Don't go overboard

It should also be noted that 14-15 sections for one radiator is the maximum. Installing radiators of 20 or more sections is inefficient. In this case, you should divide the number of sections in half and install 2 radiators of 10 sections. For example, put 1 radiator near the window, and the other near the entrance to the room or on the opposite wall. In general, at your discretion.

With steel radiators the same story. If the room is large enough and the radiator comes out too big, it's better to put two smaller ones, but the same total power.

If there are 2 or more windows in a room of the same volume, then a good solution would be to install a radiator under each of the windows. In the case of sectional radiators, everything is quite simple.

14/2=7 sections under each window for a room of the same volume

But, since such radiators are usually sold in 10 sections, it is better to take an even number, for example 8. A stock of 1 section will not be superfluous in case of severe frosts. The power from this will not change much, however, the inertia of heating the radiators will decrease. This can be useful if cold air enters the room frequently. For example, if it is an office space that customers often visit. In such cases, radiators will heat the air a little faster.

What to do after the calculation

After calculating the power of the heating radiators of all rooms, it will be necessary to select a pipeline by diameter, taps. Number of radiators, pipe length, number of radiator taps. Calculate the volume of the entire system and choose a suitable boiler for it.

For a person, a house is often associated with warmth and comfort.

And in order for the house to be warm, it is necessary to pay due attention to its heating system. Modern manufacturers use the latest technology to produce various elements of heating systems

However, without proper planning of such a system, for certain premises, these technologies may be useless.

Steel panel radiators are a competitor to conventional sectional type heaters. They are attractive in that compared to all sectional models with smaller dimensions they have a higher heat transfer coefficient. They consist of panels in which the coolant moves along the formed passages. There can be several panels: one, two or three. The second component is corrugated metal plates, which are called fins. It is due to these plates that a high level of heat transfer of these devices is achieved.

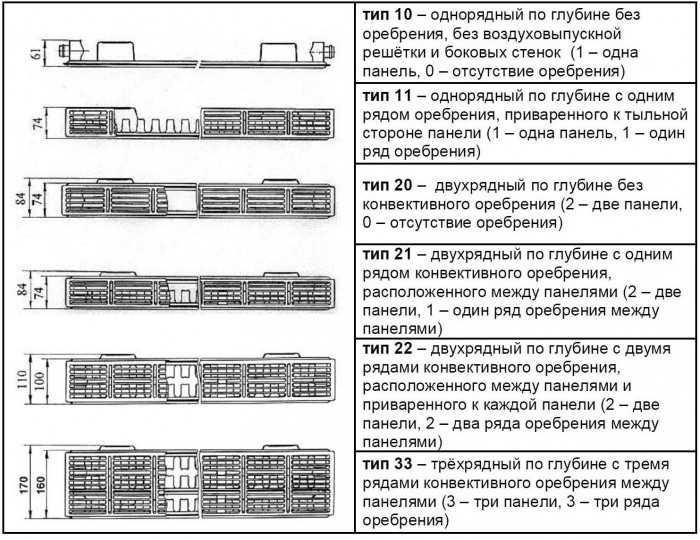

To obtain different thermal power, panels and fins are combined in several versions. Each option has a different power. To choose the right size and power, you need to know what each of them is. By structure, steel panel batteries are of the following types:

- Type 33 - three-panel. The most powerful class, but also the most overall. It has three panels, to which three finning plates are connected (which is why it is designated 33).

- Type 22 - two-panel with two fins.

- Type 21. Two panels and between them one plate with corrugated metal. These heaters, with equal dimensions, have a lower power compared to type 22.

- Type 11. Single panel steel radiators with one finned plate. They have even less thermal power, but also less weight and dimensions.

- Type 10. This type has only one heating medium panel. These are the smallest and lightest models.

All these types can have different heights and lengths. Obviously, the power of panel radiators depends on both the type and dimensions. Since it is impossible to calculate this parameter on their own, each manufacturer compiles tables in which he enters the test results. According to these tables, radiators are selected for each room.

We determine the power

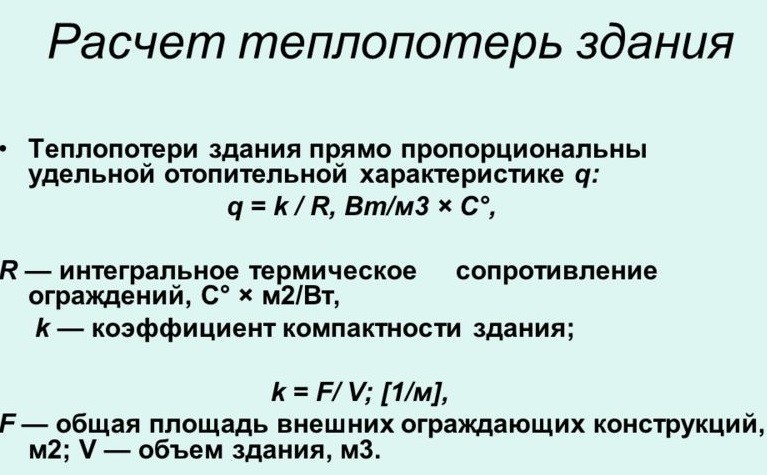

The power of steel panel radiators must be determined based on the heat loss of the room in which they will be installed.For apartments located in standard houses, one can proceed from the norms of SNiP, which normalize the required amount of heat per 1 m 3 of the heated area:

- Premises in brick buildings require 34W per 1m 3.

- For panel houses, 1m 3 takes 41W.

Based on these standards, determine how much heat is required to heat each of the rooms.

For example, a room in a panel house is 3.2m * 3.5m, the ceiling height is 3m. Let's calculate the volume 3.2 * 3.5 * 3 \u003d 33.6 m 3. Multiplying by the norm according to SNiP for panel houses, we get: 33.6 * 41 \u003d 1377.6 W.

SNiPa norms are indicated for the average climatic zone. For the rest, there are corresponding coefficients depending on the average temperatures in winter:

- -10 o C and above - 0.7

- -15 o C - 0.9

- -20 o C - 1.1

- -25 o C - 1.3

- -30 o C - 1.5

It is also necessary to correct heat losses depending on the number of external walls, because it is clear that the more such walls, the more heat escapes through them. Therefore, we take them into account: if one wall goes out, the coefficient is 1.1, if two - we multiply by 1.2, if three, then we increase by 1.3.

Let's make adjustments for our example. Let the average winter temperatures in the region be -25 o C, there are two outer walls. It turns out: 1378W * 1.3 * 1.2 \u003d 2149.68W, rounding up 2150W.

Let's use this number as an example. Provided that the insulation of the house and windows is average, the figure found is quite accurate.

Panel steel radiators KERMI ThermX2

Made according to all European standards, they have a wavy profile surface and are notable for their low price. They are only suitable for closed heating systems. A small volume of hot water, coupled with a high heat output, makes these devices the most suitable for autonomous heating. Moreover, it is better to use them in systems where the coolant is not excessively hot.

These radiators are made according to the latest patented X2 technology, which significantly increased the efficiency of heating devices. By doubling the infrared spectrum, this technology has made radiators very comfortable. Heating time has been accelerated by about a quarter, and savings have increased by 11%. The meaning of the X2 principle is that the front panel heats up first, and only after that - the back. See the video below for more on this.

Video: Technical features of Kermi steel panel radiators

After connecting the panels into the body, the finished product is first thoroughly degreased, then it is phosphated. The final finishing is done by electrostatic painting. The top layer of paint is processed at a temperature of 180 degrees. This makes it durable. The shimmery coating gives the batteries a smart look.

The radiator has screen grilles on top and on the side. They allow to achieve a significant increase in the efficiency of heat transfer - by 60%. The kit comes with 4 pads designed to mount equipment.

There are 2 lines of Kermi panel radiators, which differ from each other in the place of connection to the heating network. Radiators of the Kermi ThermX2 Profil-K (FKO) line are connected on the side. And devices such as Kermi ThermX2 Profil-V (FKV or FTV) are designed to be connected from below.

Side connected Kermi ThermX2 Profil-K

These radiators are equipped with convectors, and their panels are made of two profiled steel sheets connected by welding. There are screens on the sides, and on top there is an overhead grill. Radiators with a side connection type are marked with the letter combination FKO. To connect to the system on the sides, the Kermi Profil-K FKO device has four branch pipes with internal threads (1/2″ in diameter). You can connect the radiator to the pipes from any side.

Technical characteristics of heating radiators Kermi ThermX2 FKO:

- Connecting thread: 4 x G1/2” (female)

- Height: 300, 400, 500, 600, 900

- Center distance: total height minus 50 mm

- Length: from 400mm to 3000mm

- Depth: type 10 and 11 - 61mm, type 12 - 64mm, type 22 - 100mm, type 33 - 155mm

- Working pressure - 10 atm. (1.0 MPa)

- Crimping pressure - 13 atm. (1.3 MPa)

- Max. heating medium temperature: 110°C

- Working temperature - 95°

Bottom connection Kermi ThermX2 Profil-V

All these radiators have a thermal valve built into the design. Its thread is right-handed, with a pitch of M30x1.5. The temperature controller is not included in the package, it must be purchased separately. The thread at the branch pipe is external, its diameter is 3/4″. The center distance is 5 cm. This design is intended for two-pipe heating systems. If you need to connect to a single-pipe system, then they acquire special fittings.

Specifications Kermi ThermX2 FKV:

- Connection thread: 2 x G3/4” (male),

- Radiator heights: 300, 400, 500, 600, 900

- Radiator length: from 400mm to 3000mm

- Distance between supply pipes: 50mm

- Radiator depth: type 10 and 11 - 61mm, type 12 - 64mm, type 22 - 100mm, type 33 - 155mm

- Working pressure - 10 atm. (1.0 MPa)

- Crimping pressure - 13 atm. (1.3 MPa)

- Maximum heating medium temperature: 110°C

- Working temperature - 95 ° C

In addition to connection methods, panel radiators also differ in types. In total, Kermi produces 5 types of steel panel radiators:

Type 10 - single row, has a depth of 6.1 cm. Facing and convector are missing. Manufactured by pre-order only.

Type 11 - single-row, lined, depth - 6.1 cm. There is one convector.

Type 21 - two-row, lined, with a depth of 6.4 cm. One convector.

Type 22 - two-row, lined. Two convectors.

Type 33 - three-row, lined. Three convectors.

The most popular and frequently used is type 22.

Choosing a radiator based on the calculation

Steel radiators

Let's leave out the comparison of different types of heating radiators and note only the nuances that you need to be aware of when choosing a radiator for your heating system.

In the case of calculating the power of steel heating radiators, everything is simple. There is the necessary power for the already known premises - 2025 watts. In this case, we look at the table and look for steel batteries that produce the required number of watts. Such tables are easy to find on the websites of manufacturers and sellers of similar products.

Here is an example of such a table:

The table indicates the type of radiator, in this example we take type 22, as one of the most popular and quite worthy in terms of its consumer qualities. And a 600×1400 radiator is perfect for us. The power of the heating radiator will be 2015 watts. But it's better to take a little more than a little less power

Aluminum and bimetal radiators

In this case, there is one important difference in calculating the power of radiators. Aluminum and bimetal radiators are often sold in sections

And the power in the tables and catalogs is indicated for one section. Then it is necessary to divide the power required to heat a given room by the power of one section of such a radiator, for example:

2025/150 = 14 (rounded up)

And we got the required number of sections of such a radiator for a room with a volume of 45 cubic meters.

Power calculation

The capacity of the internal volume of the cast-iron sample filled with the coolant is 13 liters.

From the Kermi battery passport, it is easy to find out that the heat transfer from a typical single-section unit under code 10 is about 2100 W (with a working volume of 6.3 liters). Using these data when replacing cast-iron batteries with new samples, you can be sure that their heat transfer will be no worse, and even slightly higher.

- the amount of heat loss in the apartment;

- liquid carrier parameters;

- estimated room temperature.

When choosing, the dimensions of the radiator are also taken into account, after which appropriate adjustments are made to the selection algorithm. The desired value of heat transfer is determined by the summary table provided by the manufacturer of a particular radiator from the popular Kermi line. The desired model is located in the corresponding column, opposite which the power value suitable for it is indicated. Experts advise taking this indicator with a small margin, which guarantees the desired result.

After all the parameters are taken into account, the user will be able to more accurately determine the model that is suitable for specific operating conditions.