces efficiency and increases the cost of heating. At the same time, to date, there is no truly effective way to purify such water. The significant length of the pipelines actually makes this procedure useless.

The circulation of water in such a system occurs due to the consideration of thermodynamic processes in the design. The heated liquid rises and leaves the heater due to the increase in pressure. At the same time, cool water creates a slightly lower pressure at the boiler inlet. This is what allows the coolant to move independently through communications.

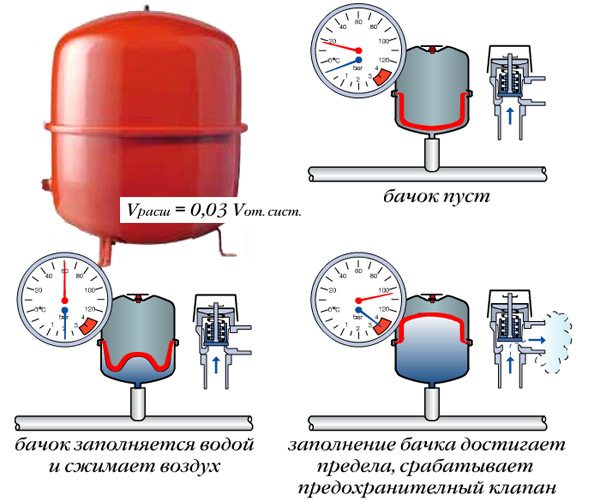

Water, like any other liquid, increases in volume when heated. Therefore, in order to prevent excessive load on the heating networks, their design necessarily includes a special open expansion tank located above the level of the boiler and pipes. Excess coolant is squeezed out there. This gives grounds to call such a system open.

Heating in this case occurs up to 65 degrees Celsius, and then water flows directly through the taps to the consumers' houses. This system allows the installation of inexpensive simple mixers.

Due to the fact that it is impossible to predict how much hot water will be used, it is always supplied taking into account the highest demand.

Drawing up a heat supply scheme

The heat supply scheme is a pre-project document that reflects legal relations, the conditions for the functioning and development of the system for providing heat to an urban district, settlement. In relation to it, federal law includes certain rules.

- for settlements are approved by executive authorities or local self-government, depending on the population.

- There should be a single heat supply organization for the respective territory.

- The scheme indicates the energy sources with their main parameters (loading, work schedules, etc.) and the radius of action.

- Measures are indicated for the development of the heat supply system, the conservation of excess capacities, and the creation of conditions for its uninterrupted operation.

Heat supply facilities are located within the boundaries of the settlement in accordance with the approved scheme.

Heating network pipes

Currently, domestic are in disrepair. Due to the high wear and tear of communications, it is cheaper to replace the pipes for the heating main with new ones than to engage in constant repairs.

It is impossible to immediately update all the old communications in the country. During the construction or major repairs of houses, new pipes are installed in several times reducing heat loss. Pipes for heating mains are made according to a special technology, filling the gap between the steel pipe located inside and the shell with foam.

The temperature of the transported liquid can reach 140°C.

The use of polyurethane foam as thermal insulation allows you to retain heat much better than traditional protective materials.

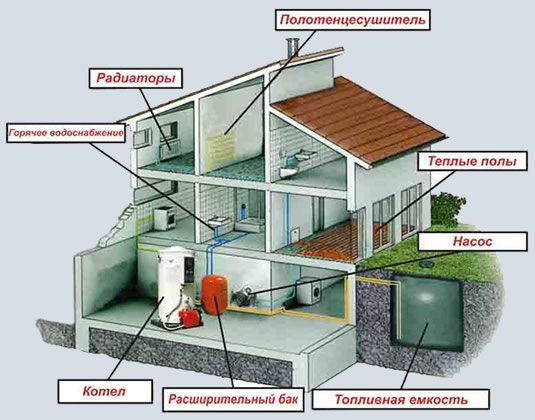

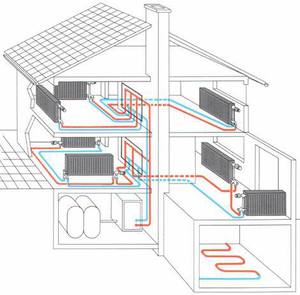

Autonomous heating of a residential building

In buildings of the old type, the project provides for a centralized system. Individual schemes allow you to choose the types of heat supply systems in terms of reducing energy costs. Here it is possible to turn them off mobile if not needed.

Autonomous systems are designed taking into account heating standards. Without this, the house cannot be put into operation. Following the norms guarantees the comfort for the residents of the house.

The source of water heating is usually a gas or electric boiler. It is necessary to choose a method for flushing the system. In centralized systems, the hydrodynamic method is used. For standalone, you can use a chemical. In this case, it is necessary to take into account the safety of the influence of reagents on radiators and pipes.

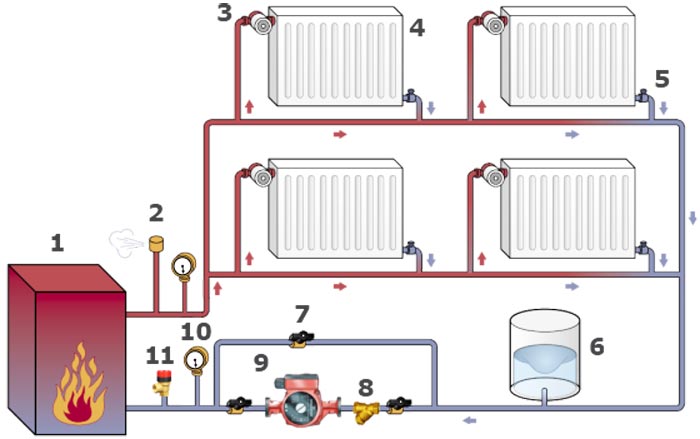

Independent closed heating system

At present, when installing new boiler houses, an independent scheme for connecting the heating system has become more often used. It has a main and an additional circulation circuit, hydraulically separated by a heat exchanger. That is, the coolant from the boiler house or CHP goes to the central heating point, where it enters the heat exchanger, this is the main circuit. An additional circuit is a house heating system, the coolant in it circulates through the same heat exchanger, receiving heat from the network water from the boiler room. The scheme of operation of an independent system is shown in the figure:

But what about the centralized supply of hot water, because now it is impossible to take it from the main, the temperature is too high there (from 105 to 150 ºС)? It's simple: an independent connection scheme allows the installation of any number of plate heat exchangers connected to the main pipelines. One will provide heat to the heating system at home, and the second can prepare water for household needs. How this is implemented is shown in the diagram:

To ensure that hot water always arrives at the same temperature, the DHW circuit is closed with the organization of automatic make-up in the return pipeline. In apartment buildings, the DHW circulation return line can be seen in the bathroom, heated towel rails are connected to it.

Obviously, the operation of an independent heating system has a lot of advantages:

- the home heating circuit does not depend on the quality of the external coolant, the condition of the main networks and pressure drops. The entire load falls on the plate heat exchanger;

- it is possible to regulate the temperature in the rooms with the help of thermostatic valves;

- the coolant in a small circuit can be filtered and cleaned of salts, the main thing is that the pipes are in good condition;

- in the DHW system there will be drinking quality water entering the house through the water main.

However, due to the dirty low-quality coolant in the central network, periodic flushing of an independent heating system, or rather, a plate heat exchanger, will be required. Fortunately, this is not so difficult to do. Another disadvantage is the higher costs for the purchase of equipment, namely: heat exchangers, circulation pumps and shut-off and control valves. But a closed system is more reliable and safer than an open one, it meets modern requirements more and is better adapted to new equipment.

Differences between open and closed heating systems

There are the following distinctive features of open and closed heating systems:

The location of the expansion tank.

In an open heating system, the tank is located at the highest point in the system, and in a closed system, the expansion tank can be installed anywhere, even next to the boiler.

The closed heating system is isolated from atmospheric flows, which prevents air from entering. This increases the service life.

Due to the creation of additional pressure in the upper nodes of the system, the possibility of air pockets is reduced

in radiators located on top.

In an open heating system, pipes with a large diameter are used,

which creates inconvenience, also the installation of pipes is carried out at an angle to ensure circulation. It is not always possible to hide thick-walled pipes

To ensure all the rules of hydraulics

it is necessary to take into account the slopes of the distribution of flows, the height of the lift, turns, narrowing, connection to radiators.

In a closed heating system, pipes of a smaller diameter are used, which reduces the cost of construction.

Also, in a closed heating system, it is important to correctly install the pump,

to avoid noise.

Benefits of an open heating system

- simple maintenance of the system;

- lack of a pump ensures silent operation;

- uniform heating of the heated room;

- quick start and stop of the system;

- independence from power supply, if there is no electricity in the house, the system will be operational;

- high reliability;

- no special skills are required to install the system, first of all, a boiler is installed, the power of the boiler will depend on the heated area.

Disadvantages of an open heating system

- the possibility of reducing the life of the system when air enters, as heat transfer decreases, resulting in corrosion, water circulation is disturbed, and air plugs are formed;

- the air contained in an open heating system can cause cavitation, which destroys the elements of the system located in the cavitation zone, such as fittings, pipe surfaces;

-

possibility of freezing

coolant in the expansion tank; -

slow heating

systems after switching on; - needed constant level control

coolant in the expansion tank to prevent evaporation; - the impossibility of using antifreeze as a coolant;

- cumbersome enough;

- low efficiency.

Advantages of a closed heating system

-

simple installation

; - there is no need to constantly monitor the level of the coolant;

- opportunity antifreeze applications

without fear of defrosting the heating system; - by increasing or decreasing the amount of coolant supplied to the system, it is possible to regulate the temperature

in room; - due to the lack of evaporation of water, the need to feed it from external sources is reduced;

- independent pressure regulation;

- the system is economical and technologically advanced, has a longer service life;

- the possibility of connecting additional heating sources to a closed heating system.

Disadvantages of a closed heating system

- the main drawback is the dependence of the system on the availability permanent power supply

; - the pump requires electricity;

- for emergency power supply, it is recommended to purchase a small generator

; - in case of violation of the tightness of the joints, air may enter the system;

- dimensions of expansion membrane tanks in large enclosed spaces;

- the tank is filled with liquid by 60–30%, the smallest percentage of filling falls on large tanks, at large facilities tanks with an estimated volume of several thousand liters are used.

- there is a problem with the placement of such tanks, special installations are used to maintain a certain pressure.

Open heating system thanks to ease of use,

high reliability, used for optimal heating small spaces.

It can be small one-story country houses, as well as country houses.

The closed heating system is more modern and more complex. It is used in multi-storey buildings and cottages.

Features of a closed system

The heat main is made in the form of a separate closed circuit. The water in it is heated through heat exchangers from the CHP main. Required here. The temperature regime is more stable, and the water is better. It remains in the system and is not taken by the consumer. Minimal water losses are restored by automatic make-up.

A closed autonomous system receives energy from the coolant supplied to the heat points. There, the water is brought to the required parameters. For heating and hot water systems, different

The disadvantage of the system is the complexity of the water treatment process. It is also expensive to deliver water to heat points located far from each other.

Dependent open heating system

The main feature of the dependent system is that the coolant flowing through the main networks directly enters the house. It is called open because a coolant is taken from the supply pipeline to provide the house with hot water. Most often, such a scheme is used when connecting multi-apartment residential buildings, administrative and other public buildings to heating networks. The operation of the scheme of the dependent heating system is shown in the figure:

When the temperature of the coolant in the supply pipe is up to 95 ºС, it can be directed directly to the heating devices. If the temperature is higher and reaches 105 ºС, then a mixing elevator unit is installed at the entrance to the house, whose task is to mix the water coming from the radiators into the hot coolant in order to lower its temperature.

The scheme was very popular during the Soviet era, when few people cared about energy consumption. The fact is that a dependent connection with elevator mixing units works quite reliably and practically does not require supervision, and installation work and material costs are quite cheap. Again, there is no need to lay additional pipes to supply hot water to houses when it can be successfully taken from the heating main.

But this is where the positive aspects of the dependent scheme end. And there are many more negative ones:

- dirt, scale and rust from the main pipelines safely enters all consumer batteries. Old cast-iron radiators and steel convectors didn’t care about such trifles, but modern aluminum and other heating appliances definitely didn’t care;

- due to a decrease in water intake, repair work and other reasons, a pressure drop often occurs in a dependent heating system, and even water hammer. This threatens with consequences for modern batteries and polymer pipelines;

- the quality of the coolant leaves much to be desired, but it goes directly to the water supply. And, although the water in the boiler room goes through all the stages of purification and desalination, kilometers of old rusty highways make themselves felt;

- it is not easy to regulate the temperature in the rooms. Even full bore thermostatic valves quickly fail due to the poor quality of the coolant.

Advantages

Unfortunately, in the post-Soviet space, heat supply to the vast majority of consumers is still organized according to the old, open scheme. A closed circuit promises a significant gain in many ways. That is why the transition to closed heating, on a national scale, can bring serious economic benefits. For example, in Russia, at the state level, the transition to a more economical option has become part of an energy-saving program for the future.

The rejection of the old scheme will bring a reduction in heat loss, due to the possibility of precise adjustment of consumption. Each heat point has the ability to finely regulate heat consumption by subscribers.

Heating equipment operating in the isolated mode of a closed system is much less affected by the factors introduced by an open network. The consequence of this is an extended life of boilers, heat-preparation installations and intermediate communications.

It does not require increased resistance to high pressure throughout the heat-conducting lines, this significantly reduces the accident rate of pipelines due to pressure bursts. In turn, this reduces heat loss due to leaks. As a result, savings, stability and quality of heat and hot water supply compensate for the shortcomings of the system. And they also exist. Procedures cannot be carried out centrally. Each individual closed circuit requires its own maintenance. Be it turbines, subscriber circuits or an intermediate line.

Each heat station is a separate unit for water treatment.Most likely, when upgrading the circuit from open to closed, in most cases it will be necessary to increase the area required for installing ITP equipment, as well as reorganize the power supply. In addition, the consumption of cold water for supplying the building increases significantly, since it is it that is used for heating in heat exchangers and further to the consumer, with independent connection of hot water. This will invariably entail the reconstruction of the water supply, for the sake of switching to a closed hot circuit.

The global introduction of independent connection of hot equipment to heating networks will entail a significant increase in the load on external cold water supply networks, since consumers will have to be fed with increased volumes required for hot water supply, which are now provided through heating networks. For many localities, this will become a serious obstacle to modernization. Additional equipment with pumping units in hot supply and circulation installations, in the heating mechanisms of buildings will cause an additional load on the electrical networks and it is also impossible to do without their reconstruction.