Buleryan furnace with a water circuit principle of operation, pros and cons

This design is not only a successful hybrid of a potbelly stove with a conventional long-burning wood stove. If previously they had not been able to heat separate rooms, then the connection to the water circuit opened up the possibility of heating entire houses, rather than individual rooms.

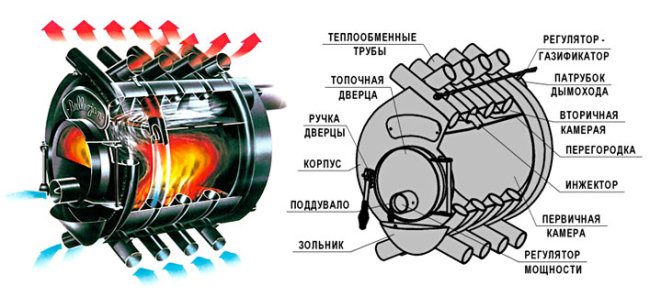

The shape of the buleryan oven resembles a large round barrel. internally divided into two parts. The lower compartment of the furnace body is designed for ignition and burning firewood. High temperature is formed there and heat is concentrated.

After the firewood burns out, the gases rise into the upper compartment of the case. In the center of the furnace there are curved pipes welded into it, or, as they are called, radius pipes.

They provide forced convection, i.e. moving heat to heat the air and distribute it evenly throughout the space.

The design of the stove is such that the pipes tightly fit the firebox with firewood, “wrapping” it by 70%. They play the role of a heat exchanger or heater, since all the heat from the combustion chamber goes to heat the coolant in the pipes.

A specially installed pressure manifold provides the right pressure to move the liquid in addition to its natural circulation.

Thus, the basic principles of operation are heat transfer, heat transfer and convection. Unlike the well-known potbelly stove, the surface of the furnace does not heat up. which means oxygen is conserved.

System with radiators

The design of the boiler with a water circuit is identical to the buller. Only it is not the air that heats up here, but water or antifreeze. Circulation is carried out in a natural or forced way. The liquid coolant is supplied to the upper point of the system, goes to the radiators, then along the return line to the stove, where a drain valve is installed.

When arranging such a system, the unit can be installed anywhere in the building where a chimney can be removed.

It is important to observe the minimum distance to the wall - 0.5 m. For the water circuit, it is better to use reinforced polypropylene pipes that do not deform from high temperatures

Buleryan efficiency in comparison with gas heating

Before buying any heating equipment, you need to make sure that it will be beneficial for the potential owner. The stores now offer a large number of boilers that have excellent designs. but they are quite expensive to operate. Therefore, it is necessary to find such an installation model that has an aesthetic appearance, is inexpensive, and does not require large financial costs from the owner during operation.

Positive characteristics

- The use of Buleryan stoves provides fast and uniform heating of a large area. If the installation is equipped with a water circuit, then the generated thermal energy is easily transported even to rooms located on the second and third floors.

- This model is small.

- After installation, the owner is provided with ease of use. The installation process is not very difficult. However, a chimney device is necessary, for which it is better to invite a professional stove-maker.

- Compared to traditional ovens, this oven consumes less fuel during operation. One full load will be enough for 12 hours of plant operation.

Cons of buleryan

When using this stove, only firewood with a low percentage of moisture can be loaded into the combustion chamber. It is advisable to use those tree species that do not form resins during combustion.

During operation, the resulting generator gases in such models are not fully used. In the combustion chamber, their combustion occurs in a volume of less than 70%, so such a furnace cannot be called perfect.

Performing work on the construction of the chimney, special attention must be paid to the insulation of the pipe. If this is not done, then during the operation of the equipment condensate will occur, which will reduce the efficiency of the buleryan

In most cases, these stoves are made of metal.Therefore, a suitable protection should be placed a meter from the installation. If the location of the boiler is the corner at the junction of two walls, then you need to think about protecting them. They cannot be placed close to the walls. This is a big problem for small spaces. 20 cm is the maximum allowable distance from these units to the wall.

If you want to save space and place the stove as close to the wall as possible, you will have to sheathe them with long metal sheets that exceed the height of the stove. It is advisable to install basalt insulation between the wall and the sheet. When this is done, the metal screen will perform two functions at once - to protect the system from heating and act as an additional source of heat.

There is one more thing to be aware of. It concerns the design features of the furnace. During operation of the unit, dust will enter the openings of the pipes. During the operation of the furnace, a high temperature arises, which burns out everything in its path. When using buleryan, an unpleasant odor may occur. In addition, positively charged ions appear in the air near the furnace. They well attract particles of dirt that are inside the human body. If cold viruses predominate in the room, then the risk of illness for healthy people is high. Therefore, in order to avoid this, it is necessary to regularly ventilate the room, as well as perform wet cleaning 2 times a day.

Features of equipment with a water circuit

A number of undeniable advantages are characteristic of any furnace. Buleryan is no exception. The effectiveness of the use of this equipment largely depends on:

- in which room it will be installed;

- what expenses the owner is willing to go.

It should be understood that the prices for such installations are quite high. In addition, during the operation, you also have to bear serious costs.

The main features of Buleryan with a water circuit:

- in the design of the furnace there is a gas afterburner chamber, which is located on top of the combustion chamber;

- the oven is equipped with hermetically closing doors;

- the casing with which this equipment is equipped increases the convection of hot air masses;

- an ash pan is not provided in such furnaces.

Buleryan differs from other types of furnaces in that it has a special arrangement of pipes. Due to this, heat transfer increases when using this equipment. Cold air enters the lowest pipe. When it is heated to a certain temperature, it spreads throughout the room.

It is worth noting that, unlike other types of wood-fired space heating equipment, the design of the buleryan is thought out in detail. In the combustion chamber, during the operation of the furnace, not only firewood is burned, but also combustion products. Therefore, in order to create a comfortable temperature in the room, the owner can use natural fuel to a minimum.

Advantages and features

Heating furnaces Buleryan have a variety of configurations and sizes, allowing you to heat up to 1100 cubic meters of space without any problems. Finding the right model is not difficult. The use of this equipment for heating a house is largely advisable, as evidenced by the following points:

- Safety. The heating furnace of this configuration does not heat up to metal incandescence, does not burn out oxygen.

- Heating is carried out evenly over the area of the entire house.

- heating speed. The Buleryan stove of any configuration is able to warm up even a large room quickly enough.

Breneran with water circuit

The operation of the furnace is autonomous - it runs on fuel, using neither gas nor electricity.

Maintenance of the furnace is not a laborious process, since the amount of ash is very small.

One load of fuel can give the furnace operation for 8–12 hours without additional lining.

The heating process can be controlled.

Afterburning gas in a separate chamber provides an efficiency of 85%.

But Buleryan furnaces with a water circuit have other features that should not be forgotten during its operation:

- Firewood for the stove must be well dried. It is also best to use rocks that do not emit resins.

- When equipping a chimney, it is necessary to produce high-quality insulation of the pipe. Otherwise, condensation may occur. All this reduces heat transfer.

- In the second combustion chamber, the gases do not burn completely.

- The distance between the oven and the walls, which must be at least half a meter to meet fire safety conditions. This is a fairly significant problem for small houses. In some way, wall cladding allows you to solve this issue. next to which the installation is located, with metal using basalt insulation. First, the wall is sheathed with insulation, and then the sheets of metal are fastened. This will ensure not only the fire safety of the room, but also enhance the effect of heat transfer. In this case, the maximum allowable distance is 20 cm.

- Dust and dirt is another important problem of Buleryan furnaces. The dust that enters the pipes is burned out at a very high temperature, as a result of which an unpleasant odor is formed. And since the appearance of dust in the pipes is inevitable, then the unpleasant smell during the operation of the furnace is also. Also, dirt, attracted by positive ions that form near the stove, spreads through the rooms, entering the human body. This is how various viral diseases spread. Therefore, in houses heated with such stoves, it is necessary to do wet cleaning more often, and so maintain good ventilation.

Perhaps a bath stove of this model will be an ideal heating device in your steam room, so check out the article Buleryan (Breneran) Sauna Stoves.

When choosing a Buleryan heating furnace with a water circuit, you should pay attention not only to its configuration, but also to the door material. They are made out of metal

as well as glass. Of course, the glass looks quite impressive, but during the operation of the furnace it does not carry anything but the collected dust and dirt. If the burning process is visible through it, then only at the very first moment when the firewood is kindled. In addition, a glass door significantly increases the cost of the entire structure.

Furnace installation

choose a seat

When the installation of the furnace is completed, it must be connected to the heating system. When performing installation work, experts advise using pipes with a layer of reinforcement. The use of such products eliminates their deformation when exposed to high temperatures. In addition, they are best suited for such a heating system.

When the installation of the elements of the heating system is completed, a procedure such as pressure testing is carried out. Then the entire system is filled with water. After that, the furnace can be started, and then you should observe its operation. If no errors were made during installation, the equipment will work properly without causing problems to the owner.

But even when using such equipment in the house, one should not forget about safety. To do this, the wall near which the furnace will be installed should be treated with fireproof material. It is applied to the wall surface above the top point of the furnace by 1 m.

Step-by-step instruction

The tightness of the chamber depends on the quality of the seams, so an inexperienced craftsman should practice and check the material for weldability. As a basis, you can take the drawings of a small oven for small utility rooms and increase to the required size.

Cutting parts, forming blanks

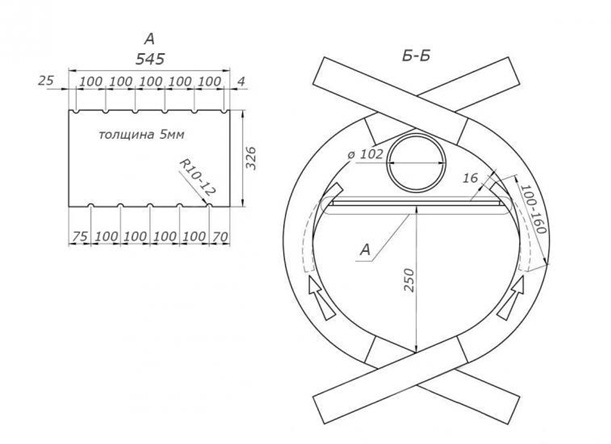

We cut off 8 pieces from the pipe from 1 to 1.5 m long. Cut out ribbons from the sheets with semicircular notches at the ends.

We bend air ducts at an angle of approximately 80º. We bend the metal strips under the same degree.

Assembly and welding

We lay the curved convection pipes with the outlet part outward in a checkerboard pattern, starting from the back wall to the exit to the front level. For stability, we put wooden bars between them. Align the structure. We grab with spot seams at the junctions.

We weld the pallet horizontally into the inner part of the body of the body. To remove combustion products, it is better to make grate from two halves connected at an angle. First, we grab it pointwise, then we pass the entire plane with a continuous seam. We insert bent steel strips between the pipes, weld them.

Front and back walls

First you need to make a template. We attach the cardboard to the sidewall and circle it with a pencil. Along the contour, we cut out a part from sheet metal. On it we cut out a loading window with a diameter of half the wall, shifting the center slightly below the axis. We weld a strip 40 mm wide around the perimeter of the window from the outside for a short “collar”.

We make the back wall in a similar way. A hole corresponding to the diameter of the outlet pipe is cut out in the upper part of the circle. We insert a T-shaped piece from a pipe 100 - 110 mm with a valve into it, connect it to the body. We put the walls in their places.

door

The furnace door is a short cylinder that must be accurately put on the “collar”, falling into the gap between the outer and inner rings. To increase the sealing between the rings, you need to drive an asbestos rope.

In the workpiece, we cut out a hole for the blower, weld a pipe with a throttle valve. The damper can be made by cutting through the walls of the pipe along the axes. We take a pin, weld a flat disk on it, insert it into the perforation of the pipe. From the inside, we install a semicircular heat-reflecting screen on metal spacers. We hang the door on hinges, equip the lock. We make them from scraps of a sheet. You can buy ready-made parts.

In order for the stove to be located at a sufficient height from the floor, we bend the legs from the remnants, weld them into the body in the places indicated in the drawing. After cleaning and cosmetic grinding of the surface, the structure is ready for installation.

Buleryan with a water jacket

A new modification with a water circuit is manifested in the connection of pipes with a water heating system from above - to the water supply, and below - to the return manifold.

Thus, the stove, as a heating element, receives hydropiping or additional opportunities to distribute heat through the movement of hot water through pipes encircling the living space.

Buleryan can be compared to a solid fuel boiler, but without an automatic system. The design of the stove allows the connection of several water circuits for maximum heating of various rooms.

Due to the active water circulation in the connected radiators, ideal heating of country houses occurs. cottages or cottages.

Buleryan Aqua is a modification of the good Buleryan stove, in which a water jacket enhances overall performance. Furnaces of this group are connected to the heating system, in the upper part of which there is an expansion tank for accumulating excess heated water.

Water in its movement passes through the radiators, after cooling it returns to the chimneys.

What features do bullers have

The units are installed in garden houses, garages, greenhouses, workshops, places where there is no natural gas, electricity.

They can work, providing burning in the smoldering mode up to 10-12 hours, on firewood, as well as woodworking products: dry pellets, briquettes, wood chips, paper, cardboard.

Whose invention is this

Canadian heating specialists were tasked with developing a furnace for logging teams that runs on waste material: branches, cones, sticks.

The firebox had to accommodate wood of a non-standard configuration, warm up the house in a maximum of 10-20 minutes.

According to the requirements, according to the drawings, a mobile device was created that works like a heater, safe, easy to operate.

Structure

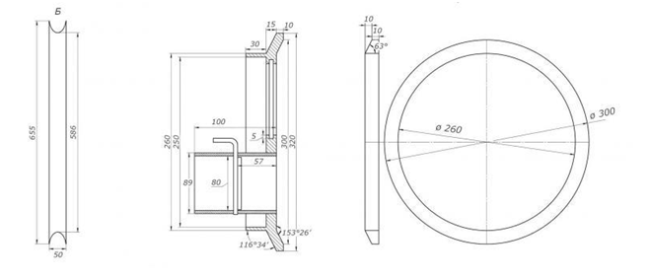

Structurally, the Buleryan slow-burning stove is an oval sealed barrel-shaped boiler. The main feature is the presence in the body of two rows of air pipes, between which metal (usually steel) strips are welded. The tubes are bent in the form of a parabola and are immersed in the furnace compartment by two thirds of the diameter.

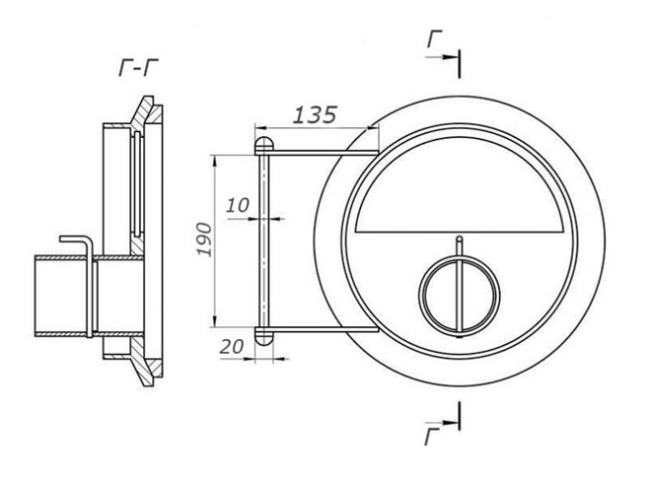

The large round door is equipped with an air supply regulator in the form of a pipe with a smoke damper (throttle). A window with heat-resistant glass allows you to control combustion. On the throttle handle there is a scale with degrees and a movable stop limiter.

The heating chamber is divided into three parts. Below is a grate made of cast iron or steel, the upper partition in the form of a sheet with holes separates the afterburning zone. The pallet for removal of ashes is absent as superfluous. Ash particles fly out through the chimney.

On the back wall there is an exit with a damper. The gaps on it do not allow carbon monoxide gases to enter the room even with the door open. The branch pipe is connected to the chimney by a horizontal section, in which unburned pyrolysis gases cool down.

How is heating

The operation of the device is based on forced convection heat transfer. After ignition, cold air is sucked in through the lower openings of the air ducts, warms up quickly, and exits the upper opening in a hot intense flow. It is smoothly, evenly distributed throughout the room, cools, falls down. The unit, which combines three devices at once: the buleryan furnace itself, the heater, the gas generator, operates in two modes:

- Kindling, which provides quick heating up to 120-150º C.

- Gasification that supports smoldering firewood at a level of 50-55º C.