Ways to adjust the heating system

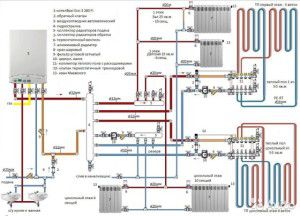

Heating system with control valves

There are several ways to change the characteristics of heat supply. Timely hydraulic adjustment of the heating system is necessary to stabilize the pressure in certain areas and the entire scheme as a whole. Temperature correction serves as a tool for changing the degree of air heating in a particular room. Most often, a tap is used to adjust the heating temperature.

All of the above characteristics largely depend on the operation of the boiler. However, to normalize the system parameters, it is necessary to install additional components. Depending on the function, they are divided into the following types:

- Temperature. Serve for partial or complete blocking of the coolant flow in radiators or in a separate circuit. With the help of taps, a thermostat or mixing units, the heating batteries in the apartment are adjusted;

- Pressure. Temperature differences between flow and return can cause pressure surges. This will unbalance the system, which will worsen its performance. To eliminate this problem, hydraulic arrows are mounted, as they do collector pipework.

In practice, timely adjustment of taps on heating radiators reduces energy costs. Also, with the help of control valves, you can change the degree of heating of the air in the room.

The actual performance of the heating system must match the calculated ones. In this way, the number of adjustment elements can be reduced.

How to choose equipment

Such crane is widely used on equipment in the oil and chemical industries.

For a conventional pipeline with water, you can safely choose a valve made of gray cast iron. A device made of bronze, nickel or stainless steel is suitable for aggressive environments that cause metal corrosion. For high pressure service, durable and reliable carbon steel valves are chosen. For heating pipes, taps made of heat-resistant chromium-molybdenum steel are used.

Needle valves must meet the following requirements:

- When the valve is opened, the needle does not fall out of the socket, when it is closed, it rests against the support.

- The arrow must indicate the direction of closing.

- The thread on the screw makes it possible to close as early as half of one turn, but not more than one turn.

- The needle from the body should not be removed completely when unscrewing it.

It is important

- If the heating system has a large length and a smooth adjustment of the pressure is required, the choice of a needle valve will be the best solution.

- The valve material is selected depending on the working environment.

- If the body has a galvanized coating, the crane can be used in rooms with high humidity and temperature changes.

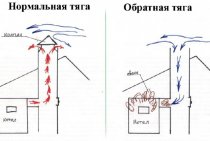

- If the coolant circulates unevenly, air may enter the system. Air locks are the most common cause of cold radiators. Therefore, a needle crane (Maevsky crane) is installed in the upper part of the battery. The valve can be moved with a locking screw with a square head. In its absence, you can use a screwdriver. The valve is mounted on the side opposite to the one from where the heat moves through the pipe. The stainless steel needle faucet is turned counterclockwise. After all the air is out, the valve is screwed.

Inside the valve there is a shutter in the form of a body of revolution with an axis perpendicular to the flow of the medium. The shutter (plug) has an opening for the passage of the working medium. If the axis of the hole coincides with the axis of the pipe, the valve is open; if the axis is perpendicular to the axis of the pipeline, the valve is closed.Thus, to open the valve, only one rotation of the valve by an angle of 90 ° is needed, while for the valve several rotations are required.

A needle valve is used to regulate the flow of a liquid or gaseous medium in a pipeline. The scope of its application is extensive: from water pipes to equipment in oil refineries, in utilities and in heat supply.

Works on adjusting heating with shut-off valves

Throughout the process, the water entering the system must have a constant temperature. As a rule, regulation is carried out according to temperature differences by changing the volume of water supplied, which depends on the type of heating system and the thermal input.

Temperature drops depend on the volume of water consumed and this value is inversely proportional. Thus, in order to increase the difference to the required value, it is necessary to reduce the flow rate of the coolant. To do this, either cover the valve located at the input, or reduce the flow itself.

The more water passes through the heating devices, the higher the speed of its movement and, accordingly, the coolant cools less. As a result, the average temperature in the radiator rises and the heat transfer of the device increases. After completion of the adjustment in the thermal unit, separate risers of the structure are subject to adjustment. In case of problems, repairs are carried out so that control valves for the heating system on the risers or balancing valves can be used (for more details: “Control valves for heating radiators, valve installation“).

One of the ways to adjust the heating system is shown in the video:

When there are only taps on the heating risers, only preliminary adjustment is made. At the same time, it is taken into account that the closer the riser is to the input, the more the tap should be slightly opened. This is necessary so that the shut-off valves for heating at the nearest riser pass a minimum amount of water.

At the same time, on the riser located farthest, you need to open a tap, such as in the photo. First, they check the quality of heating of the farthest riser in terms of location and finish with the one that is closest.

Usually, in two-pipe systems, appliances on the upper floors overheat due to pressure. If this drawback is not present on the lower floor, then adjustment of the upper heating radiators is necessary. In the presence of a double adjustment valve, it is possible to reduce the flow area. In the absence of such taps, the heating batteries are adjusted by installing throttle washers.

In two-pipe heat supply systems, the uniformity of heating of radiators will increase with an increase in water consumption. The most important parameter for heating structures is the operating pressure (read: “Losses and pressure drops in the heating system - we solve the problem“). To lower it, use a pressure regulator in the heating system, and to increase it, use circulation pumps.

The temperature of the heat carrier during the regulation of the device cannot exceed 50-60 °C. After completing the adjustment, the water temperature must be brought to 90 ° C, and the heating of the radiators should be checked again at this temperature regime. It is advisable to seek the service of specialists to adjust heating systems.

Advantages and disadvantages of needle faucets

The benefits are:

- smooth flow adjustment;

- the valve is made of anti-corrosion material, so the needle valve is strong and durable;

- the possibility of disassembling the valve in order to replace the old seal;

- protection against hydraulic shocks that can occur when the tap is quickly opened and closed;

- the valve withstands a maximum pressure of 220 bar;

- the medium temperature can vary from −20° to +200°С;

- the tap can be connected with an inch thread or a cylindrical one.

Needle cranes also have disadvantages:

- one-way feed;

- impossibility of application for pipelines with dirty water;

- large construction length;

- the needle valve cannot be repaired (when buying a new one, do not save on quality, otherwise the valve will not last long).

Heating control valves

However, in addition to the types of valves described above, valves are installed to regulate heating. As the main mechanism for shutting off water, a needle locking structure or with an adjusting plate is used. Depending on the functions they perform, they are divided into two types:

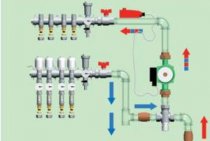

- Automatic adjustment of the volume of water - most often used for this purpose is the design of a needle valve for heating;

- Mixing of 2 streams (with hot and cold water) to create the desired temperature regime. In autonomous heating, such valves are mounted on a collector of a water-heated floor.

Valves with thermal head

Valve with thermal head

The simplest design of a heating expansion valve includes a needle stem that is connected to a thermostatic control element. Depending on the temperature of the medium, it tends to expand or contract. This regulates the amount of coolant entering the radiator.

This device is mounted directly on the radiator inlet pipe. When choosing, it should be taken into account that balancing valves for the heating system can be of two types - with manual setting of the boundary temperature of the coolant and with the ability to connect to external sensors. The latter are called servomotors and are intended for mounting on needle valves for heating radiators or mixing units.

Servo drives on the water floor heating collector

Unlike a valve designed for heating, the actuator is connected to an external temperature sensor or an electronic control unit. When any parameters of heating the air in the room or the temperature outside change, the valve stem shifts. Thus, the flow of coolant in a particular section of the system is regulated.

The outdoor thermometer connected to the thermostatic expansion valve must be mounted in a location that is not exposed to direct sunlight.

Can this device be used with a radiator valve in heating? Most often they are mounted on a 2-way or 3-way valve for mixing hot and cold water. Installation in radiators is impractical, since the control valve on the radiator will perform the same functions, but its cost is much less.

| Name | Note | price, rub. |

| Ball valve Valtec ½” | Stainless steel | 160 |

| Needle valve Fiv Oasi ½” | With the possibility of mounting a thermal head | 310 |

| Thermal head Danfoss | Horizontal mounting | 816 |

| Servo Kermi | Installation via valve adapter | 703 |

Regardless of the choice of valve for the heating system: needle, regulating, for the radiator, you need to choose the right model with the appropriate mounting assembly. After installing the device, the system throughput and its characteristics should not change.

The video tells about the nuances of installing a thermostatic valve on a radiator in a single-pipe heating system:

https://youtube.com/watch?v=83LWCYqAFEk

Stainless steel needle faucet

Needle crane drawing.

Smoothly regulates the flow of the moving medium, and is often used at high pressure. The body is made of stainless carbon steel and the seal has high electrical resistance and can run dry.

The device is necessary for disconnecting, purging and connecting a pressure gauge. The valve is mounted in front of the pressure gauge so that, if necessary, it is possible to block the flow to the sensitive device. A sharp shutoff can destroy the pipe, a stainless steel needle valve helps to withstand the loads.The valve has three positions: "closed", "open" and "partially open".

Valves can be shut-off, regulating or balancing (depending on the purpose). Pass-through, angular or direct-flow (according to design features). Disc-shaped and needle-shaped (by type of constipation). Gland or bellows (by type of sealing of the spindle and cover). The thread on the valve can be external or submersible (depending on the location of the stem nut).

Main settings:

- manual switching;

- flanged connection with the pipeline, coupling - with a pressure gauge;

- automatic closing of the valve in the event of a pressure gauge failure.

The valve has a narrow plug in the form of a cone. The drawing of the needle valve shows that its gate looks like a needle.

The valve consists of a body (1), a cover (2), a union nut (3), a needle (4), a stem (5), an o-ring (6), a sealant (7), a handle (8), a nut (9), washers (10).