Characteristics of brass

Brass alloy is obtained by combining zinc with copper, to which nickel, iron, manganese, tin, and lead are sometimes added. Typically the material consists of 70% copper component, with 30% zinc component. Almost half of the produced alloy consists of secondary zinc. Technical metal contains about 50% zinc part with 4% lead.

There is also a special type of brass connection called “tompac”. In it, the copper component reaches 97%, and zinc - from 10 to 30%. From this compound, excellent jewelry, various art products, insignia, accessories are obtained.

A couple of centuries ago, brass alloys were often used as counterfeit gold, which was achieved by using pure zinc rather than ore. Such a connection was very difficult to recognize by inexperienced users. It has become actively used in various industrial fields due to its unique properties. These alloys have high ductility, abrasion resistance and good corrosion resistance.

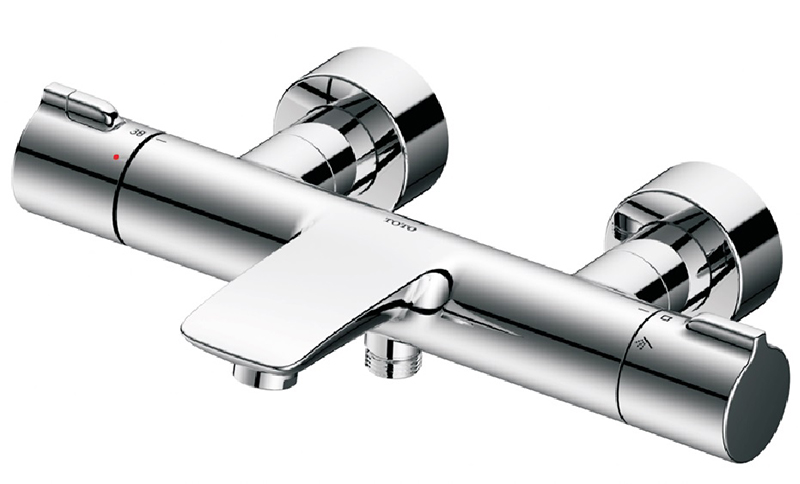

Single Lever or Single Lever Models

These models have only one handle. It is she who regulates the parameters of the water flow. It is worth noting that you can adjust the water temperature both separately and simultaneously. Such devices are also called single-handed and single-grip. If we consider the principle of operation of these mixers, then they are divided into ball and cartridge. The latter are more widespread. If the product has a control knob located horizontally, then it is called joystick.

The main advantage of single-lever designs is comfortable operation. They are very easy to operate with just one hand. Moreover, these products can last for many years. True, the last factor strongly depends on what kind of water flows in the pipes, that is, on its quality. It is from here that the main drawback of single-lever models follows. So, in urban networks, water enters apartments and houses with a lot of garbage that cannot be seen with the naked eye. Because of this, the mixers break down ahead of schedule. For this reason, it is better to install a water filter for using single-lever products. After all, if a mixer of this type breaks down, you will have to buy a new cartridge for it, the cost of which is quite high.

As with valve models, single-lever mixers also have improved models. They are distinguished by the presence of a function that allows you to save water. It consists of two operating modes. One mode for economy, and the second supplies water with a strong stream. But in order to switch to it, you need to make some efforts to overcome the resistance that occurs when you try to fully open the lever.

How to distinguish a fake

In view of the fact that now a lot of goods, including mixers, are faked, it makes sense to figure out how to distinguish a branded product from a fake counterpart.

First of all, you need to carefully inspect the galvanized coating. The presence of any scratches and black dots is unacceptable. Some manufacturers label their products for added protection. It can be a company logo, which marks the faucet handles and the back surface of the case. In no case should you trust sellers who persuade you to purchase products without such markings. In addition, branded faucets are sold in their original packaging. Therefore, the usual "cardboard" or bag is evidence of counterfeit products.

The name of the company, printed with a typo, should also be alarming. Moreover, each branded product must have its own warranty card with the addresses of service centers.If there is no such coupon, then it is better to refuse to buy a mixer altogether.

In order to extend the life of the mixer, it is advisable to install an additional filter for water purification. This is especially true for new buildings. Water enters them through new pipes, which, as a rule, contain quite a lot of garbage and various technical impurities. It is better to install mortise filters. Naturally, this process is costly, but you will be sure of the reliable operation of the mixer.

Note that domestic-made mixers, which are equipped with the usual rubber gaskets, tolerate contact with poor-quality water well. Domestic models are even better because they can be disassembled and repaired. With foreign analogues, such a number will not work.

When buying a mixer, special attention should be paid to the connecting pipes through which water will be supplied. The tubes are rigid, made of copper or brass, as well as flexible, which are metal-polymer hoses.

For hard tubes, you need to buy an adapter in addition. The latter do not always come with a mixer.

Video. GROHE bathroom faucet installation

The faucet in the kitchen is an actively used appliance. It keeps the water in the closed state, in the open state it mixes the cold jet with the hot one, sets the pressure. These factors, together with improper handling, contribute to rapid wear. Therefore, when choosing, it is necessary to take into account not only the appearance, but also the reliability of the product, you must agree.

In order to purchase a reliable working product, you need to know the design of the kitchen faucet. In addition, this information will help you understand how difficult or simple the repair will be. Will the owner be able to do it on his own or will he need to call a plumber?

You will learn everything about the design features of kitchen faucets from our article. We have described in detail the varieties presented to the consumer by the market. For a visual perception of the information, diagrams, a selection of photos and video repair instructions were attached.

The name "faucet" directly indicates the main function of this plumbing equipment - mixing water. The device is connected to the pipes of cold and hot water supply, and its task is to supply water in the required proportion.

Adjustment is carried out manually by the user. In addition to temperature correction, the mixer also adjusts the pressure of the water jet.

Mixer - a device that combines two taps in a single housing, connected by separate nozzles to cold water and hot water pipelines

Materials used in production

A modern kitchen faucet can be made from the following materials:

- metal alloys (bronze, brass, silumin);

- polymers;

- ceramics.

A metal faucet is the most popular option for use in the kitchen. Brass and bronze do not oxidize or corrode from regular contact with water. In addition, these materials are chemically neutral, which means that deposits of mineral salts do not occur on their surface.

Image Gallery

What materials are mixers made of?

Truly high-quality faucets are made from brass - a material that is a copper-based alloy. It accounts for up to 60%. Usually zinc is added to copper, metals such as:

- lead;

- manganese;

- nickel;

- iron;

- tin;

- aluminum.

Brass is resistant to constant exposure to water and is safe for the human body. There is one thing - before buying it is worth asking about the content of lead. The norm assumes 2.0-2.5%, however, some manufacturers increase the presence of plumbum to 5-6%. It is not dangerous for health, but problems may arise during the operation of the mixer. The risk of "hot" cracks, leading to leaks or even bursting of the tap, increases.

What are sink and shower faucets made of besides brass? Chinese models are most often made from Zamak (in our country, this composition is better known as TsAM). Its basis is zinc alloyed with aluminum, copper and magnesium. This material costs much less, thanks to which manufacturers can set low prices for the final product. But in terms of reliability and durability, Zamak is significantly inferior. Additives that are added to tap water corrode the faucet body relatively quickly.

As a result, leaks are formed that will need to be eliminated. Usually, parts that are not in constant contact with water, such as handles, are made from TsAM. This alone allows you to seriously reduce the cost of the mixer without losing quality.

How to check - brass or Zamak?

It is not always possible to be sure that the model is made of brass. Some unscrupulous manufacturers "improve" the quality of their product by providing false information about its composition. Faucets made from Zamak tend to be whiter and have a rougher surface. In addition, they are much lighter, although not in all cases. Cunning counterfeiters sometimes put a metal ball inside for weighting, so it’s better not to focus on weight.

In general, the original bath, shower or kitchen sink faucet from a well-known brand contains an engraved or lasered logo. On fakes, there is no such sign, since its application is too expensive and deprives the fraud of any meaning.

Spraying

The answer to the question of what mixers are made of will be incomplete if we do not mention the spraying of the body and tap. The surface of the device can be coated with almost any material, including:

- chrome (Grohe Euroeco 32734000, Lemark Pramen LM3306C);

- copper (Migliore Princeton ML.PRN-802 Ra, Edelform Mollis ML1812C);

- bronze (Lemark Vintage LM2806B, Elghansa Retro 2702754);

- gold (Cezares Elite LSM1-03/24-Bi, Migliore Prestige ML.PRS-744).

The quality of the coating plays an important role in the issue of durability. Most often, chrome is used, giving the mixer a modern look. If you are more interested in the noble "old", check out the models covered with gilding, bronze or copper. The surface of the product must be as smooth as possible. If, as a result of the inspection, bumps, sagging, or even color heterogeneity is simply observed, it is better to refrain from buying.

Types of mixers

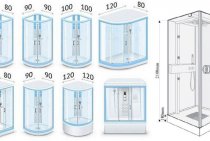

In order to understand how to choose a quality faucet in a bathroom with a shower, you need to have a clear idea of what they are, how they should be attached and what functions they perform. To facilitate the selection process, mixers are divided into the following types:

1) According to its purpose:

- faucets with low spout. It can be short or long. Such faucets have a water switch in the shower and spout.

- shower mixer. Mainly used in showers. A distinctive feature is the absence of a spout and a water flow switch.

- universal models. It is equipped with a long spout and can be used for bath and sink at the same time. Great option for small bathrooms.

2) By type of fastening:

mortise. Mounted on the side of the bathroom. Such models look beautiful, due to the fact that the hose is hidden under the bath, but if replaced with a new one, difficulties may arise. In such models, it is the hose that often fails.

stand mixers. Usually used for freestanding bathtubs. They are the most expensive option. Pipes lead directly from under the floor.

Wall mixer. The most commonly used models. Equipped with a long or short spout and a hose with a watering can, which are hung on the wall.

3) By design, they can be divided:

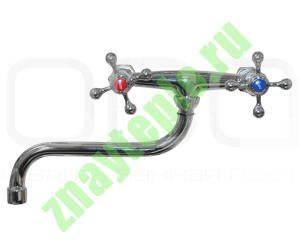

Two-valve. Such mixers have two handles - for hot and cold water. The water supply is carried out at the expense of the bushing valve, which blocks or opens the flow. The main advantages include quick temperature control and ease of installation. However, such taps constantly require gasket replacement, otherwise it leaks. If you have meters installed, then such a purchase will be costly, because while you set the desired temperature and adjust the flow, a lot of water will flow out.

Single valve.They have one lever, due to which the total water supply is regulated. It is convenient that you can simultaneously control the flow and temperature. Many models have valves that save water supply. The main disadvantage is that in the event of a breakdown, it is necessary to change the entire module.

Contactless. Water is supplied automatically by infrared sensors. They save water but run on mains electricity or batteries, which can sometimes lead to difficulties in the event of a power outage or lack of batteries. Not suitable for bathtubs, only for sinks.

What materials are modern mixers made of?

When choosing a new faucet, you need to find out what material it is made of.

Please note that the heavier the unit, the longer it will last you.

At the moment, manufacturers most often use the following materials:

- Plastic. Such mixers are not expensive, easy to install, not heavy. But their huge minus is that they will not serve you for many years and can break at the most unforeseen moment.

- Alloy steel. Such mixers are resistant to corrosion, however, this model can be found on the market less and less, because. their output was reduced due to the complexity of processing the material. In addition, they have a short service life.

- Silumin is a special alloy of aluminum and silicon. It does not corrode, but is a rather fragile material.

- The most durable and popular material is brass. An alloy of copper and zinc is added to it in such proportions so as not to harm human health. The top layer of brass mixers is nickel-plated or chrome-plated. The chromeplating increases the service life of the product.

Additional elements (watering cans, handles) of mixers are made of ABS plastic - it is quite durable and will last a long time.

The difference between copper and brass

Copper has features that make it popular in the manufacture of various decorative elements. In addition, it has good electrical parameters, as a result of which it is used in the manufacture of electrical apparatus. At home, you can distinguish copper elements from brass by several criteria.

:

- color;

- hardness;

- marking;

- area of use.

Color

To determine the metal, it should be cleaned. The metal surface is freed from contamination using a solution of plain water with vinegar. This removes not only dirt, but also an oxidizing film. Under the white light source, the product being tested is carefully examined. A brass thing differs from copper by a simple visual observation. A copper object will have a brownish-red color of a uniform appearance, while brass will look lighter, with multi-color tints. This heterogeneity indicates the presence of several metals in the composition, which determine the color shade. It is practically impossible to determine copper under a yellow lamp or in daylight.

Hardness

To understand how to distinguish copper from brass, you should tap them lightly. A copper product makes a muffled sound when it hits a hard area. This is due to the special softness of the metal. Brass objects are characterized by a sharp, ringing sound of impact. This check is used for large items.

Marking

Some items have special markings on their surface. For brass products, the letter "L" is used. On copper elements, the designation is practically not put. Some parts may be marked with the letter "M" with a numerical addition. In this case, special reference books are used to determine the specific composition of the material.

Application area

Distinguish between these materials and the area of use. Brass alloys are often used for the manufacture of various components and parts. Copper is an ideal element for the production of electrical wires and other electrical parts.This is due to its excellent electrical parameters.

Materials from which mixers are made.

Modern mixers are made mainly of two materials:

- Silumin is an alloy of aluminum and silicon. It is made from low quality Chinese faucets. The main disadvantage of this material is its fragility (it can literally be broken with bare hands). The silumin mixer is easily recognizable by its light weight and low price. In appearance, it will be nondescript - with poor, cheap coverage and backlash

- Brass is an alloy of copper and zinc. Strong and expensive material. Faucets made from it are more expensive, but they can last five or more years without the need for repair. A brass faucet can also be identified by weight, but only in its case this weight will be impressive. There is a large selection of European and Chinese brass faucets on the market.

For those who doubt, I post a video from HansGrohe, which shows the process of making a real brass mixer. This is how plumbing is done in Europe. High-quality materials and expensive, skilled labor are used here.

Models with valves or valves

These products differ in that they have two valve handles. One of them opens the supply of cold water, and the other - hot. These models are easy to recognize. They equip most bathrooms. Often they are called two-valve. This is easy to understand, because in their design there are two valves.

Faucet mixers belong to the classic style, to retro and country styles. They have such advantages as simplicity of the device, classic appearance and low price. In addition, these products are highly reliable. They perfectly tolerate contact with hard chlorinated water. As for the shortcomings, they include the fragility of the sealing gaskets. Over time, they become unusable and the faucet leaks. Although this disadvantage is easily eliminated by replacing the old gaskets with new ones. Also considered a disadvantage is the high water consumption, the difficulty in adjusting the pressure of the jet, its temperature. This implies a certain inconvenience, which lies in the fact that the regulation must be carried out with two hands.

But now on sale you can find more advanced models of valve-type mixers. They are valves that are made of ceramic and have a rotation mechanism. Such products are two rounded plates. Their surface is perfectly smooth with through holes. The valve can rotate ninety and one hundred and eighty degrees. So it is much more convenient to set the parameters of the water flow.

Where is silumin used

The popularity of the use of silumin is by far the highest in the field of mechanical engineering and aircraft building. And this is not surprising, since the material is light and durable. For airplanes, it makes it easier to lift, and for cars, this affects the cost: the more weight, the lower the price.

Parts such as pistons, engines, body parts and cylinders are made from it. Slav is often used in the manufacture of weapons, for example, air rifles, including boxes for barrels and almost all components of these weapons. In the modern version, weapons made of silumin are light and comfortable to handle. The main disadvantage of structural elements is the fragility of the material, that is, with any slight impact, the product can crack or break. Silumin pans are light, but, again, fragile.

Silumin, application

which has become popular for gas turbine generators consisting of plate heat exchangers - an excellent solution for equipping energy supply systems. The melting temperature allows the material to be used for these products.

Material Description

Definition

silumin is easy to find on wikipedia

It is an alloy based on aluminum with the addition of silicon.At the same time, the content of the additional component ranges from 4 to 22%, and the main part is aluminum.

Silumin alloy composition

also contains a small amount of impurities of other metals: copper, calcium, titanium, iron, zinc, manganese and others.

Since the maximum amount of silicon is up to 22%, outwardly it is easy to distinguish it from real metal. It is slightly darkened, therefore it resembles cast iron, but in fact only a person with experience will be able to recognize this material.

What is silumin

in real life, and where does he meet?

Contactless models

Technology, as you know, does not stand still. Technological development has not bypassed the creation of mixers. As a result, designs appeared equipped with infrared sensors, as well as a water supply mechanism without any mechanical action. Water flows if you simply put your hands under the faucet spout. It must be understood that such devices depend on the source of energy. Based on this, they are:

- Autonomous, that is, it has a working battery that needs to be changed from time to time.

- Powered by electricity.

Contactless devices may have a display, but there are models on the market that are not equipped with one. Of course, the presence of the display adds comfort. It displays the temperature and strength of the water flow. Contactless products are often installed in public facilities. But they are also found in residential areas.

The main advantages of such structures include a beautiful view, the ability to save water, a high level of comfort during use. At the same time, they also have disadvantages. These include high cost, dependence on the power source.

The difference between silumin and brass

The silumin material consists of an aluminum base with the addition of silicon, as well as a small amount of copper, iron, and manganese. It has good wear resistance and strength in relation to aluminum things. The difference between silumin and brass lies in the fragility of this material and the features of its application. They are used for casting many products used in various fields, including for household goods, as well as for the manufacture of costume jewelry. Silumin object is characterized by high porosity and low strength. During processing, silumin begins to crumble, which clearly distinguishes it from brass things.

To buy a truly high-quality, durable and reliable faucet for your home, you should be extremely careful and study the information on the topic in advance. For example, tips on how to distinguish brass from silumin. The clearest way to explain to readers is how to distinguish silumin from brass in a mixer, experts in this field. It's actually quite simple to do this. Modern faucets are made from a variety of materials. This depends on their price and quality. But most often, manufacturers use silumin and brass. The first material is an alloy of silicon and aluminum. It is used to create low-quality budget plumbing. Of course, it has a corresponding price. The main disadvantage of silumin mixers lies in its fragility. A strong strong man can break such a product with his bare hands, without using any special tools.

The second type of material most commonly used today for the manufacture of mixers is brass. It is an alloy of zinc and copper. As you can see from the composition, this is a strong and reliable material. It will serve its owner for many years and will always delight with excellent quality. Without the need for even minimal repairs, brass faucets can work for more than 5 years. Among their shortcomings, one can note only the high cost. Today in stores you can find brass plumbing made in Europe or China.Interestingly, mixers from the material under discussion from Asian manufacturers are in no way inferior in quality. Therefore, they can also be safely purchased.

Some sellers, in order to raise prices for their goods, give incorrect information about what material the mixers they offer are made of.

Therefore, it will be useful for each buyer to be able to independently understand this important issue. Experts note that on the modern market, more than 90 percent of sanitary products supposedly made of brass are fake.

In appearance, they are almost impossible to distinguish from silumin mixers. The thing is that both types use the same external coating - chrome. Therefore, when choosing, you need to focus on other signs. The first step is to pick up the vending product. If it is really made of high-quality durable material, then its weight will exceed 3 kilograms. This can usually be determined without weights. Too light mixers are probably silumin.

Having dealt with the weight of the product, you will need to study its internal part. In a quality product, this surface will be yellow and smooth to the touch. This is because brass faucets are always made by casting. Only at the next stage they are mechanically processed. Therefore, inside the product there will definitely not be any roughness and other imperfections. Silumin mixers cannot be created in a similar way. This material is extremely fragile, so joints, depressions and irregularities will always be noticeable on it. The main thing is not to be shy to study the mixer so closely and in detail. It depends on how high-quality, strong and durable the product can be purchased. You can safely ask the seller, among other things, to demonstrate the documents for the goods, which will indicate its material.

Plumbing products made of brass always look very simple and concise. The special technology of their manufacture does not allow creating any decorations and patterns on the surface.

In the process of choosing a mixer, you should pay attention to its labeling. Silumin is marked with the letters "AL", and an alloy of zinc and copper - with the letter "L"

Usually this information is specified in the technical data of the product.

Faucets according to the application

For the shower - it is compact, does not have a spout and a switch to the bath and. Water immediately enters the shower set and mixes there, water of the required temperature is obtained.

For a bath - they often have a low spout, they are swivel or fixed. Products are available with a hand shower, with a shower holder (adjustable height) and wall-mounted. Some models may have an electronic control system.

Faucets are also distinguished by the fact that they are designed for 3 or 4 holes. It looks like several handles - for filling a bathtub, a hand shower, etc.

Bathtub and sink faucets are similar to bathtub faucets, mostly looking at the wrong ones when choosing. characteristics, but on compatibility with the rest of the plumbing. There are models that have a special drain set, you can close or open the drain hole with one touch of the lever on the mixer.

The basin faucet can also be 1 or multi-hole, because of the ease of installation, single-hole is more popular. For easy maintenance of the sink, there are faucets that are equipped with a special retractable spout.

The bidet faucet resembles a sink faucet, mounted on the side and designed for 1 or 3 holes. They differ in that the bidet set has an aerator with a ball joint, which makes it possible to change the direction of the jet and simplifies the use of the mixer.

Expert answers

gorynych:

brass ... from brass, and nickel-plated and chrome-plated can be made of steel ... and rust from the inside

yang bong:

There is no difference between brass and nickel! but there is a silumin neckel but rarely, still a thin-walled nickname. fitting brass not ok.the most Ok fitting CAST IRON!!!!

Alexander:

Often, non-water-conducting grades of brass are hidden under the coating, which the pros might notice by surface oxidation.

leonmelesh:

the term / concept fitting is very vague. for example, a metro tunnel is assembled from fittings weighing approximately 100 kg

Vyachesl@v:

Take brass.

Loiso:

1. Brass fittings are brass2 fittings. Nickel-plated fittings are fittings made from almost any material that are plated for corrosion protection or for aesthetic purposes with an alloy of chromium or nickel. again, it all depends on the thickness of the layer and the reasons for the chrome plating.

I usually look at unfamiliar fittings by weight. Silumin is a very fragile and lightweight material, I usually sift it out.

Dmitry:

they make mixers from brass, less often silumin and very rarely from bronze. It seems that I also met stainless steel. Brass is an alloy of copper and zinc. Zinc, by the way, leaches out of brass over time (in some grades). And in some varieties there is also lead (why it is not put on drinking water). Bronze is the more expensive option. It is brighter new than brass. Over time, it gives a greenish coating. (and figli is also an alloy of copper). And you should not be afraid of copper - it has a permit for drinking water and is very durable ... And pink spots - they can be a reaction to bleach! I know one pool, with bleach just right: there all the fittings are just pink. And by the way, they buy it periodically comes - they fall apart ....

Andrey Ponomarev:

No, definitely not copper. Copper is too soft a metal, so brass is the best option for plumbing faucets. What you see showing colored spots (pinkish color) is probably a thin layer of copper plating to improve adhesion with the next layer of paint material.

Irina Zasekina:

This is bronze (and this is an alloy based on copper). Auxiliary metals can be nickel, zinc, tin, aluminum and other cheap additives.

TV networks Novocherkassk:

I think brass, just the coating is not of high quality. And the turntables are made of another material, which is covered with copper, so that the decorative coating holds well. Through copper plating, even plastic is coated with chromium.

Vladimir Petrov:

And what difference does it make to you, the main thing is that it is heavy and of high quality. And then copper brass bronze what's the difference all is well. It would not be superfluous silumin

Elena:

To fill in surface defects, a layer of copper is applied to the brass to fill in irregularities, dents, scratches, and only then - a layer of nickel and chromium or some other coating

Timon:

This is a golden tap covered with copper for better adhesion with a galvanized coating)))) Saw Shura saw)))

Alexander Vakhromov:

Inspired. I remembered as a plumber, chopping new taps with a chisel before installation. I ask: Why? Answers: I will put a new, shiny one - they will twist it by the evening! And with notches, who needs it?! Copper taps have sunk into oblivion. Your faucet is brass. Pink spots are the result of a chemical reaction, the aggressive component of detergents (rather acids). Battery terminals also have pink spots.

Can't find the fire?

Brass is an alloy of copper and zinc, and when it is exposed to acid (solutions that have an acidic reaction), the acid and zinc interact - dezincification, so the pink color is brass devoid of zinc, i.e. pure copper. This can be verified at home by placing some brass piece in a solution of citric acid for a while.

Anatoly Bondar:

Most likely, a cheap zinc alloy has a copper substrate galvanically applied, and a decorative bronze layer on top. Soon you will find, under the copper plating, a gray alloy.