Advantages of cork sound insulation

Cork soundproofing the ceiling in the apartment provides many advantages:

- The external attractiveness of the material allows it to be used without a finish coat. It itself will perform the functions of finishing the ceiling.

- Due to its environmental friendliness, cork is allowed to be used in homes where allergy sufferers and small children live.

- The coating does not attack mold and rot, it does not electrify, does not absorb odors and does not accumulate pollution.

- The sound absorption coefficient of the cork is 0.85, provided that the wave frequency does not exceed 2.1 kHz. Other materials with similar properties have a lower coefficient (0.7). However, in comparison with them, cork dampens low-frequency noise and vibrations worse.

- The material has low thermal conductivity, therefore it additionally protects the room from the cold.

- The coating is wear-resistant, elastic and durable. Although these properties are not as important on the ceiling surface as on the wall, it still affects the durability of the finish.

- The material is resistant to burning and does not require special care. The cork finish is opened with varnish, after which the surface is allowed to be washed.

Methods for laying cork

To fix cork sound insulation to the ceiling, you can use one of the following methods:

- The material can simply be glued to a flat ceiling surface, but then it will not work to use other soundproof materials. This option is suitable for living rooms with a home theater or a music lover's room.

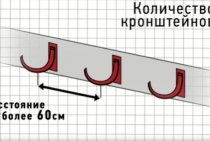

- To ensure comprehensive protection of your and neighboring premises from different sound waves, a supporting frame is built on the base ceiling. It is made from bars or galvanized profiles. Between the slats of the frame, a soft soundproof material (mineral wool) is placed in the spacer. Then the crate is hemmed with plasterboard sheets, and a cork is glued on top of the plasterboard surface.

In both cases, the cork coating is glued to an even and prepared base, so we will describe step by step the technology for gluing cork insulation to the ceiling.

Types of parameter comparison table

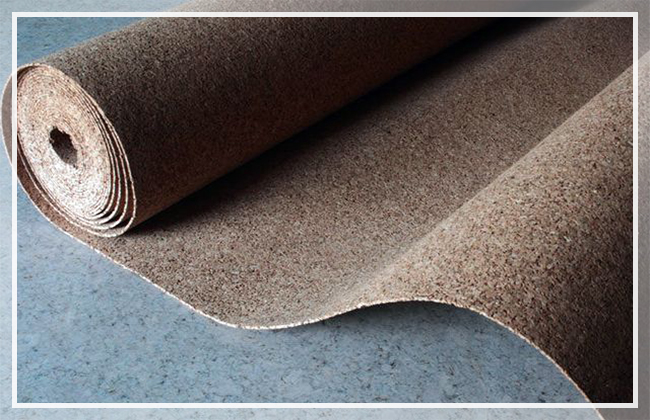

Cork bedding can combine several types of materials, which explains the presence of such types of it:

- Bitumen-cork substrate;

- Rubber cork.

The bitumen-cork gasket consists of kraft paper, which is impregnated with bitumen, and a layer of cork is applied on one side. Such material is laid on the floor with a cork layer, and the seams are glued with adhesive tape. A feature of this gasket is that it can be laid without waterproofing.

The rubber-cork underlay consists of a combination of cork granules and synthetic rubber. This mixture is pressed, making the material a good shock absorber and sound insulator. It is good to use such a layer under a laminate, which is one of the "noisy" floor coverings.

|

Types of cork substrate |

The size |

m2 in the package |

Specifications |

|

cork underlay 2 mm in a roll |

10mkh1mkh2mm |

10 |

Density - 200-260kg / m3; Tensile strength 2 kg/cm2; Compression resistance - 7 kg / cm2; Sound absorption coefficient - 0.85. |

|

3 mm per roll |

10mkh1mkh3mm |

10 |

|

|

cork underlay 5 mm in a roll |

25mkh1mkh5mm |

25 |

|

|

4 mm in sheets |

915kh610kh4mm |

0,558 |

|

|

6 mm in sheets |

915kh610kh6mm |

0,558 |

|

|

8 mm |

915kh610kh8mm |

0,558 |

|

|

10 mm |

915kh610kh10mm |

0,558 |

Coating selection

- For maximum insulation, it is better to cover the walls with a thin coating in several layers than to stick one layer of thick cork.

- For the integrity of the structure, glue must be applied not only to the walls, but also to the seams between the cork.

- Cork sheets are recommended to be applied to the wall by shifting in a checkerboard pattern.

Whatever type of cork is chosen, for its safety and durability, it is recommended to apply a layer of varnish. It will protect against mechanical damage and walls, it can be washed and not be afraid for the coating.

Advantages of cork material

The most important advantage of cork is that it is a completely natural material. It does not contain any polymer additives. The ceiling lined with cork will "breathe". The material has good vapor permeability.

Cork has a low thermal conductivity. As a cladding, you will get a good insulation and high-quality noise insulation.

Another advantage of cork material is its resistance to moisture. Tiles and wallpaper can be glued in the relaxation corner of the sauna.

The cork coating itself looks spectacular, but if you do not like the brown color, then the surface can be painted. It will not affect the structure of the material.

Another plus in favor of finishing the ceiling with cork is the versatility of the material. It adheres well to any surface. On an untreated ceiling, wallpaper will hide bumps and roughness.

Advantages and disadvantages

Cork underlayment is a natural material. In addition, it has a number of advantages and disadvantages.

Among the advantages can be called its durability and resistance to abrasion. The service life of the cork is approximately 200 years. It happens that when changing the floor covering, the replacement of the substrate is not required, as it remains in excellent condition.

The advantages include the possibility of using a cork substrate not only for the floor, but also on the wall. It has porosity, holds its shape well, is easy to cut, has low weight and good thermal insulation properties.

Of the minuses of the natural layer, softness can be called, with prolonged contact with heavy things (furniture), it is pressed through, and dents appear. Also, do not take cork as a substrate for underfloor heating due to its low thermal conductivity. Is it possible to use a gasket with a layer of foil applied for these purposes. In damp rooms, it is better to use another material as a separator-leveler, since natural cork absorbs moisture well and loses its properties. To do this, you can lay a waterproofing layer or a rubber-cork substrate.

Properties, functions and characteristics of the cork substrate

Cork backing for walls under wallpaper is produced by pressing pre-crushed cork oak bark. Gluing of granules is carried out thanks to the natural substance suberin, which resembles wax.

Cork material consists of many hollow cells. Their feature is the composition of the walls, characterized by a five-layer structure:

- Cellulose, which occupies two layers. Air located in the cells is "attached" to each of them.

- Two waterproof layers, the effectiveness of which is achieved due to their dense and oily structure.

- A woody layer that gives the cells the necessary rigidity.

Technical cork is available in three forms:

- Sheet. The thickness can vary from 0.4 to 1 cm. The length is 0.915 m, and the width is 0.61 m.

- Roll. The thickness ranges from 0.2 to 0.4 cm. The standard length is 10 m, but 25 meter samples can also be found. The width is 1 m.

- Cork panels.

Cork has one variety - cork agglomerate. It has a slightly lower density, but it is also successfully used as a lining for wallpaper.

Functions of the cork backing

- alignment of the wall base;

- increasing the thermal insulation characteristics of the room;

- soundproofing of space;

- prevention of formation of condensate;

- increased adhesion between cork and wallpaper.

Specifications

|

Indicator |

unit of measurement |

Indicator value |

| Density | kg / m 3 | 220-250 |

| Thermal conductivity | W/m∙k | 0,042 |

| Sound absorption coefficient | 0,85 | |

| Sonic shock resistance | dB | 12 |

| Humidity (natural) | % | 7 |

| Water absorption capacity (by volume) | 0,01 | |

| Tensile strength | kg/cm2 | 2 |

| The ability to compress and restore shape under a load of 7 kg / cm 2 | % | initial value - 10; residual (with hourly exposure) - 0.7 |

| Deformation modulus of elasticity | kg/cm2 | 2000—2500 |

| Chemical resistance | inert material |

Like any wood product, a cork wallpaper substrate tends to be highly flammable, however, in most cases, the production stage includes fire-resistant processing of the blanks, which makes them completely non-combustible (flammability class B1).

Tools and materials

At work you will need the following:

- sandpaper or grinder;

- rubber roller;

- technical roll stopper;

- primer for the ceiling;

- stationery knife or regular scissors;

- dry rag;

- putty;

- containers for primer and mortar;

- wool roller;

- notched trowel;

- long-handled roller or primer brush;

- chopping cord;

- roulette;

- pencil;

- moisture resistant glue;

- a set of spatulas;

- ladder.

Like any natural material, after purchase, the cork should lie down for a couple of days in the room where it will be glued. During this time, the material will adapt to the microclimate in the room, will not deform after installation.

The use of cork coatings in the interior

In addition to walls, floors, ceilings, furniture can be mounted with cork, and it will look no less modern.

Floors. In order to cover the floor with cork, there is no need to remove the previous coating. Linoleum, laminate - all this can be left in place. You can assemble a floating cork floor very quickly, like a puzzle, and in case of a move, you can assemble it in reverse order and take it with you. Such floors do not absorb dirt, do not collect dust, withstand heavy furniture, are useful for people with joint diseases, do not cause allergies, soften sounds (the sound of heels, falling objects).

Ceiling. Cork ceilings are moisture-proof, resistant to mold. For coating, everything is the same as for walls: rolled wallpaper, tiles. You can cover the entire ceiling, or you can fragment it, as fantasy tells. Before installation, the ceiling surface should be cleaned of the previous coating.

Synthetic wallpaper backings

There is an extensive range of synthetic substrates for wallpaper on the construction market, but all these materials do not particularly differ in their properties and usability. Nevertheless, there are some differences, as each manufacturer strives to make its products more attractive to the buyer.

Most often, closed-cell polyethylene foam is used for the manufacture of wallpaper substrates, which is important for improving thermal insulation properties and moisture resistance. Usually this is a rolled material, the thickness of the polyethylene web in which may differ depending on the specified thermal conductivity parameters.

Such a substrate is usually covered with a layer of paper from above and below in order to ensure a strong connection with the wall and the wallpaper glued to it during installation.

A well-known material for insulating walls under wallpaper is the Ecoheat substrate (“Ekohit”), which not only performs the function of insulation or sound insulation, but also in the process of finishing work allows you to do without a thorough leveling of the walls with plaster. This material is able to hide small surface defects and at the same time maintain the smoothness of its outer side, on which the wallpaper will be glued. The advantage of Ecoheat in comparison with analogues is that this product is produced with an exclusively white paper coating, which allows it to be used as a substrate for thin, light-colored wallpapers.The fact is that gray paper, which is often covered with similar products from other manufacturers, can shine through such wallpapers, giving them a dirty tint.

Among the analogues of Ecohit, such heaters as foam and Polyfom have become widely known. They have similar performance characteristics and composition. Their differences from "Ecohit" mainly lie in the fact that the substrate under the foam foam wallpaper, as well as "Polyf", can serve as a heater in rooms with high humidity. As for Ecoheat, the manufacturer advises not to use this substrate in damp rooms, and also does not recommend pasting all the walls in the room with this material.

Advantages of synthetic substrates and their installation technology

Using Ecoheat, Polyfom or other material of similar quality as a heater under wallpaper, you can count on a number of advantages.

- The thermal insulation properties of the wall will improve to the same extent as if brickwork 120 mm thick was added to it from the outside.

- The audibility of impact noise, the source of which is located behind the pasted wall, will decrease by 21-22 dB.

- The substrate will not promote the reproduction of harmful microorganisms, as it is made of synthetic raw materials.

- The material will hold firmly on the wall, and also hold the wallpaper pasted on it well due to the outer layers of paper, which is literally soldered to the polyethylene foam.

- For 50 years, the substrate will serve its intended purpose without losing its properties.

In order for the wallpaper substrate of the Polyfom or Ecohit type to perform its function with the success mentioned in the previous list, it is important to follow the rules for its installation established by the manufacturer, which include the following points:

- preliminary cleaning of the wall from the previous facing coating or unstable elements such as peeling plaster;

- coating the wall with a primer;

- cutting glued parts to size;

- applying glue for heavy wallpaper on the wall and on one side of the substrate;

- gluing the material with a rubber roller 10 minutes after applying the adhesive.

In the process of finishing work and during drying, it is important to ensure that there are no drafts in the room. The manufacturer also recommends that installation work be carried out at a temperature not lower than 10 ° C and relative humidity not exceeding 70%

Sometimes, when preparing a wall for pasting, it may be necessary to take measures to destroy fungus or mold. And in some cases, in order to level or make the glued surface able to absorb moisture, it may be necessary to apply a layer of putty to the wall. The procedure for gluing wallpaper on a substrate does not differ from the usual one, the rules of which can be found in the instructions attached to the wallpaper.

Benefits of cork underlay

The cork backing under the wallpaper is durable. The operational period is calculated not just in decades, but in centuries. And throughout the entire operational period, it does not tend to "age".

You can re-paste the wallpaper countless times. This will not affect the technical characteristics of the cork.

Technical cork is extremely wear-resistant. It perfectly tolerates mechanical stress, which is facilitated by sufficient elasticity. In this case, the linear dimensions of the substrate remain unchanged even with prolonged exposure.

Inert to temperature fluctuations - even the heated material is not subject to stretching. The extraordinary strength and density allows it to retain its original shape and not shrink.

Sticking a cork backing on the wall under the wallpaper ensures the leveling of the base. Therefore, the puttying stage can be safely excluded if we are talking about minor surface imperfections.

The agglomerate, like the technical type of cork, is antistatic - it does not conduct current, and also does not accumulate electric charges in the thickness.In addition, the substrate can protect the room from radiation.

Resistance to mold and antiseptic properties are due to the presence of suberin - released when the fabric is heated, it serves not only as an adhesive, but also as a disinfectant that can destroy bacteria.

In addition, the cork backing for walls, despite the 100% content of tree bark, is practically not affected by pests and rodents. Protection is achieved through special sanitization carried out at the production stage.

Environmental friendliness is another undeniable advantage. Cork flooring is an exclusively natural material that does not contain impurities of synthetic origin.

The production process eliminates the use of harmful compounds, which makes the substrate absolutely safe and hypoallergenic.

Immediately it is worth focusing on the fact that the cork is not capable of spreading a flame - it is non-combustible. It tends to only smolder, without releasing toxic phenolic or formaldehyde substances.

And, of course, the main advantage of a cork substrate is effective sound insulation. The advantage is due to the porous structure of the material filled with air gaps, which allows not only to absorb noise, but also to keep heat in the room.

Stages of cork wall installation

Before the coating can be glued, the walls must be carefully prepared and the most suitable cork adhesive must be selected.

Adhesive selection

Which glue is better to choose depends on many indicators:

- level of toxicity;

- setting time;

- reliability and durability.

Not every glue has only positive characteristics, but you still have to stop at some choice. Therefore, you can see how to glue the cork coating further:

- "Moment". You can stick the cork on the wall with this glue. Glue universal, strong. Dot or line application is very convenient, especially if tiles are glued. But there are disadvantages: it can destroy the cork layer or deform it. In addition, Moment is a rather expensive and toxic option. Therefore, if you already choose Moment glue for cork, then it is better to take a special option - Moment Cork.

- "Moment Cork". An excellent alternative to the usual "Moment", non-toxic, water and frost resistant (can be used when pasting a glazed balcony), does not contain toxic solvents.

- Decol Vern. It is used specifically for cork coatings, a very reliable option. But: highly toxic (you need to work in a respirator), its chemically active composition obliges you to avoid getting glue on the skin. Flammable. Like "Moment", "Decol Vern" adhesive sets quickly, so applying to the wall must be accurate the first time. For the same reason, it is not suitable for wallpaper.

- "PVA". Whoever glued the cork on PVA knows that this option is not for wallpaper: the glue simply cannot withstand their weight. Suitable for tiles, but with the threat of deformation of the cork coating due to the water-based adhesive.

- Wacol, Cork House. Great options if you need odorless cork glue. Also, these options do not contain solvents, environmentally friendly, moisture resistant, quick-drying.

- Acrylic glue for cork. It is used for one-sided gluing, when only the coating is spread.

If a suitable option was not found here, you can consult the construction department on what to glue the cork coating on

In the case of using the substrate as an intermediate layer, it is important to know how to glue the cork to the cork: any suitable glue is used here, but the surface of the substrate must be rough (without varnish)

Wall preparation

Before gluing the walls must be cleaned, dry, leveled. It is also necessary to remove possible mold, damaged previous coating, putty crumbling areas.Do not ignore the need for a primer.

It is better not to neglect these rules, otherwise the cork on the walls will lie unevenly, and in some places it may peel off.

If fragmentary pasting is to be done, it is necessary to mark it on the walls, as well as draw a scheme for gluing tiles.

We glue the coating

When everything is ready, you can proceed directly to gluing. To know how to stick cork on the wall, you need to follow the following rules:

Gluing the cork must be carried out at a temperature not lower than 18 degrees!

Something needs to be changed in the interior from time to time, and sometimes in such cases the question arises: is it possible to glue wallpaper on cork? Yes, but it is better to do it on top of a technical cork that has a rough surface, or use acrylic primer for a regular coating, and then putty it.

It is unlikely that cork coatings will lose their popularity, because their environmental friendliness, versatility, beauty and ease of use are what the modern consumer needs.

Criterias of choice

Which of the varieties is better to choose for internal wall insulation will depend on a number of factors related to the circumstances and wishes of the owner of the home, including:

- the degree of thermal conductivity and noise absorption that they hope to achieve;

- the usual level of humidity in the room where the walls are lined with wallpaper with a backing;

- the willingness or unwillingness of the owner of the house to put up with the fact that the walls will be soft to the touch;

- the susceptibility of the tenants of the apartment to the chemicals used for decoration that can cause an allergic reaction;

- the financial possibilities of the owners.